Yethula:

Umhlangano webhodi lesifunda ophrintiwe oguquguqukayo, owaziwa nangokuthi umhlangano webhodi lesifunda ophrintiwe, uwubuchwepheshe obusha nobubucayi obusetshenziswa ezimbonini ezahlukahlukene.Lesi sihloko sihlose ukuhlolisisa ubunkimbinkimbi benhlangano ye-PCB eguquguqukayo, igxile ezinqubweni kanye nobuchwepheshe obuphambili obuhilelekile ekukhiqizeni kwayo.Ukwengeza, sizohlola ukubaluleka kwalobu buchwepheshe ezindaweni ezahlukene. Ukuze ubambe ngokugcwele umhlangano we-PCB oguquguqukayo, umuntu kufanele aqonde izingxenye zayo ezibalulekile nokubaluleka kwazo enqubweni yokukhiqiza.

I-Flexible PCB Assembly: Isingeniso

Umhlangano we-PCB oguquguqukayo uguqule indlela izinto zikagesi eziklanywa futhi ezikhiqizwa ngayo. Ngekhono lawo eliyingqayizivele lokugoba, ukusonta, nokuvumelana nezimo eziyinkimbinkimbi, amabhodi esekethe aphrintiwe avumelana nezimo anikeza ukuguquguquka okungakaze kubonwe ngaphambili. Le khwalithi ibenza babaluleke kakhulu ezimbonini ezehlukene ezihlanganisa ezogesi ezithengwayo, ezezimoto, izisetshenziswa zezokwelapha, i-aerospace kanye nezokuvikela.

Izingxenye eziyinhloko zomhlangano webhodi lesifunda ophrintiwe oguquguqukayo zihlanganisa ibhodi lesifunda eliguquguqukayo ngokwalo, elenziwe ngezingqimba ezincane zezinto eziqhutshwayo ezihlanganiswe phakathi kwezingqimba zezinto ezivikelayo. Ezinye izakhi zifaka izakhi ezifana ne-solder mask, i-solder paste, ama-resistors, ama-capacitor nama-circuits ahlanganisiwe (ama-IC), kanye nokuxhuma okufana ne-vias.

Qonda izindleko zomhlangano we-PCB oguquguqukayo

Ukuze uqonde izindleko zomhlangano we-PCB oguquguqukayo, kunezici ezihlukahlukene okufanele zicatshangelwe. Lezi zici zifaka phakathi ukukhethwa kwezinto, ubunkimbinkimbi bomklamo, kanye nomthamo wokukhiqiza.

A. Ukukhetha okubalulekile

Ama-PCB aguqukayo akhiqizwa ngezinto ezahlukahlukene, kufaka phakathi i-polyimide, i-polyester, ne-PTFE. Impahla ngayinye inezici zayo ezihlukile kanye nezinzuzo ezithinta izindleko ezihlobene nenqubo yokuhlanganisa. Ukukhetha izinto zekhwalithi ephezulu kungase kubangele izindleko zokuqala eziphezulu, kodwa kungaveza ukusebenza okungcono nokuphila isikhathi eside ngokuhamba kwesikhathi.

B. Ubunkimbinkimbi bomklamo

Ubunkimbinkimbi bomklamo budlala indima ebalulekile ekunqumeni izindleko zomhlangano we-PCB eziguquguqukayo. Uma umklamo uyinkimbinkimbi, isikhathi esiningi nomzamo odingekayo enqubweni yokukhiqiza. Imiklamo eyinkimbinkimbi ingase ihlanganise izendlalelo eziningi, ukuhlukana okuqinile, nokuma okungajwayelekile, konke okwandisa izindleko zokuhlanganisa.

C. Ivolumu yokukhiqiza

Ivolumu yokukhiqiza ingathinta kakhulu izindleko zomhlangano we-PCB oguquguqukayo. Amanani aphezulu okukhiqiza anika amandla umnotho wesilinganiso, okuholela ezindleko eziphansi zamayunithi. Ngokuphambene, ukukhiqizwa kwevolumu ephansi kuvame ukubiza kakhulu ngenxa yenani elilinganiselwe nezindleko zokufaka.

