Amabhodi esekethe aguquguqukayo, awaziwa nangokuthi amasekethe aguquguqukayo noma amabhodi esekethe aphrintiwe (ama-PCB), aguqule imboni yezogesi ngokufaka esikhundleni sama-PCB endabuko aqinile nanamandla. Lezi zimangaliso ze-elekthronikhi zithole ukuduma eminyakeni yamuva ngenxa yezici zazo ezihlukile kanye nezinhlelo zokusebenza.Lesi sihloko sihlose ukunikeza abaqalayo umhlahlandlela ophelele kumabhodi wesifunda aguquguqukayo - incazelo yawo, isakhiwo, izinzuzo, izinhlelo zokusebenza, kanye nezitayela zesikhathi esizayo kulobu buchwepheshe. Ngemva kokufunda lesi sihloko, uzoba nokuqonda okucacile kokuthi amabhodi wesifunda aguquguqukayo asebenza kanjani kanye nezinzuzo zawo ngaphezu kwamabhodi wesifunda aqinile.

1.Iyini ibhodi lesifunda eliguquguqukayo:

1.1 Incazelo kanye nesifingqo:

Ibhodi lesifunda eliguquguqukayo, elaziwa nangokuthi isekethe eguquguqukayo noma ibhodi lesekethe eliphrintiwe (PCB), ibhodi lesekethe ye-elekthronikhi eliguquguqukayo futhi eligobekayo, elivumela ukuthi livumelane nezimo ezihlukahlukene kanye namakhonco. Ngokungafani nama-PCB endabuko aqinile, enziwe ngezinto eziqinile njenge-fiberglass noma i-ceramics, ama-flex circuits enziwe ngezinto ezincane, eziguquguqukayo njenge-polyimide noma i-polyester. Lokhu kuvumelana nezimo kuzivumela ukuthi zigoqe, zisonteke noma zigobe ukuze zilingane nezikhala eziqinile noma zivumelane nejometri eyinkimbinkimbi.

1.2 Lisebenza kanjani ibhodi lesifunda eliguquguqukayo:

Ibhodi lesifunda eliguquguqukayo liqukethe i-substrate, iminonjana ye-conductive, nezingqimba zezinto zokuvikela. Ukulandela umkhondo kwenziwa iphethini kokusebenza okuguquguqukayo kusetshenziswa amasu ahlukene njengokuqopha noma ukuphrinta. Lawa mathrekhi asebenza njengezindlela zokugeleza kwamanje phakathi kwezingxenye ezihlukene noma izingxenye zesekethe. Amabhodi esekethe aguquguqukayo asebenza njengama-PCB endabuko, anezingxenye ezifana nezimbangi, ama-capacitor, namasekethe ahlanganisiwe (ICs) afakwe ebhodini futhi axhunywe kusetshenziswa ama-conductive traces. Nokho, ukuguquguquka kwe-flex pcb kuzivumela ukuthi zigotshwe noma zigoqwe ukuze zilingane izindawo eziqinile noma zivumelane nokuma kwedivayisi ethile noma uhlelo lokusebenza.

1.3 Izinhlobo zamabhodi esekethe aguquguqukayo:Kunezinhlobo ezimbalwa zamabhodi esekethe aguquguqukayo, ngalinye lakhelwe ukuhlangabezana nezidingo ezithile zohlelo lokusebenza:

1.3.1Isekhethi eguquguqukayo yohlangothi olulodwa:

Lawa ma-circuits anemikhondo ye-conductive ohlangothini olulodwa lwe-substrate eguquguqukayo. Kungase kube khona i-adhesive noma evikelayo ngakolunye uhlangothi. Zivame ukusetshenziswa ku-elekthronikhi elula noma lapho isikhala silinganiselwe.

1.3.2Amasekhethi aguquguqukayo anezinhlangothi ezimbili:

Amasekhethi aguquguqukayo anezinhlangothi ezimbili anemikhondo yokuqondisa ezinhlangothini zombili ze-substrate eguquguqukayo. Lokhu kuvumela imiklamo eyinkimbinkimbi yesekethe kanye nokukhula kwengxenye yengxenye.

1.3.3Amasekhethi amaningi aguquguqukayo:

Amasekhethi e-multilayer flex aqukethe izendlalelo eziningi zokulandela umkhondo nezinto zokuvikela. Lawa ma-circuits angakwazi ukusekela imiklamo eyinkimbinkimbi enobuningi bengxenye ephezulu kanye nokusebenza okuthuthukile.

1.4 Izinto ezisetshenziswa kaningi zamabhodi esekethe aguquguqukayo: Amabhodi esekethe aguquguqukayo akhiqizwa kusetshenziswa izinto ezahlukahlukene ngokuya ngezidingo ezithile zohlelo lokusebenza. Ezinye izinto ezisetshenziswa kakhulu zihlanganisa:

I-Polyimide (PI):

Lokhu kuyisinqumo esithandwayo samabhodi wesifunda aguquguqukayo ngenxa yokumelana nokushisa kwawo okuhle kakhulu, ukumelana namakhemikhali kanye nokuzinza kwe-dimensional.

I-Polyester (PET):

I-PET ingenye into esetshenziswa kabanzi eyaziwa ngokuguquguquka kwayo, umnotho, kanye nezakhiwo ezinhle zikagesi.

I-PTFE (Polytetrafluoroethylene):

I-PTFE yakhethwa ngenxa yezakhiwo zayo ezinhle kakhulu zokuvikela ugesi kanye nokuzinza okuphezulu kokushisa.

Ifilimu elincanyana:

Amabhodi wesekethe wefilimu azacile asebenzisa izinto ezifana nethusi, i-aluminium noma isiliva, ezifakwa kuma-substrates aguquguqukayo ngobuchwepheshe be-vacuum deposition.

