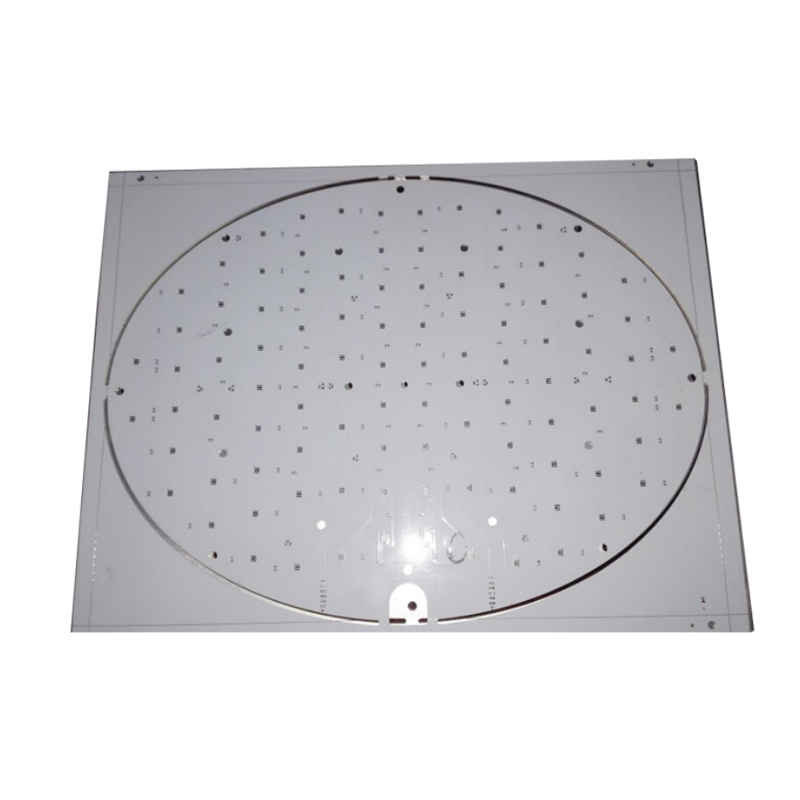

I-Aluminium Enohlangothi Olulodwa PCB Manufacrturin

Ikhono lenqubo ye-PCB

| Cha. | Iphrojekthi | Izinkomba zobuchwepheshe |

| 1 | Isendlalelo | 1-60(ungqimba) |

| 2 | Indawo yokucubungula ephezulu | 545 x 622 mm |

| 3 | Ubuncane bobukhulu | 4(ungqimba)0.40mm |

| 6(ungqimba) 0.60mm | ||

| 8(ungqimba) 0.8mm | ||

| 10(ungqimba)1.0mm | ||

| 4 | Ububanzi bomugqa obuncane | 0.0762mm |

| 5 | Isikhala esincane | 0.0762mm |

| 6 | Imbobo encane yomshini | 0.15mm |

| 7 | Imbobo yodonga lwethusi ukujiya | 0.015mm |

| 8 | Ukubekezelelwa kwe-metalized aperture | ±0.05mm |

| 9 | Ukubekezelela ukungena kwe-metallized | ±0.025mm |

| 10 | Ukubekezelelana kwezimbobo | ±0.05mm |

| 11 | Ukubekezelela Dimensional | ±0.076mm |

| 12 | Ibhuloho elincane le-solder | 0.08mm |

| 13 | Ukumelana ne-insulation | 1E+12Ω (evamile) |

