Ngenxa yesakhiwo sayo esiyinkimbinkimbi nezici eziyingqayizivele,ukukhiqizwa kwamabhodi aqinile-flex kudinga izinqubo ezikhethekile zokukhiqiza. Kulokhu okuthunyelwe kwebhulogi, sizohlola izinyathelo ezihlukahlukene ezihilelekile ekukhiqizeni lawa mabhodi e-PCB aqinile aqinile futhi sibonise ukucatshangelwa okuqondile okufanele kucatshangelwe.

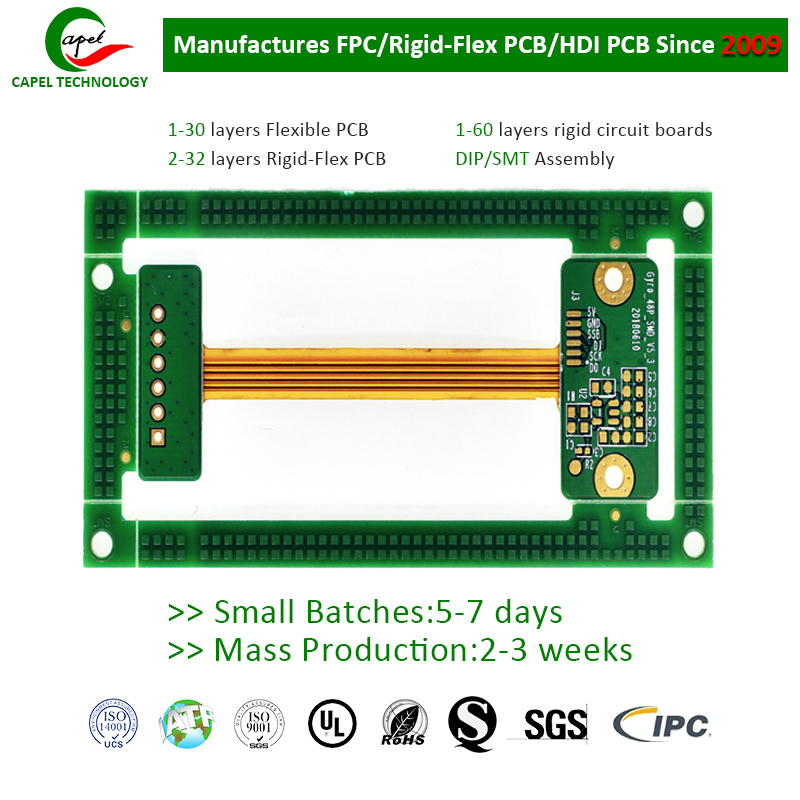

Amabhodi esekethe aphrintiwe (ama-PCB) awumgogodla wezinto zikagesi zesimanje. Ziyisisekelo sezingxenye ze-elekthronikhi ezixhumene, okuzenza zibe yingxenye ebalulekile yamadivayisi amaningi esiwasebenzisa nsuku zonke. Njengoba ubuchwepheshe buthuthuka, kanjalo nesidingo sezixazululo eziguquguqukayo nezihlangene. Lokhu kuye kwaholela ekuthuthukisweni kwama-PCB aqinile-flex, anikeza inhlanganisela eyingqayizivele yokuqina nokuguquguquka ebhodini elilodwa.

Dizayina ibhodi eliqinile elivumelana nezimo

Isinyathelo sokuqala nesibaluleke kakhulu enqubweni yokukhiqiza eguquguqukayo ukuklama. Ukuklama ibhodi eliguquguqukayo eliqinile kudinga ukucatshangelwa ngokucophelela kwesakhiwo sebhodi lesifunda kanye nokubekwa kwengxenye. Izindawo ze-Flex, i-bend radii kanye nezindawo zokugoqa kufanele zichazwe ngesikhathi sesigaba sokuklama ukuze kuqinisekiswe ukusebenza kahle kwebhodi eliqediwe.

Izinto ezisetshenziswa kuma-PCB aqinile kufanele zikhethwe ngokucophelela ukuze kuhlangatshezwane nezidingo ezithile zohlelo lokusebenza. Ukuhlanganiswa kwezingxenye eziqinile neziguquguqukayo kudinga ukuthi izinto ezikhethiwe zibe nenhlanganisela eyingqayizivele yokuguquguquka nokuqina. Kusetshenziswa ama-substrates avumelana nezimo njenge-polyimide ne-FR4 ezacile, kanye nezinto eziqinile ezifana ne-FR4 noma insimbi.

