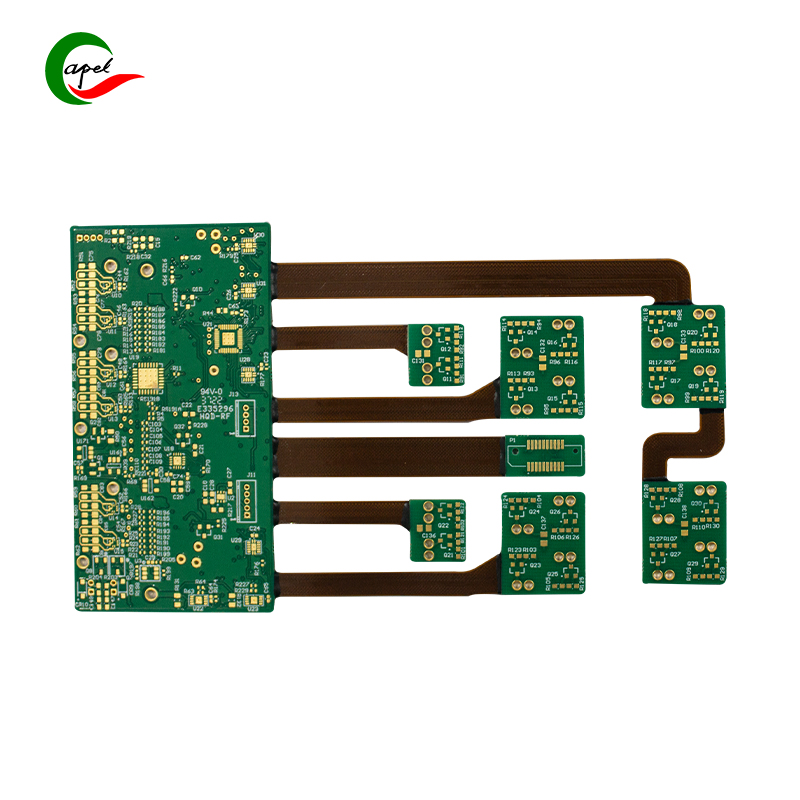

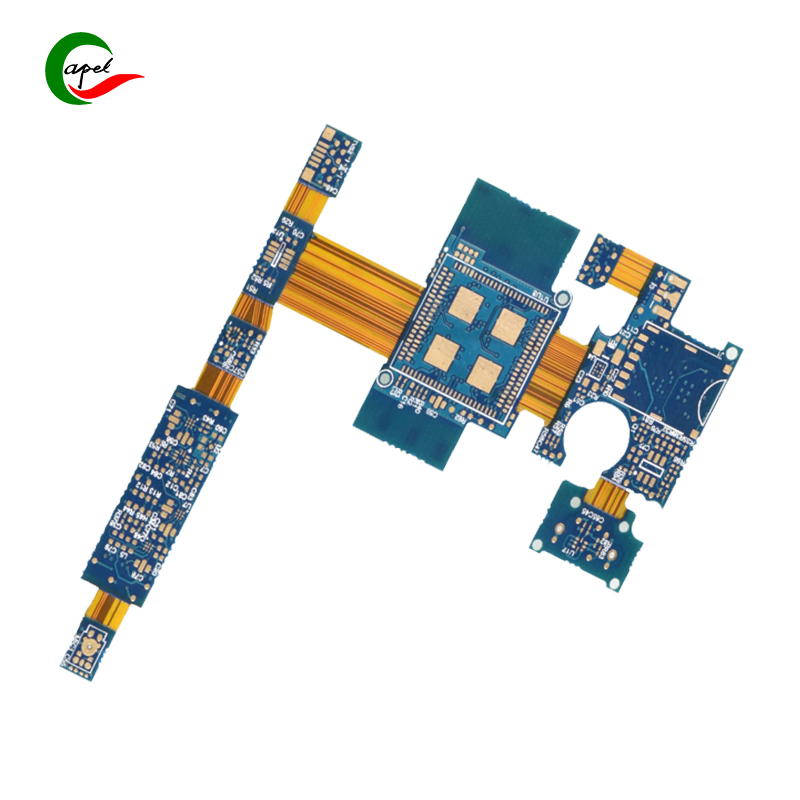

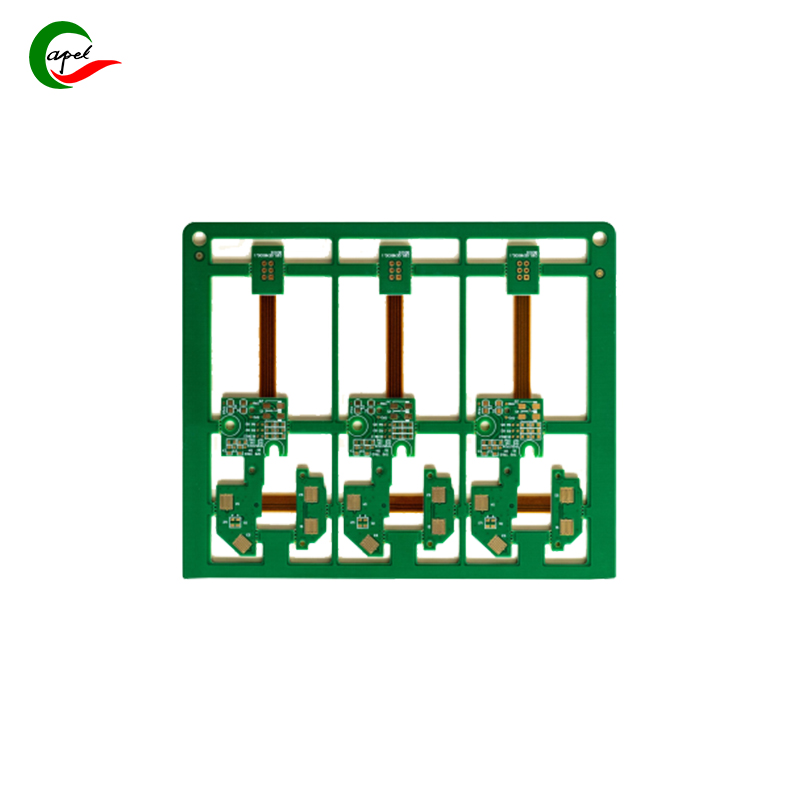

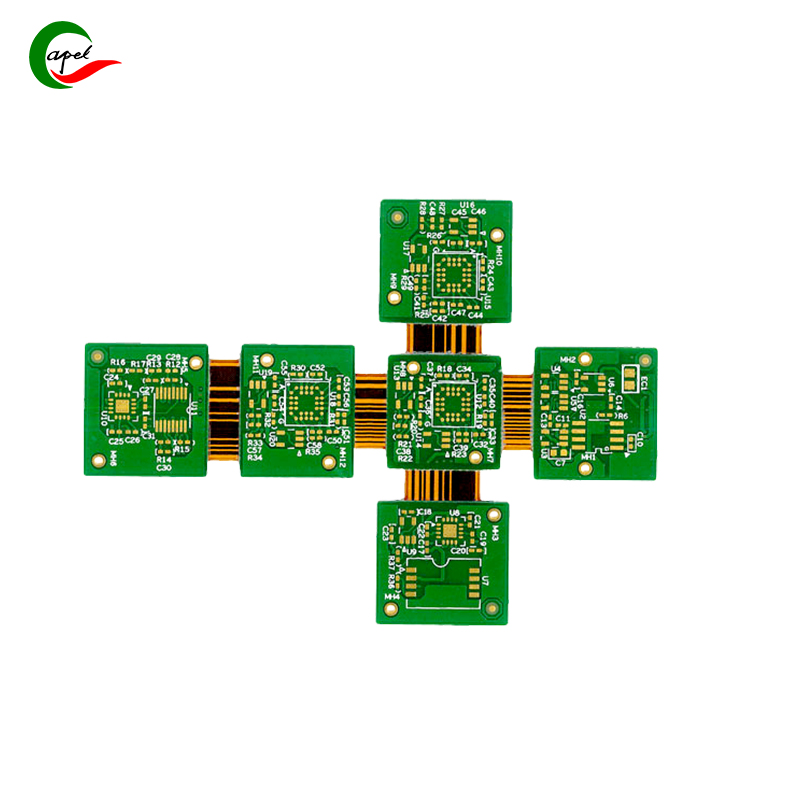

Isevisi Yokwenza I-Rigid-Flex PCB

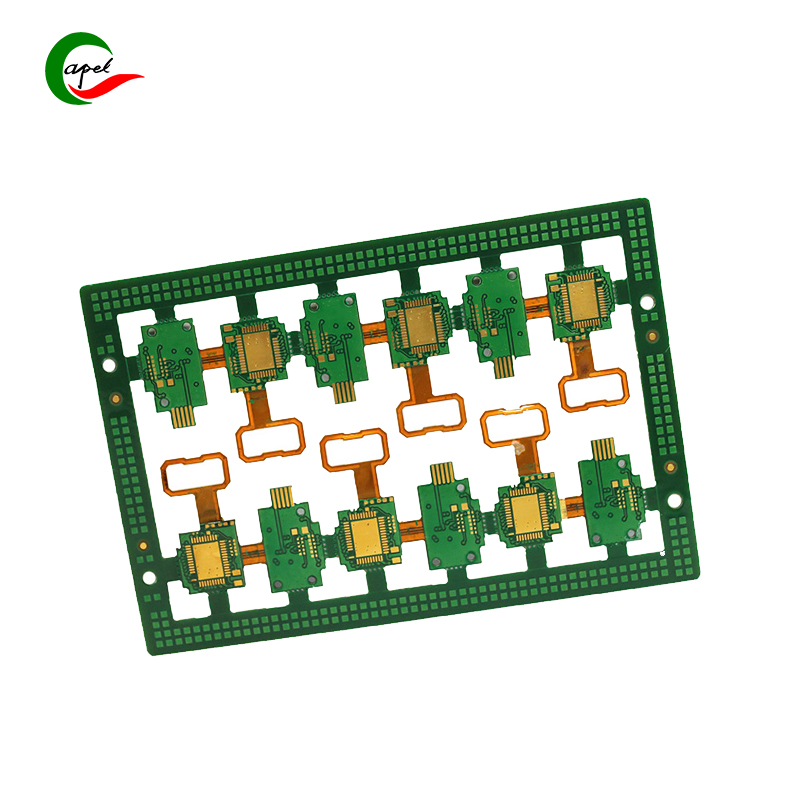

Ithimba likaCapel leminyaka engu-15 leRigid flexible flexible printed printed circuit technology technology

-hlinzeka ngemininingwane ebalulekile kanye nesiqondiso kumakhasimende ethu;

-Ukuqonda okujulile kwezici zobuchwepheshe bobuchwepheshe bebhodi lesifunda eliqinile-flex libenza bakwazi ukunikeza izixazululo ezihambisana nezidingo eziyingqayizivele zekhasimende ngalinye.

