Kulokhu okuthunyelwe kwebhulogi, sizohlola ukujiya okujwayelekile kwama-PCB aqinile-flex futhi kungani kubalulekile ukucatshangelwa ekwakhiweni kwe-elekthronikhi.

Amabhodi esekethe aphrintiwe (ama-PCB) ayingxenye ebalulekile emishinini yesimanje kagesi. Banikeza inkundla yokufaka nokuxhuma izingxenye ezihlukahlukene ze-elekthronikhi. Ngokuhamba kweminyaka, ama-PCB aqhubekile nokuvela ukuze ahlangabezane nezidingo zemiklamo eyinkimbinkimbi nezinhlelo zokusebenza ezihlukahlukene. Okunye okunjalo ukwethulwa kwama-PCB aguquguqukayo aqinile, anikeza izinzuzo ezihlukile kumabhodi wesifunda aqinile noma avumelana nezimo.

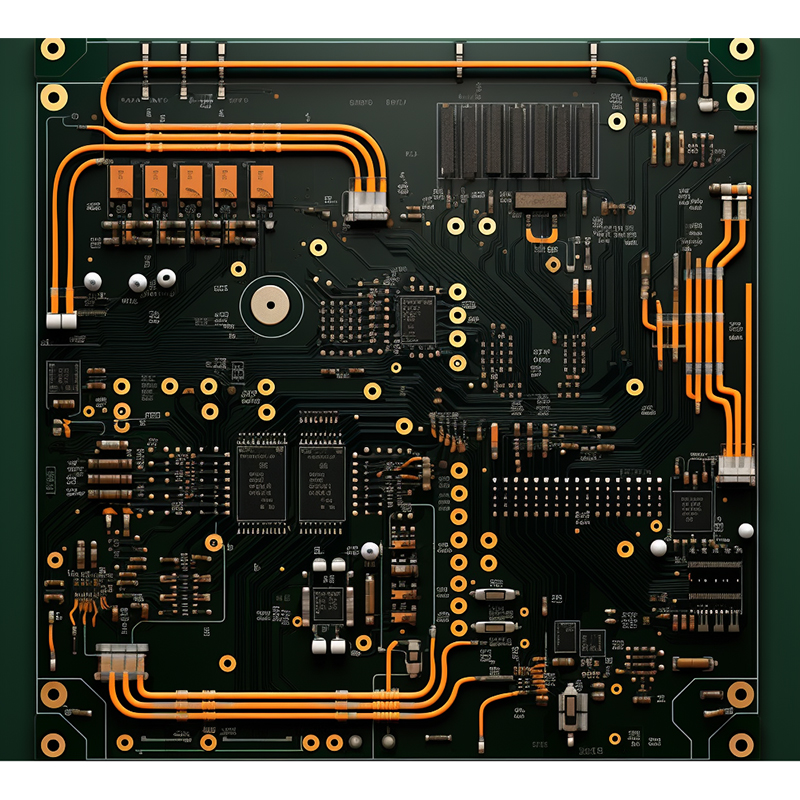

Ngaphambi kokuthi singene ekujimeni okujwayelekile, ake siqale siqonde ukuthi iyini i-rigid-flex.I-PCB eguquguqukayo eqinile iyinhlanganisela yamasekhethi aqinile futhi aguquguqukayo ahlanganiswe ebhodini elilodwa. Bahlanganisa izinzuzo zama-PCB aqinile futhi aguquguqukayo ukuze banikeze izixazululo eziguquguqukayo zezinhlelo zokusebenza eziningi. Lawa mabhodi aqukethe izendlalelo eziningi zamasekhethi astakiwe axhunywe izendlalelo eziguquguqukayo, anikeze isisombululo esihlangene nesithembekile sezingxenye ze-elekthronikhi.

Manje, uma kukhulunywa ngogqinsi lwebhodi eliguquguqukayo eliqinile, abukho ugqinsi oluthile olujwayelekile olusebenza kuyo yonke imiklamo.Ubukhulu bungahluka kuye ngezidingo ezithile zohlelo lokusebenza. Ngokuvamile, ukujiya kwamabhodi aqinile-flex kusuka ku-0.2mm kuya ku-2.0mm. Kodwa-ke, izici ezihlukahlukene kufanele zicatshangelwe ngaphambi kokunquma ukushuba okuphelele komklamo othile.

Isici esibalulekile okufanele sicatshangelwe yizidingo zemishini ze-PCB. Amabhodi e-Rigid-flex anekhono elihle kakhulu lokuguquguquka kanye nekhono lokugoba, kodwa ukujiya kudlala indima ebalulekile ekunqumeni ukuguquguquka okuphelele kwebhodi.Amabhodi azacile ajwayele ukuguquguquka kalula futhi kube lula ukugoba futhi angena ezindaweni eziqinile. Ngakolunye uhlangothi, amapuleti aminyene anikeza ukuqina okungcono futhi angakwazi ukumelana namazinga aphezulu okucindezeleka. Abaklami kufanele balinganise phakathi kokuvumelana nezimo nokuba lukhuni kuye ngohlelo oluhlosiwe.

