Yethula:

Kulokhu okuthunyelwe kwebhulogi, sizocubungula imininingwane yokuthi izendlalelo zebhodi lesifunda le-rigid-flex zihlanganiswa kanjani, sihlola amasu ahlukahlukene asetshenziswa kule nqubo.

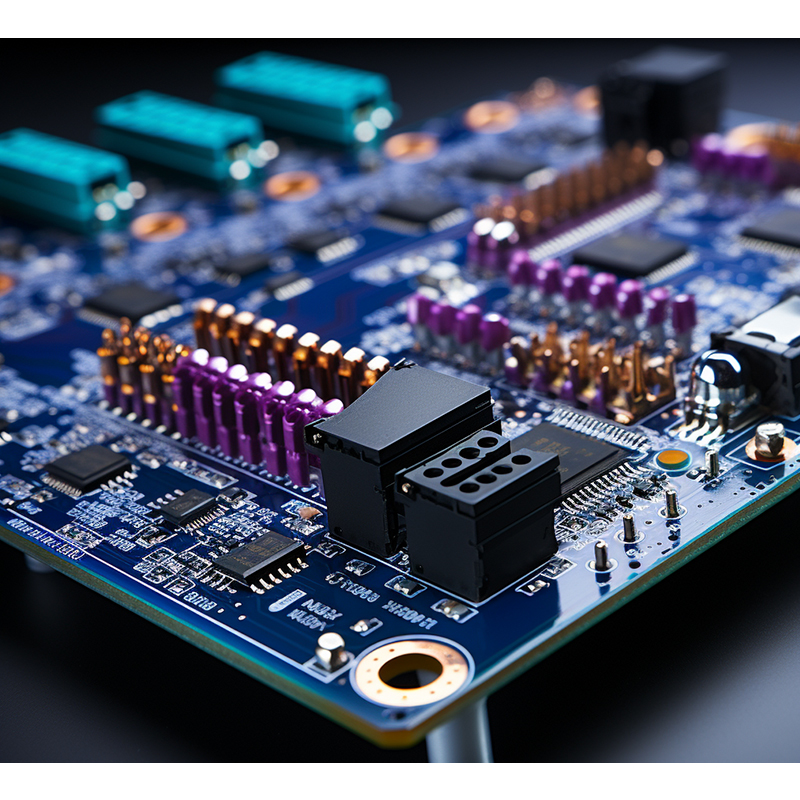

Amabhodi esekethe e-Rigid-flex adumile ezimbonini ezahlukahlukene ezihlanganisa i-aerospace, medical, kanye ne-consumer electronics.Lawa mabhodi ahlukile ngoba ahlanganisa ukujikeleza okuguquguqukayo nezigaba eziqinile, anikeze ukuqina nokuguquguquka.Esinye sezici ezibalulekile eziqinisekisa ukusebenza nokuthembeka kwamabhodi aqinile-flex ubuchwepheshe bokubopha obusetshenziselwa ukuxhuma izingqimba ezihlukene.

1. Ubuchwepheshe bokubambisana:

Ubuchwepheshe be-Adhesive bonding busetshenziswa kabanzi ekukhiqizeni ibhodi lesifunda eliqinile-flex.Kubandakanya ukusetshenziswa kwe-adhesive ekhethekile equkethe i-ejenti yokwelapha ukushisa.Lezi zinamathiselo zisetshenziselwa ukuhlanganisa izendlalelo eziguquguqukayo ezingxenyeni eziqinile zamabhodi wesekethe.I-adhesive ayinikezeli nje ukwesekwa kwesakhiwo kodwa futhi iqinisekisa ukuxhumana kukagesi phakathi kwezingqimba.

Phakathi nenqubo yokukhiqiza, i-adhesive isetshenziswa ngendlela elawulwayo futhi izendlalelo ziqondaniswe ngokunembile ngaphambi kokuba zihlanganiswe ndawonye ngaphansi kokushisa nokucindezela.Lokhu kuqinisekisa isibopho esiqinile phakathi kwezingqimba, okuholela ebhodini lesifunda eliqinile-flex elinezakhiwo ezinhle kakhulu zemishini kanye nogesi.

2. Ubuchwepheshe be-Surface Mount (SMT):

Enye indlela edumile yokuhlanganisa izendlalelo zebhodi lesifunda eliqinile-flex isebenzisa ubuchwepheshe bokukhweza komhlaba (SMT).I-SMT ihlanganisa ukubeka izingxenye zokukhweza ngaphezulu ngqo engxenyeni eqinile yebhodi lesekethe bese unamathisela lezi zingxenye kumaphedi.Lobu buchwepheshe buhlinzeka ngendlela enokwethenjelwa nephumelelayo yokuxhuma izendlalelo ngenkathi uqinisekisa ukuxhumana kukagesi phakathi kwabo.

Ku-SMT, izendlalelo eziqinile nezivumelana nezimo ziklanywe ngendlela efanayo namaphedi ukuze kube lula inqubo yokunamathisela.Faka i-solder paste endaweni yephedi bese ubeka ingxenye ngokunembile.Ibhodi lesifunda libe selifakwa ngenqubo ye-reflow soldering, lapho i-solder paste iyancibilika futhi ihlanganisa izendlalelo, idale isibopho esiqinile.

3. Ngokufakwa kwezimbobo:

Ukuze kuzuzwe amandla athuthukisiwe emishini kanye nokuxhumana kukagesi, amabhodi esekethe aqinile ajwayele ukusebenzisa i- through-hole plating.Inqubo ihlanganisa ukubhoboza izimbobo ezingqimbeni nokusebenzisa izinto eziqhutshwayo ngaphakathi kwalezo zimbobo.I-conductive material (imvamisa yethusi) ifakwa ngogesi ezindongeni zembobo, iqinisekisa isibopho esiqinile nokuxhumana kukagesi phakathi kwezingqimba.

I-Plating-Hole Plating inikeza ukwesekwa okwengeziwe kumabhodi aqinile-flex futhi kunciphisa ingcuphe ye-delamination noma ukwehluleka ezindaweni ezinengcindezi ephezulu.Ukuze uthole imiphumela engcono kakhulu, izimbobo zokubhoboza zidinga ukubekwa kahle ukuze ziqondaniswe nama-vias namaphedi ezendlalelo ezahlukene ukuze kuzuzwe ukuxhumana okuphephile.

Ekuphetheni:

Ubuchwepheshe bokunamathela obusetshenziswa kumabhodi esekethe e-rigid-flex budlala indima ebalulekile ekuqinisekiseni ubuqotho bawo besakhiwo nokusebenza kukagesi.I-Adhesion, ubuchwepheshe bokukhweza okungaphezulu kanye ne- through-hole plating yizindlela ezisetshenziswa kabanzi zokuxhuma ngaphandle komthungo izendlalelo ezahlukene.Ubuchwepheshe obunye bunezinzuzo zabo futhi bukhethwa ngokusekelwe ezidingweni ezithile zomklamo we-PCB nokusebenzisa.

Ngokuqonda amasu okubopha asetshenziswa kumabhodi esekethe e-rigid-flex, abakhiqizi nabaqambi bangakha imihlangano ye-elekthronikhi eqinile futhi enokwethenjelwa.Lawa mabhodi esekethe asethuthukile ahlangabezana nezidingo ezikhulayo zobuchwepheshe besimanje, okuvumela ukuqaliswa kokusetshenziswa kwe-elekthronikhi eguquguqukayo futhi ehlala isikhathi eside ezimbonini ezihlukahlukene.

Isikhathi sokuthumela: Sep-18-2023

Emuva