| 14 | Isilinganiso sobukhulu bepuleti | 1:10 |

| 15 | Ukushaqeka okushisayo | 288 ℃ (izikhathi ezi-4 ngemizuzwana eyi-10) |

| 16 | Ihlanekezelwe futhi igobile | ≤0.7% |

| 17 | Amandla okulwa nogesi | >1.3KV/mm |

| 18 | Amandla okulwa nokuhlubula | 1.4N/mm |

| 19 | I-Solder imelana nobunzima | ≥6H |

| 20 | Ukuncipha komlilo | 94V-0 |

| 21 | Ukulawulwa kwe-impedance | ±5% |

Senza i-Aluminium PCB ngesipiliyoni seminyaka engu-15 ngobungcweti bethu

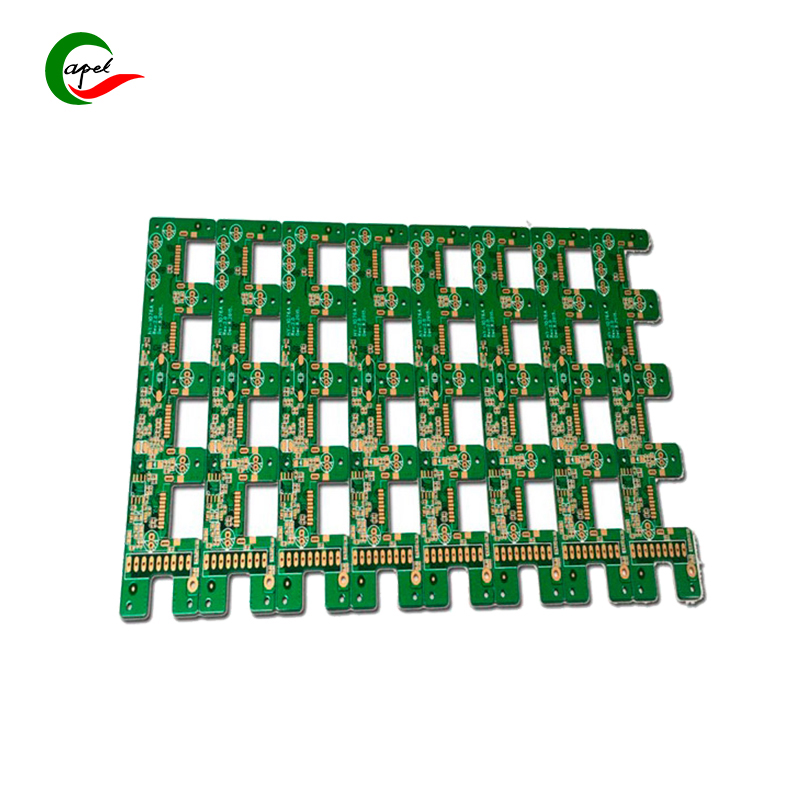

4 ungqimba Amabhodi Flex-Rigid

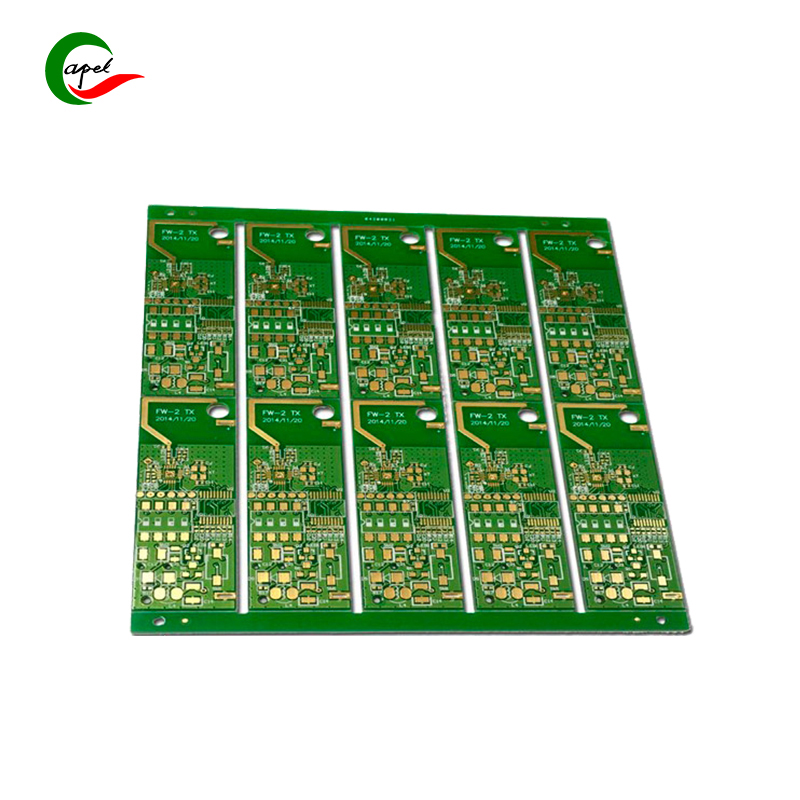

8 ungqimba we-Rigid-Flex PCBs

8 ungqimba HDI Amabhodi Esifunda Aphrintiwe

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

Isevisi yethu ye-Aluminium PCB

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Izimoto, Izindiza, I-Consumer Electronics, i-IOT, i-UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