-hlanganisa ubuchwepheshe obusezingeni eliphezulu kanye nezimiso zokuklama emikhiqizweni yabo, kuqinisekisa ukuthi amakhasimende aseCapel athola amabhodi wesifunda aqinile-aqinile ahlangabezana noma adlule izindinganiso zemboni.

Umthamo wokukhiqiza we-Rigid-Flex PCBs ungafinyelela ngaphezu kuka-70000sqm ngenyanga

--phatha ama-oda evolumu ephezulu futhi uhlangabezane nezinhlelo zokukhiqiza eziqinile. Kungakhathaliseki ukuthi udinga amanani amancane noma amakhulu, singagcwalisa izidingo zakho ze-oda ngokushesha nangempumelelo.

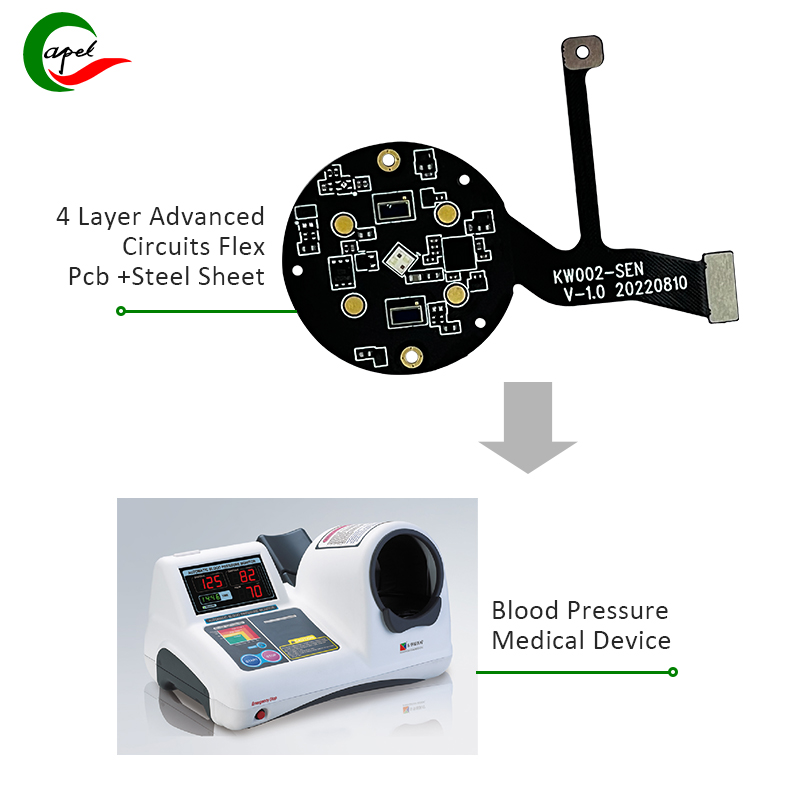

Ukusekela ngokwezifiso 2-32 ungqimba high-ngokunemba eqinile nezimo pcb wesifunda ibhodi

-ubuchwepheshe obuthuthukisiwe, imishini, nezinqubo zokuqinisekisa ukukhiqizwa okunembile nokuthembekile. Ukunaka kwethu imininingwane, izinyathelo eziqinile zokulawula ikhwalithi, nokuhlola okuphelele kusisiza ukuthi silethe ama-PCB aqinile ekhwalithi ephezulu ahlangabezana nezindinganiso eziphakeme kakhulu zomkhakha.