I-Layer Stacking kanye nokulungiselela i-Substrate yokukhiqiza i-pcb eguquguqukayo eqinile

Uma umklamo usuqedile, inqubo yokunqwabelanisa isendlalelo iyaqala. Amabhodi esekethe aphrintiwe aqinile ahlanganisa izendlalelo eziningi zama-substrates aqinile futhi aguquguqukayo ahlanganiswe ndawonye kusetshenziswa izinto ezinamathelayo ezikhethekile. Lokhu kubopha kuqinisekisa ukuthi izendlalelo zihlala ziqinile ngisho nangaphansi kwezimo eziyinselele ezifana nokudlidliza, ukugoba nokushintsha kwezinga lokushisa.

Isinyathelo esilandelayo senqubo yokukhiqiza ukulungisa i-substrate. Lokhu kuhlanganisa ukuhlanza nokuphatha indawo engaphezulu ukuze kuqinisekiswe ukunamathela kahle. Inqubo yokuhlanza isusa noma yikuphi ukungcola okungase kuvimbele inqubo yokubopha, kuyilapho ukwelashwa okungaphezulu kuthuthukisa ukunamathela phakathi kwezingqimba ezihlukene. Amasu afana nokwelashwa kwe-plasma noma ukufakwa kwamakhemikhali avame ukusetshenziswa ukuze kuzuzwe izakhiwo ezifiselekayo ezingaphezulu.

Iphethini yethusi kanye nokwakheka kwesendlalelo sangaphakathi sokwenziwa kwamabhodi esekethe aguquguqukayo aqinile

Ngemuva kokulungisa i-substrate, qhubeka nenqubo yokwenza iphethini yethusi. Lokhu kuhilela ukufaka ungqimba oluncane lwethusi ku-substrate bese kwenziwa inqubo ye-photolithography ukuze udale iphethini yesekethe efunekayo. Ngokungafani nama-PCB endabuko, ama-PCB aqinile-flex adinga ukucatshangelwa ngokucophelela kwengxenye eguquguqukayo phakathi nenqubo yokwenza iphethini. Ukunakekelwa okukhethekile kufanele kuthathwe ukugwema ukucindezeleka okungadingekile noma ukulimala ezingxenyeni eziguquguqukayo zebhodi lesifunda.

Uma iphethini yethusi isiqediwe, ukwakheka kongqimba lwangaphakathi kuyaqala. Kulesi sinyathelo, izendlalelo eziqinile neziguquguqukayo ziqondaniswe futhi ukuxhumana phakathi kwazo kuyasungulwa. Lokhu kuvame ukufezwa ngokusebenzisa i-vias, ehlinzeka ngoxhumano lukagesi phakathi kwezingqimba ezihlukene. I-Vias kumele yakhelwe ngokucophelela ukuze ivumelane nokuguquguquka kwebhodi, iqinisekise ukuthi ayiphazamisi ukusebenza okuphelele.

I-Lamination kanye nokwakheka kwesendlalelo sangaphandle sokukhiqiza i-pcb eqinile-flex

Uma ungqimba lwangaphakathi lwakhiwe, inqubo ye-lamination iqala. Lokhu kuhlanganisa ukupakisha izendlalelo ngazinye futhi uzibeke ngaphansi kokushisa nokucindezela. Ukushisa nokucindezela kusebenze i-adhesive futhi kukhuthaze ukubopha kwezingqimba, kudala isakhiwo esiqinile nesiqinile.

Ngemuva kwe-lamination, inqubo yokwakheka kwezingqimba zangaphandle iqala. Lokhu kuhilela ukufaka ungqimba oluncane lwethusi endaweni engaphandle yebhodi lesifunda, okulandelwa inqubo ye-photolithography ukuze kwakhiwe iphethini yokugcina yesifunda. Ukwakhiwa kwesendlalelo sangaphandle kudinga ukunemba nokunemba ukuze kuqinisekiswe ukuqondana okulungile kwephethini yesifunda nesendlalelo sangaphakathi.

Drilling, Plating kanye nokwelashwa surface for eqinile nezimo pcb amabhodi ukukhiqizwa

Isinyathelo esilandelayo enqubweni yokukhiqiza ukubhola. Lokhu kubandakanya ukubhoboza izimbobo ku-PCB ukuvumela izingxenye ukuthi zifakwe kanye nokuxhumana kukagesi. I-Rigid-flex flex PCB drilling idinga okokusebenza okukhethekile okungamukela ubukhulu obuhlukahlukene namabhodi wesekethe aguquguqukayo.

Ngemva kokubhoboza, i-electroplating yenziwa ukuthuthukisa ukuqhutshwa kwe-PCB. Lokhu kuhilela ukufaka ungqimba oluncane lwensimbi (ngokuvamile ithusi) ezindongeni zembobo ebhoboziwe. Izimbobo ezinamaphiko zinikeza indlela enokwethenjelwa yokusungula ukuxhumana kukagesi phakathi kwezingqimba ezihlukene.

