Emhlabeni wanamuhla wedijithali osheshayo, isidingo semishini kagesi emincane, elula futhi enamandla kakhulu siyaqhubeka sikhula. Ukuze kuhlangatshezwane nalezi zidingo, abakhiqizi bezinto zikagesi bethule ubuchwepheshe be-PCB obuguquguqukayo be-high-density interconnect (HDI).Uma kuqhathaniswa nama-PCB endabuko aguqukayo,HDI flex PCBszinikeza ukuguquguquka okukhulu komklamo, ukusebenza okuthuthukisiwe, nokuthembeka okuthuthukisiwe. Kulesi sihloko, sizohlola ukuthi ayini ama-HDI flex PCB, izinzuzo zawo, nokuthi ahluke kanjani kuma-PCB aguquguqukayo endabuko.

1. Ukuqonda i-HDI Flex PCB:

I-HDI flexible PCB, eyaziwa nangokuthi i-high-density interconnect flexible flexible circuit board, iyibhodi lesifunda eliguquguqukayo elihlinzeka ngobuningi besifunda futhi livumela inkimbinkimbi futhi

imiklamo miniaturized. Ihlanganisa izinzuzo zama-PCB aguquguqukayo, aziwa ngekhono lawo lokugoba nokuzivumelanisa nezimo ezihlukahlukene, ngobuchwepheshe bokuxhumana obuphezulu bokuminyana ukuze

hambisa imikhondo yesekhethi eyengeziwe endaweni ehlangene.

1.2 Yenziwa kanjani i-HDI flexible PCB?

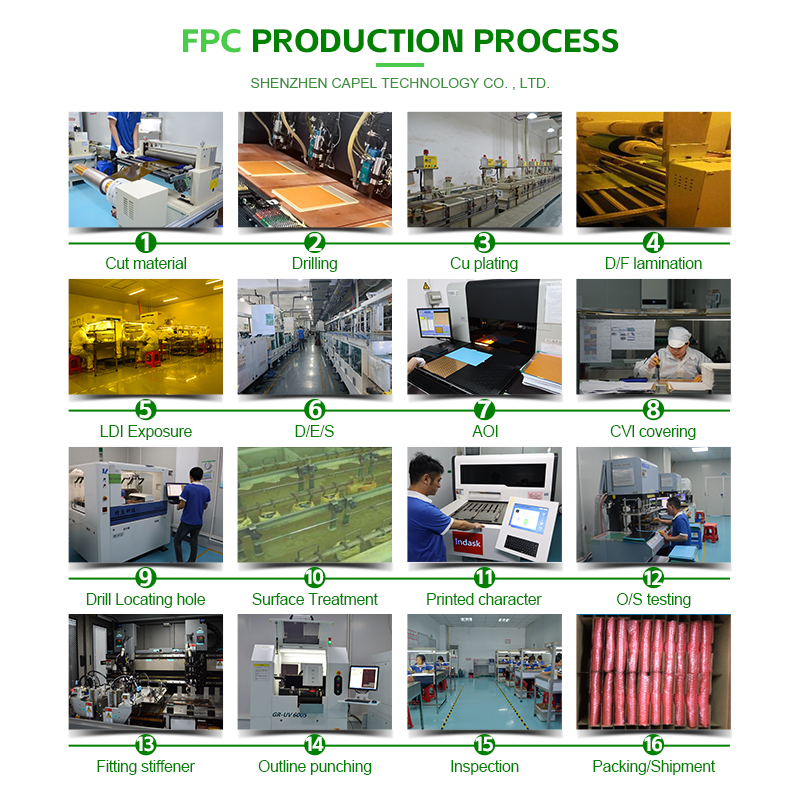

Inqubo yokukhiqiza ye-HDI eguquguqukayo PCBkuhilela izinyathelo ezimbalwa ezibalulekile:

Idizayini:

Isinyathelo sokuqala ukuklama isakhiwo sesifunda, kucatshangelwa ubukhulu, ukuma nokuhlelwa kwezingxenye kanye nomsebenzi oyifunayo.

Ukulungiswa kwezinto:

Khetha futhi ulungise izinto ezidingekayo kuma-PCB aguquguqukayo, njenge-copper foil, izinto zokunamathisela, nezinto ze-substrate eziguquguqukayo.

Ukunqwabelanisa isendlalelo:

Izendlalelo eziningi zezinto eziguquguqukayo, ucwecwe lwethusi, nezinamatheliso kupakishwa ndawonye ukuze kube isisekelo sesekhethi. I-Laser Drilling: I-laser drilling isetshenziselwa ukudala izimbobo ezincane noma ama-vias axhuma izingqimba ezihlukene zesekethe. Lokhu kuvumela izintambo ezindaweni eziqinile.

I-Copper Plating:

Izimbobo ezakhiwe nge-laser drilling zigcwele ithusi ukuqinisekisa ukuxhumana kukagesi phakathi kwezingqimba ezihlukene.

I-Circuit Etching:

Ithusi elingadingekile liyaqoshwa, lishiye iminonjana yesifunda oyifunayo.

Isicelo Semaski Solder:

Imaski ye-solder isetshenziselwa ukuvikela izifunda futhi ivimbele izifunda ezimfushane ngesikhathi somhlangano.

Ukukhwezwa kwengxenye:

Izingxenye ezifana namasekhethi ahlanganisiwe, ama-resistors, nama-capacitor afakwe ku-PCB eguquguqukayo kusetshenziswa ubuchwepheshe bokukhweza komhlaba (SMT) noma ezinye izindlela ezifanele.

Ihloliwe futhi yahlolwa:

Ama-PCB e-HDI flex aqediwe ahlolwe futhi ahlolwe ukuze kuqinisekiswe ukusebenza okufanele kanye nekhwalithi.

1.3 Izinzuzo ze-HDI eguquguqukayo PCB:

Izinzuzo ze-HDI eziguquguqukayo ze-PCB Uma ziqhathaniswa ne-PCB evamile eguquguqukayo, i-HDI eguquguqukayo i-PCB inezinzuzo ezimbalwa, okuhlanganisa:

Ukuminyana kwesekethe okukhulisiwe:

Ubuchwepheshe be-HDI buvumela umzila wokulandela umkhondo wokuminyana okuphezulu, okuvumela izingxenye eziningi ukuthi zibekwe endaweni encane. Lokhu kubangela umklamo omncane futhi ohlangene.