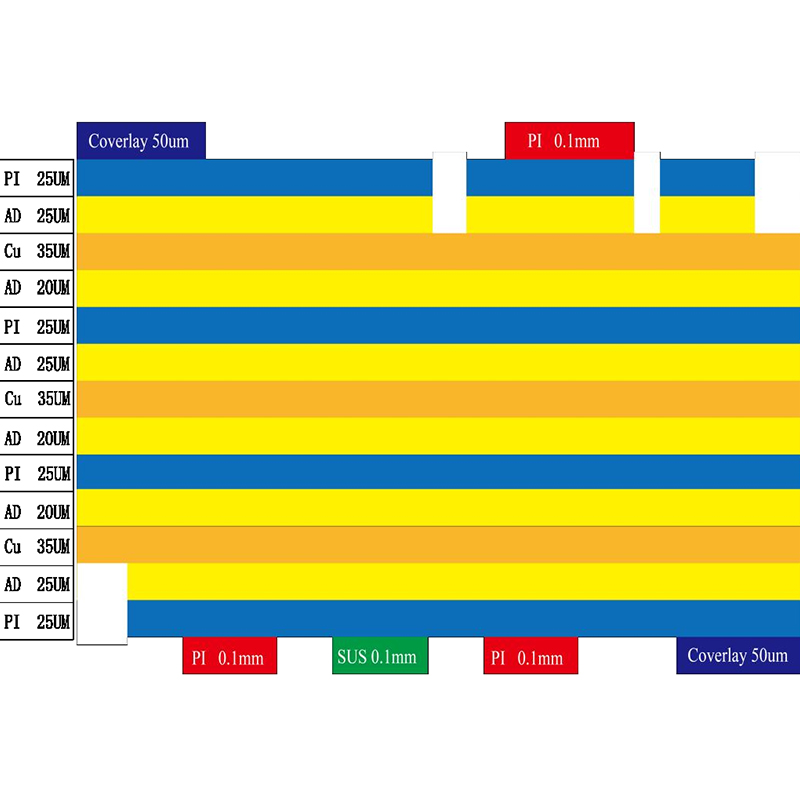

2. Ukwakhiwa kwamabhodi esekethe aguquguqukayo:

Ukwakhiwa kwesekethe ephrintiwe eguquguqukayo kuhilela ukukhethwa okuqondile kwezinto ezingaphansi kwe-substrate, iminonjana eqhubayo, izembatho ezivikelayo, izembozo, izingxenye kanye namasu okukhweza, nezindawo zokuxhuma kanye nokuxhumana. Lokhu kucatshangelwa kubalulekile ukuze kuqinisekiswe ukuguquguquka, ukuqina, kanye nokusebenza kwamasekhethi aguqukayo ezinhlelo zokusebenza ezihlukahlukene.

2.1 I-substrate material:

I-substrate material yebhodi lesifunda eliguquguqukayo iyingxenye ebalulekile ehlinzeka ngokuzinza, ukuguquguquka, nokufakwa kukagesi. Izinto ezijwayelekile ze-substrate zifaka i-polyimide (PI), i-polyester (PET), ne-polyethylene naphthalate (PEN). Lezi zinto zinezici ezinhle kakhulu zemishini futhi zingamelana namazinga okushisa aphezulu, zizenze zilungele izinhlelo zokusebenza eziningi.

Ukukhethwa kwezinto ezibonakalayo ze-substrate kuncike ezidingweni ezithile zebhodi lesifunda, njengokuguquguquka, ukumelana nokushisa nokumelana namakhemikhali. Ama-Polyimides ngokuvamile athandwa ngenxa yokuguquguquka okuphakeme, kuyilapho ama-polyester ethandwa ngenxa yezindleko zawo kanye nezakhiwo ezinhle zikagesi. I-polyethylene naphthalate yaziwa ngokuzinza kwayo okuhle kakhulu nokumelana nomswakama.

2.2 Imikhondo elandelwayo:

Imikhondo ye-conductive izindlela ezithwala amasignali kagesi phakathi kwezingxenye ezihlukene ebhodini lesekethe eliguquguqukayo. Lezi zinsalela ngokuvamile zenziwe ngethusi, eline-conductivity kagesi enhle kanye nokunamathela okuhle kakhulu ku-substrate material. Ukulandelelwa kwethusi kwenziwa iphethini ku-substrate kusetshenziswa amasu anjenge-etching noma ukuphrinta kwesikrini. Kwezinye izimo, ukuze kuthuthukiswe ukuguquguquka kwesifunda, imikhondo yethusi ingancishiswa ngenqubo ebizwa ngokuthi i- selective thinning noma i-microetching. Lokhu kusiza ukukhulula ingcindezi kumjikelezo oguqukayo ngesikhathi sokugoba noma ukugoqa.

2.3 I-Protective coating:

Ukuze uvikele imikhondo ye-conductive ezicini zangaphandle ezifana nomswakama, uthuli noma ukucindezeleka kwemishini, i-coating yokuzivikela isetshenziswa kumjikelezo. Lokhu kunamathela kuvame ungqimba oluncane lwe-epoxy noma i-polymer ekhethekile eguquguqukayo. I-coating evikelayo ihlinzeka nge-insulation kagesi futhi yandisa ukuqina nokuphila kwesevisi yesifunda. Ukukhethwa kokugqoka okuvikelekile kuncike ezintweni ezifana nokumelana nokushisa, ukumelana namakhemikhali kanye nezidingo zokuguquguquka. Kumasekhethi adinga ukusebenza kwezinga lokushisa eliphezulu, izigqoko ezikhethekile ezimelana nokushisa ziyatholakala.

2.4 Imbondela:

Imbondela izendlalelo ezengeziwe ezibekwe phezu kwamasekhethi aguquguqukayo ukuze kuvikelwe futhi kuhlanganiswe. Ngokuvamile kwenziwa ngezinto eziguquguqukayo ezifana ne-polyimide noma i-polyester. Ukumboza kusiza ukuvikela ekulimaleni kwemishini, ukungena komswakama kanye nokuchayeka kwamakhemikhali. Isembozo ngokuvamile siboshelwa kumjikelezo oguquguqukayo kusetshenziswa i-adhesive noma inqubo yokubopha okushisayo. Kubalulekile ukuqinisekisa ukuthi ukumbozwa akukhawuli ukuguquguquka kwesifunda.