I-Aluminium PCB isetshenziswa Kudivayisi Yezokwelapha

1. Ukwelapha okusekelwe ku-LED: Ama-PCB e-Aluminium asetshenziswa kumadivayisi asebenzisa ubuchwepheshe be-LED ekwelapheni okufana nokwelapha nge-photodynamic kanye nokwelashwa nge-laser kwezinga eliphansi. I-aluminium conductivity ephezulu ye-thermal isiza ukuqeda ukushisa ngempumelelo, iqinisekisa ukuthi ama-LED asebenza ngezinga lokushisa elilungile ukuze zelashwe ngempumelelo.

2. Imishini yokuthwebula yezokwelapha: Ama-PCB e-aluminium asetshenziswa emishinini yokuthwebula yezokwelapha, njengezinhlelo ze-MRI (magnetic resonance imaging) kanye nemishini ye-X-ray. Izakhiwo ezinhle kakhulu ze-Aluminium zokuvikela ugesi zisiza ukuvimbela ukuphazamiseka futhi ziqinisekise ukuthwebula okunembile, kwekhwalithi ephezulu.

3. Imishini yokuqapha yezokwelapha neyokuxilonga: Ama-PCB e-aluminium angasetshenziswa emishinini enjengamamonitha esiguli, ama-defibrillator, nemishini ye-electrocardiogram (ECG). I-aluminium conductivity ephezulu kagesi isiza ukudluliswa kwesignali okuthembekile futhi iqinisekisa ukuqapha okunembile kanye nokuxilongwa.

4. Imishini yokuvuselela imizwa: I-Aluminium PCB isetshenziswa kwizikhuthazi zobuchopho ezijulile, izikhuthazi zomgogodla nezinye izinto zokusebenza. Imvelo engasindi ye-aluminium yenza idivayisi ikhululeke kakhudlwana esigulini, futhi ukuqhutshwa kwayo okuphezulu kwe-thermal kusiza ukuqeda ukushisa okukhiqizwa ngesikhathi sokuvuselela.

5. Imishini yezokwelapha ephathekayo: Ama-PCB e-Aluminium alungele izinto zezokwelapha eziphathwayo njengezibonisi eziphathwayo kanye namadivayisi okulandelela ezempilo agqokekayo. Imvelo engasindi futhi ehlangene yama-PCB e-aluminium inegalelo ekuphathekeni kukonke nasekusebenzisekeni kwamadivayisi anjalo.

6. Imishini yezokwelapha efakelwayo: Ama-PCB e-Aluminium nawo asetshenziswa emishinini ethile yezokwelapha efakelwayo njengama-pacemaker nama-neurostimulators. Lawa madivaysi adinga izingxenye ze-elekthronikhi ezithembekile nezinto ezihlala isikhathi eside, futhi ama-PCB e-aluminium angahlangabezana nalezi zidingo.

