Emhlabeni wamabhodi esekethe aphrintiwe (ama-PCB), ukukhethwa kwezinto zokwakha nezinqubo zokukhiqiza kungaba nomthelela omkhulu kwikhwalithi nokusebenza kwezinto zikagesi. Okunye okuhlukile yi-PCB yegolide ewugqinsi, enikeza izinzuzo ezihlukile kuma-PCB ajwayelekile.Lapha sihlose ukunikeza ukuqonda okuphelele kwe-PCB yegolide eliwugqinsi, sichaza ukwakheka kwayo, izinzuzo, kanye nomehluko kuma-PCB endabuko.

1.Ukuqonda Thick Gold PCB

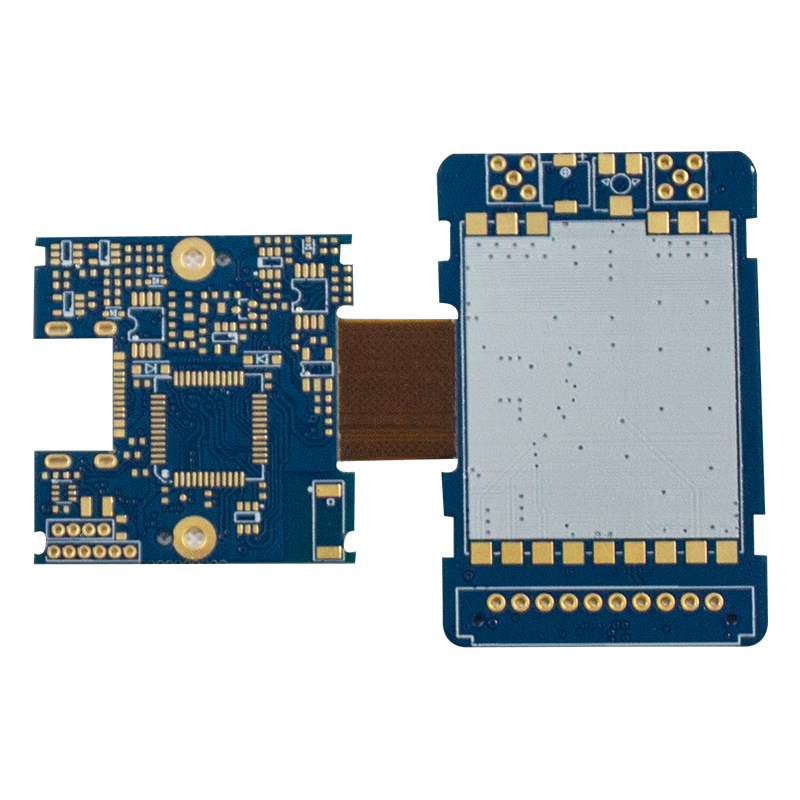

I-PCB yegolide ewugqinsi iwuhlobo olukhethekile lwebhodi lesifunda eliphrintiwe elinongqimba lwegolide olugqinsile kakhulu endaweni yalo.Zakhiwe ngezingqimba eziningi zethusi kanye nezinto ze-dielectric ezinesendlalelo segolide esingezwe phezulu. Lawa ma-PCB akhiqizwa ngenqubo ye-electroplating eqinisekisa ukuthi ungqimba lwegolide lulingana futhi luboshwe ngokuqinile.Ngokungafani nama-PCB ajwayelekile, ama-PCB egolide agqinsi anongqimba lwegolide olugqinsile kakhulu endaweni yokugcina. Ugqinsi lwegolide ku-PCB evamile luvamise ukuba ngamayintshi amancane angu-1-2 noma ama-microns angu-0.025-0.05. Uma kuqhathaniswa, ama-PCB egolide awugqinsi ngokuvamile anogqinsi lwesendlalelo segolide elingamayintshi amancanyana angama-30-120 noma ama-microns angu-0.75-3.

2.Izinzuzo ze-PCB yegolide eliwugqinsi

Ama-PCB egolide awugqinsi anikeza izinzuzo eziningi ngaphezu kwezinketho ezijwayelekile, okuhlanganisa ukuqina okuthuthukisiwe, ukuqhutshwa kwe-conductivity okuthuthukisiwe nokusebenza okuphezulu.

Ukuqina:

Enye yezinzuzo eziyinhloko zama-PCB egolide awugqinsi ukuqina kwawo okungavamile. Lawa mabhodi aklanyelwe ngokukhethekile ukumelana nezindawo ezinokhahlo, awenze alungele izinhlelo zokusebenza ezivame ukuchayeka kumazinga okushisa aphakeme noma izimo ezinzima. Ugqinsi lwe-plating yegolide lunikeza ungqimba lwesivikelo ekugqwaleni, ekufakweni kwe-oxidation nezinye izinhlobo zomonakalo, okuqinisekisa impilo ende ye-PCB.

