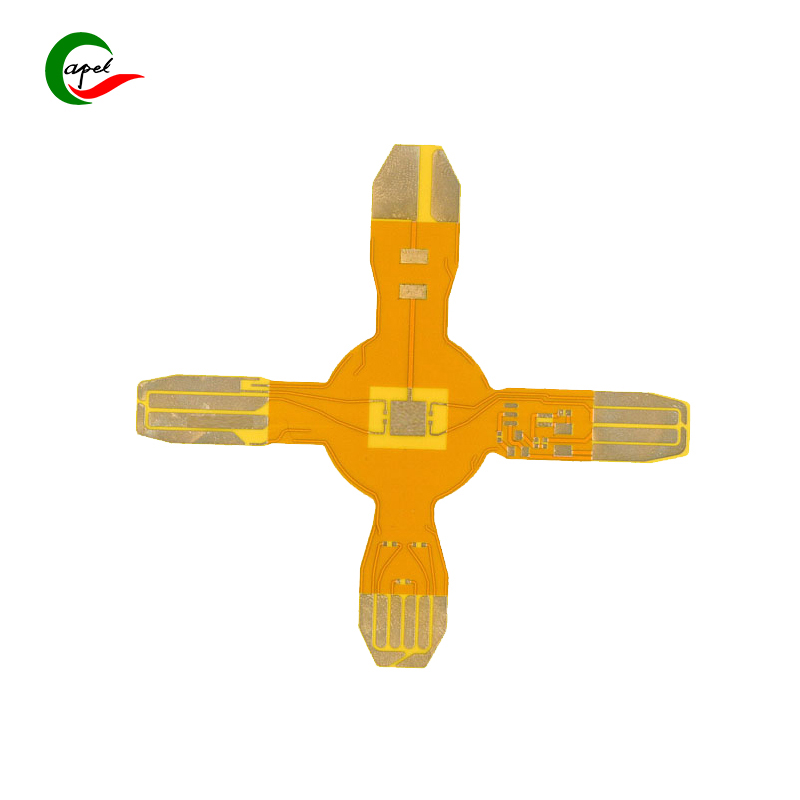

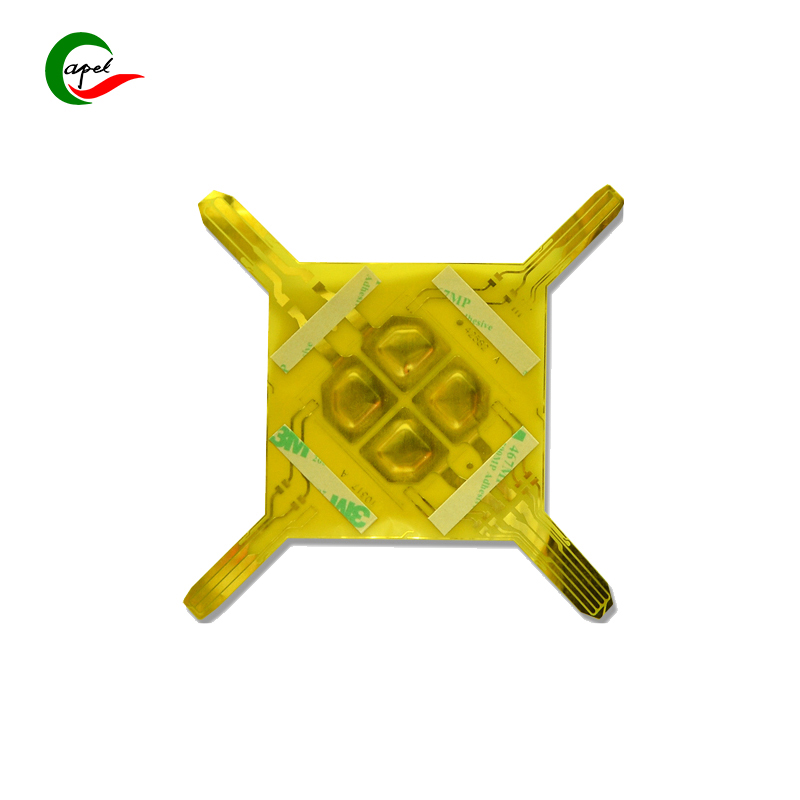

Quick-Turn PCB Prototyping 6 Layer High-Density Multi-Layer Flexible Boards For Automotive

