Iyini i-High-Precision PCBs

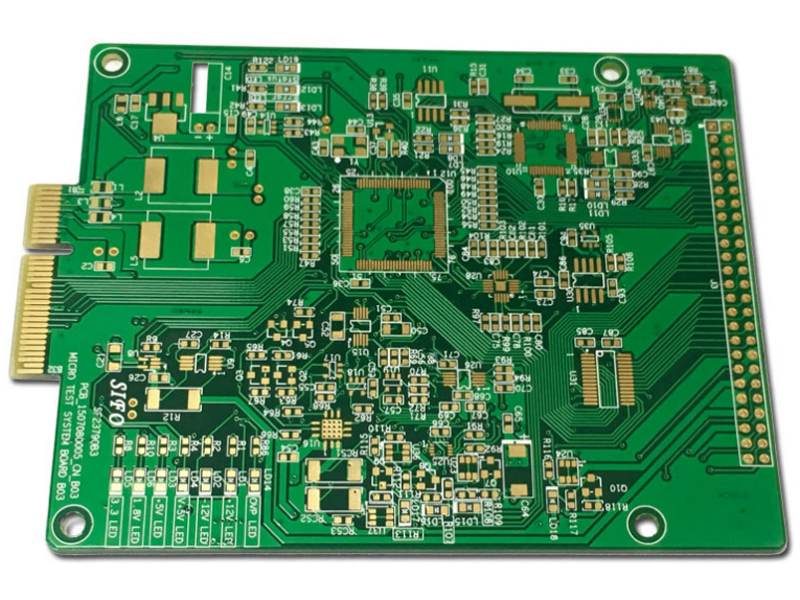

Ibhodi lesifunda eliphrintiwe ngokunemba okuphezulu, elaziwa nangokuthi ibhodi lesifunda eliphrintiwe ngokunemba okuphezulu,

iyingxenye ye-elekthronikhi esetshenziswa kakhulu ezinhlelweni ezidinga amasekhethi anembayo futhi anembe.

Lawa ma-PCB aklanywe futhi akhiqizwa ngokunaka okukhulu emininingwaneni, okuqinisekisa izinga eliphezulu lokunemba nokuthembeka.

Ama-PCB anembe kakhulu avame ukusetshenziswa ezimbonini ezifana ne-aerospace, okokusebenza kwezokwelapha, ezokuxhumana, nezezimoto. Zibaluleke kakhulu ezinhlelweni zokusebenza ezidinga ubuqotho besignali obunembayo, ukusebenza kwemvamisa ephezulu, ukubekezelelana okuqinile, nokuhlanganiswa kobuchwepheshe obuthuthukile.

Lawa ma-PCB ngokuvamile akhiqizwa kusetshenziswa izinqubo ezithuthukisiwe kanye namasu afana nezintambo ezivimbelayo ezilawulwayo, izingxenye zephimbo elihle, ama-micro vias, ama-vias angaboni kanye nangcwatshwe, kanye nezixhumi ezixhumene kakhulu. Angase futhi afake izendlalelo eziningi, izifunda eziyinkimbinkimbi nezinto ezikhethekile ukuze kuhlangatshezwane nezidingo ezithile zohlelo oluhlosiwe.

Inqubo yokukhiqiza yama-PCB anembe kakhulu ihilela izinyathelo eziqinile zokulawula ikhwalithi, okuhlanganisa nezinqubo zokuhlola eziqinile nezinqubo zokuhlola, ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana nezicaciso ezidingekayo. Lokhu kunemba nokunemba kwenza ukusebenza kahle nokuthembekile, ikakhulukazi ezinhlelweni zikagesi eziyinkimbinkimbi.

I-CAPEL High-Precision PCBs

Ama-PCB anembe kakhulu aklanyelwe ukuhlinzeka ngoxhumano lukagesi oluthembekile nolunembayo. Bangena ezinqubweni zokukhiqiza ezihlukahlukene futhi banamathela kumklamo oqinile kanye namazinga okuhlola ukuze bahlangabezane nezidingo ezithile zezicelo ezifunwayo ezimbonini ezihlukahlukene.

Izinto Ezisezingeni Eliphezulu

Ama-PCB anembe kakhulu ngokuvamile enziwa kusetshenziswa izinto ezisezingeni eliphezulu, njengamalaminates akhethekile anesivinini esiphezulu noma izitsha zobumba ezithuthukisiwe. Lezi zinto zinezici ezithile ezisiza ukuthuthukisa ukusebenza kukagesi kwe-PCB nobuqotho besignali.

