Yethula:

Ukwenziwa kwe-PCB eguqukayo kudlala indima ebalulekile embonini yokukhiqiza izinto zikagesi. Njengoba ubuchwepheshe buthuthuka, isidingo sama-PCB avumelana nezimo sikhule kakhulu. Kulo mhlahlandlela oyinhloko, sizohlola ukwakhiwa kwe-PCB eguquguqukayo, isakhiwo, nezinhlobo zezitaki. Kubalulekile ukuqonda amagama angukhiye alandelayo:Ukwenziwa Kwe-PCB Eguquguqukayo, Isakhiwo se-PCB Esishintshashintshayo, Ukuqina Kwethusi Kwe-PCB Evumelana Nezimo, I-Flexible PCB Solder Mask, I-Flexible PCB Layout, Flexible PCB Adhesive Sheet, kanye ne-Flexible PCB Layup Izinhlobo njengoba zibalulekile ekwenzeni umkhiqizo wakho uphumelele.Kubalulekile.

1. Ulwazi oluyisisekelo lokukhiqiza i-PCB eguquguqukayo:

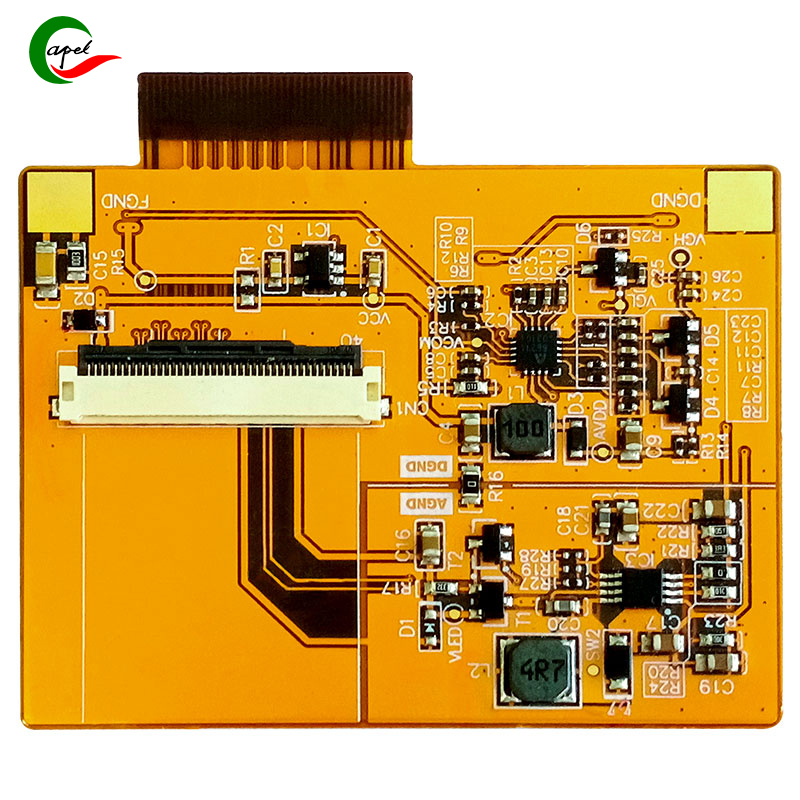

A. Incazelo nezici zebhodi eliguquguqukayo: I-PCB eguquguqukayo, eyaziwa nangokuthi isekethe eguquguqukayo, ibhodi lesifunda eliphrintiwe elingagotshwa, ligoqwe, noma lisontwe ngaphandle kokuphuka. Banikeza izinzuzo ezimbalwa phezu kwama-PCB aqinile, okuhlanganisa ukuguquguquka, ukulula, nokuqina. Lezi zakhiwo zizenza zilungele izinhlelo zokusebenza ezihlukahlukene, ikakhulukazi lezo ezidinga ama-electronics ahlangene futhi agobekayo.

B. Isakhiwo se-PCB esivumelana nezimo: Inqubo yokwakha ye-PCB eguquguqukayo ihilela ukusetshenziswa kwama-substrates aguquguqukayo. Ama-substrates asetshenziswa kakhulu yi-polyimide ne-polyester, ehlinzeka ngokuguquguquka okudingekayo kanye nezakhiwo zokuvikela ezidingekayo kuma-PCB aguquguqukayo. Lawa ma-substrates athola uchungechunge lwezinyathelo zokukhiqiza ezifana ne-etching, plating, kanye ne-lamination ukudala iphethini yesekethe efunekayo.

C. Qonda ukujiya kwethusi ku-PCB eguquguqukayo: Ugqinsi lwethusi ludlala indima ebalulekile ekusebenzeni kwe-PCB eguquguqukayo. Inquma umthamo wamanje wokuthwala, i-impedance, kanye nokuvumelana nezimo kwe-PCB. Ukukhetha okuhlukile kokuqina kwethusi kungenziwa ngokuya ngezidingo ezithile zomklamo. Ithusi eliwugqinsi linikeza amandla aphezulu okuthwala wamanje kodwa futhi yehlisa ukuguquguquka kwe-PCB. Kufanele kwenziwe ibhalansi efanele phakathi kwalezi zici ukuze kuzuzwe ukusebenza kahle.