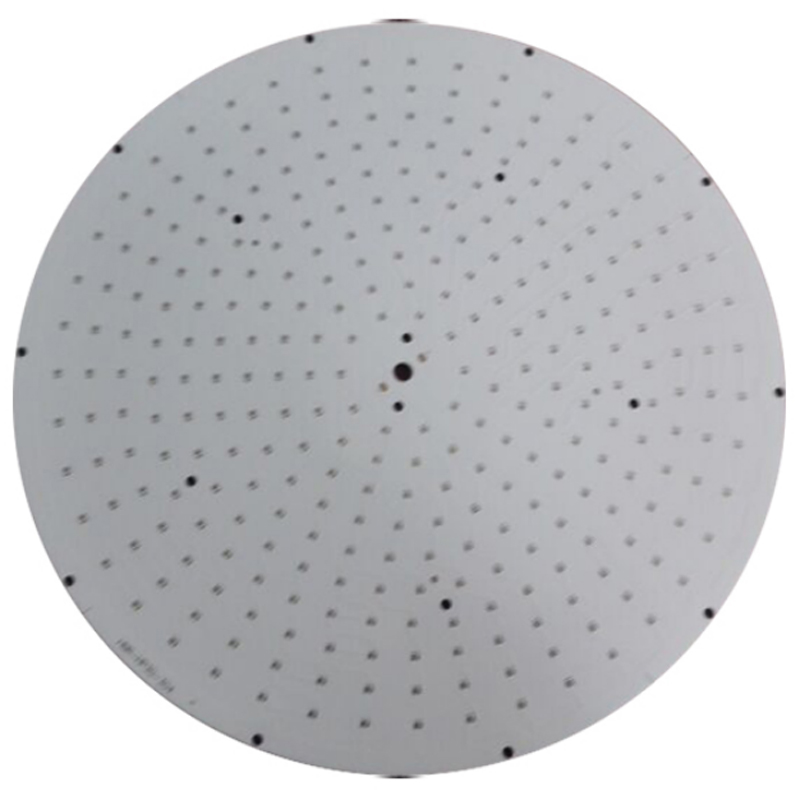

I-PCB Ebuzwa Nge-Aluminium Enohlangothi Olulodwa

Q: Yiziphi izinzuzo zokusebenzisa i-aluminium substrate enohlangothi olulodwa?

Impendulo: I-substrate ye-aluminium enohlangothi olulodwa inamandla amahle kakhulu okukhipha ukushisa ngenxa ye-aluminium substrate.

Ayisindi, ayabiza futhi anamandla amahle okusebenza. Idizayini yohlangothi olulodwa yenza inqubo yokukhiqiza ibe lula futhi yehlise ubunkimbinkimbi buphelele be-PCB.

Q: Yiziphi izinhlelo zokusebenza ezifanele i-aluminium yohlangothi olulodwa?

A: Ama-PCB e-aluminium anohlangothi olulodwa avame ukusetshenziswa ezinhlelweni ezidinga ukuchithwa kokushisa okuphumelelayo, njengezibani ze-LED, izinto zamandla, izinto zikagesi zezimoto, ukulawula kwezimoto, nezikhulisi zomsindo.

Q: Ingabe i-PCB ye-aluminium enohlangothi olulodwa ilungele izinhlelo zokusebenza zemvamisa ephezulu?

A: Ama-PCB e-aluminium anohlangothi olulodwa ngokuvamile awanconyelwe izinhlelo zokusebenza zemvamisa ephezulu ngenxa yobuqotho besignali obulinganiselwe.

Isendlalelo se-conductive esisodwa singase sibangele ukulahleka kwesignali okuningi kanye ne-crosstalk kune-PCB enezingqimba eziningi

Q: Yiziphi izinketho zokujiya ezijwayelekile ze-PCB enohlangothi olulodwa lwe-aluminium?

A: Ubukhulu obujwayelekile be-aluminium core ku-PCB ye-aluminium yohlangothi olulodwa busuka ku-0.5 mm ukuya ku-3 mm.

Ubukhulu bengqimba yethusi bungahluka ngokuya ngezidingo ezithile zohlelo lokusebenza.

Q: Ifakwa kanjani i-PCB ye-aluminium enohlangothi olulodwa ohlelweni lwe-elekthronikhi?

A: Ama-PCB e-aluminium anohlangothi olulodwa angafakwa ngokusebenzisa imbobo noma amasu okukhweza ngaphezulu, kuye ngezingxenye nezidingo zokuhlanganisa. Indlela yokuhlanganisa efanelekile inganqunywa ngokuya ngemikhombandlela ethile yokuklama kanye nokukhiqiza.

Q: Yiziphi izinzuzo zokuphatha okushisayo ngokusebenzisa i-PCB ye-aluminium enohlangothi olulodwa?

IMP: I-Aluminum inokuhamba kahle kakhulu kwe-thermal futhi ingadlulisela ngempumelelo ukushisa kude nezingxenye ezikhiqiza ukushisa.

Lokhu kusiza ukunciphisa izinga lokushisa lokusebenza kwe-PCB futhi kuthuthukisa ukuthembeka okuphelele nokusebenza kohlelo lwe-elekthronikhi.