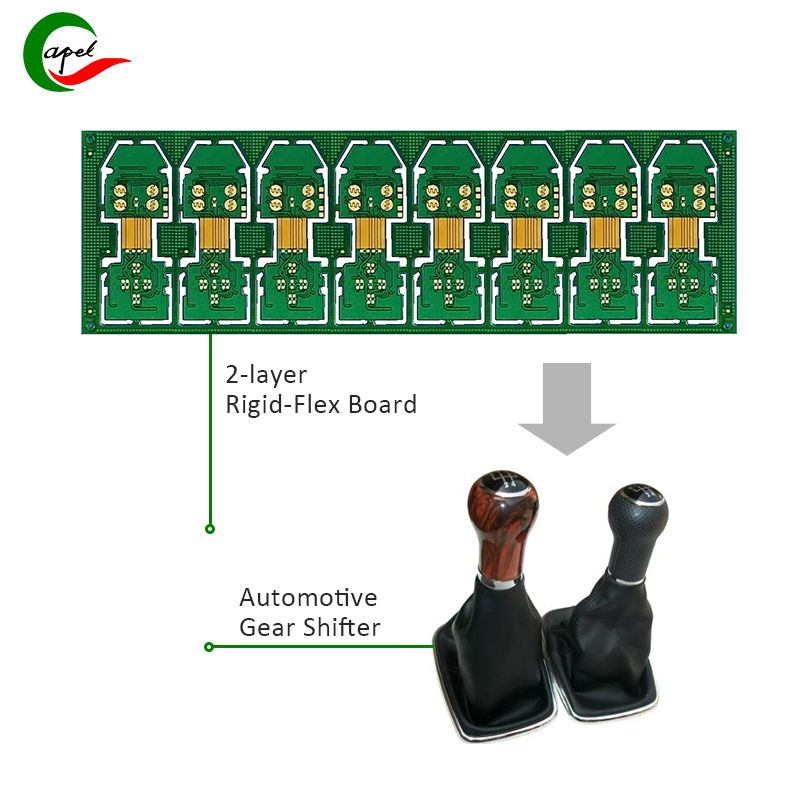

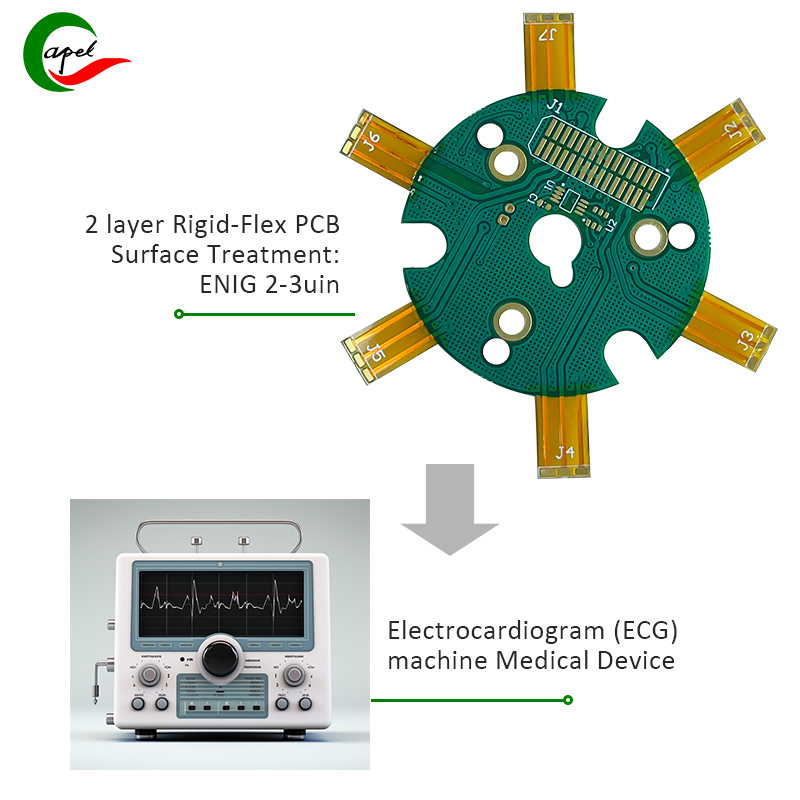

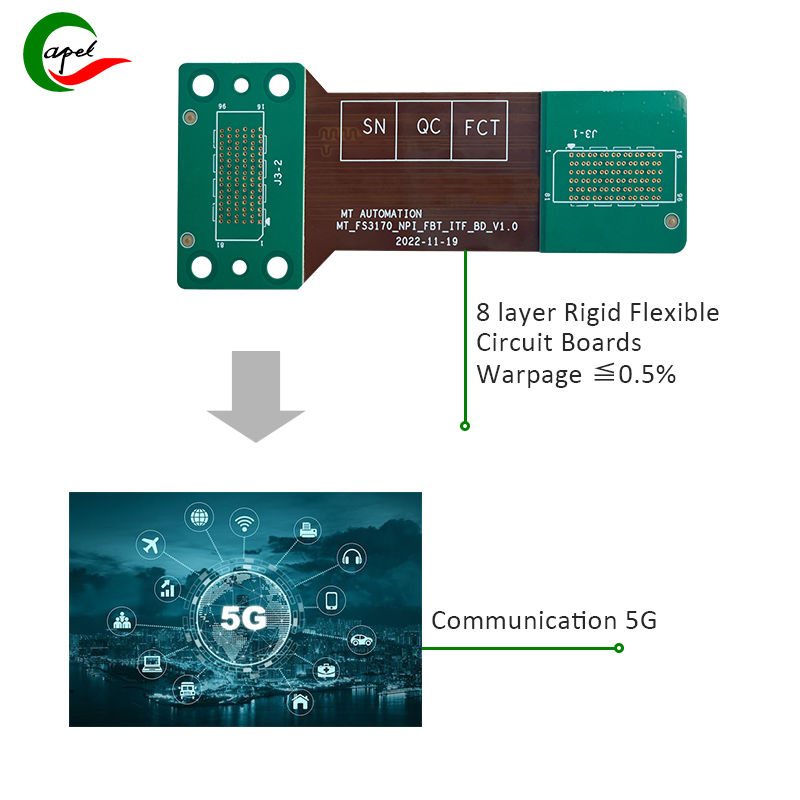

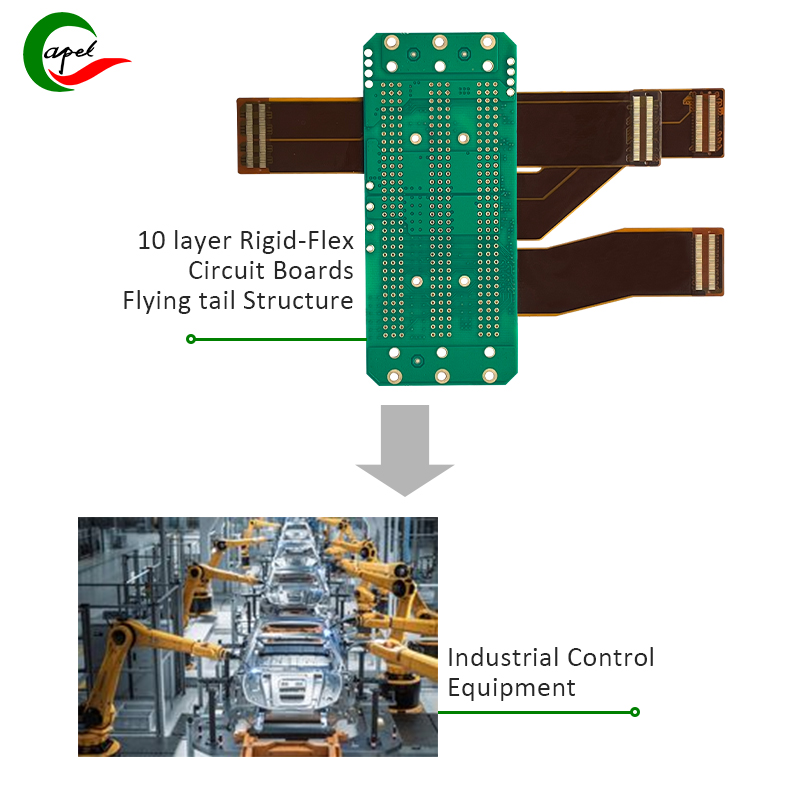

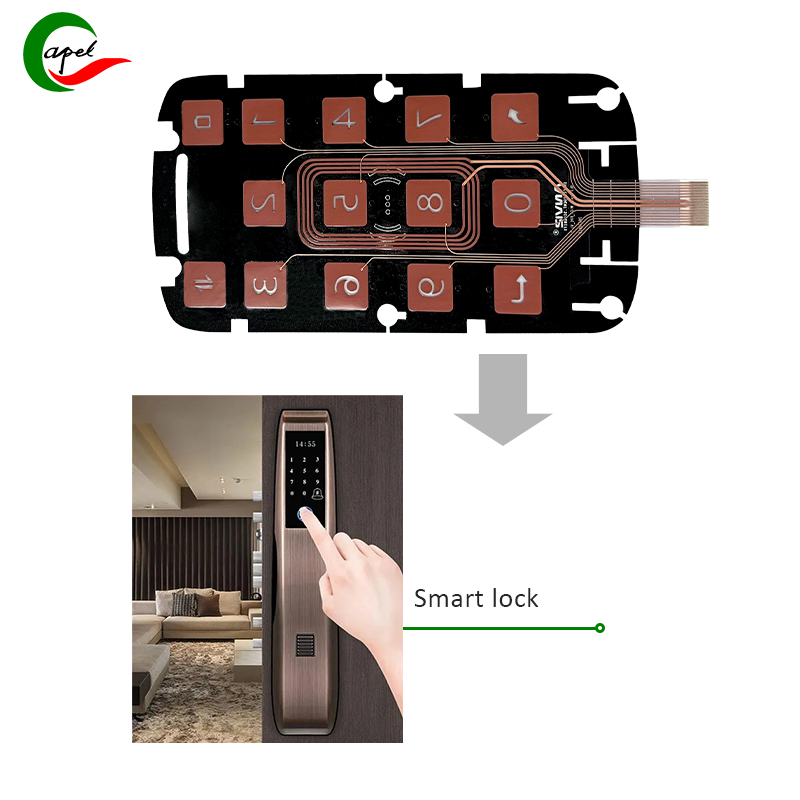

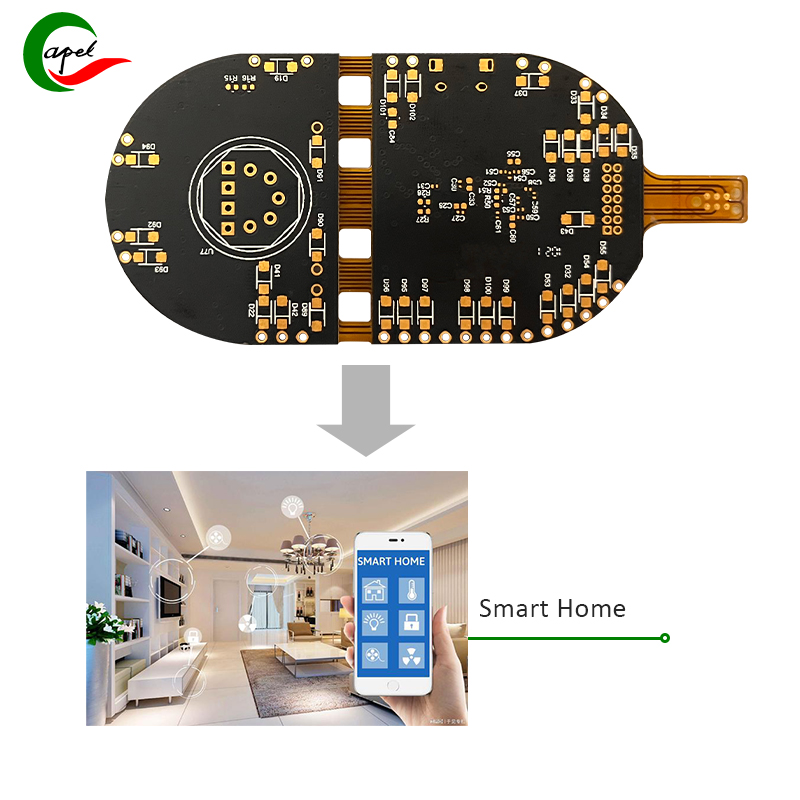

Amacala Okusebenza Wamabhodi Esifunda Se-Rigid-Flex PCB

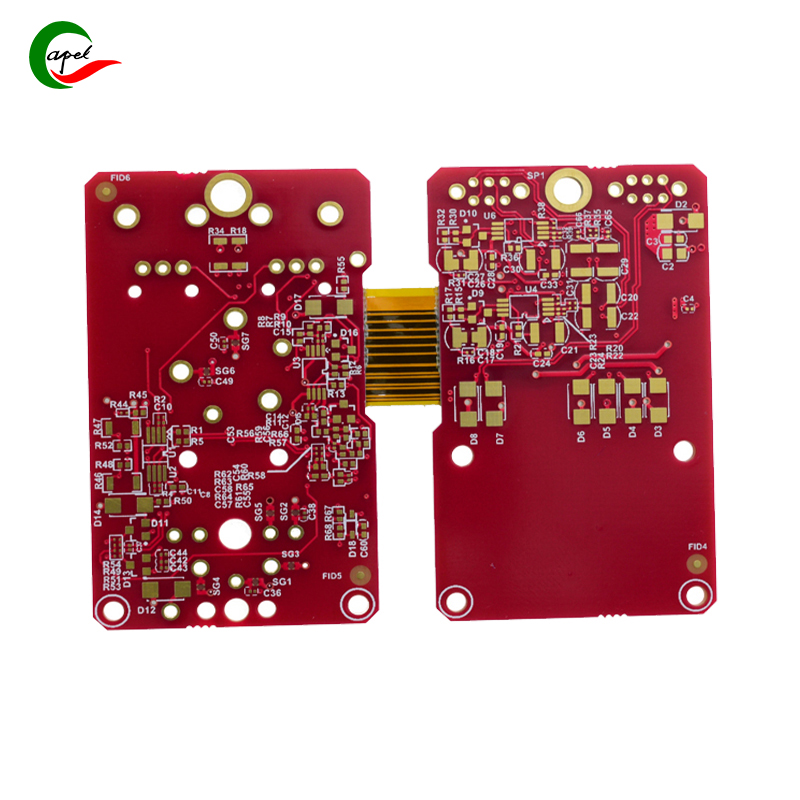

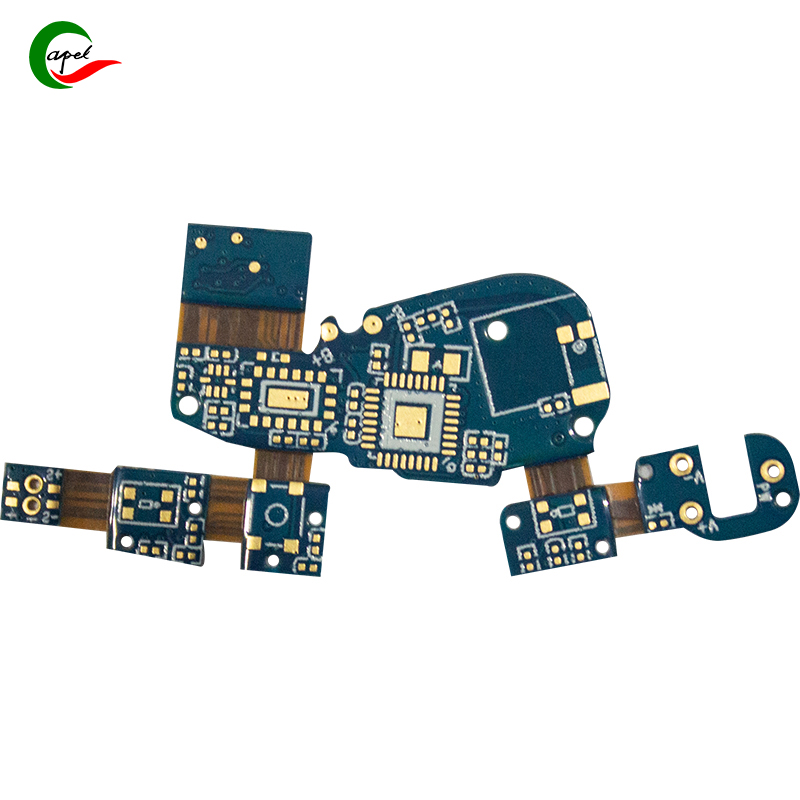

Nikeza izixazululo ezinokwethenjelwa ekukhiqizeni amabhodi esekethe aqinile aguquguqukayo kumakhasimende kumadivayisi agqokekayo, okokusebenza kwezokwelapha, i-aerospace nezinhlelo zokuzivikela, amasistimu ezimoto, izinto zikagesi zabathengi, ezishintshayo zezimboni, kanye nezokuxhumana.

-Ama-PCB enziwe ngokwezifiso aqinile avumelana nezimfuneko zawo ezithile;

-Ngokuya ngezidingo eziqondene nomkhakha wakho, singakunikeza amabhodi esifunda aphrintiwe aqinile avumelana nezimo anezinto ezikhethekile ezifana nezinto ezimelana nezinga lokushisa eliphezulu zezinhlelo zokusebenza zezimoto kanye ne-aerospace, kanye nezinto ezisezingeni lezokwelapha zezinhlelo zokusebenza zemishini yezokwelapha. Futhi sihlala sinolwazi lwakamuva ngobuchwepheshe bakamuva bokukhiqiza be-PCB obuqinile ukuze sihlangabezane nezidingo eziguqukayo zalezi zimboni.

