Isingeniso:

Kulokhu okuthunyelwe kwebhulogi, sizobhekisisa impilo ye-PCB eguquguqukayo, izici zayo, nezindlela zokuqinisekisa ukusebenza kahle kuwo wonke umjikelezo wayo wokuphila.

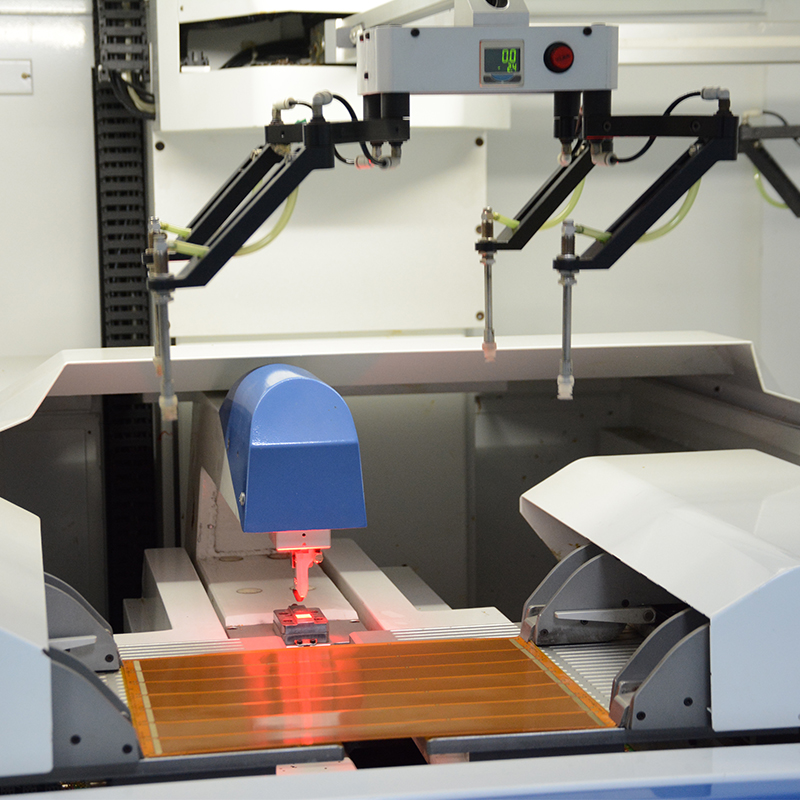

Ama-Flex PCB, aziwa nangokuthi amabhodi esekethe aphrintiwe aguqukayo, athole ukuduma ezimbonini ezahlukahlukene ngenxa yokuguquguquka kwawo kanye nekhono lokumelana nokugoba nokusonteka. Lezi zisekhethi zisetshenziswa kakhulu kumishini kagesi efana nama-smartphone, ubuchwepheshe obugqokekayo, izinsiza zezokwelapha, nezinhlelo zokusebenza zezimoto. Nokho, naphezu kokuduma okwandayo kwama-PCB aguquguqukayo, abantu abaningi abakaqapheli impilo yeshalofu yama-PCB aguquguqukayo kanye nomthelela wawo ekuthembekeni komkhiqizo.

Impilo yeshelufu ye-PCB eguquguqukayo isikhathi lapho isekethe igcina ugesi wayo olindelwe kanye nemishini

izakhiwo uma zigcinwe kahle. Ithintwa yizici ezihlukahlukene, okuhlanganisa ukwakheka kwezinto ezibonakalayo, ukukhiqizwa

izinqubo, izimo zokugcina, izici zemvelo, ukuhlanganisa nesikhathi sokuhlanganisa.

Enye yezinto eziyinhloko ezithinta impilo yeshalofu yama-PCB aguquguqukayo ukukhetha izinto ezibonakalayo.Ama-PCB aguqukayo ngokuvamile enziwa ngefilimu ye-polyimide noma ye-polyester futhi anikeza ukuguquguquka nokuqina. Lezi zinto zinikeza ukumelana okuhle nokushisa, umswakama, namakhemikhali, okuvumela amasekhethi ukuthi asebenze ezindaweni ezinokhahlo. Kodwa-ke, ngokuhamba kwesikhathi, lezi zinto zingehlisa noma zimunce umswakama, zibangele ukuwohloka kokusebenza noma ukwehluleka kwesifunda. Ngakho-ke, kubalulekile ukukhetha izinto ezisezingeni eliphezulu zokucaciswa okufanele ukuze kuqinisekiswe impilo yeshalofu ende.