Isakhiwo Sezingqimba Eziningi

Ama-PCB anembe kakhulu ngokuvamile anesakhiwo esinezingqimba eziningi, esivumela imiklamo yesekethe eyinkimbinkimbi futhi eminyene. Ukwakhiwa kwezendlalelo eziningi kusiza ukuthuthukisa ukuhlukaniswa kwesignali, ukunciphisa i-crosstalk nokwandisa ukusatshalaliswa kwamandla.

I-Fine Line ne-Space

Ama-PCB anembe kakhulu ngokuvamile adinga ulayini omuhle kakhulu nobubanzi besikhala, ngokuvamile obukalwa ngama-microns. Lawa mathrekhi amancane avumela umzila wesignali ongcono futhi anciphise ukulahleka kwesignali noma ukuphazamiseka.

I-Impedans elawulwayo

Ukulawulwa kwe-impedance kubalulekile ekugcineni ubuqotho besignali ezinhlelweni ezisebenza ngesivinini esikhulu. I-PCB enembayo ilawula ukuthinteka kwayo yonke i-trace ukuze ifane nokuphazamiseka kwesici okudingwa idizayini.

I-Advanced Technology

Ama-PCB anembe kakhulu ngokuvamile asebenzisa ubuchwepheshe bokukhiqiza obuthuthukisiwe obufana nokubhola nge-laser nokuthwebula okuqondile. I-Laser drilling inika amandla amancane, anembe kakhulu ngobukhulu, kuyilapho ukuthwebula izithombe okuqondile kwenza ukubhaliswa okunembe kakhudlwana kwemaski ye-solder.

Ukuhlola Nokuhlola

Ukulawulwa kwekhwalithi kubalulekile kuma-PCB anembe kakhulu. Ukuhlola okuqinile nezinqubo zokuhlola ezifana nokuhlola okuzenzakalelayo (i-AOI) kanye nokuhlolwa kwe-X-ray kusetshenziswa ukuze kuhlonzwe noma yikuphi ukukhubazeka okungaba khona noma izinkinga futhi kuqinisekiswe ukuthi i-PCB ihlangabezana nezicaciso ezidingekayo.

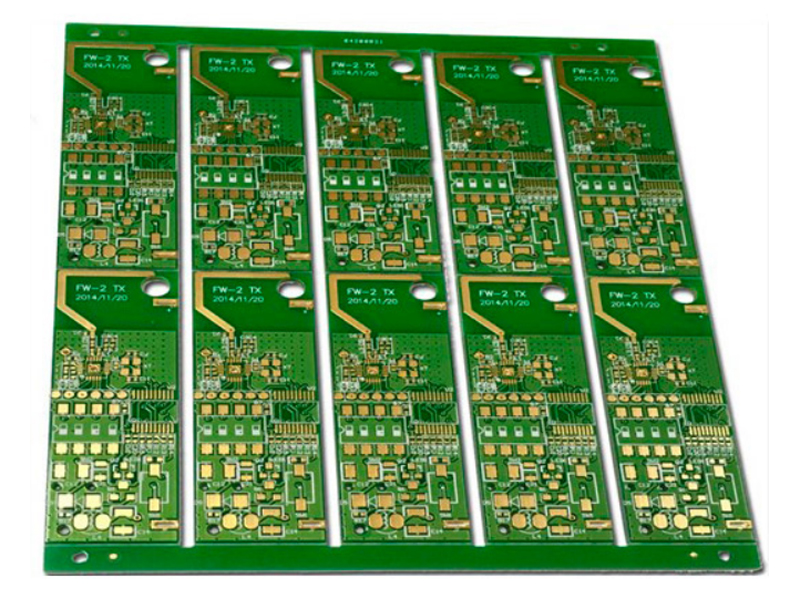

Idizayini Yokwenziwa

Ama-PCB anembe kakhulu adinga ukucatshangelwa okuphelele kwe-DFM phakathi nesigaba sokuklama ukuze kuqinisekiswe ukuthi amadizayini angenziwa ngempumelelo nangokunembile. Amasu e-DFM asiza ukuthuthukisa ukuklama kwenqubo yokukhiqiza futhi andise isivuno sokukhiqiza sisonke.

Izingxenye ze-Miniaturized

Ama-PCB anembe kakhulu ngokuvamile aklanyelwe ukuthwala izingxenye ezincane ezifana ne-surface mount device ama-microelectromechanical systems (MEMS). Ukubekwa okunembayo nokuhlanganiswa kwalezi zingxenye ezincane kunomthelela ekunembeni okuphelele nasekusebenzeni kwe-PCB.