Amabhodi esekethe aphrintiwe aguqukayo (ama-PCB), abuye aziwe ngokuthi ama-PCB aguqukayo, asedume kakhulu eminyakeni yamuva nje ngenxa yamakhono awo ahlukile okugoba nokusonta. Lawa mabhodi esekethe aguquguqukayo ashintshashintsha kakhulu futhi athola izinhlelo zokusebenza ezimbonini eziningi, ezihlanganisa ezezimoto, ugesi wabathengi, ukunakekelwa kwezempilo, kanye nezokuxhumana. Lapho u-oda ama-PCB aguquguqukayo, kubalulekile ukuqonda izici ezithinta amanani awo ukuze kuzuzwe ukusebenza kahle kwezindleko nokusebenza kahle.Kulesi sihloko, sizocubungula izici ezibalulekile ezithonya ikhotheshini ye-PCB eguquguqukayo, ekuvumela ukuthi wenze izinqumo ezinolwazi lapho ufaka ama-oda. Ngokuthola ulwazi ngalezi zici, ungakwazi ukwandisa isabelomali sakho futhi uqinisekise ukuthi izidingo zakho ze-PCB zihambisana nezidingo zakho ezithile kanye namazinga omkhakha.

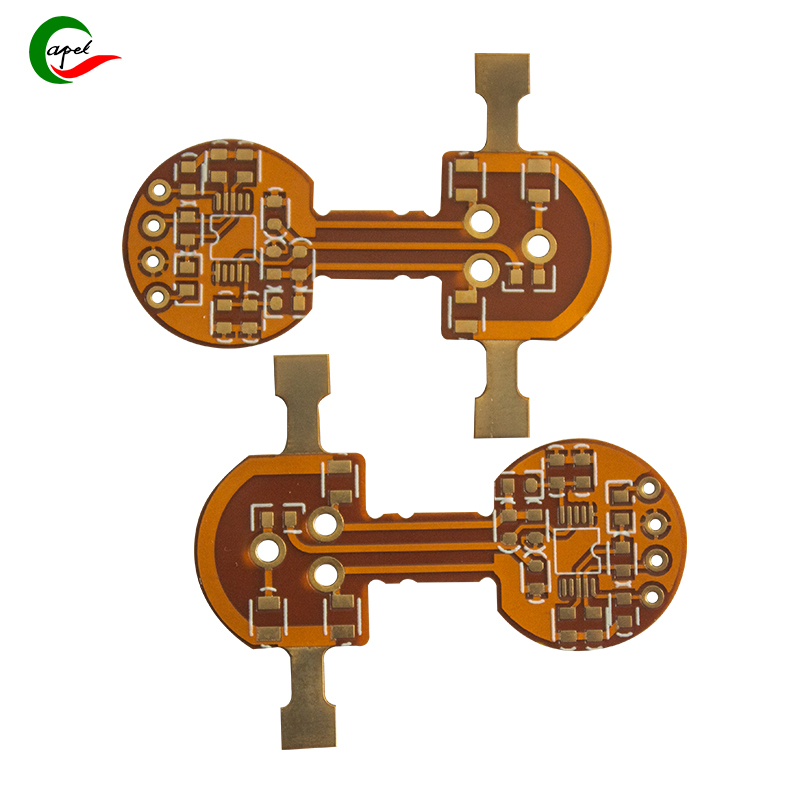

1.I-Design Complexity:Enye yezinto eziyinhloko ezithinta izingcaphuno ze-PCB eziguquguqukayo ubunkimbinkimbi bomklamo.

Ubunkimbinkimbi bomklamo budlala indima ebalulekile ekunqumeni izindleko zokukhiqiza zama-PCB aguquguqukayo. Imiklamo eyinkimbinkimbi ivamise ukubandakanya ukujikeleza okuyinkimbinkimbi, ukusebenza okuthuthukile, nezidingo ezihlukile ezidinga imishini nezinqubo ezikhethekile. Lezi zidingo ezengeziwe zandisa isikhathi nomzamo wokukhiqiza, okuholela ezindlekweni zokukhiqiza eziphakeme.