Inqubo yokukhiqiza nayo idlala indima ebalulekile ekunqumeni impilo yeshalofu yama-PCB aguquguqukayo.Ukuphatha ngendlela efanele, ukugcinwa kanye namasu okuhlanganisa kufanele kulandelwe ukuvimbela ukungcoliswa, ukumuncwa komswakama noma ukulimala ngesikhathi sokukhiqiza. Noma yikuphi ukuchezuka emihlahlandlela yokukhiqiza enconyiwe kuzofaka engcupheni ukwethembeka kwesekethe futhi kufinyeze impilo yayo yeshalofu. Abakhiqizi kufanele bahambisane nezindinganiso zemboni futhi bagcine izinyathelo eziqinile zokulawula ikhwalithi ukuze baqinisekise ubude besikhathi eside bama-PCB aguquguqukayo.

Izimo zesitoreji zithinta kakhulu impilo yeshalofu yama-PCB aguquguqukayo.Lawa masekhethi kufanele agcinwe endaweni elawulwayo engenawo umswakama oweqile, ukushintshashintsha kwezinga lokushisa nokukhanya kwelanga okuqondile. Umswakama ungangena kumjikelezo ngokusebenzisa imiphetho kanye ne-vias, ubangele ukubola noma ukugqwala kwemikhondo ye-conductive. Amazinga okushisa aphezulu asheshisa inqubo yokuguga futhi anciphise izinto ezibonakalayo. Ngakho-ke, kunconywa ukugcina ama-PCB aguquguqukayo ezikhwameni ze-polyethylene ezivaliwe ezinamaphakethe we-desiccant noma ezitsheni ezivalwe nge-vacuum ukuze unciphise ukumuncwa komswakama.

Izici zemvelo ezifana nokudlidliza, ukugoba kanye nokuchayeka kumakhemikhali nakho kungathinta impilo yeshalofu yama-PCB aguquguqukayo.Amasekhethi aguquguqukayo aklanyelwe ukumelana nokugoba noma ukusonteka okuphindaphindiwe, kodwa ukucindezeleka komshini okwedlulele kungabangela ukuqhekeka noma ukuphuka kwe-trace noma ukwahlukanisa. Ukwengeza, ukuchayeka kumakhemikhali abolayo noma amagesi kungonakalisa izinto zesekethe futhi kukhinyabeze ukusebenza kwazo. Ngakho-ke, izimo zokusebenza ezilindelekile kufanele zicatshangelwe futhi kufanele kuthathwe izinyathelo zokuvikela ezifanele, ezifana ne-conformal coating noma i-encapsulation, ukuze kuthuthukiswe ukuqina kwesekethe futhi kunwetshwe isikhathi seshalofu layo.

Ukuqinisekisa ukuthi ama-PCB avumelana nezimo asebenza kahle kuyo yonke impilo yawo yeshalofu, ukuhlolwa okuvamile nokuhlolwa kuyadingeka.Ukuhlola okuvamile kungakhomba noma yiziphi izimpawu zokuwohloka, njengokushintsha kombala, ukuncipha, noma izinguquko ekusebenzeni kukagesi. Ukwengeza, ukuhlola okusebenzayo kungahlola ukusebenza kwesekethe ngaphansi kwezimo zokusebenza ezilingisayo, okuvumela izinkinga ezingaba khona ukuthi zitholwe futhi zilungiswe ngaphambi kokuthi ziholele ekuhlulekeni okuphelele. Ukwenza lezi zivivinyo ngezikhathi ezithile kusiza ukunweba impilo yeshalofu ye-PCB eguquguqukayo futhi kuvimbele ukuhluleka okungalindelekile.

Ukwelula impilo yeshelufu yama-PCB aguquguqukayo, ukuhlanganiswa kwe-PCB kudlala indima ebalulekile.Ukuhlanganiswa kwe-PCB kubhekisela ohlelweni lokukhweza izingxenye ze-elekthronikhi ku-PCB. Amasu afanele wokuhlanganisa aqinisekisa ukuthi izingxenye zinamathiselwe ngokuphephile ku-PCB nokuthi amalunga e-solder athembekile.

Uma kukhulunywa ngokunweba impilo yeshalofu yama-PCB, isikhathi sokuhlangana ngemuva kokupakishwa siyisici esibalulekile.I-PCB kufanele ihlanganiswe ngesikhathi esifanele ngemuva kokupakishwa. Ukugcinwa isikhathi eside kwama-PCB apakishiwe kungabangela ukucekelwa phansi kwezinto nezinto ezisetshenziswayo, ngaleyo ndlela kuthinte impilo yeshalofu.