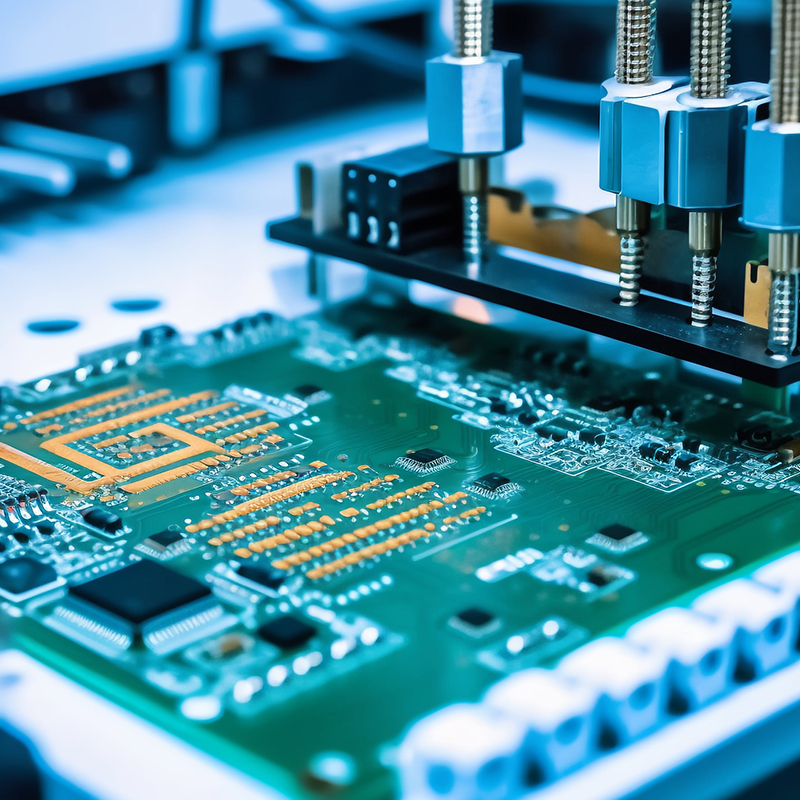

Inqubo yokuhlanganisa ibhodi lesifunda eguquguqukayo

Inqubo yokuhlanganisa ye-PCB eguquguqukayo ibandakanya izinyathelo eziningi, ngasinye sidinga ukunemba nobungcweti. Ukuqonda le nqubo kunikeza ukuqonda ngezinqubo kanye nobuchwepheshe obuhilelekile ekukhiqizeni amabhodi esekethe aphrintiwe avumelana nezimo.

A. Umklamo kanye nesakhiwo

Izigaba zokuqala zomhlangano we-PCB oguquguqukayo zibandakanya ukuklanywa nokuhlelwa kwebhodi lesifunda. Ukucatshangelwa kwedizayini njengokubekwa kwengxenye, ubuqotho besignali, nokuphathwa kokushisa kubalulekile ekuhlanganiseni ngempumelelo.

B. Ukulungiswa nokukhethwa kwezinto

Ukukhetha izinto ezifanele nokuzilungiselela ukuhlanganisa kubalulekile. Lesi sinyathelo sihlanganisa ukukhetha okufanelekile kwe-substrate impahla, ukukhetha nokulungiselela izinto zokuqhuba, nokuqinisekisa ukuthi zonke izingxenye ezidingekayo kanye nokuxhuma kuyatholakala.

C. Ukuphrinta Nokufanekisa

Izigaba zokuphrinta nezithombe zibandakanya ukudlulisa iphethini yesifunda ku-substrate. Lokhu ngokuvamile kufezwa nge-photolithography, lapho okokusebenza kwe-photosensitive kuvezwa ngokukhetha ekukhanyeni ukuze kwakhe iphethini yesekethe efunekayo.

D. Etching and Cleaning

Ngesikhathi senqubo yokufaka, ithusi eliningi likhishwa ebhodini, lishiya imikhondo edingekayo yokuhambisa. Bese uhlanza ibhodi lesifunda kahle ukuze ususe noma imaphi amakhemikhali asele noma ukungcola.

E. Ukubhola nokuPlating

Ukubhoboza kubandakanya ukudala izimbobo noma ama-vias asetshenziswa ukuxhuma izingqimba ezihlukene ze-PCB eguquguqukayo. I-Electroplating ibe seyenzeka, lapho i-conductive material isetshenziswa ezindongeni zalezi zimbobo ukuze kube lula ukuxhumana kukagesi.