Ubuqotho besignali obuthuthukisiwe:

Amabanga amafushane omzila kuma-HDI flex PCBs aphumela ekuphazamisekeni okuncane kwe-electromagnetic (EMI), okuholela ekuthembekeni okungcono kwesignali, ukunciphisa ukuhlanekezela kwesignali nokuqinisekisa ukusebenza okuthembekile.

Ukuthembeka Okuthuthukisiwe:

Uma kuqhathaniswa nama-PCB aguquguqukayo endabuko, ama-PCB aguquguqukayo e-HDI anamaphuzu okucindezeleka ambalwa futhi amelana kangcono nokudlidliza, ukugoba, kanye nengcindezi yokushisa. Lokhu kuthuthukisa ukwethembeka okuphelele kanye nempilo yonke yesekethe.

Ukuvumelana nezimo zedizayini:

Ubuchwepheshe be-HDI buvumela imiklamo yesekethe eyinkimbinkimbi, evumela ukuhlanganiswa kwezingqimba eziningi, ama-vias angaboni futhi angcwatshwe, izingxenye ze-pitch-pitch, kanye nomzila wesignali wesivinini esikhulu.

Ukonga izindleko:

Naphezu kobunzima bayo kanye ne-miniaturization, ama-PCB aguquguqukayo e-HDI angonga izindleko ngokunciphisa usayizi nesisindo somkhiqizo wokugcina, awenze angabizi kakhulu izinhlelo zokusebenza lapho isikhala nesisindo kubaluleke kakhulu.

2.Ukuqhathaniswa kwe-HDI eguquguqukayo ye-PCB kanye ne-PCB evamile evumelana nezimo:

2.1 Umehluko oyisisekelo ngesakhiwo:

Umehluko omkhulu phakathi kwesakhiwo esiyisisekelo se-HDI eguquguqukayo ye-PCB kanye ne-PCB evamile eguquguqukayo ilele ekuminyana kwesekethe kanye nokusetshenziswa kobuchwepheshe bokuxhumanisa.

Ama-PCB aguquguqukayo endabuko ngokuvamile ahlanganisa isendlalelo esisodwa se-substrate eguquguqukayo njenge-polyimide, enemikhondo yethusi eqoshwe phezulu. Lawa mabhodi avamise ukuba nokuminyana kwesekethe okulinganiselwe ngenxa yokuntuleka kwezendlalelo eziningi nokuxhuma okuyinkimbinkimbi.

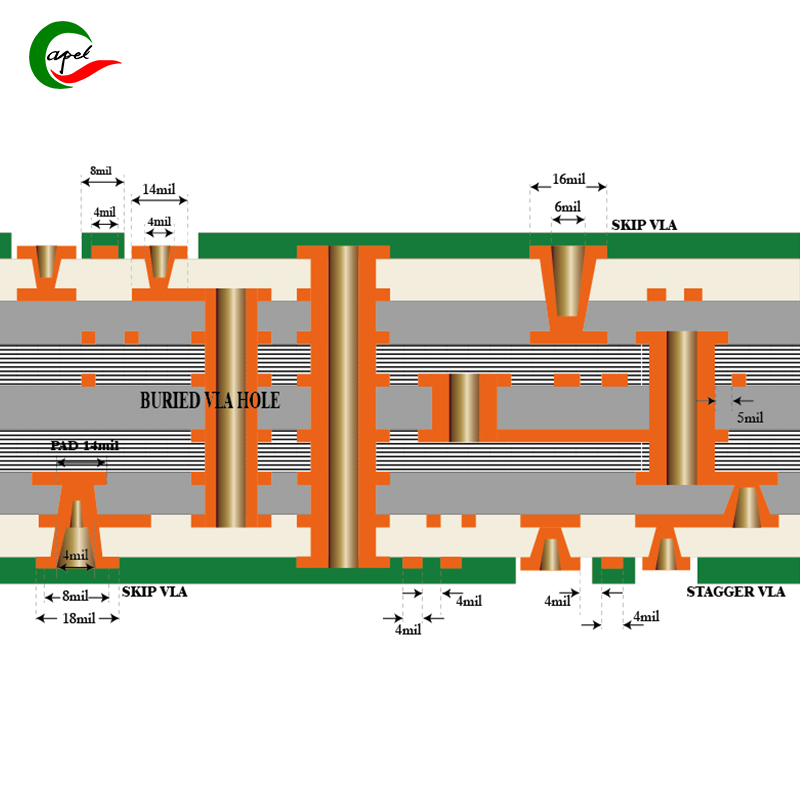

Ngakolunye uhlangothi, i-HDI eguquguqukayo i-PCB isebenzisa ubuchwepheshe bokuxhumanisa obunokuminyana okuphezulu, obungakwazi ukuhambisa imikhondo yesifunda endaweni ehlangene. Lokhu kufinyelelwa ngokusebenzisa izendlalelo eziningi zezinto eziguquguqukayo ezinqwabelene ngemikhondo yethusi nezinamatheliso. Ama-PCB aguquguqukayo e-HDI ngokuvamile asebenzisa i-vias eyimpumputhe negqitshiwe, okuyizimbobo ezibhobozwe ngezingqimba ezithile ukuze kuxhunywe imikhondo yesifunda ngaphakathi kwebhodi, ngaleyo ndlela kuthuthukiswe ikhono lomzila jikelele.

Ukwengeza, ama-PCB aguquguqukayo e-HDI angasebenzisa ama-microvias, okuyizimbobo ezincane ezivumela umzila wokulandelela ominyene. Ukusetshenziswa kwama-microvias nobunye ubuchwepheshe bokuxhumana obuthuthukile kungakhuphula kakhulu ukuminyana kwesekethe uma kuqhathaniswa nama-PCB aguquguqukayo endabuko.

2.2 Inqubekelaphambili enkulu ye-HDI eguquguqukayo PCB:

I-HDI flex PCBs ibe nokuthuthuka okukhulu nokuthuthuka phakathi neminyaka edlule. Eminye yentuthuko enkulu eyenziwe kubuchwepheshe be-PCB obuguquguqukayo be-HDI ihlanganisa:

I-Miniaturization:

Ubuchwepheshe be-HDI buvumela ukwenziwa kancane kwemishini kagesi ngokuvumela ukulandelelwa kwesekethe okwengeziwe ukuthi kuhanjiswe endaweni encane. Lokhu kuvula indlela yokuthuthukiswa kwemikhiqizo emincane, ehlangene efana nama-smartphone, izinto ezigqokekayo nezigxivizo zezokwelapha.

