ake sihlole inqubo yokukhiqiza amasekethe aguquguqukayo futhi siqonde ukuthi kungani esetshenziswa kakhulu ezimbonini ezahlukahlukene.

Amasekhethi aguqukayo, aziwa nangokuthi amasekethe aphrintiwe aguqukayo noma ama-FPC, adumile kuzo zonke izimboni ezahlukahlukene. Kusukela kuma-electronics abathengi kuya ezinsizakalweni zokunakekelwa kwempilo, amasekhethi aguquguqukayo aguqule indlela izingxenye ze-elekthronikhi eziklanywa futhi ezakhiwe ngayo. Njengoba isidingo samadivaysi e-elekthronikhi ahlangene futhi angasindi siqhubeka nokwanda, kubalulekile ukuqonda inqubo yokukhiqiza yamasekhethi aguquguqukayo nokuthi abe yingxenye ebalulekile yobuchwepheshe besimanje.

Amasekhethi e-Flex empeleni ayinhlanganisela yezendlalelo eziningi zezinto eziguquguqukayo, njenge-polyester noma i-polyimide, lapho kufakwa khona imikhondo, amaphedi, kanye nezingxenye. Lawa masekhethi ayashintshashintsha futhi angagoqwa noma asongwe, awenze alungele izinhlelo zokusebenza lapho isikhala silinganiselwe.

1. Isakhiwo sedizayini ekukhiqizeni isekethe eguqukayo:

Isinyathelo sokuqala sokukhiqiza isekethe eguquguqukayo yinqubo yokuklama kanye nesakhiwo. Onjiniyela nabaklami basebenzisana eduze ukuze bakhe izakhiwo ezihlangabezana nezidingo ezithile zohlelo lokusebenza. Isakhiwo sihlanganisa ukubekwa kokulandela umkhondo, izingxenye, nanoma yiziphi izici ezengeziwe ezingase zidingeke.

2. Ukukhethwa kwempahla ekwenziweni kwesekethe eguqukayo:

Ngemuva kwesigaba sokuklama, isinyathelo esilandelayo ukukhetha izinto ezifanele zesekethe eguquguqukayo. Ukukhethwa kwezinto kuncike ezintweni ezifana nokuguquguquka okudingekayo, izinga lokushisa lokusebenza, kanye nezakhiwo ezidingekayo zikagesi nemishini. I-Polyimide ne-polyester yizinto ezisetshenziswa kakhulu ngenxa yokuguquguquka okuhle kakhulu kanye nokuzinza kokushisa.

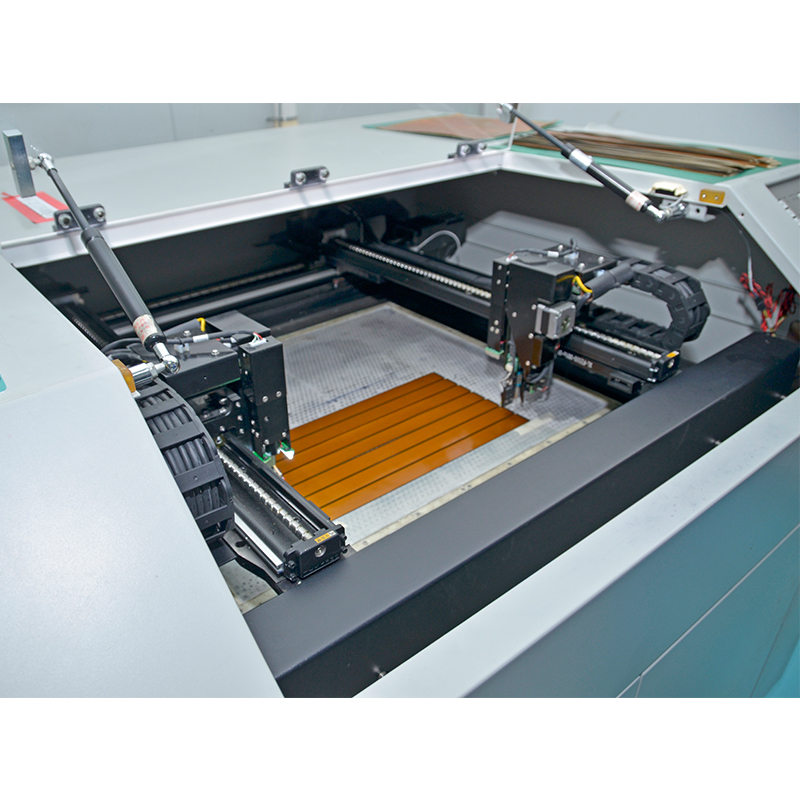

3. Ukukhiqizwa kwe-base substrate ekwenzeni i-flex circuit:

Uma impahla isikhethiwe, ukwakhiwa kwe-substrate yesisekelo kuqala. I-substrate ngokuvamile iyingqimba encane yefilimu ye-polyimide noma ye-polyester. I-substrate iyahlanzwa, iboshwe nge-adhesive, futhi i-laminated nge-copper copper foil. Ubukhulu be-foil yethusi ne-substrate bungahluka kuye ngezidingo ezithile zohlelo lokusebenza.

