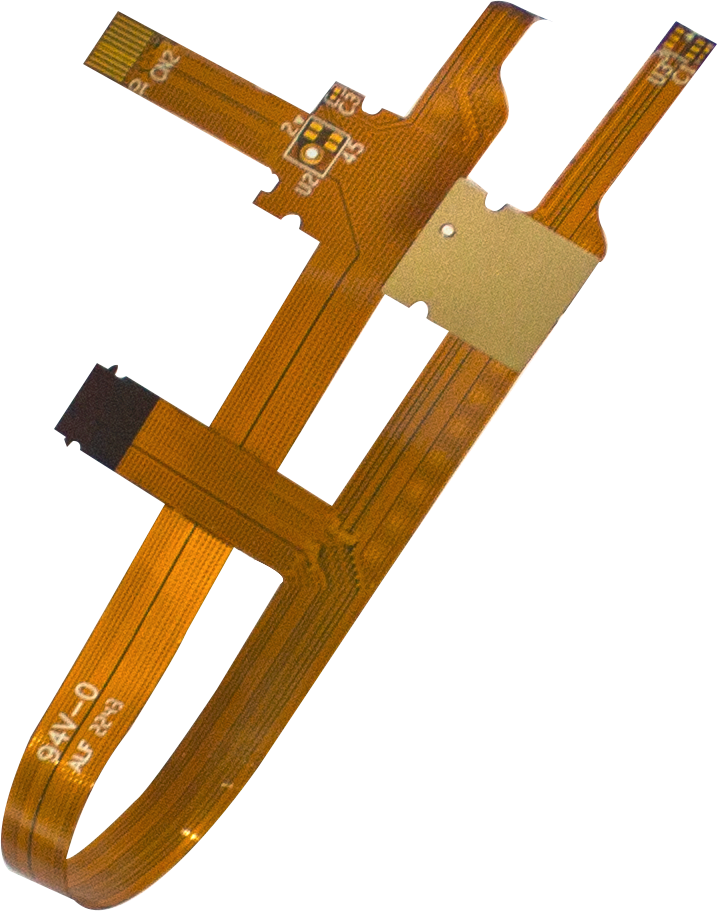

Ukucatshangelwa kwedizayini yama-PCB avumelana nezingqimba eziningi kudlala indima ebalulekile ekuqinisekiseni ukwethembeka nokusebenza kwezisetshenziswa zikagesi. Njengoba ubuchwepheshe buqhubeka nokuvela, isidingo sama-PCB avumelana nezimo sikhula ngokushesha ngenxa yezinzuzo zawo eziningi mayelana nokunciphisa usayizi, ukunciphisa isisindo, kanye nokwanda kokuguquguquka. Kodwa-ke, ukuklama i-PCB yezendlalelo eziningi eguquguqukayo kudinga ukucatshangelwa ngokucophelela kwezinto ezahlukahlukene ukuze kuqinisekiswe ukusebenza kahle.Kulokhu okuthunyelwe kwebhulogi, sihlola ukucatshangelwa okubalulekile kwedizayini yama-PCB avumelana nezimo eziningi futhi sixoxa ngezinselele ezihambisana nokuklama kwawo kanye nenqubo yokukhiqiza.

Enye yezinto ezibalulekile zokucatshangelwa kwedizayini yama-PCB e-multilayer flex ukukhetha kwe-substrate material.Ama-PCB avumelana nezimo ancike ezintweni ze-substrate eziguquguqukayo njenge-polyimide (PI) noma i-polyester (PET) ukuze inikeze ukuguquguquka okudingekayo nokuqina. Ukukhethwa kwe-substrate material kuncike ezidingweni ezithile zohlelo lokusebenza, okuhlanganisa ukumelana nezinga lokushisa, amandla emishini, nokuthembeka. Izinto ezihlukile ze-substrate zinamazinga ahlukene okuqina okushisayo, ukuzinza kobukhulu, kanye ne-bend radii, futhi lezi kufanele zihlolwe ngokucophelela ukuze kuqinisekiswe ukuthi i-PCB ingakwazi ukumelana nezimo zokusebenza ezobhekana nazo.

Okunye okucatshangelwayo okubalulekile ukwakheka kwesitaki se-PCB enezingqimba eziningi. Idizayini yesitaki isho ukuhlelwa kwezendlalelo eziningi zokulandela umkhondo kanye nokokusebenza kwe-dielectric ngaphakathi kwe-PCB.Ukuhlela ngokucophelela ukuhleleka kongqimba, umzila wesignali, kanye nokubekwa kwendiza yamandla/ephansi kubalulekile ukuze kuqinisekiswe ubuqotho besignali obufanele, ukuhambisana kwe-electromagnetic (EMC), nokuphathwa okushisayo. Idizayini yesitaki kufanele yehlise isignali ye-crosstalk, ukungafani kokuphazamiseka, kanye nokuphazanyiswa kwe-electromagnetic (EMI) ukuze kuqinisekiswe ukusebenza okuthembekile nokuqinile kwamadivayisi kagesi.