Ukucaciswa

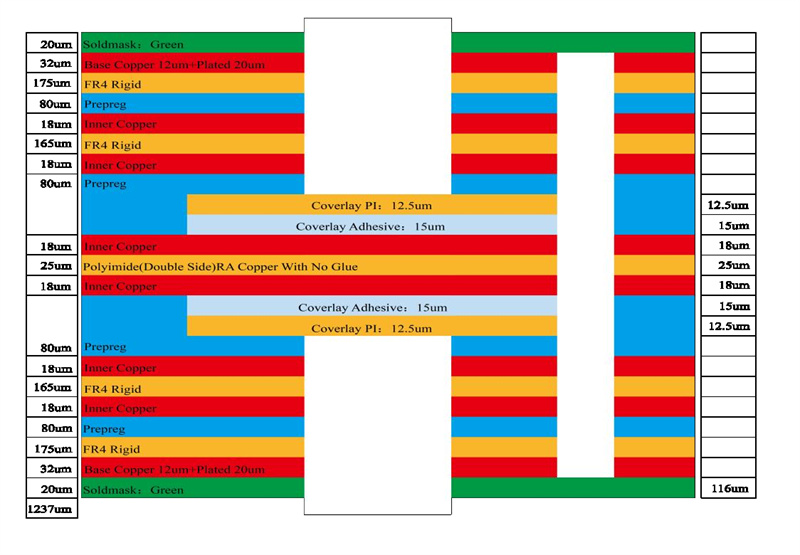

| Isigaba | Amandla okucubungula | Isigaba | Amandla okucubungula |

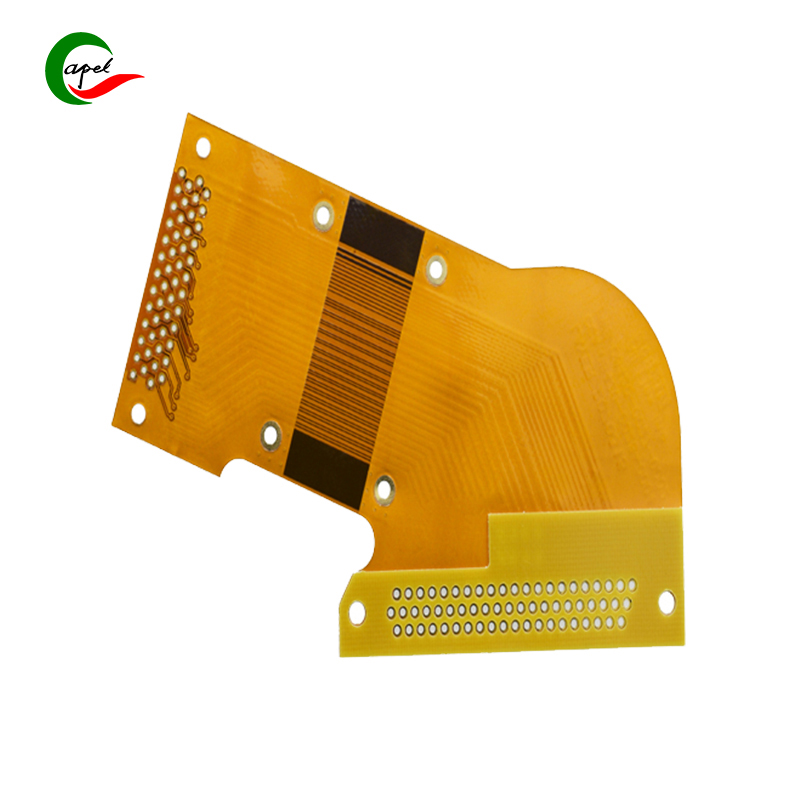

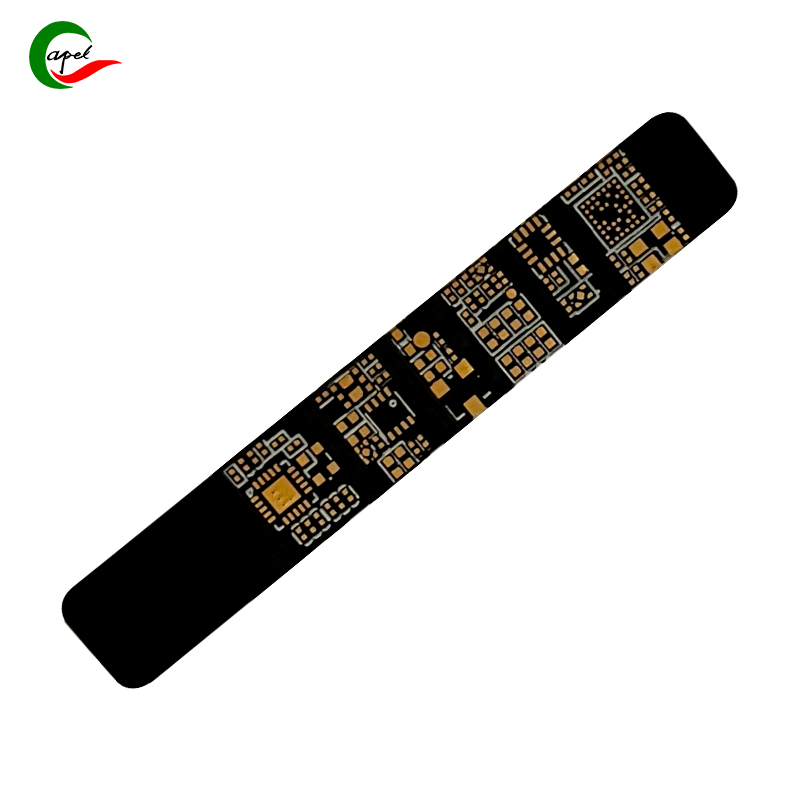

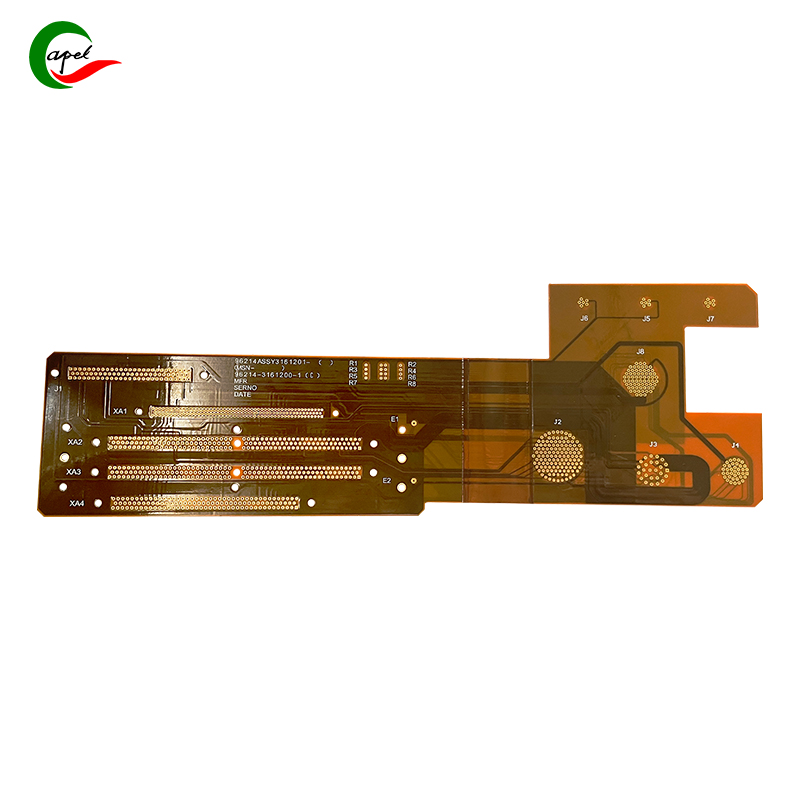

| Uhlobo Lokukhiqiza | I-Single layer FPC / I-Double layers FPC I-Multi-layer FPC / Aluminium PCBs I-Rigid-Flex PCBs | Inombolo