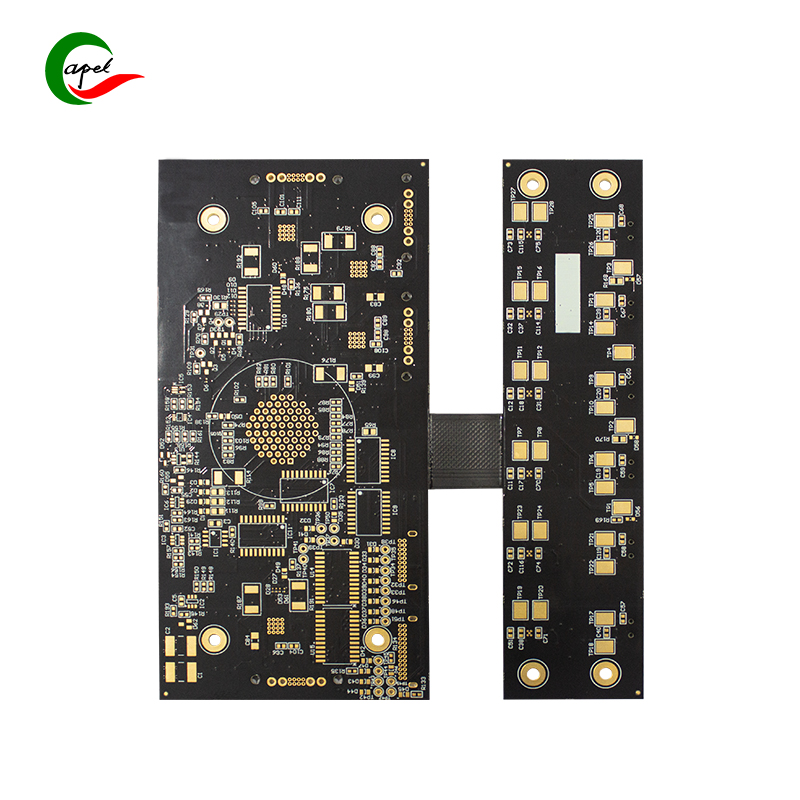

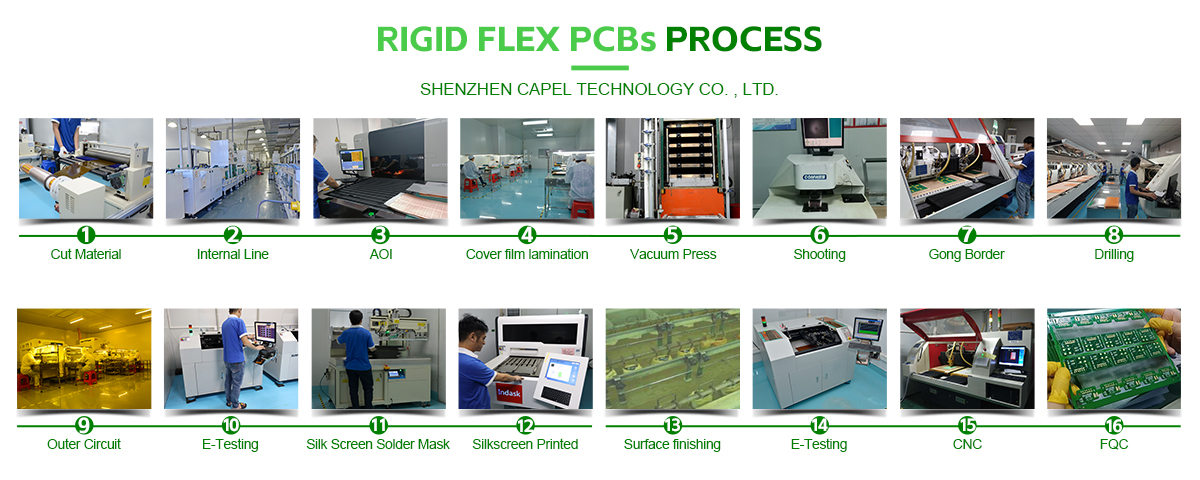

I-Rigid Flexible PCB Fabrication Process

1. Ukusika:Ukusika isisekelo sebhodi eliqinile: Sika indawo enkulu yebhodi eligqoke ithusi libe ngusayizi odingwa umklamo.

2. Ukusika impahla yesisekelo sebhodi eguquguqukayo:Sika okokusebenza kokuqala (isisekelo, iglue, ifilimu eyisimbozo, ukuqinisa i-PI, njll.) kusayizi odingwa umklamo wobunjiniyela.

3. Ukumba:Geza emigodini ukuze uthole ukuxhumana kwesekethe.

4. Imbobo emnyama:Sebenzisa i-potion ukwenza i-toner inamathele odongeni lwembobo, edlala indima enhle ekuxhumekeni nasekuqhubeni.

5. I-Copper Plating:Gcoba ungqimba lwethusi emgodini ukuze ufeze ukuqhutshwa.

6. Ukuchayeka kokuqondanisa:Qondanisa ifilimu (negethivu) ngaphansi kwendawo yembobo ehambisanayo lapho ifilimu eyomile inamathiselwe khona ukuze kuqinisekiswe ukuthi iphethini yefilimu ingadlula ngendlela efanele nendawo yebhodi. Iphethini yefilimu idluliselwa kwifilimu eyomile endaweni yebhodi ngokusebenzisa isimiso sokucabanga okukhanyayo.

7. Ukuthuthukiswa:Sebenzisa i-potassium carbonate noma i-sodium carbonate ukuze uthuthukise ifilimu eyomile ezindaweni ezingaveziwe zephethini yesifunda, ushiye iphethini yefilimu eyomile endaweni eveziwe.

8. Ukufaka:Ngemuva kokuthi iphethini yesifunda isithuthukisiwe, indawo eveziwe yendawo yethusi iqoshwa yisisombululo sokunamathisela, ishiya iphethini embozwe ifilimu eyomile.

