Emhlabeni ohlale uvela wezinto zikagesi, amabhodi esekethe aphrintiwe (PCBs) adlala indima ebalulekile. Zakha isisekelo lapho kufakwe khona izingxenye ze-elekthronikhi ezihlukahlukene, okuvumela amadivayisi esiwasebenzisa nsuku zonke ukuthi asebenze ngaphandle komthungo. Olunye uhlobo oluthile lwe-PCB oluthole ukunakwa okuningi eminyakeni yamuva nje i-Rogers PCB. Lapha uCapel uhlola umhlaba wama-PCB akwaRogers ukuthola ukuthi ayini, akhiwa kanjani, izakhiwo zawo ezihlukile kanye nomthelela wawo embonini yezogesi.

1. Qonda Rogers PCB

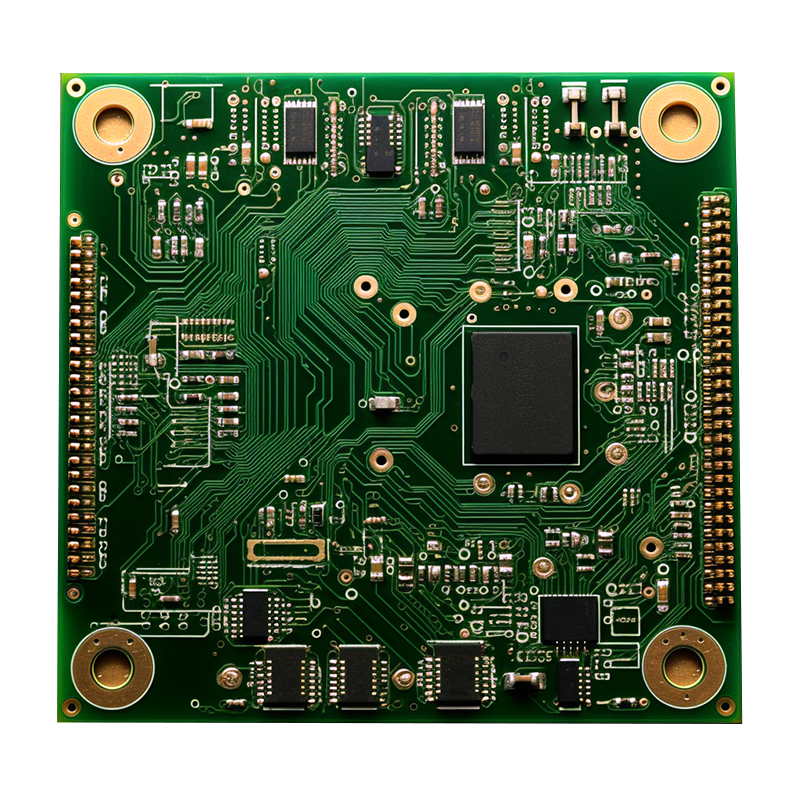

I-Rogers PCB, eyaziwa nangokuthi i-Rogers Printed Circuit Board, iyibhodi lesifunda elakhiwe ngezinto ezisebenza kahle ze-laminated ze-Rogers Corporation. Ngokungafani nama-PCB endabuko e-FR-4 enziwe ngama-epoxy laminates aqiniswe ngengilazi, ama-Rogers PCB aqukethe izinto ezikhethekile eziklanyelwe ukukhombisa izakhiwo eziphakeme zikagesi, ezishisayo nezomshini. Lawa mabhodi asetshenziswa kakhulu ezinhlelweni zemvamisa ephezulu lapho ubuqotho besignali nokusebenza kubaluleke kakhulu, njengezinhlelo zokuxhumana ezingenantambo, ubunjiniyela be-aerospace, nezinhlelo ze-radar yezimoto.

2. Izici eziyinhloko ze-Rogers PCB

Ama-PCB akwaRoger anezimfanelo ezimbalwa ezihlukile eziwahlukanisa kuma-PCB endabuko. Nazi izici ezibalulekile ezibenza bafuneke kakhulu:

a) I-Dielectric Constant:Ama-PCB akwa-Rogers ane-dielectric engaguquki ephansi futhi ezinzile esiza ukugcina ubuqotho besignali ngokunciphisa izinguquko ze-impedance. Lesi sici sibalulekile ezinhlelweni zokusebenza zemvamisa ephezulu.

b) I-Loss Tangent:I-tangent yokulahlekelwa okuphansi kwama-Rogers PCBs isiza ukunciphisa ukuncishiswa kwesignali, iqinisekise ukudluliswa okuphumelelayo nokwamukela amasiginali aphezulu. Lesi sici sinenzuzo ikakhulukazi ezinhlelweni zokuxhumana ezingenazintambo.

c) I-Thermal conductivity:Izinto ze-Rogers PCB zinokusebenza okuphezulu kwe-thermal futhi zingahlakaza ngempumelelo ukushisa okuvela ezingxenyeni ze-elekthronikhi. Lesi sici sibalulekile ezinhlelweni zokusebenza ezikhiqiza ukushisa okuningi, njengezikhulisamandla.

d) Ukuzinza kweDimensional:Ama-PCB akwa-Rogers akhombisa ukuzinza kwe-dimensional okuhle kakhulu ngisho nasezimweni zokushisa ezeqisayo. Lokhu kuzinza kuvumela ukuqondanisa okunembile kwezingxenye ngesikhathi sokukhiqiza, ukuqinisekisa ukusebenza okungaguquki nokuthembekile.