2.5 Izingxenye nezindlela zokukhweza:

Amabhodi wesekethe aguquguqukayo angabamba izinhlobonhlobo zezingxenye ezihlanganisa ukumelana, ama-capacitor, amadivayisi wokukhweza phezulu (ama-SMD) namasekethe ahlanganisiwe (ama-IC). Izingxenye zifakwe kumjikelezo oguquguqukayo kusetshenziswa amasu afana nobuchwepheshe bokukhweza komhlaba (SMT) noma ukukhweza ngembobo. Izingxenye ze-Surface Mount zidayiswa ngokuqondile emithonjeni ye-conductive ye-flex circuit. Imikhondo yezingxenye ze- through-hole ifakwa emigodini ebhodini lesifunda futhi ithengiswa ngakolunye uhlangothi. Amasu okukhweza akhethekile avame ukudingeka ukuze kuqinisekiswe ukunamathela okufanele kanye nokuzinza kwemishini kwama-flex circuits.

2.6 Izindawo zokuxhuma kanye nezindawo:

Amabhodi esekethe aguquguqukayo ngokuvamile anezindawo zokuxhuma noma izixhumanisi lapho izixhumi noma izintambo zingaxhunywa. Lezi zindawo zokuxhuma zivumela isifunda se-flexible ukuthi sihlangane namanye amasekhethi noma amadivaysi. Izixhumi zingathengiswa noma zifakwe ngomshini ku-flex circuit, zinikeze uxhumano oluthembekile phakathi kwe-flex circuit kanye nezingxenye zangaphandle. Lezi zindawo zokuxhuma zenzelwe ukumelana nokucindezeleka kwemishini phezu kwempilo ye-flex circuit, ukuqinisekisa ukusebenza okuthembekile, okuqhubekayo.

3.Izinzuzo zamabhodi esekethe aguquguqukayo:

amabhodi wesifunda aguquguqukayo anezinzuzo eziningi ezihlanganisa ukucatshangelwa kobukhulu nesisindo, ukuguquguquka okuthuthukisiwe nokugoba, ukusetshenziswa kwendawo, ukwethembeka okukhulayo nokuhlala isikhathi eside, ukuphumelela kwezindleko, ukuhlanganisa nokuhlanganisa okulula, ukuchithwa okungcono kokushisa kanye nezinzuzo zemvelo. Lezi zinzuzo zenza amabhodi esekethe aguquguqukayo abe yinketho ekhangayo ezimbonini ezahlukahlukene nezinhlelo zokusebenza emakethe yanamuhla ye-elekthronikhi.

3.1 Ubukhulu Nesisindo Amanothi:

Ngokuphathelene nobukhulu nesisindo, amabhodi wesifunda aguquguqukayo anezinzuzo ezibalulekile. Ngokungafani namabhodi esekethe aqinile, ama-flex circuits angaklanywa ukuthi alingane nezikhala eziqinile, amakhona, noma agoqwe noma agoqwe. Lokhu kwenza amadivaysi e-elekthronikhi akwazi ukubumbana futhi angasindi, okuwenza alungele izinhlelo zokusebenza lapho usayizi nesisindo kubaluleke kakhulu, njengobuchwepheshe obugqokekayo, i-aerospace kanye nezimboni zezimoto.

Ngokususa isidingo sezixhumi ezinkulu namakhebuli, amasekhethi aguqukayo anciphisa usayizi nesisindo samaqoqo kagesi, okuvumela imiklamo ephathekayo nesitayela ngaphandle kokuphazamisa ukusebenza.

3.2 Ukuvumelana nezimo okuthuthukisiwe nokugoba:

Enye yezinzuzo eziyinhloko zamabhodi wesifunda aguquguqukayo yikhono lawo lokugoba nokugoba ngaphandle kokuphuka. Lokhu kuvumelana nezimo kuvumela ukuhlanganiswa kwezinto zikagesi ezindaweni ezigobile noma ezinomumo ongajwayelekile, okuwenza afaneleke izinhlelo zokusebenza ezidinga imiklamo ehlelekile noma enezinhlangothi ezintathu. Amasekhethi e-Flex angagotshwa, agoqwe futhi asonteke ngaphandle kokuphazamisa ukusebenza kwawo. Lokhu kuvumelana nezimo kunenzuzo ikakhulukazi ezinhlelweni zokusebenza lapho amasekhethi adinga ukungena ezindaweni ezilinganiselwe noma alandele izimo eziyinkimbinkimbi, ezifana nemishini yezokwelapha, amarobhothi, nogesi wabathengi.

3.3 Ukusetshenziswa Kwendawo:

Uma kuqhathaniswa namabhodi esekethe aqinile, amabhodi esekethe aguquguqukayo anendawo ephakeme yokusebenzisa. Imvelo yabo encane nelula ivumela ukusetshenziswa kahle kwendawo etholakalayo, okuvumela abaklami ukuthi bakhulise ukusetshenziswa kwengxenye futhi banciphise usayizi wabo wonke wamadivayisi kagesi. Amasekhethi aguquguqukayo angaklanywa ngezendlalelo eziningi, okuvumela ukujikeleza okuyinkimbinkimbi nokuxhumana kuzici zefomu elihlangene. Lesi sici sizuzisa kakhulu ezinhlelweni zokusebenza eziminyana kakhulu, njengama-smartphones, amaphilisi, namadivayisi we-IoT, lapho isikhala siphezulu futhi kubalulekile ukwenza okuncane.

3.4 Thuthukisa ukwethembeka nokuqina:

Amabhodi esekethe aguquguqukayo anokwethenjelwa kakhulu futhi ahlala isikhathi eside ngenxa yamandla awo emishini engokwemvelo kanye nokumelana nokudlidliza, ukushaqeka nokuhamba ngebhayisikili okushisayo. Ukungabikho kwamajoyinti e-solder, izixhumi nezintambo kunciphisa ingozi yokuhluleka kwemishini futhi kwandisa ukuthembeka okuphelele kohlelo lwe-elekthronikhi. Ukuguquguquka kwesekethe nakho kusiza ukumunca nokusabalalisa ukucindezeleka komshini, ukuvimbela ukuphuka noma ukuhluleka kokukhathala. Ngaphezu kwalokho, ukusebenzisa i-substrate impahla eguquguqukayo enokuqina okuhle kakhulu kwe-thermal kwenza ukusebenza okuthembekile ngisho nangaphansi kwezimo zokusebenza ezinzima.