Esinye sezici zobunzima bomklamo ukusetshenziswa kwezingxenye zephimbo elihle. Izingxenye ze-fine-pitch zinezikhala zokuhola ezincane, ezidinga ukunemba okuphezulu kunqubo yokukhiqiza. Lokhu kudinga amathuluzi akhethekile kanye nezinqubo zokuqinisekisa ukulingana okunembile. Izinyathelo ezengeziwe nezinyathelo zokuphepha ezidingekayo zezingxenye ze-fine-pitch zengeza enkingeni yokukhiqiza kanye nezindleko.

I-bend radii encane ingenye into ethinta ubunkimbinkimbi bomklamo. Amabhodi esekethe aphrintiwe avumelanayo aziwa ngekhono lawo lokugoba nokusonta, kodwa uma i-gobe radii incane kakhulu, lokhu kudala imigoqo enqubweni yokukhiqiza. Ukufeza i-radii encane yokugoba kudinga ukukhethwa kwezinto ngokucophelela kanye nezindlela zokugoba ezinembile ukuze ugweme umonakalo wesifunda noma ukuguqulwa. Lokhu kucatshangelwa okwengeziwe kwandisa inkimbinkimbi yokukhiqiza kanye nezindleko.

Ngaphezu kwalokho, umzila wesifunda oyinkimbinkimbi ungenye into ethinta ubunkimbinkimbi bomklamo. Imiklamo ethuthukisiwe ivamise ukudinga umzila wesignali oyinkimbinkimbi, ukusatshalaliswa kwamandla, nezindiza eziphansi. Ukuthola umzila oqondile kuma-PCB aguquguqukayo kungaba inselele futhi kungase kudinge izinyathelo ezengeziwe ezifana namasu okucwenga ethusi akhethekile noma ukusetshenziswa kwezimbobo eziyimpumputhe nezigqitshiwe. Lezi zidingo ezengeziwe zandisa inkimbinkimbi yokukhiqiza kanye nezindleko.

2.Ukukhetha impahla:Esinye isici esibalulekile ekunqumeni izingcaphuno ze-PCB eziguquguqukayo ukukhetha kwezinto.

Ukukhetha impahla kuwukucatshangelwa okubalulekile ekunqumeni izindleko ze-PCB eguquguqukayo. Ama-substrates ahlukene anikeza amazinga ahlukene okusebenza nomthelela wezindleko. Ukukhethwa kwezinto kuncike ezidingweni ezithile zohlelo lokusebenza.

I-Polyimide (PI) yaziwa ngezici zayo zokusebenza okuphezulu, okuhlanganisa ukuzinza okuhle kakhulu kwe-thermal kanye nokuguquguquka. Ingakwazi ukumelana namazinga okushisa aphezulu futhi ilungele izinhlelo zokusebenza ezinamazinga okushisa aphezulu okusebenza. Kodwa-ke, ukusebenza okuphezulu kwe-polyimide kuza ngezindleko eziphakeme uma kuqhathaniswa nezinye izinto. Lokhu kungenxa yenqubo yokukhiqiza eyinkimbinkimbi futhi ebiza kakhulu yezinto ezingavuthiwe ze-polyimide.

I-Polyester (PET) enye i-substrate evamile yama-PCB aguquguqukayo. Ishibhile kune-polyimide futhi inokuguquguquka okuhle. Ama-PCB e-polyester-based flex flex afanele izinhlelo zokusebenza ezinezidingo eziphansi zokushisa. Nokho, ukuzinza okushisayo kwe-polyester akukuhle njengalokho kwe-polyimide, futhi ukusebenza kwayo jikelele kungase kube phansi. Kuzinhlelo zokusebenza ezingabizi kakhulu ezinezimo zokusebenza ezingadingi kakhulu, ama-polyester ayinketho esebenzayo futhi engabizi.

I-PEEK (i-polyetheretherketone) iyinto esebenza kahle kakhulu esetshenziswa kakhulu ekusetshenzisweni okuyisidingo. Inezakhiwo ezinhle kakhulu zemishini kanye ne-thermal futhi ifanele izimo ezimbi kakhulu. Nokho, i-PEEK ibiza kakhulu kune-polyimide ne-polyester. Ivamise ukukhethelwa izinhlelo zokusebenza lapho kudingeka khona ukusebenza okuphakeme futhi nezindleko eziphezulu zezinto ezibonakalayo zingathethelelwa.