flex pcb umhlangano

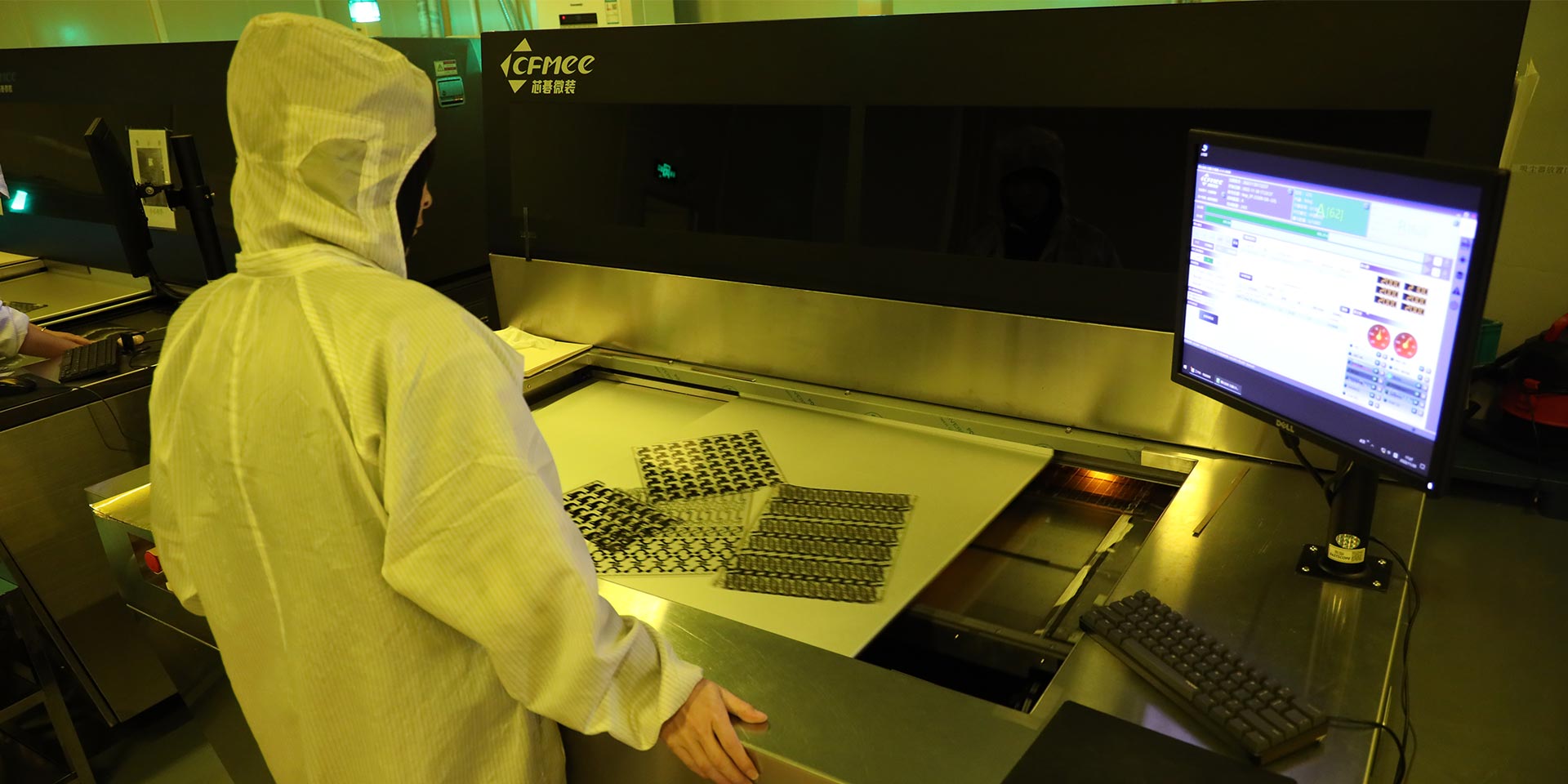

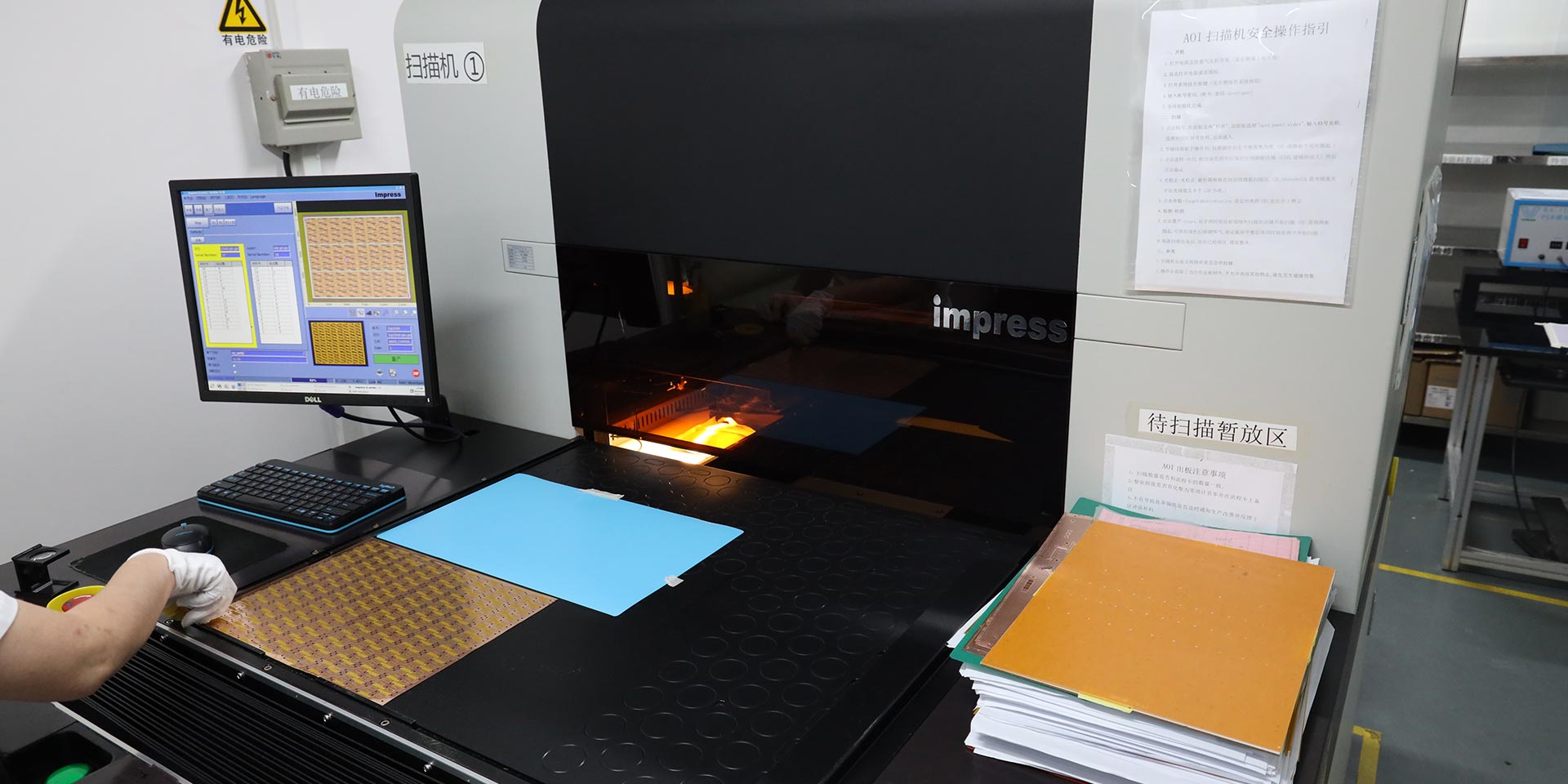

9. AOI:Ukuhlola okuzenzakalelayo. Ngokusebenzisa isimiso se-optical reflection, isithombe sidluliselwa kumishini yokucubungula, futhi uma kuqhathaniswa nedatha ebekiwe, izinkinga zesifunda ezivulekile nezifushane zomugqa zitholwa.

10. Lamination:Mboza isekethe ye-foil yethusi ngefilimu evikelayo ephezulu ukuze uvimbele i-oxidation yesifunda noma isifunda esifushane, futhi ngesikhathi esifanayo usebenze njenge-insulation kanye nokugoba komkhiqizo.

11. Laminating CV:Cindezela ifilimu yokumboza elayishiwe ngaphambili kanye nepuleti eliqinisiwe libe lilonke ngokusebenzisa izinga lokushisa eliphezulu nokucindezela okuphezulu.

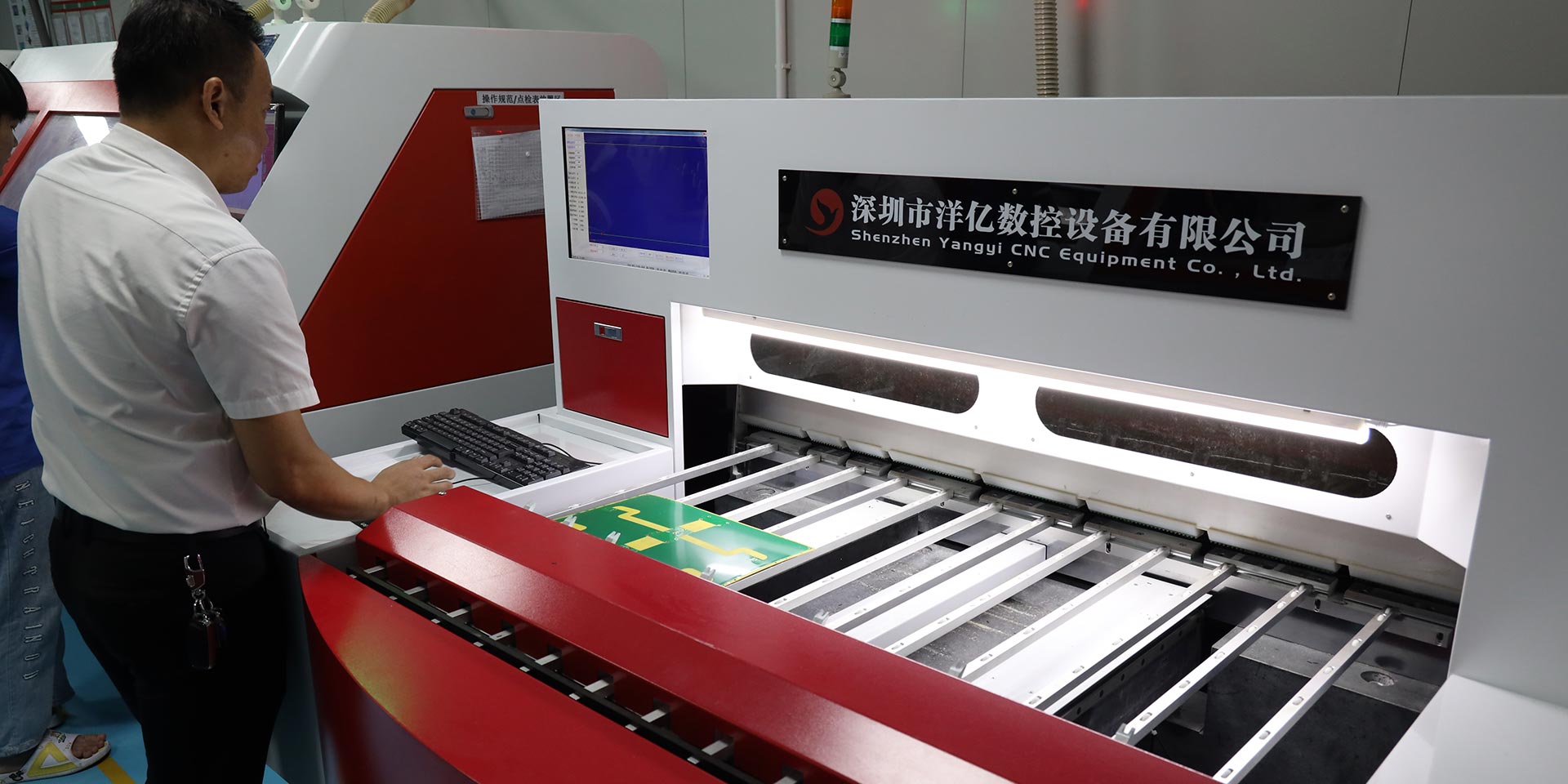

12. Punch:Sebenzisa isikhunta namandla we-punch yomshini ukuze ushaye ipuleti lomsebenzi kusayizi wokuthumela ohlangabezana nezidingo zokukhiqiza zekhasimende.

13. Lamination(i-superposition yamabhodi we-pcb aqinile-flex)

14. Ukucindezela:Ngaphansi kwezimo ze-vacuum, umkhiqizo uyafudumala kancane kancane, futhi ibhodi elithambile kanye nebhodi eliqinile kucindezelwa ndawonye ngokucindezela okushisayo.

15. Ukubhola okwesibili:Bamba imbobo ngembobo exhuma ibhodi elithambile kanye nebhodi eliqinile.

16. Ukuhlanza i-Plasma:Sebenzisa i-plasma ukuze uzuze imiphumela izindlela zokuhlanza ezijwayelekile ezingakwazi ukuyifeza.

17. Ithusi elicwilisiwe (ibhodi eliqinile):Ungqimba lwethusi lufakwe emgodini ukuze kuzuzwe ukuqhutshwa.

18. I-Copper Plating (ibhodi eliqinile):Sebenzisa i-electroplating ukujiya ubukhulu bembobo yethusi nethusi elingaphezulu.

19. Isekhethi (ifilimu eyomile):Namathisela ungqimba lwezinto ezizwela izithombe ebusweni bepuleti le-copper-plated ukuze lisebenze njengefilimu yokudlulisa iphethini. I-Etching AOI wiring: Isusa yonke indawo yethusi ngaphandle kwephethini yesekethe, ikhipha iphethini edingekayo.

20. Imaski ye-solder (isikrini sikasilika):Mboza yonke imigqa nezindawo zethusi ukuze uvikele imigqa futhi ugqume.

21. Imaski ye-solder (ukuchayeka):Uyinki uthola i-photopolymerization, futhi uyinki endaweni yokuphrinta isikrini uhlala phezu kwebhodi futhi uyaqina.