4. I-Etching kanye ne-laminating ekukhiqizeni isifunda se-flex:

Ngemuva kokuthi inqubo yokugcoba isiqediwe, i-etchant yamakhemikhali isetshenziselwa ukukhipha i-foil yethusi eyeqile, ishiya imikhondo edingekayo kanye namaphedi. Lawula inqubo yokuqopha ngokusebenzisa imaski engavimbeli i-etch noma amasu we-photolithography. Uma ukufakwa sekuqediwe, isekethe eguquguqukayo iyahlanzwa futhi ilungiselelwe isigaba esilandelayo senqubo yokukhiqiza.

5. Ukuhlanganiswa kwezingxenye ekukhiqizeni isekethe ye-flex:

Ngemuva kokuthi inqubo yokufaka isiqediwe, isifunda esiguquguqukayo silungele ukuhlanganiswa kwengxenye. Ubuchwepheshe be-Surface Mount (SMT) buvamise ukusetshenziselwa ukubekwa kwengxenye njengoba buvumela ukuhlanganisa okunembayo nokuzenzakalelayo. Gcoba unamathisele we-solder kumaphedi okuqhuba futhi usebenzise umshini wokukhetha nendawo ukuze ubeke izingxenye. Umjikelezo we-flex ube usushisa, okwenza ukuthi i-solder ihambisane namaphedi okuqhuba, ibambe ingxenye endaweni.

6. Ukuhlolwa nokuhlolwa ekukhiqizeni isekethe eguqukayo:

Uma inqubo yomhlangano isiqediwe, i-flex circuit ihlolwe kahle futhi ihlolwe. Ukuhlolwa kukagesi kuqinisekisa ukuthi ama-conductive traces kanye nezingxenye zisebenza njengoba kulindelekile. Ukuhlolwa okwengeziwe, okufana nokuhamba ngebhayisikili okushisayo nokuhlolwa kokucindezeleka kwemishini, nakho kungenziwa ukuze kuhlolwe ukuqina nokuthembeka kwamasekhethi avumelana nezimo. Noma yimaphi amaphutha noma izinkinga ezitholwe ngesikhathi sokuhlolwa ziyahlonzwa futhi zilungiswe.

7. Ukumbozwa okuguquguqukayo nokuvikelwa ekukhiqizeni isekethe eguqukayo:

Ukuze kuvikelwe izifunda eziguquguqukayo ezicini zemvelo kanye nokucindezeleka kwemishini, kusetshenziswa izembozo eziguquguqukayo noma izendlalelo zokuzivikela. Lesi singqimba singaba imaski ye-solder, i-conformal coating, noma inhlanganisela yakho kokubili. Isembozo sithuthukisa ukuqina kwe-flex circuit futhi sandise impilo yayo yesevisi.

8. Ukuhlolwa kokugcina nokupakishwa ekwenziweni kwesekethe eguqukayo:

Ngemuva kokuthi i-flex circuit ihambe kuzo zonke izinqubo ezidingekayo, ihlola okokugcina ukuze kuqinisekiswe ukuthi ihlangabezana nemininingwane edingekayo. Amasekhethi aguqukayo apakishwa ngokucophelela ukuze awavikele ekulimaleni ngesikhathi sokuthunyelwa nokugcinwa.

Kafushane, inqubo yokukhiqiza yamasekethe aguquguqukayo ibandakanya izinyathelo ezimbalwa eziyinkimbinkimbi, okuhlanganisa ukuklama, ukukhetha impahla, ukwakhiwa, ukuhlanganisa, ukuhlola, nokuvikela.Ukusetshenziswa kobuchwepheshe besimanje kanye nezinto eziphambili kuqinisekisa ukuthi izifunda eziguquguqukayo zihlangabezana nezidingo ezidingekayo zezimboni ezahlukahlukene. Ngokuguquguquka kwawo kanye nomklamo ohlangene, amasekhethi aguquguqukayo abe yingxenye ebalulekile yokuthuthukiswa kwemishini kagesi emisha futhi ehamba phambili. Kusukela kuma-smartphone kuya kumishini yezokwelapha, amasekhethi aguquguqukayo ashintsha indlela izingxenye ze-elekthronikhi ezihlanganiswe ngayo ekuphileni kwethu kwansuku zonke.

Isikhathi sokuthumela: Sep-21-2023

Emuva