Ngaphandle kwe-substrate material, ezinye izinto ezisetshenziselwa inqubo yokukhiqiza, njengama-laminates, amafilimu ekhava kanye nezinto zokunamathisela, nazo zithinta izindleko eziphelele. Izindleko zalezi zinto ezengeziwe zingahluka kuye ngekhwalithi yazo kanye nezici zokusebenza. Isibonelo, ama-laminates ekhwalithi ephezulu anezinto zikagesi ezithuthukisiwe noma amafilimu ekhava akhethekile anokuvikela okuthuthukisiwe ezicini zemvelo anganezela ezindlekweni eziphelele ze-PCB eguquguqukayo.

3.Ubuningi nendida:Inani le-PCB eguquguqukayo edingekayo lidlala indima ebalulekile ekunqumeni ikhotheshini.

Inani elidingekayo liyisici esikhulu lapho amanani entengo e-flexible PCB. Abakhiqizi bavamise ukuzijwayeza ukwenza amanani asuselwa enanini, okusho ukuthi uma inani liphezulu, izindleko zeyunithi ziyancipha. Lokhu kungenxa yokuthi ama-oda amakhulu avumela umnotho ongcono wesilinganiso futhi ngaleyo ndlela ehlise izindleko zokukhiqiza

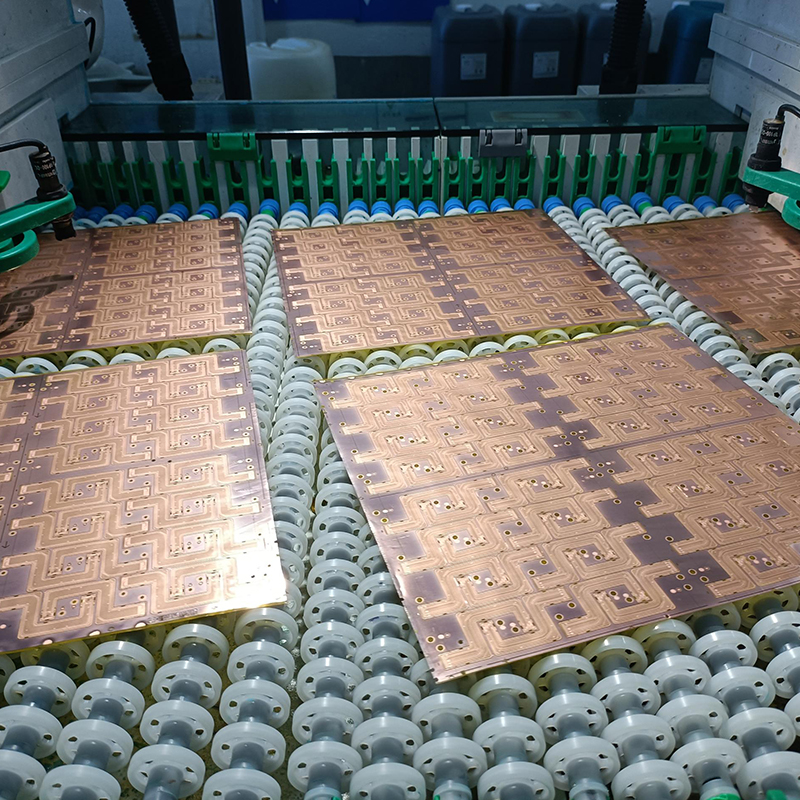

Enye indlela yokuthuthukisa ukusetshenziswa kwezinto ezibonakalayo nokusebenza kahle kokukhiqiza i-panelization. Ukufakwa kwephaneli kuhlanganisa ukuhlanganisa ama-PCB amaningi amancane abe yiphaneli enkulu. Ngokuhlela ngobuchule imiklamo kumaphaneli, abakhiqizi banganciphisa ukumosha futhi bakhulise ukukhiqiza phakathi nenqubo yokukhiqiza.

Iphaneli inezinzuzo eziningana. Okokuqala, kunciphisa udoti wezinto ezibonakalayo ngokusetshenziswa ngokuphumelelayo kwesikhala esitholakala kuphaneli. Esikhundleni sokukhiqiza ama-PCB ahlukene anemingcele yawo kanye nesikhala, abakhiqizi bangabeka amadizayini amaningi kuphaneli eyodwa, basebenzise kakhulu isikhala esingasetshenzisiwe phakathi. Lokhu kubangela ukonga okubalulekile kanye nokwehliswa kwezindleko.

