Esikhathini lapho intuthuko yezobuchwepheshe ishintsha izimpilo zethu zansuku zonke, isidingo semishini kagesi esheshayo, emincane nasebenza kahle kakhudlwana siyaqhubeka sikhula. Ubuchwepheshe be-PCB (Printed Circuit Board) budlala indima ebalulekile ekuqinisekiseni ukusebenza kahle kwamadivayisi anjalo. Enye yentuthuko ekwakhiweni kwe-PCB kwakuyi-HDI (High Density Interconnect), umqondo woguquko owaguqula imboni yezogesi. Kulesi sihloko, u-Capel uzohlola ukuthi iyini i-HDI kuma-PCB, kungani ibalulekile, kanye nezinzuzo eziningi eziletha ku-electronics yesimanje. Hlanganyela nathi njengoba sembula lobu buchwepheshe obuhehayo!

Iyini i-HDI ku-PCB?

Ukuze uqonde ngokugcwele uhlobo lwe-HDI kuma-PCB, kuyadingeka ukuqonda imigomo yayo ewumongo nokuthi ihluke kanjani kuma-PCB avamile. I-HDI empeleni iyindlela yokuklama ehlanganisa ama-PCB anezingqimba eziningi anezinto ezipakishwe kakhulu nezixhumi. Ngokungafani nama-PCB endabuko, avame ukuba nezingxenye ezinkulu nokucaciswa okubanzi, ubuchwepheshe be-HDI buvumela ukwenziwa kwe-miniaturization nokuxhumana okuyinkimbinkimbi kuyilapho kunciphisa usayizi wengxenye nesikhala.

Amabhodi e-HDI afaka ukuminyana okuphezulu kwezingxenye, ama-vias amancane, namashaneli amaningi omzila. Aqukethe ama-microvias astakiwe asiza ukuxhumana phakathi kwezendlalelo ezihlukene, okuvumela imiklamo ehlangene futhi esebenza kahle yesekethe. Ngokusetshenziswa kwamasu okukhiqiza athuthukile nezinqubo ezilawulwa ngokuqinile, ubuchwepheshe be-HDI bungamukela izingxenye zokuminyana okuphezulu ukuletha ukusebenza okuthuthukile.

Incazelo ye-HDI ku-PCB:

I-HDI iba ngokubaluleka kuma-PCB njengoba ihlangabezana nesidingo esikhulayo semishini kagesi emincane, esheshayo futhi eyinkimbinkimbi. Ake singene ngezizathu ezibalulekile zokuthi kungani ubuchwepheshe be-HDI bubaluleke kangaka embonini yezogesi zanamuhla:

1. I-Miaturization:Njengoba ubuchwepheshe buthuthuka, isidingo samadivayisi amancane nalula siba sibucayi. I-HDI inganciphisa usayizi, isisindo nokujiya kwemishini kagesi, inikeze amandla ukuthuthukiswa kwamagajethi athambile naphathekayo.

2. Engeza ukusebenza:I-HDI inika amandla abaklami ukuthi bahlanganise izici ezengeziwe nokusebenza endaweni elinganiselwe. Ngamakhono omzila athuthukisiwe kanye nama-vias amancane, amabhodi we-HDI angakwazi ukwamukela amasekhethi ayinkimbinkimbi, avumela ukuhlanganiswa kwezingxenye ezihlukahlukene njengezinzwa, ama-microcontrollers namamojula angenawaya.

3. Ubuqotho besignali obuthuthukisiwe:Izindlela ezimfushane zokuxhuma kumabhodi we-HDI zinciphisa kakhulu ingozi yokulahleka kwesignali noma ukuwohloka. Lokhu kuqinisekisa ukudluliswa kwedatha okushelelayo, ubuqotho bezimpawu zesivinini esikhulu, futhi kuthuthukisa ukusebenza kukonke kwemishini kagesi.

4. Ukuthembeka nokuqina okuthuthukisiwe:Amabhodi e-HDI akhulise ukumelana nezimo zemvelo ezifana nokushintsha kwezinga lokushisa, umswakama nokudlidliza. Ngokunciphisa inani lamalungu e-solder nokuthuthukisa ubuqotho bamandla nezindiza eziphansi, ubuchwepheshe be-HDI buthuthukisa ukuthembeka nokuqina kwemishini kagesi, okuholela ekuphileni isikhathi eside.

Izinzuzo ze-HDI ku-PCB:

Ngenxa yomklamo wayo oyingqayizivele nezici zokukhiqiza, ukusetshenziswa kobuchwepheshe be-HDI ku-PCB kuletha izinzuzo ezimbalwa ezibalulekile. Ake sihlole ezinye zalezi zinzuzo ngezansi:

1. Ukwanda kokuminyana kwesekethe:Amabhodi e-HDI angakwazi ukuhlalisa inani elikhulu lezingxenye nokuxhumana phakathi kwesikhala esilinganiselwe. Lokhu kubangela izendlalelo ezimbalwa, izici zefomu ezincane, futhi kukhulisa ukusebenza okuphelele nokuminyana kokupakishwa kwamadivayisi kagesi.