F. Ukubekwa kwengxenye kanye ne-soldering

Beka ngokucophelela izingxenye ebhodini lesekhethi ngokuvumelana nesakhiwo sokuklama. Gcoba unamathisele we-solder kumaphedi bese uthengisa izingxenye usebenzisa amasu afana nokugeleza kabusha noma i-wave soldering.

G. Ukuhlola Nokulawula Ikhwalithi

Ukuhlola kuyisinyathelo esibalulekile kunqubo yokuhlanganisa ye-PCB eguquguqukayo ukuze kuqinisekiswe ukusebenza nokwethembeka kwebhodi elihlanganisiwe. Yenza izivivinyo ezihlukahlukene ezifana nokusebenza, ugesi, nokuhlolwa kwemvelo ukuze uqinisekise ukusebenza kwebhodi nokuhambisana nezindinganiso zekhwalithi.

Umhlinzeki wesevisi womhlangano we-PCB oguquguqukayo

Ukukhetha umhlinzeki wesevisi womhlangano we-PCB ovumelana nezimo kubalulekile ukuze uqinisekise ukukhiqizwa okungenamthungo kwama-PCB athembekile naguquguqukayo ekhwalithi ephezulu.

A. Isipiliyoni nobungcweti ekuhlanganiseni okuguquguqukayo kwe-PCB

Bheka umhlinzeki wesevisi onolwazi olunzulu kanye nobuchule ekuhlanganiseni okuguquguqukayo kwe-PCB. Ulwazi lwabo ngamazinga emboni, imihlahlandlela yokuklama kanye nezinqubo zokukhiqiza kubalulekile ekuzuzeni imiphumela emihle.

B. Inqubo Yokuqinisekisa Nekhwalithi

Qiniseka ukuthi umhlinzeki wesevisi unezitifiketi ezifanele, ezifana ne-ISO 9001, ukuze uqinisekise ukuthi amazinga aqinile okulawula ikhwalithi ayalandelwa. Izinqubo zokulawula ikhwalithi eziqinile ziqinisekisa ikhwalithi yomkhiqizo engaguquki nokwethembeka.

C. Ukubuyekezwa Kwekhasimende Nobufakazi

Cabangela impendulo nezibuyekezo ezivela kumakhasimende akhona. Ukubuyekezwa okuhle kubonisa ukuzibophezela komhlinzeki wesevisi ekwanelisekeni kwamakhasimende kanye nokuphuma kwekhwalithi.

D. Intengo kanye Nesikhathi Sokushintsha

Hlola izakhiwo zamanani ezihlinzekwa abahlinzeki besevisi ukuze uqinisekise ukuthi zihambisana nesabelomali sakho kanye nezidingo zephrojekthi. Futhi, cabangela isikhathi sabo sokushintsha ukuze uqinisekise ukulethwa ngesikhathi komkhiqizo wokugcina.

Izinhlelo zokusebenza zebhodi lesifunda eliguquguqukayo

Ukuhlukahluka kwama-PCB aguquguqukayo kuwavumela ukuthi asetshenziswe ezimbonini ezahlukahlukene. Ake sihlole ukuthi amabhodi esifunda aphrintiwe asebenziseka kalula asetshenziswa kanjani ku-electronics abathengi, imboni yezimoto, izisetshenziswa zezokwelapha, kanye ne-aerospace nokuvikela.

A. Consumer electronics

Ama-PCB aguquguqukayo asetshenziswa kakhulu kuma-smartphone, amaphilisi, izinto ezigqokekayo, nezinye izinto zikagesi eziphathwayo. Ikhono lazo lokuzivumelanisa nezimo ezingajwayelekile futhi lingene ezindaweni ezihlangene lizenza zibaluleke kakhulu ekwakhiweni kwale mishini.

B. Imboni yezimoto

Ama-PCB aguqukayo abalulekile ku-automotive electronics, ukunika amandla amasistimu okusiza abashayeli (ADAS), amasistimu we-infotainment, ukulawula izibani, nezinhlelo zokuphatha injini. Ukuqina nokuthembeka kwama-PCB avumelana nezimo kuwenza afanelekele izindawo zezimoto ezinokhahlo.