3.5 Ukusebenza kahle kwezindleko:

Uma kuqhathaniswa namabhodi esifunda aqinile endabuko, amabhodi esekethe aguquguqukayo angonga izindleko ngezindlela eziningi. Okokuqala, usayizi wabo ohlangene kanye nemvelo engasindi kunciphisa impahla kanye nezindleko zokuthumela. Ukwengeza, ukuqedwa kwezixhumi, izintambo, namajoyinti e-solder kwenza inqubo yokuhlanganisa ibe lula, kunciphisa izindleko zabasebenzi nezokukhiqiza. Ikhono lokuhlanganisa amasekethe amaningi kanye nezingxenye ebhodini lesifunda elilodwa eliguquguqukayo liphinde linciphise isidingo sezintambo ezengeziwe nezinyathelo zokuhlanganisa, okuqhubeka nokunciphisa izindleko zokukhiqiza. Ukwengeza, ukuguquguquka kwesifunda kuvumela ukusetshenziswa ngokuphumelelayo kwesikhala esitholakalayo, okungenzeka kunciphise isidingo sezendlalelo ezengeziwe noma amabhodi amakhulu wesifunda.

3.6 Kulula ukuhlanganisa nokuhlanganisa:

Uma kuqhathaniswa namabhodi aqinile, amabhodi wesifunda aguquguqukayo kulula ukuhlanganisa nokuhlanganisa kumadivayisi kagesi. Ukuvumelana nezimo kwazo kuvumela ukufakwa kalula ezindaweni ezivalekile noma ezindaweni ezivalekile ezinokwakheka okungavamile. Ukungabikho kwezixhumi nezintambo kwenza inqubo yokuhlanganisa ibe lula futhi kunciphisa ubungozi bokuxhuma okungalungile noma okungalungile. Ukuvumelana nezimo kwamasekethe kuphinde kusize izindlela zokuhlanganisa ezizenzakalelayo, njengemishini yokukhetha nendawo nokuhlanganisa amarobhothi, ukukhulisa umkhiqizo kanye nokunciphisa izindleko zabasebenzi. Ukulula kokuhlanganiswa kwenza amabhodi esekethe aguquguqukayo abe inketho ekhangayo kubakhiqizi abafuna ukwenza lula inqubo yabo yokukhiqiza.

3.7 Ukukhipha ukushisa:

Uma kuqhathaniswa namabhodi esekethe aqinile, amabhodi esekethe aguquguqukayo anokusebenza okungcono kokukhipha ukushisa. Imvelo encane nelula yezinto eziguquguqukayo ze-substrate yenza ukudluliselwa kokushisa okuphumelelayo, ukunciphisa ingozi yokushisa nokuthuthukisa ukwethembeka okuphelele kwezinhlelo ze-elekthronikhi. Ukwengeza, ukuguquguquka kwesekethe kuvumela ukuphathwa okungcono kwe-thermal ngokuklama izingxenye futhi uzibeke lapho zilungele ukuchithwa kokushisa. Lokhu kubaluleke kakhulu ekusetshenzisweni kwamandla aphezulu noma ezindaweni ezinokugeleza komoya okulinganiselwe lapho ukuphathwa okushisayo okufanelekile kubalulekile ukuze kuqinisekiswe impilo ende nokusebenza kwemishini kagesi.

3.8 Izinzuzo zemvelo:

Uma kuqhathaniswa namabhodi endabuko aqinile, amabhodi wesifunda aguquguqukayo anezinzuzo zemvelo. Ukusebenzisa izinto eziguquguqukayo ze-substrate njenge-polyimide noma i-polyester kulungele imvelo kunokusebenzisa izinto eziqinile njenge-fiberglass noma i-epoxy.

Ukwengeza, usayizi ohlangene kanye nemvelo engasindi yamasekhethi aguquguqukayo kunciphisa inani lempahla edingekayo, ngaleyo ndlela kunciphisa ukukhiqizwa kukadoti. Izinqubo zokuhlanganisa ezenziwe lula nezixhumi ezimbalwa namakhebuli nakho kusiza ukunciphisa ukukhiqizwa kwe-e-waste.

Ukwengeza, ukusetshenziswa kahle kwesikhala kanye namandla okwenza i-miniaturization yamabhodi wesifunda aguquguqukayo kunganciphisa ukusetshenziswa kwamandla ngesikhathi sokusebenza, kubenze basebenzise amandla kakhudlwana futhi bangabi nemvelo.

4.Ukusetshenziswa kwebhodi lesifunda eliguquguqukayo:

amabhodi wesifunda aguquguqukayo anezinhlobonhlobo zezicelo ezimbonini ezihlukahlukene, okuhlanganisa ugesi wabathengi, imboni yezimoto, ukunakekelwa kwezempilo, i-aerospace nokuzivikela, i-automation yezimboni, ubuchwepheshe obugqokekayo, amadivaysi e-IoT, ukubonisa okuguquguqukayo kanye nezinhlelo zokukhanyisa, kanye nezinhlelo zokusebenza zesikhathi esizayo. Ngosayizi wabo ohlangene, ukuguquguquka kanye nezinye izici eziningi ezithandekayo, amabhodi esekethe aguquguqukayo azodlala indima ebalulekile ekuthuthukisweni kobuchwepheshe kanye nokwenza ngcono ukusebenza kanye nolwazi lomsebenzisi lwemishini kagesi.

4.1 I-Consumer Electronics:

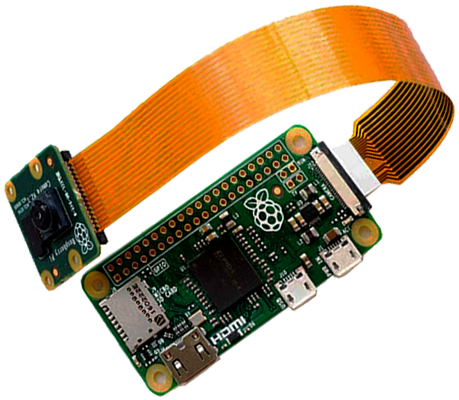

Amabhodi esekethe aguquguqukayo asetshenziswa kakhulu kuma-electronics abathengi ngenxa yobukhulu bawo obuhlangene, isisindo esilula, nekhono lokungena ezindaweni eziqinile. Asetshenziswa kuma-smartphones, amaphilisi, amakhompyutha aphathekayo, namadivayisi agqokekayo njengamawashi ahlakaniphile nezilandeleli zokuqina. Amasekhethi aguqukayo anika amandla ukuklanywa kwezinto zikagesi eziphathwayo ezisesitayeleni ngaphandle kokufaka engozini ukusebenza.