Ukubaluleka kwempilo yeshelufu ye-PCB :

Impilo yeshelufu ye-PCB ibalulekile ngezizathu ezimbalwa. Okokuqala, ukusebenzisa ama-PCB adlule impilo yawo yeshelufu kungabangela izinkinga zokusebenza noma ukwehluleka.Izakhiwo zikagesi ezifana ne-conductivity ne-impedance zingase zithinteke, kubangele ukwehluleka kwesifunda. Izici zemishini, njengokuvumelana nezimo noma ukuqina, nazo ziwohloka ngokuhamba kwesikhathi.

Okwesibili, ukuphatha izinto zokwakha kanye nezingxenye zokwandisa impilo yeshalofu ye-PCB kubalulekile ekusebenzeni kahle kwezindleko.Ngokuphatha kahle impilo yeshelufu, abakhiqizi bangagwema ukumosha kanye nezindleko ezingadingekile ezihlobene nokusebenzisa ama-PCB aphelelwe yisikhathi. Lokhu kubaluleke kakhulu ezimbonini ezinezidingo eziphezulu ze-PCB, njengoba lezi zimboni ngokuvamile zigcina inani elikhulu lama-PCB.

Ukuze kunwetshwe impilo yokugcina yama-PCB aguquguqukayo, kufanele kuthathwe izinyathelo ezithile zokuphepha.

Okokuqala, ama-PCB kufanele agcinwe endaweni elawulwayo enezinga lokushisa elifanele kanye nomswakama.Amazinga okushisa aphezulu kanye nomswakama kungasheshisa ukuwohloka kwezinto nezingxenye.

Okwesibili, ukupakishwa okufanele kubalulekile ekuvikeleni i-PCB ngesikhathi sokugcina.Kufanele zifakwe emaphaketheni avikela umswakama kanye ne-anti-static ukuvimbela noma yimuphi umonakalo noma ukungcola. Ukwengeza, ukumaka okulungile kwamadethi okukhiqiza kanye nezinsuku zokuphelelwa yisikhathi kuyadingeka ukuze kulawulwe ngempumelelo uhlu lwempahla.

Izinto ezimbalwa zingathinta impilo yeshelufu yama-PCB.

Ukuchayeka kumswakama, umswakama kanye namagesi abolayo kungabangela ukuwohloka ngokushesha.Amazinga okushisa aphezulu angagcizelela izinto futhi athinte izakhiwo zabo. Ngakho-ke, kubalulekile ukuphatha nokugcina ama-PCB ngokucophelela ukuze unciphise lezi zici.

Ukusebenzisa ama-PCB aphelelwe yisikhathi kungadala izingozi ezinkulu kanye nezingozi.Ukuxhunywa kwesekethe okungathembekile kungabangela ukungasebenzi kahle kwemishini kagesi, kuthinte ukuphepha nokusebenza. Ezinhlelweni ezibucayi ezifana nemishini yezokwelapha noma amasistimu ezimoto, imiphumela yokusebenzisa ama-PCB aphelelwe yisikhathi ingaba mibi kakhulu.

Ngamafuphi

Isikhathi sokuphila se-PCB eguquguqukayo sithintwa izici eziningi, okuhlanganisa ukwakheka kwezinto ezibonakalayo, inqubo yokukhiqiza, izimo zokugcina, izici zemvelo kanye nokuhlanganisa.Ngokukhetha izinto zekhwalithi, ngokulandela amasu okukhiqiza afanele, ukugcina amasekhethi endaweni elawulwayo futhi ucabangela izimo zokusebenza ezilindelekile, unganweba isikhathi seshelufu sama-PCB aguquguqukayo futhi uqinisekise ukusebenza okuthembekile kwesikhathi eside. Ukuhlolwa okuvamile nokuhlolwa nakho kudlala indima ebalulekile ekugcineni ubuqotho besifunda nokuhlonza noma yiziphi izinkinga ezingaba khona. Ukuqonda impilo yeshalofu yama-PCB aguquguqukayo kubalulekile kubakhiqizi, abaklami nabasebenzisi bokugcina ukuze bathuthukise ukuthembeka komkhiqizo nempilo ende.

Impilo yeshelufu yama-PCB aguquguqukayo iwukucatshangelwa okubalulekile kubakhiqizi nabasebenzisi. Ukuqonda izinto ezithinta impilo yeshelufu nokusebenzisa isitoreji esifanele nezinqubo zokuhlanganisa kungasiza ukunweba impilo ye-PCB yakho. Ngokuphatha ngempumelelo izinto zokwakha kanye nezingxenye, abakhiqizi bangaqinisekisa ukusebenza kahle, ukuphumelela kwezindleko nokuphepha. Qiniseka ukuthi ubuza umkhiqizi noma umphakeli ngolwazi oluthile mayelana nempilo yeshelufu ye-PCB eguquguqukayo.

Isikhathi sokuthumela: Oct-11-2023

Emuva