3. Inqubo yokukhiqiza ye-Rogers PCB

Inqubo yokukhiqiza yama-PCB akwa-Rogers ibandakanya izigaba ezimbalwa, ngasinye sazo esinomthelela eqophelweni eliphezulu kanye nokunemba komkhiqizo wokugcina. Yize inqubo ngqo ingahluka kumkhiqizi, izinyathelo ezijwayelekile zifaka:

a) Ukukhetha impahla:Khetha okubalulekile kwe-Rogers laminate ngokusekelwe ezimfuneko ezithile zohlelo lokusebenza njengebanga lemvamisa, ukuqhutshwa kwe-thermal, namandla okusebenza.

b) Ukulungiswa kwezinto:I-Rogers laminate ekhethiwe ihlanzwa ngomshini futhi ifakwe ungqimba lwethusi ukuze kube lula ukulungiswa kwesifunda.

c) Ukufaka:I-Photolithography isetshenziselwa ukususa ngokukhetha ithusi eliningi ku-laminate, ishiya imikhondo yesifunda oyifunayo namaphedi.

d) Ukumba:Izimbobo ezinembayo zibhojwa ku-PCB ukuvumela ukukhwezwa kwengxenye nokuxhumana.

e) Ukucwenga nokumboza:I-Copper ifakwa nge-electrop emigodini ebhoboziwe namasekhethi ukuze inikeze ukuguquguquka nokuvimbela ukugqwala. Imaski evikelayo ye-solder iphinde isetshenziswe ukuvimbela izifunda ezimfushane.

f) Ukuhlola Nokulawula Ikhwalithi:Ukuhlolwa okuhlukahlukene kwenziwa ukuze kuqinisekiswe ukuthi i-Rogers PCB ekhiqiziwe ihlangabezana nokucaciswa okudingekayo. Lokhu kuhlanganisa ukuhlolwa kukagesi, ukuhlola ukunemba kobukhulu, nokuhambisana nezindinganiso zomkhakha.

4. Umthelela we-Rogers PCB embonini yezogesi :

Ukwethulwa kwamaRogers PCB kuguqule izindawo eziningi embonini yezogesi. Ake sihlole umthelela wazo ezindaweni ezibalulekile:

a) Ukuxhumana Okungenantambo:Ama-PCB akwa-Rogers athuthukisa kakhulu ukudluliswa kwesignali nokwamukelwa ezinhlelweni zokuxhumana ezingenantambo, evula indlela yamazinga okudlulisa idatha ngokushesha, ukucaca kwesignali okuthuthukisiwe nokusebenza okuthuthukisiwe kukonke kwenethiwekhi.

b) I-Aerospace nokuvikela:Ama-PCB akwa-Rogers asetshenziswa kakhulu ku-aerospace kanye nezicelo zokuvikela ngenxa yekhono lawo lokumelana nezinga lokushisa elidlulele, amandla okuvama okuphezulu nokuzinza. Baqinisekisa ukusebenza kahle kwezinhlelo ze-radar, amasathelayithi nama-avionics.

c) Ugesi Wezimoto:Imboni yezimoto ithembele kuma-PCB akwa-Rogers ngezinhlelo zokusebenza ezihlukahlukene ezihlanganisa amasistimu okubona ukuphahlazeka, amasistimu e-GPS kanye nezinhlelo ezithuthukisiwe zokusiza abashayeli. Ukusebenza kwazo okuphezulu nokuqina kusiza ukuthuthukisa ukuphepha nokusebenza kahle kwemoto.

d) Izicelo zezimboni:Ama-PCB akwa-Rogers asetshenziswa ekulawuleni izimboni, ama-electronics kagesi kanye nezinhlelo zamandla avuselelekayo. Ukulahlekelwa kwabo okuphansi kwe-tangent kanye nokuphatha okushisayo okuhle kakhulu kusiza ukuthuthukisa ukusebenza kahle nokuthembeka ezinhlelweni zokusebenza zezimboni.

Ngokusekelwe ekuhlaziyeni okungenhla, kungaphethwa ngokuthi ama-PCB akwa-Rogers abe yingxenye ebalulekile yemishini yesimanje kagesi, ehlinzeka ngokusebenza okuthuthukisiwe, ukuzinza nokwethembeka ezinhlelweni ezisetshenziswayo. Ukuqonda izakhiwo eziyingqayizivele nezinqubo zokukhiqiza zama-Rogers PCB kusivumela ukuthi siqonde umthelela wawo obalulekile ezimbonini ezihlukahlukene. Isidingo sama-PCB akwa-Rogers kulindeleke ukuthi sikhule njengoba ubuchwepheshe buqhubeka nokuthuthuka, buqhuba ukuqanjwa kabusha kanye nokulolonga ikusasa lezinto zikagesi.

I-Shenzhen Capel Technology Co., Ltd. ineminyaka engu-15 yesipiliyoni sephrojekthi. Ngezinqubo zobuchwepheshe eziqinile, ikhono lobuchwepheshe elihle kakhulu, okokusebenza okuzishintshayo okuthuthukisiwe, isistimu yokulawula ikhwalithi ephelele, nethimba lochwepheshe elichwepheshile, sizokusebenzela ngenhliziyo yonke. Sinikeza amakhasimende omhlaba ukunemba okuphezulu, amabhodi esekethe asheshayo ekhwalithi ephezulu, okuhlanganisa amabhodi e-PCB aguquguqukayo, amabhodi esekethe aqinile, amabhodi aqinile, amabhodi e-HDI, ama-PCB akwa-Rogers, ama-PCB anemvamisa ephezulu, amabhodi ezinqubo ezikhethekile, njll. -izinsizakalo zobuchwepheshe zokuthengisa nezokuthengisa ngemuva kokuthengisa kanye nezinsizakalo zokulethwa ngesikhathi zenza amakhasimende ethu abambe ngokushesha amathuba emakethe kumaphrojekthi awo.

Isikhathi sokuthumela: Aug-24-2023

Emuva