4.2 Imboni Yezimoto:

Amabhodi esekethe aguqukayo asetshenziswa ezimotweni ngezinhlelo zokusebenza ezahlukahlukene, okuhlanganisa amayunithi okulawula injini, izibonisi zedeshibhodi, amasistimu e-infotainment, nokuhlanganiswa kwezinzwa. Ukuvumelana nezimo zabo kuvumela ukuhlanganiswa okulula ezindaweni ezigobile kanye nezikhala eziqinile ngaphakathi kwezimoto, zisebenzisa kahle indawo etholakalayo futhi kunciphise isisindo sisonke.

4.3 Amadivayisi Okunakekelwa Kwezempilo Nezokwelapha:

Ekunakekelweni kwezempilo, amabhodi esekethe avumelana nezimo adlala indima ebalulekile emishinini yezokwelapha efana nezinhliziyo ezishaya inhliziyo, ama-defibrillator, izinsiza-kuzwa, nemishini yokuthwebula yezokwelapha. Ukuvumelana nezimo kwalawa masekethi kuwavumela ukuthi afakwe kumishini yezokwelapha egqokekayo kanye nemiklamo evumelanayo elingana kahle emzimbeni.

4.4 I-Aerospace nokuvikela:

Imboni ye-aerospace neyokuvikela iyazuza ekusebenziseni amabhodi esekethe aguquguqukayo ezinhlelweni ezifana nezibonisi ze-cockpit, okokusebenza kwezokuxhumana, amasistimu e-radar namadivayisi e-GPS. Izici zabo ezingasindi nezivumelana nezimo zisiza ukunciphisa isisindo sisonke futhi zinike amandla ukuhlukahluka komklamo wendiza eyinkimbinkimbi noma izinhlelo zokuzivikela.

4.5 I-Industrial Automation:

Amabhodi esekethe aguquguqukayo angasetshenziswa ezinhlelweni zokulawula ezishintshayo zezimboni, amadrayivu ezimoto kanye namadivayisi wokuzwa. Zisiza ukusebenzisa kahle indawo emishinini yezimboni ezihlangene futhi kulula ukuzifaka nokuhlanganisa emishinini eyinkimbinkimbi.

4.6 Ubuchwepheshe Okugqokayo:

Amabhodi esekethe aguqukayo ayingxenye ebalulekile yobuchwepheshe obugqokekayo njengamawashi ahlakaniphile, izilandeleli zokufaneleka nezingubo ezihlakaniphile. Ukuvumelana nezimo kwabo kuvumela ukuhlanganiswa okulula kumadivayisi agqokekayo, okuvumela ukuqapha idatha ye-biometric kanye nokuhlinzeka ngolwazi lomsebenzisi oluthuthukisiwe.

4.7 Amadivayisi e-inthanethi Yezinto (IoT):

Amabhodi esekethe aguquguqukayo asetshenziswa kakhulu kumadivayisi e-IoT ukuxhuma izinto ezahlukahlukene ku-inthanethi, okubenza bakwazi ukuthumela nokwamukela idatha. Usayizi ohlangene nokuguquguquka kwalawa masekethi kunika amandla ukuhlanganiswa okungenamthungo kumadivayisi e-IoT, okunomthelela ekwenzeni kwawo okuncane kanye nokusebenza kwawo kukonke.

4.8 Isibonisi esiguquguqukayo nokukhanya:

Amabhodi esekethe aguquguqukayo ayizingxenye ezibalulekile zezibonisi eziguquguqukayo nezinhlelo zokukhanyisa. Bangakha izibonisi ezigobile noma ezigobekayo namaphaneli okukhanyisa. Lezi zibonisi eziguquguqukayo zifanele ama-smartphone, amaphilisi, ama-TV nezinye izisetshenziswa zikagesi ezihlukahlukene, ezihlinzeka ngolwazi lomsebenzisi oluthuthukisiwe.

4.9 Izinhlelo zokusebenza zesikhathi esizayo:

Amabhodi esekethe aguquguqukayo anamandla amakhulu wezinhlelo zokusebenza zesikhathi esizayo. Ezinye izindawo ezibalulekile lapho kulindeleke ukuthi zibe nomthelela omkhulu zihlanganisa:

Izinto zikagesi ezigoqekayo nezigoqekayo:

Amasekhethi aguquguqukayo azosiza ukuthuthukiswa kwama-smartphones agoqekayo, amaphilisi kanye namanye amadivaysi, okuletha amazinga amasha okuphatheka nokuba lula.

Amarobhothi athambile:

Ukuvumelana nezimo kwamabhodi esekethe kuvumela ukuhlanganiswa kwezinto zikagesi zibe izinto ezithambile neziguquguqukayo, okuvumela ukuthuthukiswa kwezinhlelo zamarobhothi ezithambile ezinokuguquguquka okuthuthukisiwe nokuzivumelanisa nezimo.

I-Smart Textiles:

Amasekhethi aguqukayo angahlanganiswa abe yindwangu ukuze kuthuthukiswe izindwangu ezihlakaniphile ezikwazi ukuzwa futhi ziphendule izimo zemvelo.

Isitoreji samandla:

Amabhodi esekethe aguquguqukayo angahlanganiswa kumabhethri aguquguqukayo, okuvumela ukuthuthukiswa kwezixazululo zesitoreji samandla ezingasindi, ezivumelanayo zama-elekthronikhi aphathekayo namadivayisi agqokekayo.

Ukuqapha kwemvelo:

Ukuguquguquka kwalezi zifunda kungasekela ukuhlanganiswa kwezinzwa kumadivayisi okuqapha imvelo, kube lula ukuqoqwa kwedatha yezinhlelo zokusebenza ezihlukahlukene ezifana nokulandelela ukungcola nokuqapha isimo sezulu.