Umzila wamasignali kanye nezindiza zamandla/eziphansi kuveza izinselele ezengeziwe kuma-PCB aguquguqukayo ahlukahlukene uma kuqhathaniswa nama-PCB endabuko aqinile.Ukuvumelana nezimo kwe-substrate kuvumela izintambo eziyinkimbinkimbi ze-3-dimensional (3D), ezinganciphisa kakhulu usayizi nesisindo sedivayisi yokugcina ye-elekthronikhi. Kodwa-ke, futhi kudala ubunzima ekulawuleni ukubambezeleka kokusakazwa kwesignali, ukukhishwa kwe-electromagnetic, kanye nokusatshalaliswa kwamandla. Abaklami kufanele bahlele ngokucophelela izindlela zomzila, baqinisekise ukunqanyulwa kwesignali okufanele, futhi balungise amandla/ukusabalalisa kwendiza ephansi ukuze banciphise umsindo futhi baqinisekise ukudluliswa kwesignali okunembile.

Ukubekwa kwengxenye kungenye ingxenye ebalulekile yomklamo we-PCB oguquguqukayo wezingxenye eziningi.Isakhiwo sengxenye kufanele sicabangele izici ezifana nezingqinamba zesikhala, ukuphathwa kwe-thermal, ubuqotho besignali, nenqubo yokuhlanganisa. Izingxenye ezibekwe ngokuhlelekile zisiza ukunciphisa ubude bendlela yesiginali, ukunciphisa ukubambezeleka kokudluliselwa kwesignali, nokuthuthukisa ukushabalala kokushisa. Usayizi wengxenye, umumo nezici zokushisa kufanele kucatshangelwe ukuze kuqinisekiswe ukuchithwa kokushisa okuphumelelayo nokuvimbela ukushisa ngokweqile ezakhiweni eziminyene ze-multilayer.

Ngaphezu kwalokho, ukucatshangelwa kwedizayini yama-PCB avumelana nezingqimba eziningi nakho kudlulela kunqubo yokukhiqiza.Izinto ze-substrate eziguquguqukayo, imikhondo ethambile yokuhambisa, namaphethini ezintambo eziyinkimbinkimbi kudinga amasu okukhiqiza akhethekile. Abaqambi kufanele basebenzisane eduze nabakhiqizi ukuze baqinisekise ukuthi imininingwane yedizayini iyahambisana nenqubo yokukhiqiza. Kufanele futhi bacabangele izithiyo ezingaba khona zokukhiqiza, ezifana nobubanzi obuncane bokulandela umkhondo, ubuncane besayizi yembobo kanye nezidingo zokubekezelela, ukugwema amaphutha edizayini angase athinte ukusebenza kukonke nokuthembeka kwe-PCB.

Ukucatshangelwa kwedizayini okukhulunywe ngakho ngenhla kugqamisa ubunkimbinkimbi bokuklama i-PCB enezingqimba eziningi.Bagcizelela ukubaluleka kwendlela ephelele nezinhlelo zokuklama kwe-PCB, lapho izici ezinjengokukhethwa kwempahla engaphansi, idizayini yesitaki, ukulungiselelwa komzila, ukubekwa kwengxenye, nokuhambisana kwenqubo yokukhiqiza kuhlolwa ngokucophelela. Ngokuhlanganisa lokhu kucatshangelwa esigabeni sokuklama, abaklami bangakha ama-PCB avumelana nezingqimba eziningi ahlangabezana nezidingo eziqinile zemishini yesimanje kagesi.

Kafushane, ukucatshangelwa kwedizayini yama-PCB avumelana nezingqimba eziningi kubalulekile ukuze kuqinisekiswe ukwethembeka, ukusebenza, nokusebenza kwamadivayisi kagesi. Ukukhethwa kwe-substrate, idizayini yesitaki, ukwenziwa kahle komzila, ukubekwa kwengxenye, kanye nokuhambisana kwenqubo yokukhiqiza yizici ezibalulekile okufanele zihlolwe ngokucophelela phakathi nesigaba sokuklama. Ngokucabangela lezi zici, abaklami bangakha ama-PCB avumelana nezingqimba eziningi anikeza izinzuzo zosayizi oncishisiwe, isisindo esincishisiwe, kanye nokuguquguquka okuhlukahlukene, kuyilapho behlangabezana nezidingo eziqinile zezinhlelo zokusebenza zesimanje ze-elekthronikhi.

Isikhathi sokuthumela: Sep-02-2023

Emuva