Yezendlalelo | 1-16 izingqimba FPC 2-16 izendlalelo Rigid-FlexPCB HDI Ephrintiwe Circuit Boards |

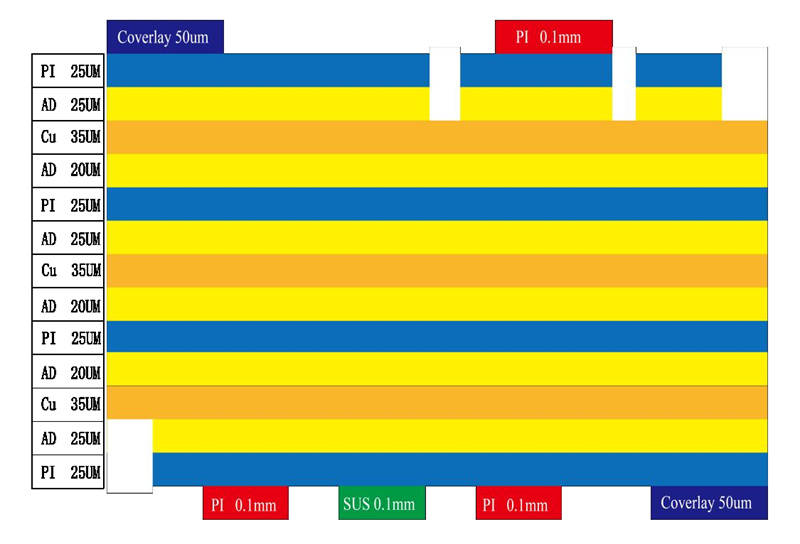

| Usayizi Wokukhiqiza Omkhulu | Isendlalelo esisodwa se-FPC 4000mm Izendlalelo ze-Doulbe FPC 1200mm Izendlalelo eziningi ze-FPC 750mm I-Rigid-Flex PCB 750mm | I-Insulating Layer Ubukhulu | 27.5um / 37.5/ 50um / 65/ 75um / 100um / 125um/150um |