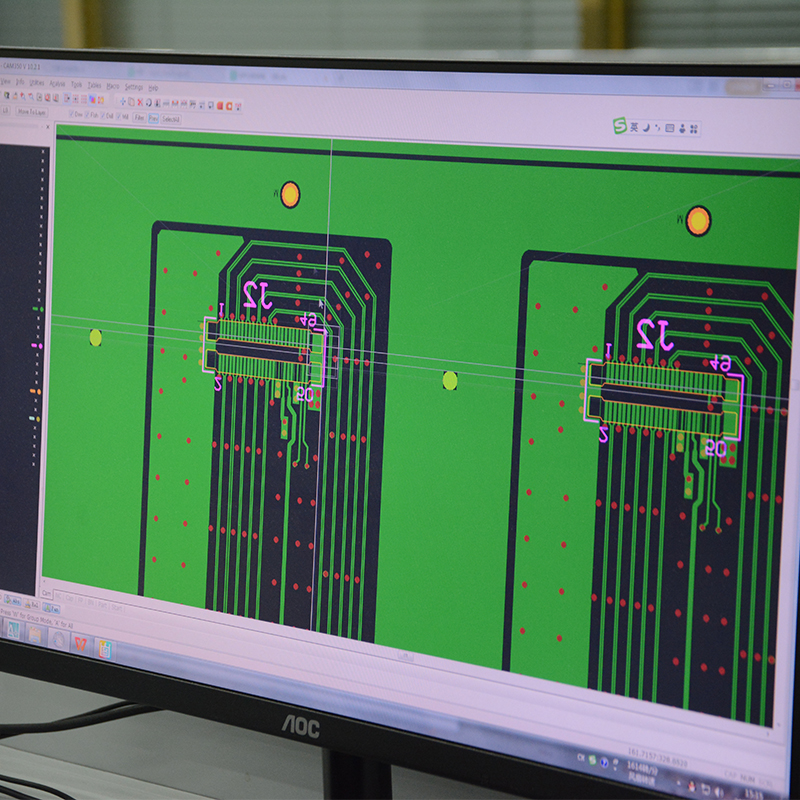

5.Ukucatshangelwa Okubalulekile Kwedizayini Yebhodi Lesifunda Eguqukayo

Ukuklama ibhodi lesifunda eliguquguqukayo kudinga ukucatshangelwa ngokucophelela kwezinto ezihlukahlukene ezifana nomklamo wokwenziwa, izidingo zokuguquguquka kanye ne-bend radius, ubuqotho besignali kanye ne-crosstalk, ukukhethwa kwesixhumi, ukucatshangelwa kwemvelo, ukuhlola, nokukhiqiza. Ngokubhekana nalokhu kucatshangelwa okubalulekile, abaklami bangaqinisekisa ukuqaliswa okuphumelelayo kwamabhodi wesifunda aguquguqukayo ezinhlobonhlobo zezinhlelo zokusebenza ngenkathi kugcinwa ukusebenza, ukwethembeka, kanye nekhwalithi.

5.1 I-Design for Manufacturability (DFM):

Uma uklama ibhodi lesifunda le-flex, kubalulekile ukucabangela ukukhiqizwa. Lokhu kuhilela ukuklama amabhodi esekethe ngendlela yokuthi angenziwa ngempumelelo nangempumelelo. Okunye okucatshangelwayo okubalulekile kwe-DFM kuhlanganisa:

Ukubekwa kwengxenye:

Beka izingxenye ebhodini lesifunda eliguquguqukayo ngendlela elula ukuhlanganisa nokuthengisa.

Landelela Ububanzi Nezikhala:

Qinisekisa ukuthi ububanzi bokulandelela kanye nesikhala kuyahlangabezana nezidingo zokukhiqiza futhi kungakhiqizwa ngendlela enokwethenjelwa ngesikhathi sokukhiqiza.

Ukubalwa Kwesendlalelo:

Ukuthuthukisa inani lezendlalelo ebhodini lesekethe eliguquguqukayo ukuze kuncishiswe inkimbinkimbi yokukhiqiza kanye nezindleko.

Iphaneli:

Ukuklama amabhodi esekethe aguquguqukayo ngendlela evumela ukufakwa kwephaneli okusebenzayo ngesikhathi sokukhiqiza. Lokhu kuhilela ukubeka amabhodi esekethe amaningi kuphaneli eyodwa ukuze kwandiswe ukusebenza kahle ngesikhathi somhlangano.

5.2 Ukuguquguquka nokugoba irediyasi:

Ukuguquguquka kwamabhodi wesifunda se-flex kungenye yezinzuzo zayo eziyinhloko. Lapho uklama ibhodi, kubalulekile ukucabangela ukuguquguquka okudingekayo kanye ne-radius yokugoba encane. Irediyasi egobile isho irediyasi encane kakhulu ibhodi lesekethe eliguquguqukayo elingakwazi ukugoba ngaphandle kokudala umonakalo noma ukubeka engcupheni ukusebenza kwebhodi. Ukuqonda izakhiwo zezinto ezibonakalayo kanye nemikhawulo kubalulekile ukuze kuqinisekiswe ukuthi ibhodi lingakwazi ukuhlangabezana nezimfuneko zokuguquguquka ezidingekayo kanye nezimfuneko zerediyasi egobayo ngaphandle kokuphazamisa ukusebenza kwayo.

5.3 Ubuqotho Besiginali neCrosstalk:

Ubuqotho besignali buwukucatshangelwa okubalulekile ekwakhiweni kwebhodi lesifunda eliguqukayo. Izimpawu zejubane eliphezulu ezihamba ngamabhodi esekethe kufanele zigcine ikhwalithi nobuqotho bazo ukuze kuqinisekiswe ukusebenza okuthembekile. Umzila wesignali ofanele, ukulawulwa kokuvinjelwa, kanye nomklamo wendiza yaphansi kubalulekile ukuze kuncishiswe ukulahlekelwa kwesignali nokugcina ubuqotho besignali. Ukwengeza, i-crosstalk (ukuphazamiseka phakathi kwemikhondo eseduze) kufanele ilawulwe ngokucophelela ukuze kuvinjelwe ukuwohloka kwesignali. Izikhala ezifanele kanye namasu okuvikela asiza ukunciphisa i-crosstalk futhi athuthukise ikhwalithi yesignali.