Ngaphezu kwalokho, i-panelization yenza inqubo yokukhiqiza ibe lula. Inika amandla inqubo yokukhiqiza ezenzakalelayo futhi esebenza kahle njengoba ama-PCB amaningi engacutshungulwa kanyekanye. Lokhu kwandisa umkhiqizo futhi kunciphisa isikhathi sokukhiqiza, okuholela ezikhathini zokuhola ezimfushane kanye nezindleko eziphansi. Ukufakwa kwephaneli okusebenzayo kudinga ukuhlela ngokucophelela nokucatshangelwa kwezinto ezifana nosayizi we-PCB, izidingo zokuklama, namandla okukhiqiza. Abakhiqizi bangasebenzisa amathuluzi esoftware akhethekile ukusiza enqubweni yokufakwa kwamaphaneli, baqinisekise ukuqondanisa okuhle nokusetshenziswa kahle kwezinto.

Futhi, ukwakheka kwephaneli kulula ukuphatha nokuthutha. Ngemuva kokuthi inqubo yokukhiqiza isiqediwe, amaphaneli angahlukaniswa abe ama-PCB ngamanye. Lokhu kwenza ukupakisha kube lula futhi kunciphisa ubungozi bokulimala ngesikhathi somkhumbi, okugcina konga imali.

4.I-Surface Finish ne-Copper Weight: I-surface finish kanye nesisindo sethusi yizinto ezibalulekile okumele zicatshangelweinqubo yokukhiqiza ye-PCB eguquguqukayo.

Ukuqedwa okungaphezulu kuyisici esibalulekile sokwenziwa kwe-PCB njengoba kuthinta ngokuqondile ukuthengiswa nokuqina kwebhodi. Ukwelashwa okungaphezulu kwakha isendlalelo esivikelayo phezu kwemikhondo yethusi eveziwe, ukuvimbela i-oxidation nokuqinisekisa amalunga athembekile e-solder. Ukwelashwa okuhlukile okungaphezulu kunezindleko nezinzuzo ezahlukene.

Isiphetho esivamile yi-HASL (Hot Air Solder Leveling), okubandakanya ukusebenzisa ungqimba lwe-solder emithonjeni yethusi bese usebenzisa umoya oshisayo ukuze ulinganise. I-HASL iyonga futhi inikeza ukuthengiselana okuhle, kodwa ingase ingafaneleki izingxenye zephimbo elihle noma ezinephimbo elihle ngenxa yendawo engalingani eyikhiqizayo.

I-ENIG (Electroless Nickel Immersion Gold) ingenye indlela yokwelapha yangaphezulu esetshenziswa kabanzi. Kuhilela ukufaka ungqimba oluncane lwe-nickel phezu kwemikhondo yethusi, kulandelwa ungqimba lwegolide. Ukudayiswa okuhle kwe-ENIG, indawo eyisicaba, nokumelana nokugqwala kuyenza ifaneleke izingxenye ezinephimbo elihle nemiklamo enokuminyana okuphezulu. Kodwa-ke, i-ENIG inezindleko eziphezulu uma iqhathaniswa nezinye izindlela zokwelapha ezingaphezulu.

I-OSP (Organic Solderability Preservative) iwukwelapha okungaphezulu okubandakanya ukusetshenziswa kongqimba oluncane lwento ephilayo ukuze kuvikelwe imikhondo yethusi. I-OSP inikeza ukuthengiselana okuhle, ukuhleleka kanye nokusebenza kahle kwezindleko. Kodwa-ke, ayiqinile njengezinye iziqephu futhi ingadinga ukuphathwa ngokucophelela ngesikhathi sokuhlanganisa.