2. Izici ezithuthukisiwe zokushisa:Ubuchwepheshe be-HDI buvumela ukuphathwa okungcono kokushisa kumadivayisi kagesi ngenxa yekhono lokuhlakaza ukushisa ngokuphumelelayo. Lokhu kubaluleke kakhulu kumasistimu asebenza kahle kakhulu akhiqiza ukushisa okuningi ukuze kuqinisekiswe ukusebenza kahle nokuvimbela ukushisa ngokweqile.

3. Izindleko nokonga isikhathi:Nakuba ubuchwepheshe be-HDI buyinkimbinkimbi, abudingi izingxenye zangaphandle ezengeziwe noma ukuxhumana. Yehlisa izindleko zokukhiqiza nesikhathi sokuhlanganisa ngokunciphisa ubunkimbinkimbi besekethe nosayizi. Ukwengeza, amabhodi e-HDI adinga izendlalelo ezimbalwa, ukunciphisa isikhathi sokukhiqiza nokwenza lula inqubo yokukhiqiza.

4. Ukuvumelana nezimo komklamo:Ubuchwepheshe be-HDI bunikeza abaklami ukuguquguquka okukhulu mayelana nezintambo zesifunda kanye nesakhiwo sengxenye. Idizayini yayo ehlangene neyinkimbinkimbi ivumela ukuhlanganiswa kwemisebenzi eminingi futhi ivumela amaphethini esekethe okudala, kuvula indlela yokuqamba kanye nokwenza ngokwezifiso.

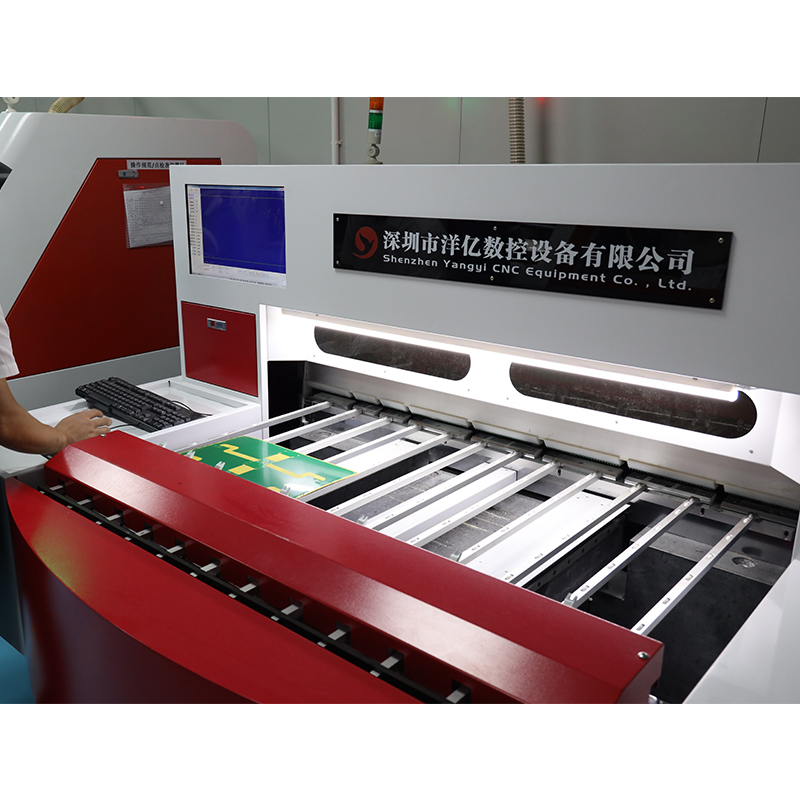

Ubuchwepheshe be-HDI buguqula imboni yezogesi ngokuphusha imingcele yokuklama kwebhodi lesifunda namandla okwenza. Ngokwenziwa kwayo okuncane, ukusebenza okuthuthukisiwe, ubuqotho besignali obuthuthukisiwe, nezinye izinzuzo eziningi, i-HDI kuma-PCB isishintshe umdlalo emkhakheni wezinto zikagesi. Njengoba ubuchwepheshe buqhubeka nokuvela ngesivinini esisheshayo, ubuchwepheshe be-HDI ngokungangabazeki buzodlala indima ebalulekile ekuhlangabezaneni nesidingo samadivayisi kagesi amancane, asheshayo, nanamandla kakhulu. Ukusebenzisa lobu buchwepheshe obuphambili kuqinisekisa ukuthi imikhiqizo yethu ye-elekthronikhi ayigcini nje ngokuhambisana nokuqanjwa kabusha, kodwa futhi ithuthukisa ulwazi lwethu olunzulu ngomsebenzisi.I-Shenzhen Capel Technology Co., Ltd. ibambe iqhaza embonini yebhodi lesifunda iminyaka eyi-15. Ngolwazi lwephrojekthi olucebile, ngokuqhubekayo uthuthukisa amakhono okukhiqiza, nobuchwepheshe obuvuthiwe kumabhodi we-HDI PCB, i-Capel iyisinqumo sakho esifanele. Ithimba lethu lochwepheshe lizonakekela iphrojekthi yakho.

Isikhathi sokuthumela: Aug-23-2023

Emuva