Ukuminyana kwesekethe okukhulisiwe:

Uma kuqhathaniswa nama-PCB endabuko aguquguqukayo, ukusetshenziswa kwezingqimba eziningi, ama-vias angcwatshwe angaboni, nama-microvias kuma-PCB aguquguqukayo we-HDI kukhulisa kakhulu ukuminyana kwesekethe. Lokhu kwenza kube nokwenzeka ukuhlanganisa imiklamo yesekethe eyinkimbinkimbi futhi ethuthukisiwe endaweni encane.

Isivinini esiphezulu nobuqotho besignali:

Ama-PCB aguquguqukayo e-HDI angakwazi ukusekela amasiginali anesivinini esikhulu futhi athuthukise ubuqotho besignali njengoba ibanga phakathi kwezingxenye nezixhumi liyancipha. Lokhu kuzenza zifanelekele izinhlelo zokusebenza ezidinga ukudluliswa kwesignali okuthembekile, njengezinhlelo zokuxhumana zemvamisa ephezulu noma okokusebenza okudinga idatha.

Isakhiwo sengxenye yephimbo elihle:

Ubuchwepheshe be-HDI busiza ukwakheka kwezingxenye ezinephimbo elihle, okusho ukuthi izingxenye zingabekwa eduze, okuholela ekuthuthukisweni okuncane kanye nokuminyana kwesakhiwo sesekhethi. Ukubekwa kwengxenye ye-Fine-pitch kubalulekile ezinhlelweni ezithuthukile ezidinga ama-electronics asebenza kahle kakhulu.

Ukuphathwa kwe-thermal okuthuthukisiwe:

Ama-PCB aguquguqukayo e-HDI anamandla angcono okuphatha okushisayo ngenxa yokusetshenziswa kwezendlalelo eziningi kanye nendawo engaphezulu eyandayo yokukhipha ukushisa. Lokhu kuvumela ukuphatha kahle futhi

ukupholisa izingxenye zamandla aphezulu, okuqinisekisa ukusebenza kwazo okuphezulu.

2.3 Umsebenzi nokuqhathaniswa kokusebenza:

Uma uqhathanisa ukusebenza nokusebenza kwe-HDI flex PCBs kuma-PCB aguquguqukayo endabuko, kunezici ezimbalwa okufanele zicatshangelwe:

Ukuminyana Kwesekethe:

Uma kuqhathaniswa nama-PCB aguquguqukayo endabuko, ama-HDI flex PCB anikeza ukuminyana kwesekethe okuphezulu kakhulu. Ubuchwepheshe be-HDI bungahlanganisa izendlalelo eziningi, i-vias eyimpumputhe, i-vias engcwatshwe, nama-microvias, okuvumela imiklamo yesekethe eyinkimbinkimbi futhi eminyene.

Ubuqotho Besiginali:

Ibanga elincishisiwe phakathi kokulandelelwa kanye nokusetshenziswa kwamasu okuxhuma athuthukile kuma-HDI flex PCB athuthukisa ubuqotho besignali. Lokhu kusho ukudluliswa kwesignali okungcono kanye nokuhlanekezela kwesignali okuphansi uma kuqhathaniswa nama-PCB aguquguqukayo avamile.

Isivinini kanye nomkhawulokudonsa:

Ama-PCB aguquguqukayo e-HDI ayakwazi ukusekela amasiginali aphezulu ngenxa yobuqotho besiginali obuthuthukisiwe kanye nokuncipha kokuphazamiseka kukazibuthe kagesi. Ama-PCB aguquguqukayo avamile angaba nemikhawulo mayelana nesivinini sokudlulisa isignali kanye nomkhawulokudonsa, ikakhulukazi ezinhlelweni ezidinga amanani aphezulu wedatha.

Ukuvumelana nezimo zedizayini:

Uma kuqhathaniswa nama-PCB aguquguqukayo endabuko, ama-HDI flex PCB ahlinzeka ngokuguquguquka okukhulu komklamo. Ikhono lokuhlanganisa izendlalelo eziningi, izimpumputhe nezingcwatshwe nge-vias, kanye nama-microvias avumela imiklamo yesekethe eyinkimbinkimbi. Lokhu kuvumelana nezimo kubaluleke kakhulu ezinhlelweni zokusebenza ezidinga ukwakheka okuhlangene noma ezinemigoqo ethile yesikhala.

Izindleko:

Ama-PCB aguquguqukayo e-HDI avame ukubiza kakhulu kunama-PCB aguquguqukayo endabuko ngenxa yokwanda kwenkimbinkimbi nezindlela zokuxhuma ezithuthukile ezihilelekile. Kodwa-ke, ukwenziwa kancane kanye nokusebenza okuthuthukisiwe okunikezwa ama-HDI flex PCB ngokuvamile kungase kuthethelele izindleko ezengeziwe lapho kucatshangelwa izindleko eziphelele zomkhiqizo wokugcina.

2.4 Ukuthembeka Nokuqina:

Ukuthembeka nokuqina yizici ezibalulekile zanoma iyiphi idivayisi ye-elekthronikhi noma isistimu. Kunezici ezimbalwa ezisebenzayo uma kuqhathaniswa ukwethembeka nokuqina kwe-HDI flex PCBs kuma-PCB aguquguqukayo endabuko:

Ukuguquguquka kwemishini:

Kokubili ama-PCB e-HDI kanye nama-PCB aguquguqukayo endabuko anikeza ukuguquguquka komshini, okuwavumela ukuthi azivumelanise nezimo ezihlukahlukene futhi agobe ngaphandle kokuphuka. Kodwa-ke, ama-PCB aguquguqukayo e-HDI angase abe nokuqiniswa okwengeziwe kwesakhiwo, njengezendlalelo ezengeziwe noma izimbambo, ukuze kusekelwe ukuminyana kwesifunda okwandisiwe. Lokhu kuqiniswa kuthuthukisa ukwethembeka okuphelele nokuqina kwe-HDI flex PCB.

I-Anti-vibration kanye nokushaqeka:

Uma kuqhathaniswa ne-PCB evamile eguquguqukayo, i-HDI evumelana nezimo PCB ingaba nekhono elingcono lokulwa nokudlidliza kanye nekhono lokushaqeka. Ukusetshenziswa kwezimpumputhe, ukungcwatshwa, kanye nama-microvias kumabhodi we-HDI kusiza ukusabalalisa ukucindezeleka ngokulinganayo, ukunciphisa amathuba okulimala kwengxenye noma ukwehluleka kwesifunda ngenxa yokucindezeleka kwemishini.