5.4 Ukukhetha Isixhumi:

Izixhumi zidlala indima ebalulekile ekusebenzeni jikelele nasekuthembekeni kwamabhodi esekethe aguquguqukayo. Lapho ukhetha isixhumi, kubalulekile ukucabangela izici ezilandelayo:

Ukuhambisana:

Qinisekisa ukuthi isixhumi sihambisana nebhodi lesifunda se-flex futhi singaxhuma ngokuthembekile ngaphandle kokulimaza ibhodi.

Amandla Emishini:

Khetha izixhumi ezingamelana nokucindezeleka komshini nokugoba okuhambisana namabhodi aguquguqukayo.

Ukusebenza kukagesi:

Khetha izixhumi ezinokulahleka kokufakwa okuphansi, ubuqotho besignali enhle, nokudluliswa kwamandla okuphumelelayo.

Ukuqina:

Khetha izixhumi ezihlala isikhathi eside futhi ezikwazi ukumelana nezimo zemvelo lapho kuzosetshenziswa khona ibhodi eliguquguqukayo. Ukuhlanganisa kalula: Khetha izixhumi okulula ukuzihlanganisa ebhodini lesifunda eliguquguqukayo ngesikhathi sokukhiqiza.

5.5 Ukucatshangelwa kwemvelo:

Amabhodi wesifunda aguquguqukayo avame ukusetshenziswa ezinhlelweni ezingase zivezwe ezimweni ezinzima zemvelo. Kubalulekile ukucabangela izici zemvelo ibhodi elizobhekana nazo futhi liklame ibhodi ngokufanele. Lokhu kungase kuhlanganise okulandelayo:

Ibanga Lokushisa:

Khetha izinto ezingamelana nebanga lokushisa elilindelekile le-ambient.

Ukumelana Nomswakama:

Gcina amabhodi ephephile kumswakama kanye nomswakama, ikakhulukazi ezindaweni lapho amabhodi angase evezwe kumswakama noma ukujiya.

Ukumelana Namakhemikhali:

Khetha izinto ezimelana namakhemikhali okungenzeka akhona endaweni ezungezile.

I-Mechanical Stress and Vibration:

Dizayina amabhodi esekethe ukuze amelane nengcindezi yemishini, ukushaqeka, nokudlidliza okungenzeka ngesikhathi sokusebenza noma sokuthutha.

5.6 Ukuhlola Nokukhiqiza:

Ukucatshangelwa kokuhlola nokukhiqiza kubalulekile ekuqinisekiseni ukwethembeka kanye nekhwalithi yamabhodi wesifunda aguquguqukayo. Okunye okucatshangelwayo okubalulekile kuhlanganisa:

Ukuhlola:

Yakha uhlelo lokuhlola oluphelele ukuze kutholwe noma yikuphi ukukhubazeka noma amaphutha ebhodini lesifunda le-flex ngaphambi kokuba lihlanganiswe libe umkhiqizo wokugcina. Lokhu kungase kuhlanganise ukuhlolwa kukagesi, ukuhlolwa okubonakalayo kanye nokuhlolwa kokusebenza.

Inqubo Yokukhiqiza:

Cabangela inqubo yokukhiqiza futhi uqinisekise ukuthi iyahambisana nomklamo webhodi lesifunda le-flex. Lokhu kungabandakanya ukuthuthukisa izinqubo zokukhiqiza ukuze kuzuzwe isivuno esikhulu nokunciphisa izindleko.

Ikhwalithi yokulawula:

Izinyathelo zokulawula ikhwalithi zisetshenziswa kuyo yonke inqubo yokukhiqiza ukuze kuqinisekiswe ukuthi umkhiqizo wokugcina uhlangabezana namazinga adingekayo kanye nemibandela.

Amadokhumenti:

Amadokhumenti afanelekile emiklamo, izinqubo zokukhiqiza, nezinqubo zokuhlola kubalulekile ukuze kusetshenziswe ireferensi yesikhathi esizayo, ukuxazulula izinkinga, nokuqinisekisa ikhwalithi engaguquki.

6.Amathrendi nekusasa lamabhodi esekethe aguquguqukayo:

Amathrendi esikhathi esizayo amabhodi esekethe avumelana nezimo ukuguqulwa nokudidiyelwa okuncane, ukuthuthuka kwezinto ezibonakalayo, ukuthuthukiswa kobuchwepheshe bokukhiqiza, ukuhlanganiswa okuthuthukisiwe ne-inthanethi Yezinto kanye nobuhlakani bokwenziwa, intuthuko esimeme, kanye nobuchwepheshe bemvelo. Lezi zindlela zizoqhuba ukuthuthukiswa kwamabhodi esekethe amancane, adidiyelwe, avumelana nezimo ukuze ahlangabezane nezidingo eziguqukayo zezimboni ezihlukahlukene.

6.1 I-Miniaturization kanye nokuhlanganiswa:

Enye yezinto ezihamba phambili kumabhodi esekethe aguquguqukayo wukuqhubekela phambili kwe-miniaturization kanye nokuhlanganiswa. Njengoba ubuchwepheshe buthuthuka, kunesidingo esikhulayo semishini ye-elekthronikhi emincane, engasindi, futhi ehlangene kakhudlwana. Inzuzo yamabhodi esekethe aguquguqukayo yikhono lawo lokwenziwa ngezindlela ezihlukahlukene zomumo nosayizi, okuvumela ukuguquguquka okukhulu komklamo. Ngokuzayo, silindele ukubona amabhodi esekethe amancane, ahlanganiswe kakhudlwana avumelana nezimo, esiza ukuthuthukiswa kobuchwepheshe obusha nokonga isikhala.

6.2 Ukuthuthukiswa kwezinto zokwakha:

Ukuthuthukiswa kwezinto ezintsha kungenye inkambiso ebalulekile embonini yebhodi lesifunda eguquguqukayo. Izinto ezinezici ezithuthukisiwe ezifana nokuguquguquka okukhulu, ukuphathwa okushisayo okuthuthukisiwe kanye nokuqina okwenyukayo ziyacwaningwa futhi ziyathuthukiswa. Isibonelo, izinto ezinokumelana nokushisa okuphezulu zingenza ama-flex pcbs asetshenziswe ezinhlelweni lapho amazinga okushisa aphakeme ekhona. Ngaphezu kwalokho, ukuthuthukiswa kwezinto zokwenziwa kuphinde kwakhuthaza ukuthuthukiswa kokusebenza kwamabhodi esekethe aguquguqukayo.

