Ubuchwepheshe bokuhlanganisa i-PCB prototype budlala indima ebalulekile ekwenziweni nasekuhlanganiseni amabhodi esekethe.Lobu buchwepheshe buqinisekisa ukukhiqizwa okusebenzayo, okuphezulu kanye nokonga kwamabhodi wesekethe ye-prototype.Kulokhu okuthunyelwe kwebhulogi, sizohlola izindlela ezijwayelekile zokuhlanganisa i-PCB prototyping. Ngaphambi kokungena emininingwaneni, ake sethule kafushane i-Capel, inkampani enesipiliyoni seminyaka engu-15 embonini yebhodi lesifunda, enethimba lezobuchwepheshe elichwepheshile, ubuchwepheshe bokuhlanganisa ibhodi lesifunda elithuthukisiwe, kanye nefekthri yayo yokukhiqiza nokuhlanganisa.

U-Capel ube ngumholi embonini yebhodi lesifunda iminyaka engaphezu kwe-15, ezinikele ekuhlangabezaneni nezidingo ezihlukahlukene zamakhasimende ayo.Le nkampani inethimba lochwepheshe abanolwazi abaye bathola ubuchwepheshe obubalulekile ekukhiqizeni nasekuhlanganiseni amabhodi esekethe. Ubuchwepheshe bokuhlanganisa ibhodi lesifunda elithuthukisiwe laseCapel liqinisekisa amazinga aphezulu kakhulu kanye nezinqubo zokukhiqiza eziphumelelayo.

Ukuba nemikhiqizo yayo yebhodi lesifunda kanye nezitshalo zomhlangano kunikeza iCapel inzuzo yokuncintisana.Lokhu kusetha kuvumela inkampani ukuthi ilawule kangcono inqubo yokukhiqiza, iqinisekise ukulethwa okufika ngesikhathi futhi igcine ukulawulwa kwekhwalithi okuhle kakhulu. Ngaphezu kwalokho, ubuchwepheshe benkampani ekukhiqizeni nasekuhlanganiseni kwe-PCB buyenza ikwazi ukunikeza amakhasimende izixazululo eziphelele nezingabizi kakhulu.

Manje njengoba sesijwayelene neCapel namandla ayo, ake sihlole amasu okuhlanganisa we-PCB prototyping avame ukusetshenziswa

imboni.

1. Ubuchwepheshe be-Surface Mount (SMT):

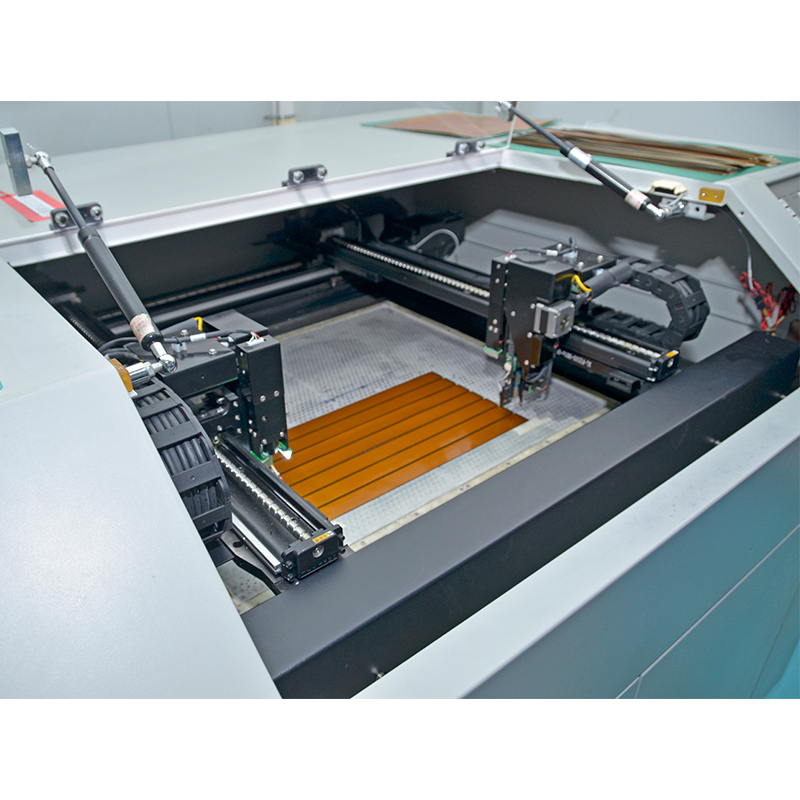

Ubuchwepheshe be-Surface Mount (SMT) bungobunye bobuchwepheshe bokuhlanganisa be-PCB obusetshenziswa kakhulu. Kubandakanya ukukhweza izingxenye ngqo endaweni ye-PCB. I-SMT inikeza izinzuzo ezimbalwa, okuhlanganisa ikhono lokwamukela izingxenye ezincane, ukuminyana kwezingxenye eziphezulu, nokusebenza okuthuthukisiwe kukagesi.