C. Imishini yezokwelapha

Ama-PCB aguquguqukayo angasetshenziswa kumishini yezokwelapha efana nezihlinzeki zenhliziyo, ama-defibrillator kanye nemishini yokuxilonga. Ukuvumelana nezimo nokubumbana kwazo kuvumela ukuhlanganiswa okungenamthungo kumadivayisi amancane ezokwelapha, kuyilapho ukwethembeka kwawo kuqinisekisa ukusebenza okungaphazamiseki.

D. I-Aerospace kanye Nezokuvikela

Imboni ye-aerospace neyezokuvikela ithembele kakhulu kuma-PCB aguquguqukayo ezinhlelweni zokuxhumana, ama-avionics, izinhlelo ze-radar kanye nemishini yezempi. Imvelo engasindi futhi ehlangene yama-PCB aguquguqukayo isiza ekwehliseni isisindo kanye nezingqinamba zesikhala ezindizeni nasezinhlelweni zokuzivikela.

Izinzuzo zokuhlanganisa i-PCB eguquguqukayo

Umhlangano we-PCB oguquguqukayo unikeza izinzuzo ezimbalwa ngaphezu kwama-PCB aqinile endabuko. Ukuqonda lezi zinzuzo kungasiza ukugcizelela ukubaluleka nokubaluleka kobuchwepheshe.

A. Ukonga isikhala kanye nokuvumelana nezimo

Ama-PCB aguqukayo alungile ekongeni isikhala futhi azivumelanise nezimo ezingajwayelekile. Lokhu kuvumelana nezimo kwenza amasistimu kagesi aklanywe futhi ahlanganiswe ekucushweni okuhlangene nokuyinkimbinkimbi, okwandisa ukusetshenziswa kwendawo yonke.

B. Ukwethenjwa okuthuthukisiwe nokuqina

Imvelo eguquguqukayo yama-PCB inyusa ukumelana kwawo nokudlidliza, ukushaqeka, kanye nengcindezi yemishini. Lokhu kuqina okuphakeme kusho ukwethembeka okukhulu nempilo yesevisi ende, ikakhulukazi ezindaweni ezinokhahlo.

C. Thuthukisa ubuqotho besignali nokusebenza kukagesi

Ama-PCB aguqukayo ahlinzeka ngobuqotho besignali obuhle kakhulu ngenxa yezindlela zesignali ezimfushane, ukuphazamiseka kwe-electromagnetic okuncishisiwe (EMI), kanye ne-impedance elawulwayo. Lokhu kuqinisekisa ukusebenza kukagesi okuthuthukisiwe, amazinga aphezulu okudluliswa kwedatha, nokuncipha kokuwohloka kwesignali.

D. Ukusebenza kahle kwezindleko kanye nesikhathi esisheshayo sokumaketha

Nakuba izindleko zokuqala zingase zibe phezulu, umhlangano we-PCB oguquguqukayo unikeza isisombululo esingabizi ngokuhamba kwesikhathi. Ukuqina nokuthembeka kwama-PCB aguquguqukayo kunciphisa isidingo sokukhanda noma ukushintshwa. Ukwengeza, ukuguquguquka kokuklama nezinqubo zokuhlanganisa ngokushesha kungasheshisa isikhathi sokumaketha, kunikeze izinkampani inzuzo yokuncintisana.

Ngokufigqiwe

Izinqubo kanye nobuchwepheshe obuhilelekile ekuhlanganiseni kwebhodi lesifunda eliphrintiwe okuguquguqukayo kubalulekile ekukhiqizeni okuphumelelayo kwamabhodi wesifunda aphrintiwe aguquguqukayo. Ukuqonda izici zezindleko, izinqubo zokuhlanganisa kanye nezinzuzo zalobu buchwepheshe kubeka isisekelo sokuhlola izinhlelo zokusebenza zayo ezihlukene zezimboni. Izakhiwo ezintsha zama-PCB avumelana nezimo zidlala indima ebalulekile kwezobuchwepheshe besimanje, ukushayela intuthuko ku-electronics abathengi, izimoto, izisetshenziswa zezokwelapha, i-aerospace nokuzivikela. Njengoba ubuchwepheshe buqhubeka nokuvela, izinkampani kufanele zihlole ukuthi kungenzeka yini ukusebenzisa ama-PCB aguquguqukayo ezinhlelweni zazo zokuqinisekisa ukusebenza okuthuthukisiwe, ukwethembeka nokusebenza kahle.

Isikhathi sokuthumela: Nov-10-2023

Emuva