6.3 Ubuchwepheshe Bokukhiqiza Obuthuthukisiwe:

Izinqubo zokukhiqiza zamabhodi esekethe aguquguqukayo ziyaqhubeka nokuthuthuka ukuze kwandiswe ukusebenza kahle kanye nesivuno. Intuthuko kubuchwepheshe bokukhiqiza obufana nokucubungula i-roll-to-roll, ukukhiqiza okungeziwe, nokuphrinta kwe-3D kuyahlolwa. Lobu buchwepheshe bungasheshisa ukukhiqiza, ukunciphisa izindleko futhi kwenze inqubo yokukhiqiza ikhule kakhulu. Ukusetshenziswa kwe-automation kanye namarobhothi nakho kusetshenziselwa ukwenza lula inqubo yokukhiqiza nokwandisa ukunemba.

6.4 Qinisa ukuhlanganiswa ne-inthanethi Yezinto kanye nobuhlakani bokwenziwa:

Amabhodi esekethe aguquguqukayo aya ngokuya ehlanganiswa namadivayisi we-inthanethi Yezinto (IoT) kanye nobuchwepheshe bobuhlakani bokwenziwa (AI). Amadivayisi e-IoT ngokuvamile adinga amabhodi avumelana nezimo angahlanganiswa kalula ezintweni ezigqokekayo, izinzwa zasekhaya ezihlakaniphile, namanye amadivaysi axhunyiwe. Ukwengeza, ukuhlanganiswa kobuchwepheshe be-AI kuqhuba ukuthuthukiswa kwamabhodi esekethe aguquguqukayo anamakhono aphezulu okucubungula kanye nokuxhumana okuthuthukisiwe kwe-edge computing kanye nezinhlelo zokusebenza eziqhutshwa yi-AI.

6.5 Intuthuko Esimeme kanye Nobuchwepheshe Bendawo:

Amathrendi kubuchwepheshe obuzinzile nobunobungani bemvelo nawo anomthelela embonini yebhodi lesifunda eguquguqukayo. Kuyakhula ukugxila ekuthuthukiseni izinto ezivumelana nemvelo nezigaywa kabusha zamabhodi esekethe aguquguqukayo, kanye nokuqalisa izinqubo zokukhiqiza ezisimeme. Ukusebenzisa amandla avuselelekayo kanye nokunciphisa imfucuza kanye nomthelela wemvelo yizinto ezibalulekile zokucatshangelwa kwekusasa lebhodi lesifunda le-flex.

Ngokufigqiwe,amabhodi esekethe aguquguqukayo aguqule imboni ye-elekthronikhi ngokunika amandla ukuguquguquka okukhulu kwedizayini, i-miniaturization, kanye nokuhlanganiswa okungenamthungo kwezingxenye ze-elekthronikhi. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, amabhodi esekethe avumelana nezimo kulindeleke ukuthi abambe iqhaza elibalulekile ekuqhubekiseni ukuqanjwa kabusha nokuthuthukiswa kwezinhlelo zokusebenza ezisafufusa. Kwabaqalayo abangena emkhakheni we-electronics, kubalulekile ukuqonda izisekelo zamabhodi wesifunda se-flex. Ngokuguquguquka nezici ezihlukile, i-flexpcb inikeza amathuba angapheli okuklama izinto zikagesi zesizukulwane esilandelayo njengobuchwepheshe obugqokekayo, izisetshenziswa zezokwelapha, amadivayisi we-IoT, nokuningi. Ngaphezu kwalokho, amabhodi wesifunda aphrintiwe aguquguqukayo awazuzi nje kuphela ekwakhiweni komkhiqizo, kodwa futhi nasekuthuthukiseni izinqubo zokukhiqiza. Ikhono lazo lokwenziwa ngezinhlobo ezihlukahlukene zomumo nosayizi futhi lihambisana nezindlela ezithuthukisiwe zokukhiqiza azenza zilungele ukukhiqiza okuphumelelayo nokungabizi. Uma ubheka phambili, kuyacaca ukuthi ibhodi le-pcb eliguquguqukayo lizoqhubeka nokuvela futhi lithuthuke. Ukuthuthuka kwezinto zokwakha, amasu okukhiqiza, kanye nokuhlanganiswa nobunye ubuchwepheshe obufana ne-IoT kanye nobuhlakani bokwenziwa kuzothuthukisa amakhono abo kanye nezinhlelo zokusebenza. Sithemba ukuthi lo mhlahlandlela ophelele ukunikeze imininingwane ebalulekile emhlabeni we-fpc flexible printed circuit. Uma uneminye imibuzo noma udinga usizo ngamabhodi esekethe aguquguqukayo nanoma yisiphi esinye isihloko, sicela ukhululeke ukusithinta. Silapha ukuze sisekele izifundo zakho futhi sikusize udizayine izixazululo ezintsha.

I-Shenzhen Capel Technology Co., Ltd. ibikhiqiza amabhodi esekethe aguquguqukayo kusukela ngo-2009. Sinefektri yethu enabasebenzi abangu-1500 futhi siqongelele isipiliyoni seminyaka engu-15 embonini yebhodi lesifunda. Ithimba lethu le-R&D lakhiwe ngochwepheshe bezobuchwepheshe abangaphezu kuka-200 abaneminyaka engu-15 yesipiliyoni futhi sinemishini ethuthukisiwe, ubuchwepheshe obusha, amandla enqubo yokuvuthwa, inqubo yokukhiqiza eqinile kanye nesistimu yokulawula ikhwalithi ephelele. Kusukela ekuhlolweni kwefayela lokuklama, ukuhlolwa kokukhiqizwa kwebhodi lesifunda se-prototype, ukukhiqizwa kwenqwaba encane kuya ekukhiqizeni ngobuningi, imikhiqizo yethu yekhwalithi ephezulu, enembayo iqinisekisa ukubambisana okushelelayo nokujabulisayo namakhasimende. Amakhasimende ethu amaphrojekthi aqhubeka kahle futhi ngokushesha, futhi sijabule ngokuqhubeka nokuletha inani lawo.

Isikhathi sokuthumela: Aug-30-2023

Emuva