Ukuphatha Okushisayo:

Uma kuqhathaniswa ne-PCB eguquguqukayo yendabuko, i-HDI flex PCB inezendlalelo eziningi nendawo enkulu engaphezulu, enganikeza ukuphathwa okungcono kokushisa. Lokhu kuthuthukisa ukunqanyulwa kokushisa futhi kusiza ukukhulisa ukuthembeka kukonke nempilo ye-electronics.

Ubude bempilo:

Kokubili ama-HDI nama-PCB aguquguqukayo endabuko angaba nempilo ende uma eklanywe kahle futhi ekhiqizwa. Kodwa-ke, ukuminyana kwesekethe okukhuphukile kanye namasu okuxhumana athuthukile asetshenziswa kuma-HDI flex PCBs adinga ukucatshangelwa ngokucophelela kwezinto ezinjengokucindezeleka okushisayo, ukuhambisana kwezinto ezibonakalayo, nokuhlolwa kokwethembeka ukuze kuqinisekiswe ukusebenza kwesikhathi eside.

Izici zemvelo:

Ama-PCB aguquguqukayo e-HDI, njengama-PCB aguquguqukayo endabuko, adinga ukuklanywa futhi enziwe ukuze amelane nezimo zemvelo ezifana nomswakama, izinguquko zezinga lokushisa, kanye nokuchayeka kumakhemikhali. Ama-PCB aguquguqukayo e-HDI angase adinge ukumbozwa okwengeziwe kokuvikela noma i-encapsulation ukuze kuqinisekiswe ukumelana nezimo zemvelo.

Ama-PCB aguquguqukayo e-HDI anikeza izinzuzo ezimbalwa kuma-PCB aguquguqukayo endabuko ngokuya ngokuminyana kwesekhethi, ubuqotho besignali, ukuguquguquka kwedizayini, nokuthembeka. Ukusetshenziswa advancedamasu okuxhumana kanye namasu okwenza ama-PCB aguquguqukayo e-HDI afanelekele izinhlelo zokusebenza ezidinga ama-electronics asebenza kahle ngendlela ehlangene.Nokho, lezi zinzuzo ziza ngezindleko eziphakeme futhi izidingo ezithile zohlelo lokusebenza kufanele zicatshangelwe ngokucophelela ukuze kunqunywe ubuchwepheshe be-PCB obufaneleka kakhulu.

3.Izinzuzo ze-HDI Flexible PCB:

Ama-PCB aguqukayo e-HDI (High Density Interconnect) athola ukuduma embonini yezogesi ngenxa yezinzuzo zawo eziningi ngaphezu kwama-PCB aguquguqukayo endabuko.

3.1 I-Miaturization kanye nokwenza ngcono isikhala:

I-Miniaturization kanye nokwenza kahle kwesikhala: Enye yezinzuzo eziyinhloko ze-HDI eguquguqukayo PCB ukwakhiwa okuncane kanye nokwenza kahle kwesikhala okokusebenza kwe-elekthronikhi.Ukusetshenziswa kobuchwepheshe be-high-density interconnect kuvumela ukulandelelwa kwesekethe okwengeziwe ukuthi kuhanjiswe endaweni ehlangene. Lokhu kusiza ukuthuthukiswa kwama-electronics amancane, ahlangene kakhulu. Ama-PCB aguquguqukayo e-HDI avame ukusetshenziswa ezinhlelweni ezifana nama-smartphone, amaphilisi, izinto ezigqokwayo, namadivayisi ezokwelapha lapho isikhala sinomkhawulo futhi usayizi ohlangene ubalulekile.

3.2 Thuthukisa ubuqotho besignali:

Thuthukisa ubuqotho besignali: Ubuqotho besignali yisici esibalulekile emishinini ye-elekthronikhi, ikakhulukazi ezinhlelweni zokusebenza ezinesivinini esikhulu kanye nemvamisa ephezulu.Ama-PCB aguquguqukayo e-HDI ahamba phambili ekuletheni ubuqotho besignali ephakeme ngenxa yebanga elincishisiwe phakathi kwezingxenye nezixhumi. Ubuchwepheshe bokuxhumana obuthuthukisiwe obusetshenziswa kuma-PCB aguquguqukayo we-HDI, njengama-vias ayimpumputhe, ama-vias angcwatshwe, nama-microvias, kunganciphisa kakhulu ukulahleka kwesignali kanye nokuphazamiseka kazibuthe kagesi. Ubuqotho besignali obuthuthukisiwe buqinisekisa ukudluliswa kwesignali okuthembekile futhi kunciphisa ingozi yamaphutha edatha, okwenza i-HDI flex PCBs ifanelekele izinhlelo zokusebenza ezibandakanya ukudluliswa kwedatha nezinhlelo zokuxhumana ngesivinini esikhulu.

3.3 Ukusabalalisa amandla okuthuthukisiwe:

Ukusabalalisa Amandla Okuthuthukisiwe: Enye inzuzo ye-HDI flex PCB ikhono layo lokuthuthukisa ukusatshalaliswa kwamandla.Ngobunzima obandayo bezinto zikagesi kanye nesidingo sezidingo zamandla aphezulu, ama-HDI flex PCB ahlinzeka ngesixazululo esihle kakhulu sokusatshalaliswa kwamandla okusebenzayo. Ukusebenzisa izendlalelo eziningi kanye nezindlela ezithuthukisiwe zomzila wamandla kwenza ukusabalalisa kwamandla ebhodi lonke kube ngcono, kunciphise ukulahleka kwamandla kanye nokwehla kwamandla kagesi. Ukusabalalisa amandla okuthuthukisiwe kwenza ukusebenza okuthembekile kwezingxenye ezilambele amandla futhi kunciphisa ingozi yokushisa ngokweqile, ukuqinisekisa ukuphepha nokusebenza okuphezulu.