Isisindo (ngama-ounces) sethusi ku-PCB sinquma ukuqhutshwa nokusebenza kwebhodi. Izendlalelo eziwugqinsi zethusi zinikeza ukumelana okuphansi futhi zingakwazi ukuphatha imisinga ephakeme, zizenze zifanelekele izinhlelo zokusebenza zamandla. Kodwa-ke, izendlalelo zethusi eziminyene zidinga izinto eziningi nezindlela zokukhiqiza eziyinkimbinkimbi, ngaleyo ndlela zikhulise izindleko zizonke ze-PCB. Ngokuphambene, izendlalelo zethusi ezacile zilungele izinhlelo zokusebenza zamandla amancane noma izinhlelo zokusebenza lapho kunezingqinamba zesikhala. Zidinga impahla encane futhi zibiza kakhulu. Ukukhethwa kwesisindo sethusi kuncike ezidingweni ezithile zomklamo we-PCB kanye nomsebenzi ohlosiwe.

5.Ubuchwepheshe Bokukhiqizakanye Nesikhunta:Izindlela zokukhiqiza namathuluzi asetshenziswa ukukhiqiza ama-PCB aguquguqukayo nawo athinta amanani entengo.

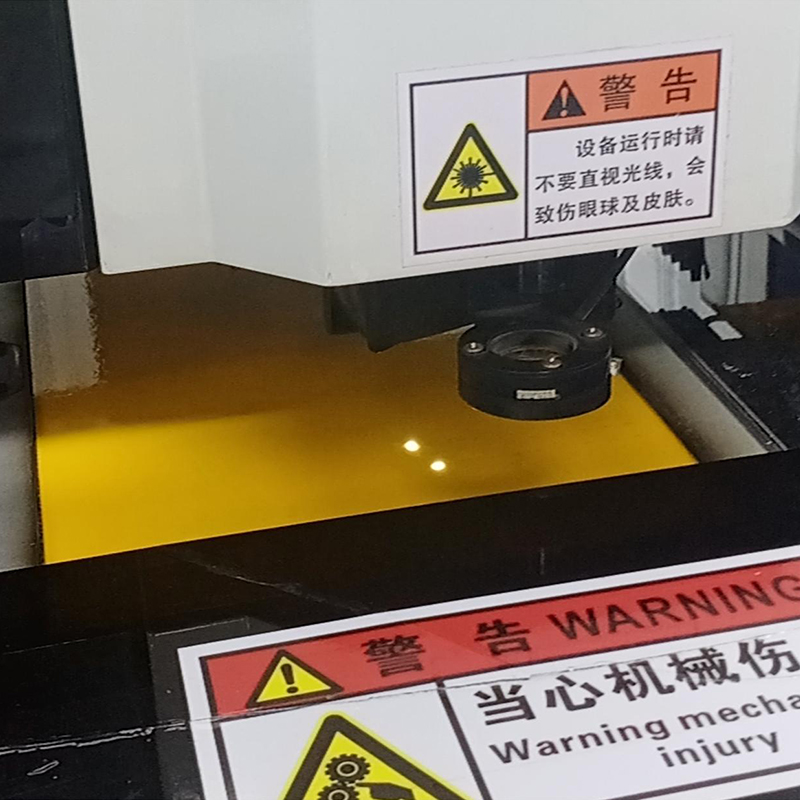

Ubuchwepheshe bokukhiqiza budlala indima ebalulekile ekukhiqizweni kwama-PCB avumelana nezimo futhi bunomthelela omkhulu emananini. Ubuchwepheshe obuthuthukisiwe, obufana nokubhoboza i-laser kanye nokwakheka okulandelanayo (i-SBU), kungakha imiklamo eyinkimbinkimbi nenembayo, kodwa lezi zindlela zivame ukuza nezindleko zokukhiqiza eziphakeme. I-Laser drilling ingakha ama-vias amahle nezimbobo ezincane, okuvumela amasekhethi asondelene kakhulu kuma-PCB aguquguqukayo. Nokho, ukusetshenziswa kobuchwepheshe be-laser kanye nokunemba okudingekayo kule nqubo kwandisa izindleko zokukhiqiza.

I-Sequential build up (i-SBU) ingenye indlela yokukhiqiza ethuthukisiwe ehlanganisa ukuhlanganisa ndawonye amasekhethi amaningi aguquguqukayo ukuze kwakheke imiklamo eyinkimbinkimbi. Lobu buchwepheshe bukhulisa ukuguquguquka komklamo futhi buvumela ukuhlanganiswa kwemisebenzi ehlukahlukene ku-PCB eyodwa eguquguqukayo. Nokho, ubunkimbinkimbi obengeziwe enqubweni yokukhiqiza kwandisa izindleko zokukhiqiza.