Thuthukisa conductivity kagesi:

Ama-PCB egolide anogqinsi anokuhanjiswa kahle kukagesi, okuwenza abe ukukhetha kokuqala kwezinhlelo zokusebenza ezidinga ukudluliswa kwesignali okusebenzayo. Ugqinsi olwengeziwe lweplating yegolide kunciphisa ukumelana futhi luthuthukisa ukusebenza kukagesi, kuqinisekisa ukudluliswa kwesignali okungenamthungo ebhodini lonke. Lokhu kubaluleke kakhulu ezimbonini ezifana nezokuxhumana, i-aerospace kanye nemishini yezokwelapha, lapho ukudluliswa kwedatha okunembile nokuthembekile kubalulekile.

Thuthukisa ukuthengiselana:

Enye inzuzo yama-PCB egolide aminyene ukuqina kwawo okuthuthukisiwe. Ukwenyuka kogqinsi kokucwenga kwegolide kuvumela ukugeleza kwe-solder nokumanzisa okungcono, kunciphisa amathuba okuba nezinkinga zokugeleza kabusha kwe-solder ngesikhathi sokukhiqiza. Lokhu kuqinisekisa amalunga aqinile futhi anokwethenjelwa solder, ukuqeda ukukhubazeka okungenzeka futhi ngcono ikhwalithi yomkhiqizo jikelele.

Impilo yokuxhumana:

Othintana nabo ngogesi kuma-PCB egolide aminyene bahlala isikhathi eside ngenxa yokuqina kwegolide kokucwenga. Lokhu kuthuthukisa ukwethembeka kothintana naye futhi kunciphisa ingcuphe yokuwohloka kwesignali noma ukuxhumeka kwezikhawu phakathi kwesikhathi. Ngakho-ke, lawa ma-PCB asetshenziswa kakhulu ezinhlelweni ezinemijikelezo ephezulu yokufaka/yokukhipha, njengezixhumi zamakhadi noma amamojula wememori, adinga ukusebenza kokuxhumana okuhlala isikhathi eside.

Thuthukisa ukumelana nokugqoka:

Ama-PCB egolide anogqinsi asebenza kahle ezinhlelweni ezidinga ukuguga okuphindaphindiwe. Ukuqina okwenyuka kokucwenga kwegolide kunikeza umgoqo ovikelayo osiza ukumelana nemiphumela yokuhlikihla nokuhlikihla yokusetshenziswa okuphindaphindiwe. Lokhu kuzenza zibe zilungele izixhumi, amaphedi wokuthinta, izinkinobho nezinye izingxenye ezijwayele ukuthintana ngokomzimba njalo, okuqinisekisa ukuphila kwazo isikhathi eside nokusebenza okungaguquki.

Yehlisa ukulahleka kwesignali:

Ukulahlekelwa kwesignali kuyinkinga evamile ezinhlelweni zokusebenza zefrikhwensi ephezulu. Kodwa-ke, ama-PCB egolide awugqinsi anikeza isixazululo esisebenzayo esinganciphisa ukulahleka kwesignali ngenxa yokwenziwa kwayo okuthuthukisiwe. Lawa ma-PCB afaka ukumelana okuphansi ukuze kuqinisekiswe ubuqotho besiginali, kuncishiswe ukulahleka kokudluliswa kwedatha kanye nokukhulisa ukusebenza kahle kwesistimu. Ngakho-ke, asetshenziswa kakhulu ezimbonini ezifana nezokuxhumana, okokusebenza okungenantambo, kanye nemishini yamaza aphezulu.

3.Ukubaluleka kokukhulisa ukujiya kwegolide kuma-PCB egolide aminyene:

Ugqinsi olwengeziwe lokucwecwa kwegolide kuma-PCB egolide agqinsile kufeza izinjongo ezimbalwa ezibalulekile.Okokuqala, inikeza ukuvikeleka okwengeziwe ngokumelene ne-oxidation nokugqwala, iqinisekisa ukwethembeka nokuzinza kwesikhathi eside ngisho nasezindaweni ezinzima. I-plating yegolide ewugqinsi isebenza njengesithiyo, evimbela noma yikuphi ukusabela kwamakhemikhali phakathi kokulandela ithusi okungaphansi nomoya wangaphandle, ikakhulukazi uma kuchayeke kumswakama, umswakama, noma ukungcola kwezimboni.