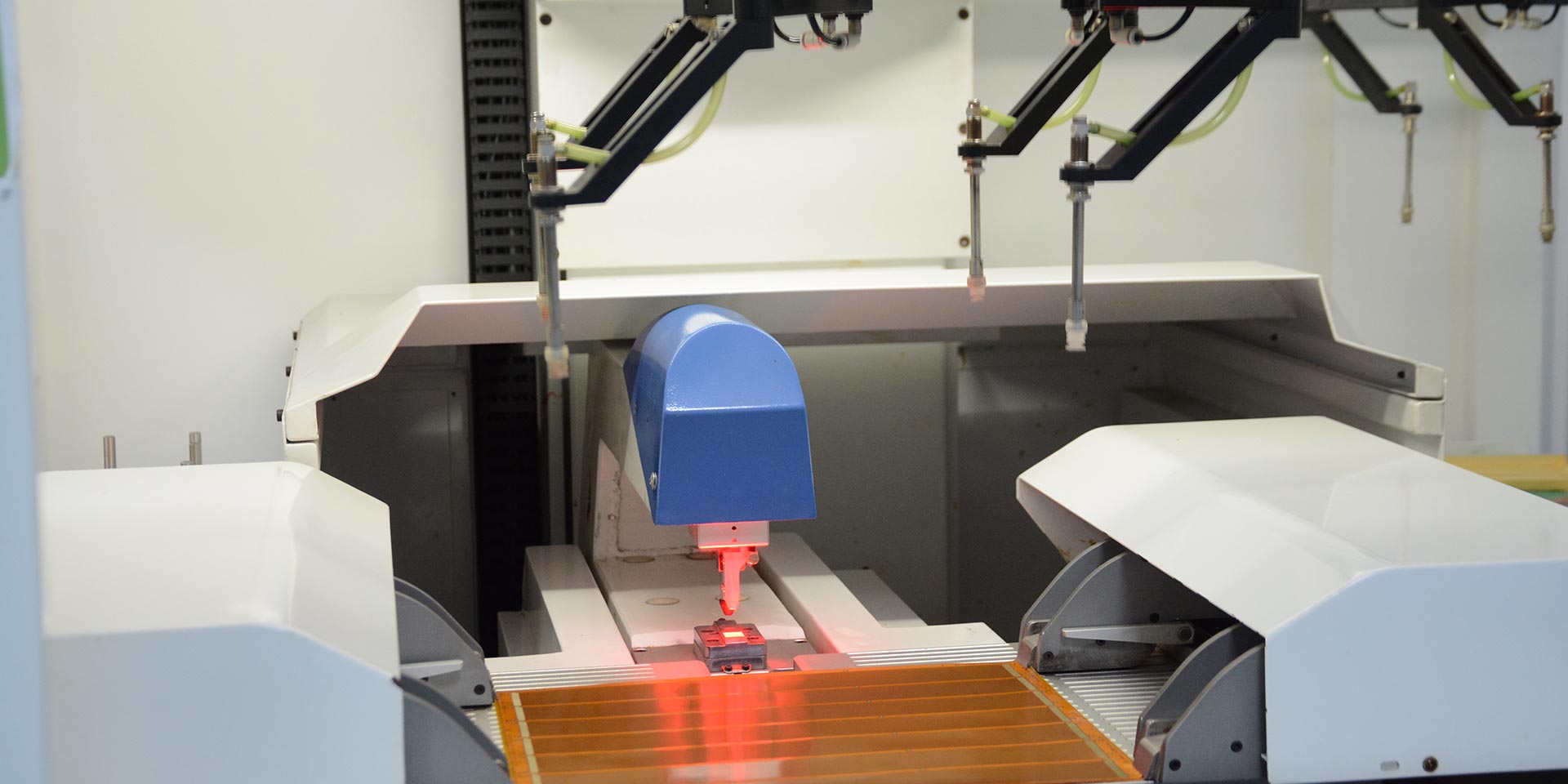

22. Ukwembulwa kwe-laser:Sebenzisa umshini wokusika we-laser ukwenza idigri ethile yokusika i-laser endaweni yemigqa yokuhlangana eqinile, ukhiphe ingxenye yebhodi eguqukayo, futhi uveze ingxenye yebhodi elithambile.

23. Umhlangano:Namathisela amashidi ensimbi noma ama-reinforcements ezindaweni ezihambisanayo zendawo yebhodi ukuze kuhlanganiswe futhi kwandise ubulukhuni bezingxenye ezibalulekile ze-FPC.

Umhlangano we-pcb oguquguqukayo oqinile

24. Isivivinyo:Sebenzisa ama-probe ukuze uhlole ukuthi akhona yini amaphutha esekethe evulekile/ emfushane ukuze uqinisekise ukusebenza komkhiqizo.

25. Izinhlamvu:Phrinta izimpawu zokumaka ebhodini ukuze kube lula ukuhlanganiswa nokuhlonzwa kwemikhiqizo elandelayo.

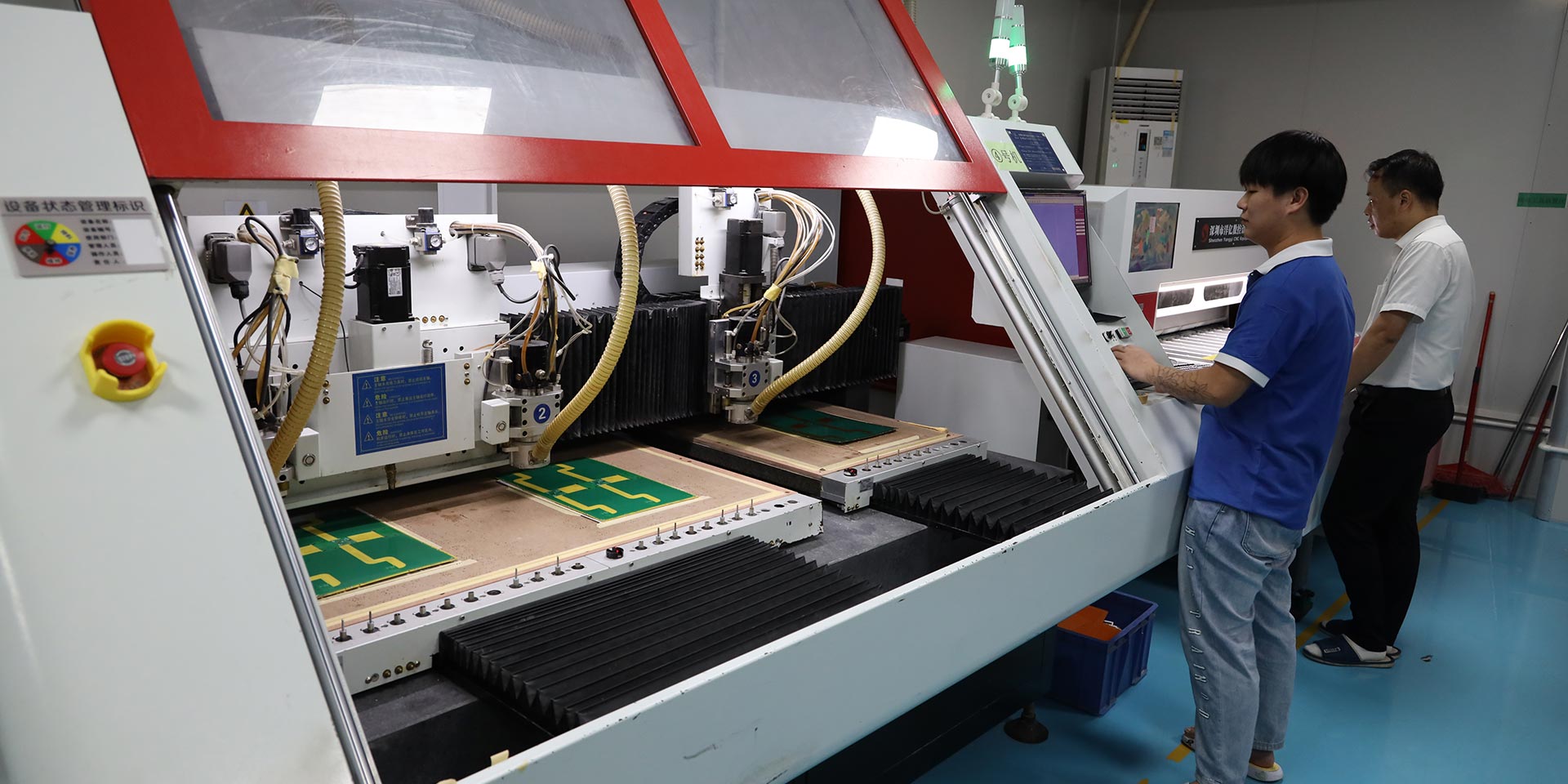

26. Ipuleti le-gong:Sebenzisa amathuluzi omshini we-CNC ukuze ukhiphe umumo odingekayo ngokwezidingo zekhasimende.

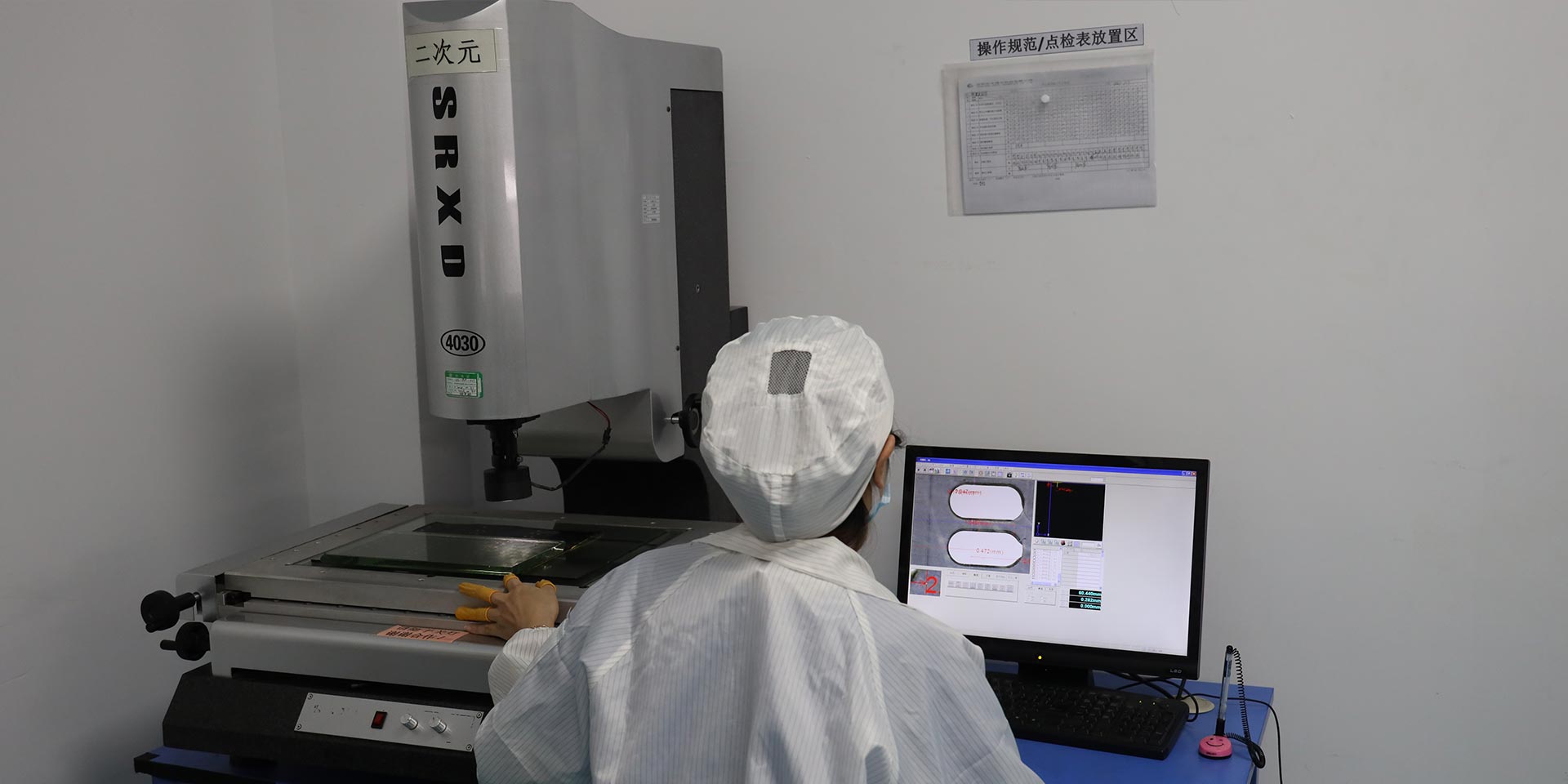

27. FQC:Imikhiqizo eqediwe izohlolwa ngokugcwele ukuthi ibukeka kanjani ngokuvumelana nezidingo zekhasimende, futhi imikhiqizo enesici izokhethwa ukuze kuqinisekiswe ikhwalithi yomkhiqizo.