Ngokungeziwe kumasu okukhiqiza, izinqubo ezithile ezihilelekile ekukhiqizeni ama-PCB aguquguqukayo nazo zingathinta intengo. Izinqubo ezifana nokucwenga, ukunamathisela, kanye ne-lamination ziyizinyathelo ezibalulekile ekwenziweni kwe-PCB esebenza ngokugcwele nethembekile eguquguqukayo. Izinga lalokhu kwakhiwa, okuhlanganisa izinto ezisetshenziswayo kanye nezinga lokunemba okudingekayo, lithinta izindleko zizonke

Amathuluzi wokuzenzakalela kanye namathuluzi amasha asiza ukwandisa ukukhiqiza nokusebenza kahle enqubweni yokukhiqiza. Imishini ezenzakalelayo, amarobhothi, nezinhlelo zokukhiqiza ezisiza ikhompyutha (CAM) zingenza ukukhiqiza kube lula, kunciphise amaphutha abantu, futhi kusheshise inqubo yokukhiqiza. Kodwa-ke, ukusebenzisa i-automation enjalo kungase kubangele izindleko ezengeziwe, okuhlanganisa ukutshalwa kwezimali kusengaphambili kwemishini nokuqeqeshwa kwabasebenzi.

Ukwengeza, ukusetshenziswa kwamathuluzi nobuchwepheshe obusha, njengesofthiwe yokuklama ye-PCB ethuthukisiwe nemishini yokuhlola, kungasiza ekunyuseni amanani. Lawa mathuluzi avame ukudinga ubuchwepheshe obukhethekile, ukulungiswa kanye nokubuyekezwa, konke okwengeza ezindlekweni zizonke. Abakhiqizi badinga ukucabangela ngokucophelela ibhalansi phakathi kobuchwepheshe bokukhiqiza, izinqubo, ezishintshayo namathuluzi amasha ukuze kuzuzwe izindleko nebhalansi yekhwalithi edingekayo ekukhiqizeni i-PCB eguquguqukayo. Ngokuhlaziya izidingo ezithile zephrojekthi nokusebenza namakhasimende, abakhiqizi banganquma ubuchwepheshe nezinqubo ezifanele kakhulu kuyilapho benciphisa izindleko futhi beqinisekisa imiphumela engcono kakhulu yokukhiqiza.

6.Isikhathi sokulethwa nokuthunyelwa:Isikhathi sokuhola esidingekayo siyisici esibalulekile esithinta ikhotheshini ye-PCB eguquguqukayo.

Uma kuziwa esikhathini sokuhola se-PCB esivumelana nezimo, isikhathi sokuhola sidlala indima ebalulekile. Isikhathi sokuhola isikhathi esisithathayo ukuze umenzi aqedele ukukhiqiza futhi alungele uku-oda ukuthunyelwa. Izikhathi zokuhola zithintwa izici eziningana, okuhlanganisa ubunkimbinkimbi bomklamo, inani lama-PCB a-odiwe, kanye nomsebenzi wamanje womkhiqizi.

Ama-oda asheshayo noma amashejuli aqinile ngokuvamile adinga ukuthi abakhiqizi babeke phambili ukukhiqizwa futhi babele izinsiza ezengeziwe ukuze bahlangabezane nezinsuku zokugcina. Ezimweni ezinjalo, ukukhiqiza kungase kudingeke ukuba kusheshiswe, okungase kubangele izindleko eziphakeme. Abakhiqizi bangase bakhokhise izimali ezisheshayo noma basebenzise izinqubo ezikhethekile zokubamba ukuze baqinisekise ukuthi ama-PCB avumelana nezimo akhiqizwa futhi alethwa phakathi nesikhathi esimisiwe.