2. Ubuchwepheshe bemigodi (THT):

Ubuchwepheshe be-Threhth-hole (THT) ubuchwepheshe obudala bokuhlanganisa obufaka izingxenye ezikhwezwayo ngokufaka umkhondo emigodini ku-PCB nokuyidambisa ngakolunye uhlangothi. I-THT ngokuvamile isetshenziselwa izingxenye ezidinga amandla emishini engeziwe noma ezinkulu kakhulu ku-SMT.

3. Ukuhlola okuzenzakalelayo (AOI):

I-Automated Optical Inspection (AOI) ubuchwepheshe obusetshenziswa ukuhlola ama-PCB aqoqiwe ukuze kutholwe amaphutha noma ukonakala. Amasistimu e-AOI asebenzisa amakhamera nama-algorithms okubona isithombe ukuze ahlole izici ezihlukahlukene ze-PCB, njengokubekwa kwengxenye, amajoyinti e-solder, kanye ne-polarity. Lobu buchwepheshe buqinisekisa ukuhlangana kwekhwalithi ephezulu futhi kunciphisa ithuba lemikhiqizo enesici ukufinyelela amakhasimende.

4. Ukuhlolwa kwe-X-ray:

Ukuhlola i-X-ray kuwubuchwepheshe bokuhlola obungonakali obusetshenziselwa ukuhlola ama-PCB ukuze kutholwe izici ezifihliwe, njengamajoyinti e-solder noma izinto zokugcwalisa ngaphansi kwezingxenye. Ukuhlolwa kwe-X-ray kusiza ukuthola iziphambeko ezifana ne-solder enganele, amajoyinti abandayo e-solder, noma izikhala ezingase zingabonakali ngokuhlola okubonakalayo.

5. Sebenza kabusha futhi ulungise:

Amasu okusebenza kabusha nokulungisa abalulekile ukuze kulungiswe iziphambeko noma esikhundleni sezingxenye ezinephutha kuma-PCB ahlanganisiwe. Ochwepheshe abanekhono basebenzisa amathuluzi akhethekile nezinto zokusebenza ukuze bachithe futhi bashintshe izingxenye ngaphandle kokudala umonakalo ku-PCB. Lezi zindlela zinciphisa ukumosha nokuhlenga amabhodi anamaphutha, zonga isikhathi nezinsiza.

6. Ukushisela okukhethekile:

I-selective soldering iyindlela esetshenziselwa ukuthengisa izingxenye zembobo ku-PCB ngaphandle kokuthikameze izinto zokukhweza ezingaphezulu. Inikeza ukunemba okukhulu futhi inciphisa ithuba lokulimaza izingxenye eziseduze.

7. Ukuhlolwa Kwe-inthanethi (ICT):

Ukuhlolwa kwe-in-circuit (ICT) kusebenzisa okokusebenza kokuhlola okukhethekile ukuhlola ukusebenza kwezingxenye zesekethe ku-PCB. Isiza ukuthola izingxenye ezinephutha, amasekhethi avulekile noma amafushane noma amanani engxenye engalungile. I-ICT inikeza impendulo ebalulekile yokuthuthukisa inqubo yokuklama nokuhlanganisa.

Lezi ezinye zezindlela ezijwayelekile zokuhlanganisa i-PCB prototyping ezisetshenziswa izinkampani ezifana neCapel. Ukuthuthukiswa okuqhubekayo kobuchwepheshe kuvumela abakhiqizi ukuthi bahlole izindlela ezintsha futhi basungule emkhakheni womhlangano webhodi lesifunda.

Isipiliyoni esibanzi se-Capel kanye nobuchwepheshe bezobuchwepheshe embonini yebhodi lesifunda, kuhambisana nobuchwepheshe bayo bokuhlanganisa i-PCB ethuthukisiwe, kuyenza umlingani othembekile kumakhasimende ayo.Ukuzibophezela kwenkampani ekuhlinzekeni ukukhiqizwa kwebhodi lesifunda esisebenza ngempumelelo, sekhwalithi ephezulu kanye nesongayo kukwenza ihluke emakethe.

Ngokufigqiwe, ukuqonda izindlela ezijwayelekile zokuhlanganisa i-PCB prototyping kubalulekile kubo bobabili abakhiqizi namakhasimende.Izinkampani ezifana neCapel zisebenzisa ubuchwepheshe bazo, isipiliyoni, kanye nobuchwepheshe obuthuthukisiwe ukuze zinikeze izixazululo ezisezingeni eliphakeme zokukhiqiza ibhodi lesifunda kanye nemihlangano. Ngokukhetha uzakwethu onokwethenjelwa njengo-Capel, amakhasimende azuza ezinqubweni eziphumelelayo, ukulawulwa kwekhwalithi ephakeme kanye nezixazululo ezingabizi kakhulu.

Isikhathi sokuthumela: Oct-19-2023

Emuva