Okwesibili, ungqimba lwegolide olujiyile luthuthukisa ukusebenza kahle kanye namakhono okudlulisa amasignali we-PCB.Igolide liyi-conductor kagesi elihle kakhulu, elingcono nakakhulu kunethusi elivame ukusetshenziselwa iminonjana ye-conductive kuma-PCB ajwayelekile. Ngokwandisa okuqukethwe kwegolide phezulu, ama-PCB egolide agqinsile angafinyelela ukumelana okuphansi, ukunciphisa ukulahleka kwesignali nokuqinisekisa ukusebenza okungcono, ikakhulukazi ezinhlelweni zokusebenza zamafrikhwensi aphezulu noma lezo ezibandakanya amasignali asezingeni eliphansi.

Ngaphezu kwalokho, izingqimba zegolide ezijiyile zinikeza ukuthengiselana okungcono kanye nengxenye eqinile yokunqwabelanisa indawo.Igolide line-solderability enhle kakhulu, okuvumela amajoyinti e-solder athembekile ngesikhathi somhlangano. Lesi sici sibalulekile ngoba uma amalunga e-solder ebuthakathaka noma engavamile, angabangela ukwehluleka kwesifunda okuphakathi noma okuphelele. Ukuqina kwegolide okunyukile kuthuthukisa ukuqina komshini, okwenza ama-PCB egolide aqinile ukuthi angabi lula ekugugekeni futhi amelane kakhulu nengcindezi yemishini nokudlidliza.

Kuyaphawuleka ukuthi ukujiya okwenyukile kongqimba lwegolide kuma-PCB egolide aminyene nakho kuletha izindleko eziphakeme uma kuqhathaniswa nama-PCB ajwayelekile.Inqubo ebanzi yokucwecwa kwegolide idinga isikhathi esengeziwe, izinsiza kanye nobuchule, okuholela ekwenyukeni kwezindleko zokukhiqiza. Kodwa-ke, ngezinhlelo zokusebenza ezidinga ikhwalithi ephezulu, ukwethembeka nokuphila isikhathi eside, ukutshalwa kwezimali kuma-PCB egolide aminyene kuvame ukudlula ubungozi obungaba khona kanye nezindleko ezihambisana nokusebenzisa ama-PCB ajwayelekile.

4.Umehluko phakathi kwe-PCB ewugqinsi yegolide ne-PCB ejwayelekile:

Ama-PCB ajwayelekile ngokuvamile enziwa ngezinto ze-epoxy ezinongqimba lwethusi ohlangothini olulodwa noma zombili zebhodi. Lezi zingqimba zethusi ziqoshwa ngesikhathi senqubo yokukhiqiza ukuze zenze ukujikeleza okudingekayo. Ugqinsi lwesendlalelo sethusi bungahluka kuye ngohlelo lokusebenza, kodwa ngokuvamile lukububanzi obungu-1-4 oz.

I-PCB yegolide ewugqinsi, njengoba negama liphakamisa, inongqimba olujiyile lwegolide oluqhathaniswa ne-PCB ejwayelekile. Ama-PCB ajwayelekile anogqinsi lwegolide lokucwenga lwama-intshi amancane angama-20-30 (ama-microns angu-0.5-0.75), kuyilapho ama-PCB egolide agqinsi anogqinsi lwegolide oluyi-50-100 amayintshi amancane (1.25-2.5 microns).

Umehluko omkhulu phakathi kwama-PCB egolide agqinsile nama-PCB ajwayelekile ukujiya kongqimba lwegolide, ubunkimbinkimbi bokukhiqiza, izindleko, izindawo zokufaka izicelo, kanye nokusebenziseka okulinganiselwe ezindaweni ezinezinga lokushisa eliphezulu.

Ugqinsi lwesendlalelo segolide:

Umehluko omkhulu phakathi kwe-PCB yegolide ewugqinsi kanye ne-PCB ejwayelekile ukujiya kongqimba lwegolide. I-PCB yegolide ewugqinsi inongqimba lwegolide olujiyile kune-PCB ejwayelekile. Lokhu ukujiya okwengeziwe kusiza ukuthuthukisa ukuqina kwe-PCB nokusebenza kukagesi. Isendlalelo segolide esiwugqinsi sinikeza isambatho esivikelayo esithuthukisa ukumelana kwe-PCB nokugqwala, i-oxidation nokuguga. Lokhu kwenza i-PCB iqine kakhulu ezindaweni ezinokhahlo, iqinisekise ukusebenza okuthembekile kwesikhathi eside. I-plating yegolide ewugqinsi iphinde ivumele ukuhanjiswa kukagesi okungcono, okuvumela ukudluliswa kwesignali okusebenzayo. Lokhu kunenzuzo ikakhulukazi ezinhlelweni ezidinga ukudluliswa kwesignali yemvamisa ephezulu noma enesivinini esikhulu, njengokuxhumana ngocingo, okokusebenza kwezokwelapha, namasistimu omkhathi.