| Ukujiya Kwebhodi | I-FPC 0.06mm - 0.4mm I-Rigid-Flex PCB 0.25 - 6.0mm | Ukubekezelelwa kwe-PTH Usayizi | ±0.075mm |

| I-Surface Qeda | Ukucwiliswa Igolide/Ukucwiliswa I-Silver/Gold Plating/Tin Plat ing/OSP | I-Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Usayizi we-Semicircle Orifice | Ubuncane 0.4mm | Isikhala somugqa omncane/ ububanzi | 0.045mm/0.045mm |

| Ukujiya Ukubekezelelana | ±0.03mm | Impedance | 50Ω-120Ω |

| Ukuqina kwe-Copper Foil | 9um/12um/18um/35um/70um/100um | Impedance Kulawulwa Ukubekezelelana | ±10% |

| Ukubekezelelwa kwe-NPTH Usayizi | ±0.05mm | I-Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Sebenzisa Okujwayelekile | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Senza amabhodi avumelana nezingqimba eziningi anolwazi lweminyaka engu-15 ngobungcweti bethu

3 ungqimba Flex PCBs

8 ungqimba we-Rigid-Flex PCBs

8 ungqimba HDI Amabhodi Esifunda Aphrintiwe

Izisetshenziswa zokuhlola nokuhlola

Ukuhlola Isibonakhulu

Ukuhlolwa kwe-AOI

Ukuhlolwa kwe-2D

Ukuhlolwa kwe-Impedans

Ukuhlolwa kwe-RoHS

I-Flying Probe

Umhloli Ovundlile

Ukugoba i-Teste

Isevisi yethu yamabhodi anezendlalelo eziningi

. Ukuhlinzeka ngosekelo lobuchwepheshe Ukuthengisa kwangaphambili kanye nangemuva kokuthengisa;

. Yenza ngokwezifiso izendlalelo ezingafika kwezingama-40, i-1-2days ijika ngokushesha i-prototyping, ukuthengwa kwengxenye, i-SMT Assembly;

. Ibhekelela kokubili Idivayisi Yezokwelapha, Ukulawulwa Kwezimboni, Izimoto, Izindiza, I-Consumer Electronics, i-IOT, i-UAV, Ezokuxhumana njll.

. Amaqembu ethu onjiniyela nabacwaningi bazinikele ekugcwaliseni izidingo zakho ngokunemba nangobuchwepheshe.

Yiziphi izimfuneko zobuchwepheshe zama-PCB ezimoto zamabhodi aguquguqukayo anezendlalelo eziningi?

1. Ukuqina: Ama-PCB ezimoto kufanele akwazi ukumelana nezimo zokusebenza ezinzima zemoto, okuhlanganisa nokuguquguquka kwezinga lokushisa, ukudlidliza, kanye nomswakama. Bathembisa impilo yesevisi ende kanye nokuzinza okuhle kakhulu kwemishini.

2. Ukuminyana Okuphezulu: I-PCB enezingqimba eziningi eguquguqukayo ivumela ukuxhumana kukagesi okwengeziwe nezingxenye ukuthi zihlanganiswe endaweni ehlangene. Idizayini enomthamo omkhulu yenza kube lula ukuzulazula futhi kunciphise usayizi we-PCB, konga isikhala esibalulekile emotweni.

3. Ukuvumelana nezimo nokugobeka: Ama-PCB avumelanayo angagoqwa kalula, agotshwe noma agotshwe ukuze alingane nezikhala eziqinile noma avumelane nokuma kwemoto. Kufanele bagcine ubuqotho babo kagesi kanye nemishini ngesikhathi sokugoba nokugoba okuphindaphindiwe.

4. Ubuqotho besignali: Kufanele kube nokulahlekelwa kwesignali okuncane noma ukuphazamiseka komsindo ku-PCB ukuze kuqinisekiswe ukuxhumana okuthembekile phakathi kwezingxenye ezahlukene ze-elekthronikhi. Sebenzisa amasu afana nokulawula i-impedance kanye nesisekelo esifanele ukuze ugcine ubuqotho besignali.