3.4 Ukuminyana kwengxenye ephezulu :

Ukuminyana kwengxenye ephezulu: Uma kuqhathaniswa ne-PCB evamile eguquguqukayo, i-HDI eguquguqukayo i-PCB ingafinyelela ukuminyana okuphezulu kwengxenye.Ukusetshenziswa kwe-multi-layer kanye nobuchwepheshe bokuxhumana obuthuthukisiwe kuvumela ukuhlanganiswa kwezingxenye ze-elekthronikhi eziningi endaweni encane. Ama-PCB aguquguqukayo e-HDI angakwazi ukwamukela imiklamo yesekethe eyinkimbinkimbi neminyene, ebalulekile ezinhlelweni ezithuthukile ezidinga ukusebenza okwengeziwe nokusebenza ngaphandle kokubeka engcupheni usayizi webhodi. Ngokuminyana okuphezulu kwezingxenye, abakhiqizi bangaklama futhi bathuthukise imikhiqizo ye-elekthronikhi eyinkimbinkimbi kakhulu futhi enothile.

3.5 Thuthukisa ukuchithwa kokushisa:

Ukukhishwa kokushisa okuthuthukisiwe: Ukukhishwa kokushisa kuyisici esibalulekile somklamo wedivayisi ye-elekthronikhi, njengoba ukushisa ngokweqile kungaholela ekulimazeni ukusebenza, ukwehluleka kwengxenye kanye nokulimala kwesistimu.Uma kuqhathaniswa ne-PCB evamile eguquguqukayo, i-HDI eguquguqukayo i-PCB inokusebenza okungcono kokukhipha ukushisa. Ukusetshenziswa kwezendlalelo eziningi kanye nokwanda kwendawo ephezulu kuvumela ukuchithwa okungcono kokushisa, ukususa ngokuphumelelayo nokukhipha ukushisa okukhiqizwa izingxenye ezilambele amandla. Lokhu kuqinisekisa ukusebenza okuphelele nokuthembeka kwemishini kagesi, ikakhulukazi ezinhlelweni zokusebenza lapho ukuphathwa kwe-thermal kubaluleke kakhulu.

Ama-PCB aguqukayo e-HDI anezinzuzo ezimbalwa eziwenza abe ukukhetha okuhle kakhulu kogesi besimanje. Ikhono lazo lokwenza izinto ezincane kanye nokuthuthukiswa kwendawo lizenza zilungele izinhlelo zokusebenza lapho usayizi ohlangene ubalulekile. Ubuqotho besignali obuthuthukisiwe buqinisekisa ukudluliswa kwedatha okuthembekile, kuyilapho ukusatshalaliswa kwamandla okuthuthukisiwe kunika amandla amandla asebenzayo ezingxenye. Ukuminyana kwengxenye ephakeme ye-HDI ye-PCB kuthwala imisebenzi nezici ezengeziwe, kuyilapho ukunqanyulwa kokushisa okuthuthukisiwe kuqinisekisa ukusebenza okuhle nokuphila isikhathi eside kwamadivayisi kagesi. Ngalezi zinzuzo, ama-PCB aguqukayo e-HDI aseyisidingo ezimbonini ezahlukahlukene ezifana nogesi wabathengi, i-telecom, eyezimoto, kanye nemishini yezokwelapha.

4.Ukusetshenziswa kwe-HDI PCB eguquguqukayo:

I-HDI flexible PCB inohlu olubanzi lwezinhlelo zokusebenza ezimbonini ezahlukene. Amandla abo okwenza ama-miniaturization, ubuqotho besignali obuthuthukisiwe, ukusatshalaliswa kwamandla okuthuthukisiwe, ukuminyana kwengxenye ephezulu, nokunqanyulwa kokushisa okuthuthukisiwe kubenza bafaneleke kumishini kagesi yabathengi, imishini yezokwelapha, imboni yezimoto, i-aerospace nezinhlelo zokuzivikela, kanye Ne-inthanethi Yezinto nezinto ezigqokwayo. ingxenye ebalulekile kudivayisi. Ama-PCB aguquguqukayo e-HDI anika amandla abakhiqizi ukuthi bakhe izinto zikagesi ezihlangene, ezisebenza kahle ukuze zihlangabezane nezidingo ezikhulayo zalezi zimboni.

4.1 I-Consumer Electronics:

I-HDI flexible PCB inezinhlobonhlobo zezinhlelo zokusebenza embonini ye-electronics yabathengi.Ngesidingo esiqhubekayo samadivayisi amancane, amancanyana, nanothile ngesici, ama-HDI flex PCB anika amandla abakhiqizi ukuthi bahlangabezane nalezi zidingo. Asetshenziswa kuma-smartphones, amaphilisi, ama-laptops, amawashi ahlakaniphile nezinye izinto zikagesi eziphathwayo. Amandla okwenza i-miniaturization ama-PCB aguquguqukayo e-HDI avumela ukuhlanganiswa kwemisebenzi eminingi endaweni ehlangene, okuvumela ukuthuthukiswa kwezinto zikagesi ezisezingeni eliphezulu nezisebenza kahle zabathengi.

4.2 Imishini yezokwelapha:

Imboni yemishini yezokwelapha ithembele kakhulu kuma-PCB aguquguqukayo e-HDI ngenxa yokuthembeka kwawo, ukuguquguquka, kanye nesici sefomu elincane.Izingxenye ze-elekthronikhi emishinini yezokwelapha efana nezihlinzeki-nhliziyo, izinsiza-kuzwa, iziqapha ushukela wegazi kanye nemishini yokuthwebula idinga ukunemba okuphezulu. Ama-PCB aguquguqukayo e-HDI angahlangabezana nalezi zidingo ngokuhlinzeka ngoxhumo oluminyanisa kakhulu nobuqotho besignali obuthuthukisiwe. Ngaphezu kwalokho, ukuguquguquka kwazo kungahlanganiswa kangcono kumishini yezokwelapha egqokekayo ukuze isiguli sikhululeke futhi kube lula.

4.3 Imboni Yezimoto:

I-HDI flex PCBs isiyingxenye ebalulekile yezimoto zesimanje.Imboni yezimoto idinga ama-electronics asebenza kahle kakhulu akwazi ukumelana nezimo eziyinselele futhi alethe ukusebenza okuphelele. Ama-PCB aguquguqukayo e-HDI ahlinzeka ngokwethembeka okudingekayo, ukuqina kanye nokwenza kahle kwesikhala kwezinhlelo zokusebenza zezimoto. Asetshenziswa kumasistimu ezimoto ahlukene okuhlanganisa amasistimu e-infotainment, amasistimu wokuzulazula, amamojula okulawula i-powertrain namasistimu okusiza abashayeli (ADAS). Ama-PCB aguquguqukayo e-HDI angakwazi ukumelana nokushintsha kwezinga lokushisa, ukudlidliza nokucindezeleka komshini, okuwenza afanelekele izindawo zezimoto ezinokhahlo.