Ekugcineni, ukuqedwa kwangaphezulu kwenziwa. Lokhu kuhilela ukusebenzisa i-coating evikelayo ezindaweni zethusi eziveziwe ukuze kugwenywe ukugqwala, ukuthuthukisa ukubola, kanye nokwenza ngcono ukusebenza kwebhodi kukonke. Ngokuya ngezidingo ezithile zohlelo lokusebenza, izindlela zokwelapha ezihlukene ezingaphezulu ziyatholakala, njenge-HASL, ENIG noma i-OSP.

Ukulawulwa kwekhwalithi nokuhlolwa kokukhiqizwa kwebhodi lesifunda eliphrintiwe eliqinile

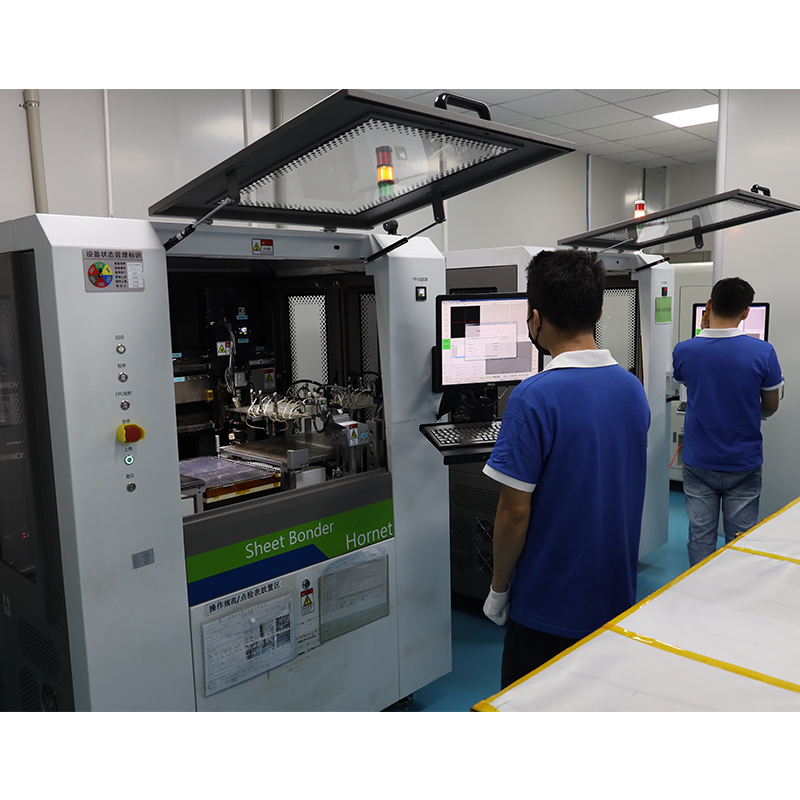

Kuyo yonke inqubo yokukhiqiza, izinyathelo zokulawula ikhwalithi ziyasetshenziswa ukuze kuqinisekiswe amazinga aphezulu okuthembeka nokusebenza. Sebenzisa izindlela zokuhlola ezithuthukisiwe ezifana nokuhlola okuzenzakalelayo kwe-optical inspection (AOI), ukuhlolwa kwe-X-ray nokuhlola ugesi ukuze uhlonze noma yikuphi ukukhubazeka okungenzeka noma izinkinga ebhodini lesekethe eliqediwe. Ngaphezu kwalokho, ukuhlolwa okuqinile kwezemvelo nokwethembeka kwenziwa ukuze kuqinisekiswe ukuthi ama-PCB aqinile angakwazi ukumelana nezimo eziyinselele.

Ngamafuphi

Ukukhiqizwa kwamabhodi aqinile-flex kudinga izinqubo ezikhethekile zokukhiqiza. Isakhiwo esiyinkimbinkimbi kanye nezici eziyingqayizivele zalawa mabhodi wesifunda athuthukile zidinga ukucatshangelwa kokuklama ngokucophelela, ukukhethwa kwezinto ezibonakalayo okunembile kanye nezinyathelo zokukhiqiza ezenziwe ngokwezifiso. Ngokulandela lezi zinqubo zokukhiqiza ezikhethekile, abakhiqizi bezinto zikagesi bangasebenzisa amandla aphelele e-PCB eguquguqukayo futhi balethe amathuba amasha emishini kagesi eshintshashintshayo, eguquguqukayo futhi ehlangene.

Isikhathi sokuthumela: Sep-18-2023

Emuva