5. Ukuphatha okushisayo: Amabhodi esekethe ezimoto kufanele akhiphe ngokuphumelelayo ukushisa okukhiqizwa phakathi nokusebenza. Amasu okuphatha okushisayo asebenzayo, njengokusebenzisa izindiza zethusi ezifanele kanye ne-thermal vias, kuyadingeka ukuvimbela ukushisa nokuqinisekisa ukusebenza okuzinzile.

6. Ukuvikela i-EMI/RFI: Ukuvimbela ukuphazamiseka kwe-electromagnetic (EMI) kanye nokuphazamiseka kwefrikhwensi yomsakazo (RFI), ama-PCB ezimoto adinga amasu okuvikela afanele. Lokhu kuhilela ukusebenzisa izindiza ezivikelayo noma eziphansi ukuze kuncishiswe imiphumela yamasignali kagesi angaphandle.

7. Ukuhlola ku-inthanethi: Idizayini ye-PCB kufanele yenze lula ukuhlolwa nokuhlolwa kwe-PCB ehlanganisiwe. Ukufinyeleleka okufanele kwamaphuzu okuhlola kanye nama-probe okuhlola kuzohlinzekwa ukuze kuqinisekiswe ukuhlolwa okunembile nangempumelelo ngesikhathi sokukhiqiza nokugcinwa.

8. Ukuthobelana nezindinganiso zezimoto: Ukuklanywa nokukhiqizwa kwama-PCB ezimoto kudingeka kulandele izindinganiso zemboni yezimoto, njenge-AEC-Q100 kanye ne-ISO/TS 16949. Ukuhambisana nalawa mazinga kuqinisekisa ukwethembeka, ukuphepha kanye nekhwalithi yama-PCB.

Kungani udinga i-Quick-turn PCB Prototyping?

1. Isivinini: I-prototyping esheshayo ye-PCB isheshisa imijikelezo yokuthuthukisa umkhiqizo. Kusiza ukunciphisa isikhathi esidingekayo sokuphindaphinda, ukuhlola, kanye nokwenza ngcono imiklamo ye-PCB, onjiniyela bakwazi ukuhlangabezana nezikhathi eziqinile zamaphrojekthi noma baphendule ngokushesha ezidingweni zemakethe.

2. Ukuqinisekiswa Kwedizayini: I-PCB Prototyping ivumela onjiniyela ukuthi baqinisekise ukusebenza, ukusebenza kanye nokwenziwa kwemiklamo yabo ye-PCB ngaphambi kokuya emkhiqizweni omkhulu. Kuyasiza ukukhomba nokubhekana nanoma imaphi amaphutha edizayini noma amathuba okuthuthukisa, ukonga isikhathi nemali ngokuhamba kwesikhathi.

3. Ubungozi obuncishisiwe: Ukwenza i-PCB esheshayo kusiza ukwehlisa ubungozi obuhambisana nokukhiqizwa kwe-PCB ngobuningi. Ngokuhlola nokuqinisekisa imiklamo ngamaqoqo amancane, noma yimaphi amaphutha noma izinkinga ezingaba khona zingabanjwa kusenesikhathi, kuvinjwe amaphutha abizayo futhi kusetshenzwe kabusha ngesikhathi sokukhiqiza okuphelele.

4. Ukonga izindleko: I-prototyping esheshayo ye-PCB ingasebenzisa kahle izinsiza nezinto zokwakha. Ngokubamba izinkinga zedizayini kusenesikhathi nokwenza izinguquko ezidingekayo, onjiniyela bangonga impahla emoshekile kanye nokuklama kabusha okubizayo.

5. Ukusabela emakethe: Embonini esheshayo, ukwazi ukuthuthukisa ngokushesha kanye nokwethula imikhiqizo emisha kunganika inkampani inzuzo yokuncintisana. I-Rapid PCB prototyping yenza izinkampani zikwazi ukuphendula ngokushesha ezidingweni zemakethe, ukushintsha amathrendi noma amathuba amasha, kuqinisekiswe ukukhishwa komkhiqizo okufika ngesikhathi.

6. Ukwenza ngokwezifiso kanye nokuqanjwa okusha: I-Prototyping isiza ukwenza ngokwezifiso kanye nokuqanjwa okusha. Onjiniyela bangahlola imiqondo emisha yedizayini, bahlole izici ezihlukile, futhi bahlole ngobuchwepheshe obuthuthukile. Ibenza bakwazi ukuphusha imingcele futhi bathuthukise imikhiqizo esezingeni eliphezulu.