4.4 I-Aerospace nokuvikela:

Imboni yasemkhathini neyezokuvikela idinga amasistimu kagesi athembeke kakhulu akwazi ukumelana nezimo ezimbi kakhulu, ukudlidliza kanye nokudluliswa kwedatha ngesivinini esikhulu.Ama-PCB aguquguqukayo e-HDI alungele izinhlelo ezinjalo ngoba ahlinzeka ngoxhumano olunokuminyana okuphezulu, ubuqotho besignali obuthuthukisiwe, nokumelana nezinto zemvelo. Zisetshenziswa ezinhlelweni ze-avionics, ezokuxhumana ngesathelayithi, izinhlelo ze-radar, imishini yezempi nama-drones. Amandla okwenza i-miniaturization we-HDI flex PCBs asiza ekuthuthukisweni kwamasistimu kagesi angasindi, ahlangene anika amandla ukusebenza okungcono nokusebenza okwengeziwe.

4.5 IoT namadivayisi agqokekayo:

I-inthanethi Yezinto (IoT) kanye namadivayisi agqokekayo aguqula izimboni kusukela kwezokunakekelwa kwempilo nokuqina kuye ezishintshayo zasekhaya kanye nokuqapha kwezimboni.Ama-PCB aguquguqukayo e-HDI ayizingxenye ezibalulekile ku-IoT namadivayisi agqokekayo ngenxa yesimo sawo esincane kanye nokuguquguquka okukhulu. Anika amandla ukuhlanganiswa okungenamthungo kwezinzwa, amamojula okuxhumana angenantambo, nezilawuli ezincane kumadivayisi afana namawashi ahlakaniphile, izilandeleli zokufaneleka, amadivayisi ahlakaniphile asekhaya, nezinzwa zezimboni. Ubuchwepheshe bokuxhumana obuthuthukisiwe kuma-HDI flex PCB buqinisekisa ukudluliswa kwedatha okuthembekile, ukusatshalaliswa kwamandla, nobuqotho besignali, okubenza bafanelekele izidingo ezifunekayo ze-IoT namadivayisi agqokekayo.

5. Ukucatshangelwa kokuklama kwe-HDI Flex PCB:

Ukuklama i-HDI flex PCB kudinga ukucatshangelwa ngokucophelela kokunqwabelaniswa kwesendlalelo, ukuhlukaniswa kwezikhala, ukubekwa kwengxenye, amasu okuklama anesivinini esikhulu, nezinselele ezihambisana nokuhlanganisa nokukhiqiza. Ngokubhekana ngokuphumelelayo nalokhu kucatshangelwa kokuklama, i-Capel ingathuthukisa ukusebenza okuphezulu kwe-HDI flex PCBs efanelekile kuzinhlelo zokusebenza ezihlukahlukene.

5.1 Ukupakisha ungqimba kanye nomzila:

Ama-PCB aguquguqukayo e-HDI ngokuvamile adinga izendlalelo eziningi ukuze afinyelele ukuxhumana okunokuminyana okuphezulu.Lapho uklama isitaki sesendlalelo, izici ezifana nobuqotho besignali, ukusatshalaliswa kwamandla, nokuphathwa kokushisa kufanele kucatshangelwe. Ukupakishwa kwesendlalelo ngokucophelela kusiza ukuthuthukisa umzila wesignali futhi kunciphise ukungqubuzana phakathi kokulandelelwa. Umzila kufanele uhlelwe ukuze kuncishiswe i-skew yesignali futhi kuqinisekiswe ukufana okufanele kwe-impedance. Kumelwe kwabelwe isikhala esanele sama-vias namaphedi ukuze kube lula ukuxhumana phakathi kwezingqimba.

5.2 Ukulandelela Isikhala Nokulawula Ukuphazamiseka:

I-HDI flex PCBs ivamise ukuba nokuminyana okuphezulu kokulandela umkhondo, ukugcina isikhala esifanele sokulandelela kubalulekile ukuze kuvinjwe ukuphazamiseka kwesignali kanye ne-crosstalk.Abaklami kufanele banqume ububanzi bokulandelela obufanele nesikhala ngokususelwe ku-impedance oyifunayo. Ukulawulwa kwe-impedance kubalulekile ekugcineni ubuqotho besignali, ikakhulukazi kumasignali anesivinini esikhulu. Abaklami kufanele abale ngokucophelela futhi balawule ububanzi bokulandelela, isikhala, kanye nokungaguquguquki kwe-dielectric ukuze kuzuzwe ivelu ye-impedance oyifunayo.

5.3 Ukubekwa kwengxenye:

Ukubekwa kwengxenye efanele kubalulekile ukuze kuthuthukiswe indlela yesignali, ukunciphisa umsindo nokunciphisa usayizi we-HDI flex PCB.Izingxenye kufanele zibekwe ngendlela ehlelekile ukuze kuncishiswe ubude bokulandelela isignali nokwandisa ukugeleza kwesignali. Izingxenye zesivinini esikhulu kufanele zibekwe eduze ukuze kuncishiswe ukubambezeleka kokusakazwa kwesignali nokunciphisa ingozi yokuhlanekezelwa kwesignali. Abaklami kufanele futhi bacabangele izici zokuphatha ukushisa futhi baqinisekise ukuthi izingxenye zibekwe ngendlela evumela ukuchithwa kokushisa.

5.4 Ubuchwepheshe bokuklama obunesivinini esiphezulu:

Ama-PCB aguquguqukayo e-HDI ngokuvamile abhekelela ukudluliswa kwedatha okunesivinini esikhulu lapho ubuqotho besignali bubalulekile.Amasu afanele edizayini anesivinini esiphezulu, anjengomzila we-impedance olawulwayo, ukubhanqa okuhlukile komzila, nobude bokulandela umkhondo obufanisiwe, kubalulekile ukuze kuncishiswe ukuncishiswa kwesignali. Amathuluzi okuhlaziya ubuqotho besignali angasetshenziswa ukulingisa nokuqinisekisa ukusebenza kwemiklamo enesivinini esikhulu.