2. Izingxenye ezibalulekile zokukhiqiza i-PCB eguquguqukayo:

A. Imaski ye-solder ye-PCB eguquguqukayo: Imaski ye-solder iyisendlalelo esivikelayo esimboza imikhondo yethusi engenalutho ku-PCB. Isiza ukuvimbela amabhuloho e-solder, ukugqwala, nezikhindi zikagesi ngesikhathi sokushisela. I-PCB eguquguqukayo isebenzisa izinto ezikhethekile zemaski ye-solder ukuqinisekisa ukuguquguquka nokuqina. Ukukhethwa kwemaski ye-solder ye-PCB eguquguqukayo kanye nenqubo yokufaka isicelo kudinga ukucatshangelwa ngokucophelela komklamo we-PCB kanye nokusetshenziswa kwayo okuhlosiwe.

B. Isakhiwo se-PCB Esivumelana nezimo: Isakhiwo se-PCB esiklanywe kahle, esivumelana nezimo sibalulekile ekusebenzeni okuhle nokuthembeka. Kubandakanya ukubekwa kwezingxenye, umzila wokulandela umkhondo, nokucatshangelwa kobuqotho besignali. Izingxenye kumele zibekwe ngendlela evumela i-PCB ukuthi igobe futhi igobe ngokufanele. Imikhondo kufanele ihanjiswe ukuze kuncishiswe ingcindezi ezindaweni eziguqukayo futhi kuqinisekiswe ukudluliswa kwesignali okusebenzayo. Imikhuba engcono kakhulu yokuklama isakhiwo se-PCB esivumelana nezimo ihlanganisa ukusebenzisa imikhondo egobile, ukugwema ama-engeli abukhali, nokuqinisekisa imvume eyanele phakathi kokulandela umkhondo.

C. Ishidi lokunamathela le-PCB elivumelana nezimo: Ishidi elinamathelayo lisetshenziswa ekwenzeni i-PCB eguquguqukayo ukuze kuhlanganiswe izendlalelo ezahlukene. Inikeza amandla emishini, ukuzinza, kanye nokwahlukanisa. Kunezinhlobo ezahlukene zamashidi okunamathela atholakalayo, njengamashidi asekelwe ku-acrylic, amashidi asekelwe epoxy, namashidi asekelwe enjoloba. Ukukhethwa kweshidi lokunamathela kuncike ezintweni ezifana nokumelana nezinga lokushisa, izidingo zokuvumelana nezimo, nokuhambisana nezinye izinto. Ukukhetha ishidi lokunamathela elifanele kubaluleke kakhulu ukuze uqinisekise ukwethembeka nokuqina kwe-PCB yakho eguquguqukayo.

3. Izinhlobo zezitaki ze-PCB eziguquguqukayo:

A. Isethulo sesitaki se-PCB: Isitaki se-PCB sisho ukuhlelwa kwezendlalelo ezihlukene ku-PCB. Ekwenziweni kwe-PCB evumelana nezimo, ukunqwabelanisa kudlala indima ebalulekile ekuthembekeni kwesignali, ekulawuleni i-impedance, kanye nokuphatha okushisayo. Ngokukhetha ngokucophelela nokuhlela izendlalelo, abaklami bangathuthukisa ukusebenza kwama-PCB aguquguqukayo.

B. Izinhlobo Zokuhlela Ezivamile Ze-PCB Ezivumelana Nezimo: Kunezinhlobonhlobo zezinhlobo zokubeka ezisetshenziswa ekukhiqizeni i-PCB eguquguqukayo, okuhlanganisa ungqimba olulodwa, ungqimba olukabili, kanye nokucushwa kwezendlalelo eziningi. Uhlobo ngalunye lokupakisha lunezinzuzo zalo kanye nemikhawulo. Ama-PCB ongqimba olulodwa aguquguqukayo ayinketho elula futhi engabizi kakhulu, kodwa anamandla omzila alinganiselwe. I-PCB enezingqimba ezimbili eguquguqukayo inikeza izinketho eziningi zezintambo futhi ingamukela imiklamo eyinkimbinkimbi. Ama-PCB avumelana nezimo eziningi ahlinzeka ngokuguquguquka okukhulu komzila, nokulawula okuthuthukisiwe kwe-impedance, futhi angasekela ukuminyana kwesekethe okuphezulu. Nokho, ziyinkimbinkimbi futhi kubiza ukuwenza.

Kafushane:

Kulo mhlahlandlela obanzi, sihlanganisa zonke izici zokwenziwa kwe-PCB eziguquguqukayo, okuhlanganisa ukwakhiwa, isakhiwo, imaski ye-solder, amashidi okunamathela, nezinhlobo zezitaki. Ukuqonda lezi zakhi ezibalulekile kuzovumela abaklami ukuthi bathuthukise ukusebenza nokuthembeka kwemiklamo yabo ye-PCB eguquguqukayo. Izinqubo nobuchwepheshe bubalulekile ekukhiqizweni kwama-PCB aguquguqukayo, futhi ngokulandela izindlela ezingcono kakhulu, abakhiqizi bangaqinisekisa ukulethwa kwemikhiqizo esezingeni eliphezulu, ethembekile ukuze kuhlangatshezwane nezidingo zemboni yezogesi.

Isikhathi sokuthumela: Nov-10-2023

Emuva