Izindleko zokuthumela nazo zithinta zonke izindleko ze-PCB eguquguqukayo. Izindleko zokuthumela zinqunywa izici ezimbalwa. Okokuqala, indawo yokulethwa idlala indima ebalulekile ezindlekweni zokuthumela. Ukuthumela ezindaweni ezikude noma ezikude kungase kuhilele izindleko eziphakeme ngenxa yokukhuphuka kwezindleko zokuthumela. Ngaphezu kwalokho, ukuphuthuma kokulethwa kuzophinde kuthinte izindleko zokuthumela. Uma ikhasimende lidinga ukuthunyelwa okusheshayo noma ebusuku, izindleko zokuthumela zizoba phezulu uma kuqhathaniswa nezinketho ezijwayelekile zokuthumela.

Inani le-oda liphinde lithinte izindleko zokuthumela. Abanye abakhiqizi bangase banikeze ukuthunyelwa kwamahhala noma okunesaphulelo kuma-oda amakhulu njengesikhuthazo kumakhasimende ukuthi afake ama-oda amaningi. Ngakolunye uhlangothi, kuma-oda amancane, izindleko zokuthumela zingase zibe phezulu ukumboza izindleko ezihilelekile ekupakisheni nasekuphatheni.

Ukuqinisekisa ukuthunyelwa okuphumelelayo nokunciphisa izindleko, abakhiqizi bangasebenzisana eduze nabahlinzeki bezokuthutha ukuze banqume indlela yokuthumela engabizi kakhulu. Lokhu kungabandakanya ukukhetha inkampani yenethiwekhi efanele, ukuxoxisana ngamanani avumayo wokuthumela, nokuthuthukisa ukupakisha ukuze kwehliswe isisindo nosayizi.

Ngamafuphi,kunezici eziningi ezithinta ukucaphuna kwe-PCB eguquguqukayo. Amakhasimende anokuqonda okucacile kwalezi zici angenza izinqumo ezinolwazi futhi athuthukise izinqubo zawo zokukhiqiza.Ubunkimbinkimbi bomklamo, ukukhethwa kwezinto kanye nenani yizici ezibalulekile ezithinta izindleko ze-PCB eguquguqukayo.Uma umklamo uyinkimbinkimbi, izindleko ziphezulu. Izinketho zezinto ezibonakalayo, njengokukhetha i-substrate yekhwalithi ephezulu noma ukuqedwa kwendawo, nakho kungathinta intengo. Futhi, uku-oda amanani amakhulu kuvame ukuholela ezaphulelweni eziyinqwaba. Ezinye izici, ezifana nepaneli, isisindo sethusi, amasu okwenziwa kanye nokusetshenziswa kwamathuluzi, nakho kunendima ekunqumeni izindleko. Iphaneli ivumela ukusetshenziswa kahle kwezinto futhi kunciphisa izindleko. Isisindo sethusi sithinta inani lethusi elisetshenzisiwe, elithinta izindleko nokusebenza kwe-flex PCB. Amasu okukhiqiza kanye namathuluzi, njengokusetshenziswa kobuchwepheshe obuphambili noma amathuluzi akhethekile, kungathinta amanani. Okokugcina, isikhathi sokuhola nokuthutha kuyizinto ezibalulekile zokucatshangelwa. Izindleko ezengeziwe zingasebenza kuma-oda asheshayo noma ukukhiqizwa okusheshayo, futhi izindleko zokuthumela zincike ezintweni ezifana nendawo, ukuphuthuma, kanye nevelu ye-oda. Ngokuhlola ngokucophelela lezi zici nokusebenza nomkhiqizi we-PCB onolwazi nothembekile, izinkampani zingenza ngokwezifiso i-PCB eguquguqukayo engabizi kakhulu nesezingeni eliphezulu ehlangabezana nezidingo zabo ezithile.I-Shenzhen Capel Technology Co., Ltd. ibikhiqiza amabhodi esekethe aphrintiwe (PCBs) kusukela ngo-2009.Njengamanje, siyakwazi ukuhlinzeka ngamabhodi wesifunda aphrintiwe wesendlalelo angu-1-30 ngokwezifiso. Ubuchwepheshe bethu bokukhiqiza be-HDI (High Density Interconnect) be-PCB buvuthwe kakhulu. Eminyakeni engu-15 edlule, siye sasungula ubuchwepheshe ngokuqhubekayo futhi saqongelela ulwazi olucebile ekuxazululeni izinkinga ezihlobene nephrojekthi kumakhasimende.

Isikhathi sokuthumela: Aug-31-2023

Emuva