5.5 Izinselelo Zokuhlanganisa kanye Nokukhiqiza:

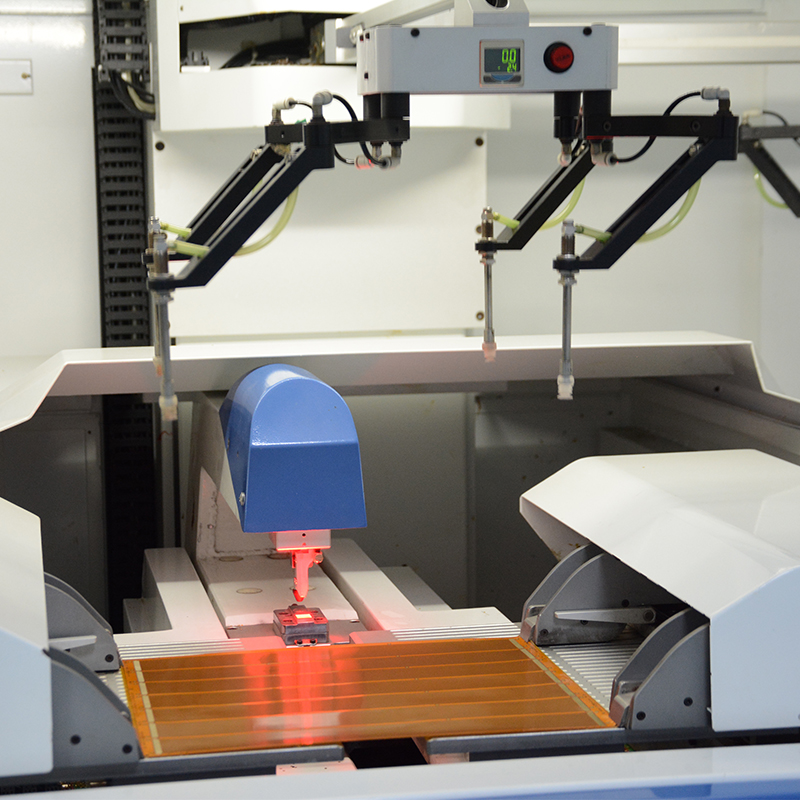

Ukuhlanganiswa nokukhiqizwa kwama-HDI flex PCB kuletha izinselelo ezimbalwa.Imvelo eguquguqukayo yama-PCB idinga ukuphathwa ngokucophelela phakathi nokuhlanganisa ukuze kugwenywe imikhondo eyingozi elimazayo kanye nezingxenye. Ukubekwa okunembile kwengxenye kanye ne-soldering kungadinga imishini namasu akhethekile. Inqubo yokwenziwa idinga ukuqinisekisa ukuqondana okunembayo kwezendlalelo nokunamathela okufanele phakathi kwazo, okungase kuhlanganise izinyathelo ezengeziwe ezifana nokubhoboza i-laser noma imaging eqondile ye-laser.

Ukwengeza, usayizi omncane kanye nokuminyana okuphezulu kwengxenye ye-HDI flex PCB kungadala izinselele zokuhlolwa nokuhlolwa. Amasu okuhlola okukhethekile afana nokuhlolwa kwe-X-ray kungase kudingeke ukuze kutholwe amaphutha noma ukwehluleka kuma-PCB. Ngaphezu kwalokho, njengoba i-HDI flex PCBs ivamise ukusebenzisa izinto ezithuthukisiwe nobuchwepheshe, ukukhethwa nokufaneleka kwabahlinzeki kubalulekile ukuze kuqinisekiswe ikhwalithi nokwethembeka komkhiqizo wokugcina.

6.Amathrendi wesikhathi esizayo we-HDI flexible PCB technology:

Ikusasa lobuchwepheshe be-PCB obuguquguqukayo be-HDI lizobonakala ngokukhula kokuhlanganiswa nokuba yinkimbinkimbi, ukwamukelwa kwezinto ezithuthukisiwe, kanye nokwandiswa kwe-IoT nobuchwepheshe obugqokekayo. Lawa mathrendi azoqhuba izimboni ukuthi zithuthukise amadivaysi e-elekthronikhi amancane, anamandla kakhudlwana, futhi anemisebenzi eminingi.

6.1 Ukwenyuka kokuhlanganiswa nokuba yinkimbinkimbi:

Ubuchwepheshe be-PCB obuguquguqukayo be-HDI buzoqhubeka nokuthuthuka ngendlela yokwandisa ukuhlanganiswa nokuba yinkimbinkimbi.Njengoba amadivaysi e-elekthronikhi eba aminyene kakhulu futhi anothile ngesici, kunesidingo esikhulayo sama-HDI flex PCB anokuminyana okuphezulu kwesekethe kanye nezici zefomu ezincane. Lo mkhuba uqhutshwa intuthuko ezinqubweni zokukhiqiza namathuluzi okuklama avumela ukulandelelwa kwephimbo elicolisekileyo, ama-vias amancane, kanye nezingqimba zokuxhuma eziqinile. Ukuhlanganisa izingxenye ze-elekthronikhi eziyinkimbinkimbi nezihlukene ku-PCB eyodwa eguquguqukayo kuzoba ngaphezulu

okuvamile, ukunciphisa usayizi, isisindo kanye nezindleko zesistimu jikelele.

6.2 Ukusebenzisa izinto ezithuthukisiwe:

Ukuze kuhlangatshezwane nezidingo zokuhlanganiswa okuphezulu nokusebenza, i-HDI flexible PCB izosebenzisa izinto ezithuthukisiwe.Izinto ezintsha ezinezimfanelo zikagesi ezithuthukisiwe, ezishisayo nezomshini zizonika amandla isignali engcono kakhulu, ukunqanyulwa kokushisa okuthuthukisiwe kanye nokuthembeka okuphezulu. Isibonelo, ukusetshenziswa kwezinto eziphansi ze-dielectric zokulahlekelwa okuncane kuzovumela ukusebenza kwemvamisa ephezulu, kuyilapho izinto ezisetshenziswayo eziphezulu zokushisa zingathuthukisa amandla okuphatha okushisayo kwama-PCB aguquguqukayo. Ukwengeza, ukuthuthuka kwezinto ezisebenzayo ezifana nama-alloys ethusi nama-polymers asebenzayo kuzonika amandla amandla aphezulu okuthwala wamanje kanye nokulawulwa okungcono kwe-impedance.