Esinye isici esithinta ukushuba inombolo kanye nohlobo lwezingxenye okufanele zifakwe ebhodini. Ezinye izingxenye zingase zibe nemikhawulo yobude edinga ibhodi lesifunda eliwugqinsi ukuze likwazi ukumumatha ngendlela efanele.Ngokufanayo, isisindo esiphelele kanye nosayizi wezingxenye kuzophinde kuthinte ukushuba okuhle kwebhodi. Abaqambi kumele baqinisekise ukuthi ubukhulu obukhethiwe bungakwazi ukusekela isisindo nobukhulu bezingxenye ezixhunyiwe ngaphandle kokuthinta ubuqotho besakhiwo sebhodi.

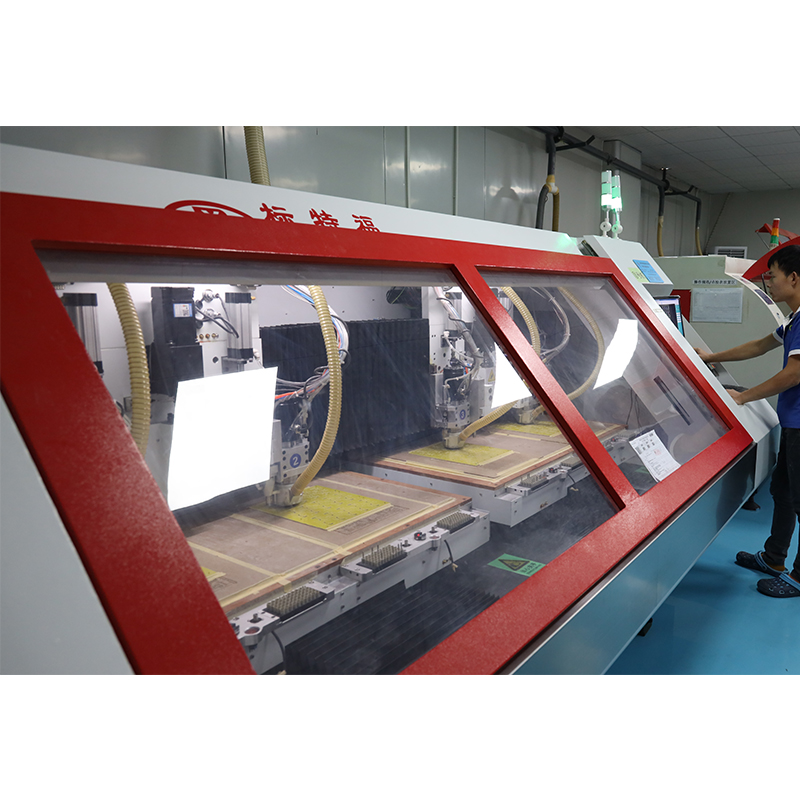

Ngaphezu kwalokho, i-izinqubo zokukhiqiza kanye nobuchwephesheasetshenziselwa ukukhiqiza amabhodi aqinile-flex futhi athinta ukushuba okujwayelekile.Amabhodi amancanyana ngokuvamile adinga amasu okukhiqiza anembe kakhudlwana futhi angase afake izindleko eziphezulu zokukhiqiza. Ngakho-ke, ubukhulu obukhethiwe kufanele buhambisane namandla enqubo yokukhiqiza ekhethiwe ukuze kuqinisekiswe ukukhiqizwa okuphumelelayo nokungabizi.

Kafushane, nakuba kungekho ukujiya okujwayelekile okumisiwe kwamabhodi aqinile-flex, kubalulekile ukucabangela izinto ezimbalwa lapho kunqunywa ukujiya okuphelele kohlelo lokusebenza olunikeziwe.Izidingo zemishini, inombolo kanye nohlobo lwezingxenye, izithiyo zesisindo nosayizi, namandla okwenza konke kudlala indima ebalulekile kule nqubo yokuthatha izinqumo. Ukuzuza ibhalansi efanele phakathi kokuguquguquka, ukuqina nokusebenza kubalulekile ekwandiseni ukusebenza nokuthembeka kwama-PCB aguquguqukayo.

Kafushane, ukujiya okujwayelekile kwamabhodi aqinile-flex kungase kuhluke kuye ngezidingo ezithile zohlelo lokusebenza.Abaklami kufanele bahlole ngokucophelela izici ezifana nezidingo zemishini, imikhawulo yengxenye namandla okukhiqiza ukuze banqume ukujiya okulungile komklamo wabo. Ngokucabangela lezi zici, abaklami bangaqinisekisa ukuthi ama-PCB abo aqinile ahlangabezana namazinga adingekayo okusebenza nokwethembeka kuyilapho enikeza ukuguquguquka okudingekayo nokusebenza.

Isikhathi sokuthumela: Sep-18-2023

Emuva