Yethula:

Kulokhu okuthunyelwe kwebhulogi, sizocubungula imininingwane yokuthi izendlalelo zebhodi lesifunda le-rigid-flex zihlanganiswa kanjani, sihlola amasu ahlukahlukene asetshenziswa kule nqubo.

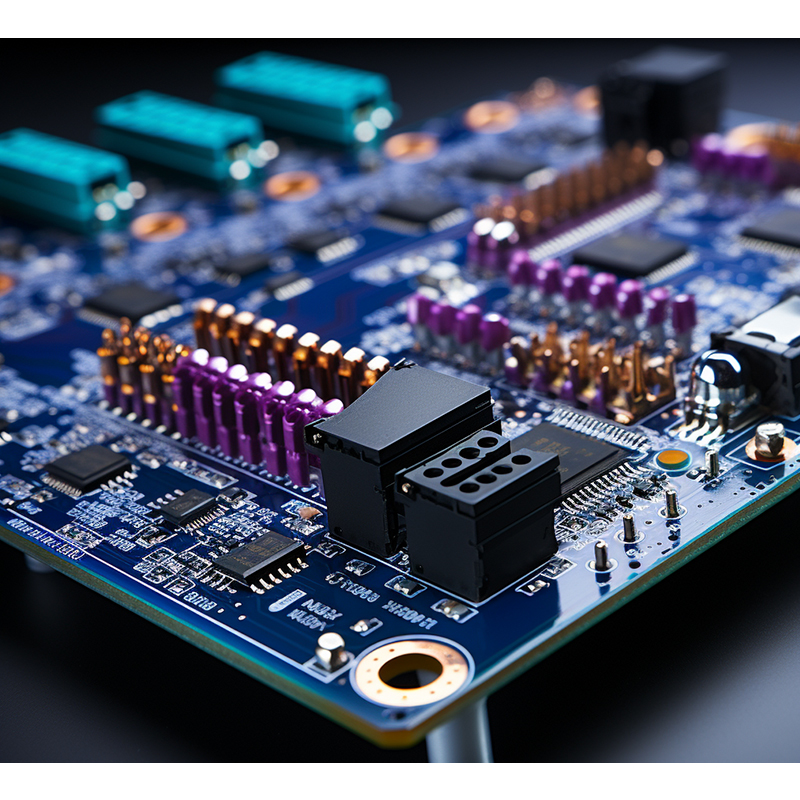

Amabhodi esekethe e-Rigid-flex adumile ezimbonini ezahlukahlukene ezihlanganisa i-aerospace, medical, kanye ne-consumer electronics. Lawa mabhodi ahlukile ngoba ahlanganisa ukujikeleza okuguquguqukayo nezigaba eziqinile, anikeze ukuqina nokuguquguquka. Esinye sezici ezibalulekile eziqinisekisa ukusebenza nokuthembeka kwamabhodi aqinile-flex ubuchwepheshe bokubopha obusetshenziselwa ukuxhuma izingqimba ezihlukene.

1. Ubuchwepheshe bokubambisana:

Ubuchwepheshe be-Adhesive bonding busetshenziswa kabanzi ekukhiqizeni ibhodi lesifunda eliqinile-flex. Kubandakanya ukusetshenziswa kwe-adhesive ekhethekile equkethe i-ejenti yokwelapha ukushisa. Lezi zinamathiselo zisetshenziselwa ukuhlanganisa izendlalelo eziguquguqukayo ezingxenyeni eziqinile zamabhodi wesekethe. I-adhesive ayinikezeli nje ukwesekwa kwesakhiwo kodwa futhi iqinisekisa ukuxhumana kukagesi phakathi kwezingqimba.

Phakathi nenqubo yokukhiqiza, i-adhesive isetshenziswa ngendlela elawulwayo futhi izendlalelo ziqondaniswe ngokunembile ngaphambi kokuba zihlanganiswe ndawonye ngaphansi kokushisa nokucindezela. Lokhu kuqinisekisa isibopho esiqinile phakathi kwezingqimba, okuholela ebhodini lesifunda eliqinile-flex elinezakhiwo ezinhle kakhulu zemishini kanye nogesi.

2. Ubuchwepheshe be-Surface Mount (SMT):

Enye indlela edumile yokuhlanganisa izendlalelo zebhodi lesifunda eliqinile-flex isebenzisa ubuchwepheshe bokukhweza komhlaba (SMT). I-SMT ihlanganisa ukubeka izingxenye zokukhweza ngaphezulu ngqo engxenyeni eqinile yebhodi lesekethe bese unamathisela lezi zingxenye kumaphedi. Lobu buchwepheshe buhlinzeka ngendlela enokwethenjelwa nephumelelayo yokuxhuma izendlalelo ngenkathi uqinisekisa ukuxhumana kukagesi phakathi kwabo.

Ku-SMT, izendlalelo eziqinile nezivumelana nezimo ziklanywe ngendlela efanayo namaphedi ukuze kube lula inqubo yokunamathisela. Faka i-solder paste endaweni yephedi bese ubeka ingxenye ngokunembile. Ibhodi lesifunda libe selifakwa ngenqubo ye-reflow soldering, lapho i-solder paste iyancibilika futhi ihlanganisa izendlalelo, idale isibopho esiqinile.

3. Ngokufakwa kwezimbobo:

Ukuze kuzuzwe amandla athuthukisiwe emishini kanye nokuxhumana kukagesi, amabhodi esekethe aqinile ajwayele ukusebenzisa i- through-hole plating. Inqubo ihlanganisa ukubhoboza izimbobo ezingqimbeni nokusebenzisa izinto eziqhutshwayo ngaphakathi kwalezo zimbobo. I-conductive material (imvamisa yethusi) ifakwa ngogesi ezindongeni zembobo, iqinisekisa isibopho esiqinile nokuxhumana kukagesi phakathi kwezingqimba.

I-Plating-Hole Plating inikeza ukwesekwa okwengeziwe kumabhodi aqinile-flex futhi kunciphisa ingcuphe ye-delamination noma ukwehluleka ezindaweni ezinengcindezi ephezulu. Ukuze uthole imiphumela engcono kakhulu, izimbobo zokubhoboza zidinga ukubekwa kahle ukuze ziqondaniswe nama-vias namaphedi ezendlalelo ezahlukene ukuze kuzuzwe ukuxhumana okuphephile.

Ekuphetheni:

Ubuchwepheshe bokunamathela obusetshenziswa kumabhodi esekethe e-rigid-flex budlala indima ebalulekile ekuqinisekiseni ubuqotho bawo besakhiwo nokusebenza kukagesi. I-Adhesion, ubuchwepheshe bokukhweza okungaphezulu kanye ne- through-hole plating yizindlela ezisetshenziswa kabanzi zokuxhuma ngaphandle komthungo izendlalelo ezahlukene. Ubuchwepheshe obunye bunezinzuzo zabo futhi bukhethwa ngokusekelwe ezidingweni ezithile zomklamo we-PCB nokusebenzisa.

Ngokuqonda amasu okubopha asetshenziswa kumabhodi esekethe e-rigid-flex, abakhiqizi nabaqambi bangakha imihlangano ye-elekthronikhi eqinile futhi enokwethenjelwa. Lawa mabhodi esekethe asethuthukile ahlangabezana nezidingo ezikhulayo zobuchwepheshe besimanje, okuvumela ukuqaliswa kokusetshenziswa kwe-elekthronikhi eguquguqukayo futhi ehlala isikhathi eside ezimbonini ezihlukahlukene.

Isikhathi sokuthumela: Sep-18-2023

Emuva