28. Ukupakisha:Amabhodi aphumelele ukuhlolwa okuphelele azopakishwa ngokuvumelana nezidingo zamakhasimende futhi athunyelwe endaweni yokugcina impahla.

I-Turkey Rigid Flexible PCB Assembly

Nikeza ubungcweti nosizo phakathi nesigaba sokuklama, usize amakhasimende athuthukise imiklamo yawo

ukusebenza, ukwethembeka, kanye nokusebenza kahle kwezindleko;

Ukwazi ukukhiqiza amanani amancane ama-prototypes e-PCB aqinile-flex ngesikhathi, okuvumela amakhasimende ukuthi ahlole futhi aqinisekise imiklamo yawo ngaphambi kokuqhubeka nokukhiqiza ngobuningi;

Gcina imibhalo enemininingwane kuyo yonke inqubo yomhlangano, okuhlanganisa izikweletu zezinto (ama-BOM), imiyalelo yomhlangano, namarekhodi okuhlola;

Ukulethwa ngesikhathi (i-Capel inokuhlela okuphumelelayo kokukhiqiza, ukuphathwa kwezinsiza okusebenzayo, nokuxhumana okuseduze namakhasimende kuyo yonke inqubo yokukhiqiza.);

Bhekana nanoma yikuphi ukukhathazeka noma izinkinga ezingase ziphakame ngemva kokulethwa futhi unikeze usizo olusheshayo lobuchwepheshe noma amasevisi ewaranti uma kudingeka.

I-Rigid Flexible PCB Fabrication Izinzuzo

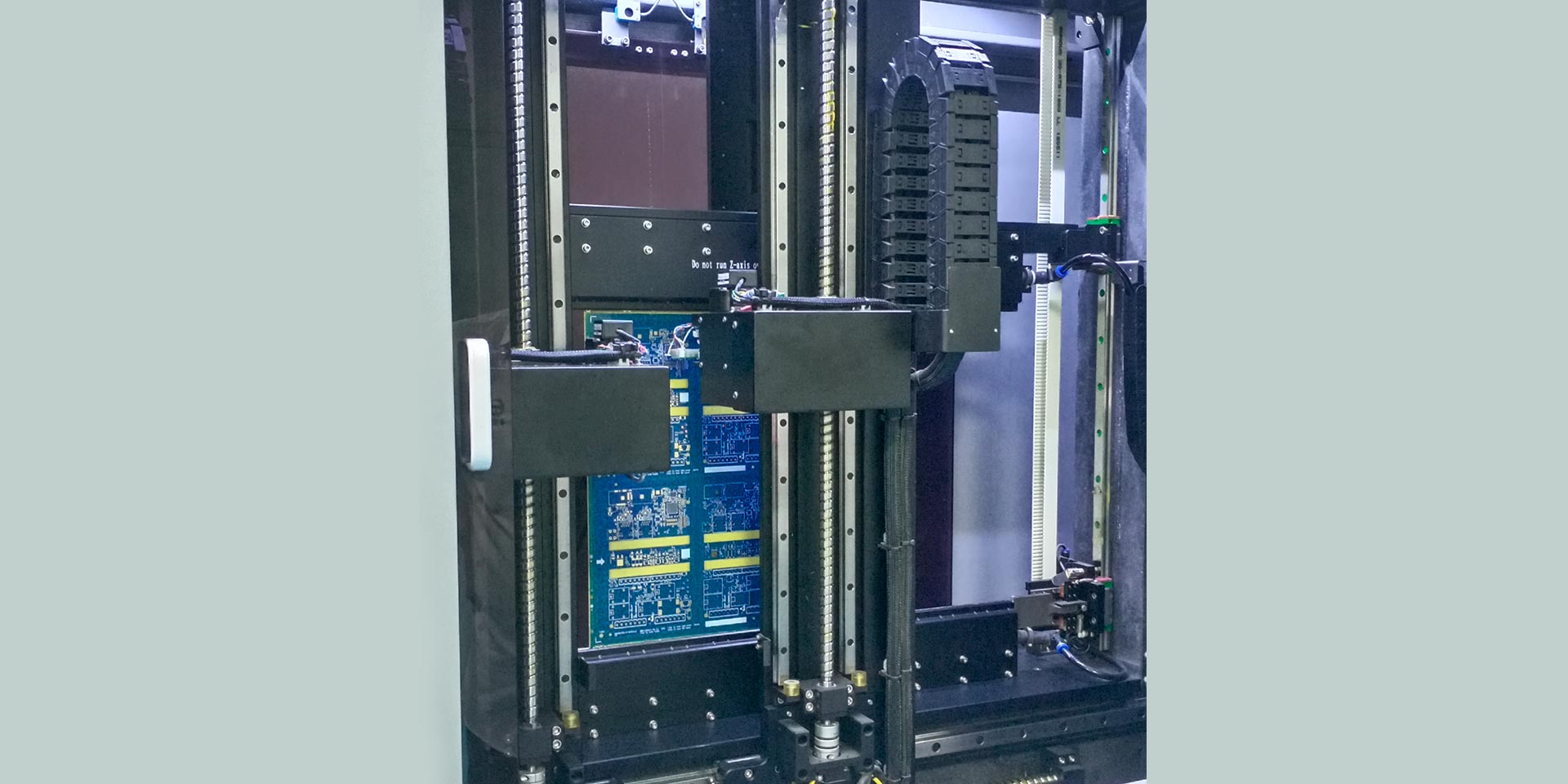

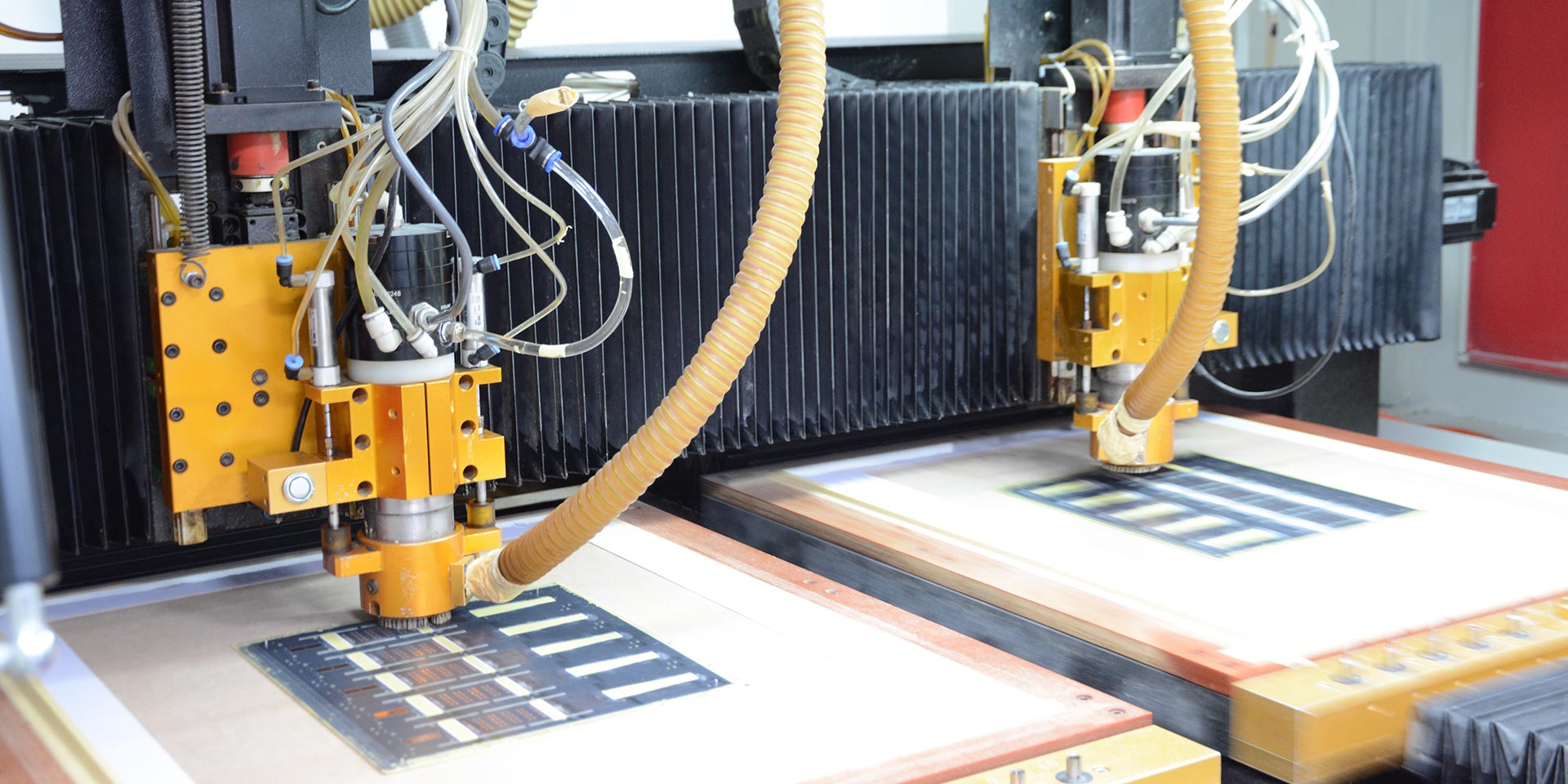

Imishini yokukhiqiza ezenzakalelayo ngokugcwele futhi enembayo ephezulu

-nciphisa amaphutha abantu, thuthukisa ukusebenza kahle, futhi uthuthukise ikhwalithi isiyonke yamabhodi wethu wesifunda aphrintiwe aqinile.

I-Capel inesisekelo sayo se-R&D, imboni yokukhiqiza, kanye nefekthri yokuchibiyela yamabhodi esekethe aqinile

-Ucwaningo oluqhubekayo kanye nentuthuko ukudala izixazululo ezintsha futhi sithuthukise ukusebenza kwemikhiqizo yamakhasimende ethu.

-I-Capel ilawula ngokugcwele inqubo yokukhiqiza, iqinisekisa ukulawulwa kwekhwalithi nokukhiqiza okuphumelelayo, inezikhathi zokuhola ezimfushane kanye nokulethwa okusheshayo.

-I-Capel ingakwazi ukusingatha ukulungiswa nokuguqulwa kwamabhodi wesifunda aqinile-flex abawakhiqizayo, inikeze ukusekelwa ngemva kokuthengisa futhi iqinisekise ukwaneliseka kwamakhasimende.