6.3 Ukunwetshwa kwe-IoT kanye Nobuchwepheshe Okugqokayo:

Ukunwetshwa kwe-inthanethi Yezinto (IoT) nobuchwepheshe obugqokekayo kuzoba nomthelela omkhulu kubuchwepheshe be-PCB obuguquguqukayo be-HDI.Njengoba inani lamadivayisi axhunyiwe liqhubeka nokukhula, kuzoba nesidingo esandayo sama-PCB aguquguqukayo angahlanganiswa abe yizici zefomu ezincane nezihluke kakhulu. Ama-HDI flex PCB azodlala indima ebalulekile ekwenziweni okuncane kwamadivayisi agqokekayo njengamawashi ahlakaniphile, izilandeleli zokufaneleka nezinzwa zokunakekelwa kwempilo. Lawa madivayisi ngokuvamile adinga ama-PCB avumelana nezimo ukuze avumelane nomzimba futhi anikeze ukuxhumana okuqinile nokuthembekile.

Ngaphezu kwalokho, ukwamukelwa okusabalele kwemishini ye-IoT ezimbonini ezahlukahlukene ezifana ne-smart home, izimoto, kanye ne-automation yezimboni kuzoqhuba isidingo sama-PCB aguquguqukayo we-HDI anezici ezithuthukile njengokudluliswa kwedatha ngesivinini esikhulu, ukusetshenziswa kwamandla aphansi, nokuxhumana okungenantambo. Lokhu kuthuthuka kuzodinga ama-PCB ukuthi asekele umzila wesiginali oyinkimbinkimbi, izingxenye ezincane kanye nokuhlanganiswa nezinzwa ezahlukene nama-actuator.

Ngokufigqiwe, Ama-PCB aguquguqukayo e-HDI ashintshe imboni ye-elekthronikhi ngenhlanganisela yawo eyingqayizivele yokuguquguquka nokuxhumanisa okuphezulu. Lawa ma-PCB anikezela ngezinzuzo eziningi ngaphezu kwama-PCB aguquguqukayo endabuko, okuhlanganisa ukwenziwa kwe-miniaturization, ukwenziwa ngcono kwesikhala, ubuqotho besignali obuthuthukisiwe, ukusatshalaliswa kwamandla okusebenzayo, kanye nekhono lokwamukela ukuminyana kwezingxenye eziphezulu. Lezi zakhiwo zenza ama-PCB aguquguqukayo e-HDI afanelekele ukusetshenziswa ezimbonini ezihlukahlukene, okufaka phakathi izinto zikagesi ezithengwayo, izisetshenziswa zezokwelapha, amasistimu ezimoto, nezinhlelo zokusebenza ze-aerospace. Kodwa-ke, kubalulekile ukucabangela ukucatshangelwa kokuklama kanye nezinselele zokukhiqiza ezihlobene nalawa ma-PCB athuthukile. Abaqambi kufanele bahlele ngokucophelela ukwakheka kanye nomzila ukuze baqinisekise ukusebenza kahle kwesignali kanye nokuphathwa kokushisa. Ngaphezu kwalokho, inqubo yokukhiqiza ye-HDI flex PCBs idinga izinqubo namasu athuthukile ukuze kuzuzwe izinga elidingekayo lokunemba nokwethembeka. Ukuqhubekela phambili, ama-PCB aguqukayo e-HDI kulindeleke ukuthi aqhubeke nokuvela njengoba ubuchwepheshe buthuthuka. Njengoba izinto zikagesi ziba zincane futhi ziba yinkimbinkimbi, isidingo sama-PCB aguqukayo we-HDI anamazinga aphezulu okuhlanganiswa nokusebenza sizokhula kuphela. Lokhu kuzoqhubeza okunye okusha kanye nentuthuko kulo mkhakha, okuholela emishinini kagesi esebenza kahle kakhulu futhi eguquguqukayo kuzo zonke izimboni.

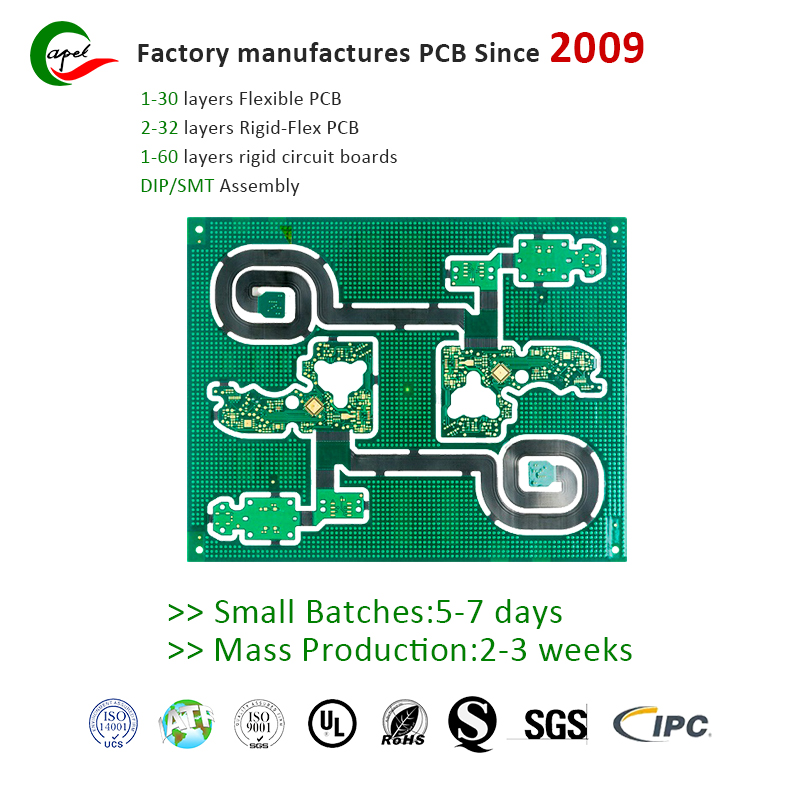

I-Shenzhen Capel Technology Co., Ltd. ibikhiqiza amabhodi esekethe aphrintiwe (PCBs) kusukela ngo-2009.Njengamanje, siyakwazi ukuhlinzeka ngamabhodi wesifunda aphrintiwe wesendlalelo angu-1-30 ngokwezifiso. Ubuchwepheshe bethu bokukhiqiza be-HDI (High Density Interconnect) be-PCB buvuthwe kakhulu. Eminyakeni engu-15 edlule, siye sasungula ubuchwepheshe ngokuqhubekayo futhi saqongelela ulwazi olucebile ekuxazululeni izinkinga ezihlobene nephrojekthi kumakhasimende.

Isikhathi sokuthumela: Aug-31-2023

Emuva