Izindleko:

Uma kuqhathaniswa ne-PCB ejwayelekile, izindleko zokukhiqiza ze-PCB ewugqinsi yegolide ngokuvamile ziba phezulu. Lezi zindleko eziphezulu ziphuma ohlelweni lokucwenga oludinga impahla yegolide eyengeziwe ukuze kuzuzwe ukujiya okudingekayo. Kodwa-ke, ukwethembeka okukhulu nokusebenza kwama-PCB egolide agqinsile kuthethelela izindleko ezengeziwe, ikakhulukazi ezinhlelweni zokusebenza lapho izidingo ezidingekayo kufanele kuhlangatshezwane nazo.

Izindawo zokufaka isicelo:

Ama-PCB ajwayelekile asetshenziswa kakhulu ezimbonini ezahlukahlukene, okubandakanya ugesi wabathengi, amasistimu ezimoto kanye nemishini yezimboni. Zifanele izicelo lapho ukwethembeka okuphezulu akuyona into ehamba phambili. Ngakolunye uhlangothi, ama-PCB egolide aminyene, asetshenziswa kakhulu emikhakheni yobungcweti edinga ukwethembeka nokusebenza okuphakeme. Izibonelo zalezi zindawo zokufaka izicelo zifaka imboni ye-aerospace, okokusebenza kwezokwelapha, okokusebenza kwezempi, namasistimu ezokuxhumana. Kulezi zindawo, imisebenzi ebalulekile incike ezingxenyeni ze-elekthronikhi ezithembekile nezisezingeni eliphezulu, ngakho-ke ama-PCB egolide aminyene ayinketho yokuqala.

Inkimbinkimbi Yokukhiqiza:

Uma kuqhathaniswa nama-PCB ajwayelekile, inqubo yokwenziwa kwama-PCB egolide aminyene iyinkimbinkimbi futhi idla isikhathi. Inqubo ye-electroplating kumele ilawulwe ngokucophelela ukuze kuzuzwe ugqinsi olufiselekayo lwesendlalelo segolide. Lokhu kwandisa ubunkimbinkimbi nesikhathi esidingekayo enqubweni yokukhiqiza. Ukulawula okunembayo kwenqubo yokucwenga kubalulekile ngoba ukuhlukahluka kogqinsi kongqimba lwegolide kungathinta ukusebenza nokuthembeka kwe-PCB. Le nqubo yokukhiqiza ecophelelayo inomthelela kwikhwalithi ephezulu nokusebenza kwama-PCB egolide aminyene.

Ukufaneleka okulinganiselwe kwezindawo zokushisa okuphezulu:

Nakuba ama-PCB egolide aminyene enza kahle ezindaweni eziningi, angase angabi inketho efanelekile kakhulu ekusetshenzisweni kwezinga lokushisa eliphezulu. Ngaphansi kwezimo zokushisa eziphakeme kakhulu, izendlalelo zegolide eziwugqinsi zingehlisa noma zinciphise, kuthinte ukusebenza kukonke kwe-PCB.

Kulesi simo, ezinye izindlela zokwelapha ezingaphezulu njenge-immersion tin (ISn) noma isiliva lokucwiliswa (IAg) zingakhethwa. Lezi zindlela zokwelapha zinikeza ukuvikeleka okwanele emiphumeleni yamazinga okushisa aphezulu ngaphandle kokuthinta ukusebenza kwe-PCB.

Ukukhethwa kwezinto ze-PCB kungaba nomthelela omkhulu kwikhwalithi nokusebenza kwezisetshenziswa zikagesi. Ama-PCB egolide aminyene ahlinzeka ngezinzuzo eziyingqayizivele njengokuqina okuthuthukisiwe, ukuthengiselana okuthuthukisiwe, ukuqhutshwa kukagesi okuhle kakhulu, ukwethembeka okuphezulu kokuxhumana, nokuphila kweshalofu okwandisiwe.Izinzuzo zabo zithethelela izindleko zokukhiqiza eziphakeme futhi zizenze zifanelekele ikakhulukazi izimboni ezikhethekile ezibeka phambili ukwethembeka, njenge-aerospace, izinto zezokwelapha, amathuluzi ezempi, nezinhlelo zokuxhumana ngocingo. Ukuqonda ukwakheka, izinzuzo, kanye nomehluko phakathi kwama-PCB egolide agqinsile nama-PCB ajwayelekile kubalulekile konjiniyela, abaklami, nabakhiqizi abafuna ukuthuthukisa ukusebenza nokuhlala isikhathi eside kwemishini yabo kagesi. Ngokusebenzisa izimfanelo ezihlukile zama-PCB egolide aminyene, bangaqinisekisa imikhiqizo ethembekile nesezingeni eliphezulu kumakhasimende abo.

Isikhathi sokuthumela: Sep-13-2023

Emuva