Ukuqamba okusha okuqhubekayo kobuchwepheshe benqubo obuhle kakhulu futhi obuthuthukisiwe

-Sibeka phambili ukusungula izinto ezintsha kanye nokwenza ngcono okuqhubekayo kwinqubo yethu yokwenziwa kwe-PCB eguquguqukayo eqinile, sihlola ngokuqhubekayo futhi samukela ubuchwepheshe obusha nobuthuthukile, sikunikeza izixazululo ezisezingeni eliphezulu futhi siqinisekisa ukuthi amabhodi akho e-PCB aqinile avumelana nezimo ahlangabezana nezindinganiso zakamuva zobuchwepheshe.

-Lungisa inqubo yokukhiqiza ukuze uthuthukise ukusebenza kahle futhi unciphise izindleko, unciphise udoti wezinto ezibonakalayo, unciphise izikhathi zokuhola, futhi unikeze izixazululo ezingabizi kakhulu kumakhasimende ethu.

I-Rigid Flexible PCB Production Amandla

| Isigaba | Amandla okucubungula | Isigaba | Amandla okucubungula |

| Uhlobo Lokukhiqiza | Isendlalelo esisodwa se-FPC eguquguqukayo i-PCB Izendlalelo ezimbili FPC flec PCB I-FPC Yezendlalelo Eziningi I-Aluminium PCB I-Rigid-Flex PCB | Izendlalelo Inombolo | 1-30 izendlalelo FPC Flexible PCB 2-32 izendlalelo Rigid-FlexPCB 1-60 izingqimba Rigid PCB Amabhodi we-HDI |

| Ubukhulu Ukukhiqiza Usayizi | Isendlalelo esisodwa se-FPC 4000mm I-Doublelayers FPC 1200mm Izendlalelo eziningi ze-FPC 750mm I-Rigid-Flex PCB 750mm | I-insulating Isendlalelo Ubukhulu | 27.5um / 37.5/ 50um / 65/75um 100um/125um/150um |

| Ibhodi Ubukhulu | I-FPC0.06mm-04mm I-Rigid-Flex PCB025-60mm | Ukubekezelelana kwe Usayizi we-PTH | +0.075mm |

| Ubuso Qeda | Ukucwiliswa kwegolide/ukucwiliswa emanzini Isiliva/Igolide Plating /I-Tin Plating/OSP | I-Stiffener | FR4 /PI/PET/SUS/PSA/Alu |

| I-Semicircle Usayizi we-Orifice | Ubuncane 0.4mm | Ububanzi beSikhala Somugqa omncane | 0.045mm/0.045mm |

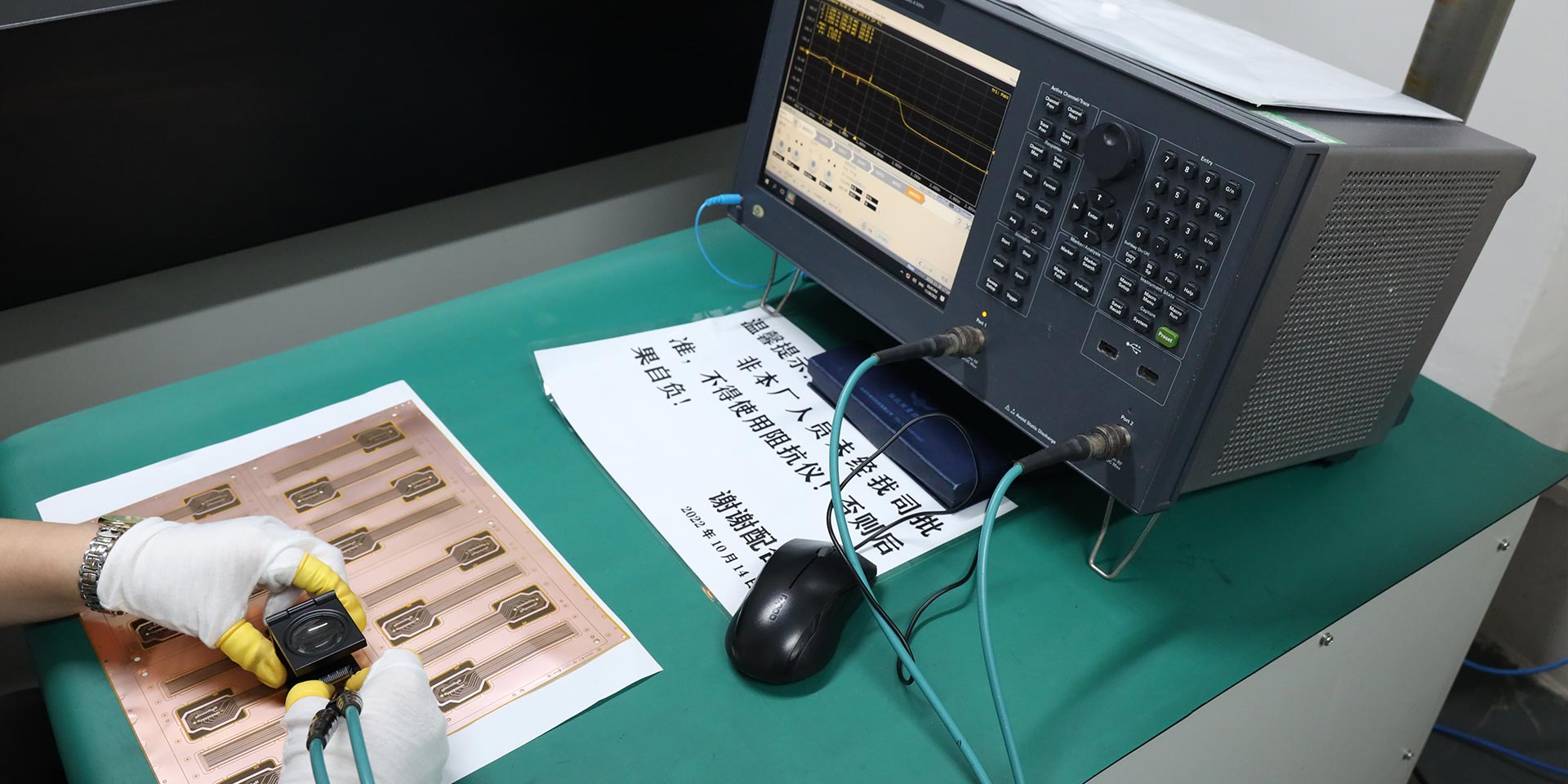

| Ubukhulu Ukubekezelelana | +0.03mm | Impedance | 500-1200 |

| I-Copper Foil Ubukhulu | 9um/12um/18um/ 35um/70um/100um | Impedance Kulawulwa Ukubekezelelana | +10% |

| Ukubekezelelana ot Usayizi we-NPTH | +0.05mm | I-Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | ukufezekisa Okujwayelekile | GB/IPC-650/PC-6012IPC-01311/ IPC-601311 |

| Izitifiketi | ULand ROHS 5014001:2015 IS0 9001:2015 IATF16949:2016 | Amalungelo obunikazi | amamodeli obunikazi ukusungulwa kwamalungelo obunikazi |

Ukulawulwa Kwekhwalithi Ye-Rigid Flexible PCB Production

Gcwalisa uhlelo lokulawula ikhwalithi

- Senze uhlelo oluphelele lokulawula ikhwalithi ukuze siqinisekise amazinga aphakeme kakhulu ekukhiqizeni i-PCB eguquguqukayo eqinile (ukuhlolwa kwezinto, ukuqapha inqubo, ukuhlolwa komkhiqizo, nokuhlola)

Ukusebenza kwethu yi-ISO 14001:2015, ISO 9001:2015, IATF16949:2016 kuqinisekiswe

-Ukuzibophezela kwethu ekuphathweni kwekhwalithi, ukusimama kwemvelo, kanye nokwenza ngcono okuqhubekayo, ukuzinikela kwethu ekuletheni amabhodi esekethe athembekile nasezingeni eliphezulu aqinile.

Imikhiqizo yethu i-UL kanye ne-ROHS imakwe

-uqinisekisa ukuthi ama-PCB ethu aqinile avumelana nezimo ahlangabezana nezindinganiso zokuphepha futhi athobela imithetho yemboni, engenazo izinto eziyingozi, awenza alungele imvelo futhi aphephe ukusetshenziswa ezinhlelweni ezihlukahlukene

Ithole amaphathenti wemodeli yensiza engaphezu kuka-20 kanye namagunya okusungulwa

-Ukugxila kwethu ekuthuthukiseni izixazululo eziyingqayizivele nezokudala ekukhiqizeni i-PCB eguquguqukayo eqinile, ukuzibophezela kwethu ekusunguleni izinto ezintsha kuqinisekisa ukuthi uthola imikhiqizo esezingeni eliphezulu ehlangabezana nezidingo zakho ezithile.

Quick Turn Rigid-Flex PCB Prototyping

Isevisi yokukhiqiza yeprototype yebhodi lesifunda yamahora angu-24 engami eqinile

Ukulethwa kwama-oda amaqoqo amancane ngokuvamile kuthatha izinsuku ezingu-5-7

Ukulethwa kokukhiqiza okuningi kuvame ukuthatha izinsuku eziyi-10-15

| Ukukhiqiza | Inombolo yezendlalelo | Isikhathi sokudiliva (izinsuku zebhizinisi) | |||

| Amasampula | Ukukhiqiza Okuningi | ||||

| I-FPC | 1L | 3 | 6-7 | ||

| 2L | 4 | 7-8 | |||

| 3L | 5 | 8-10 | |||

| Kuma-PCB aguqukayo e-FPC anezendlalelo ezingaphezu kwezi-3, engeza izinsuku zebhizinisi ezi-2 kusendlalelo ngasinye esengeziwe | |||||

| HDI wangcwatshwa izimpumputhe nge PCB kanye I-Rigid-Flex PCB | 2-3L | 7 | 10-12 | ||

| 4-5L | 8 | 12-15 | |||

| 6L | 12 | 16-20 | |||

| 8L | 15 | 20-25 | |||

| 10-20L | 18 | 25-30 | |||

| I-SMT: Engeza ezinye izinsuku zebhizinisi ezingu-1-2 esikhathini sokulethwa esingenhla | |||||

| RFQ:2 amahora okusebenza CS:24 amahora okusebenza | |||||

| EQ:4 amahora okusebenza Umthamo wokukhiqiza: 80000m/ngenyanga | |||||

I-Quote esheshayo ye-Flexible PCB ne-Flex PCB Assembly

I-Capel ikhiqiza embonini yayo futhi ilawulwa ithimba lochwepheshe abanolwazi lweminyaka engu-15 ukuqinisekisa ukuthi umkhiqizo ngamunye ufanelekile ngo-100%.