Esikhathini sanamuhla sokuthuthuka okusheshayo kwezobuchwepheshe, izinto zikagesi seziyingxenye ebalulekile yokuphila kwethu kwansuku zonke. Kusukela kuma-smartphone kuya kumishini yezokwelapha, amabhodi esekethe aphrintiwe (ama-PCB) adlala indima ebalulekile ekunikezeni amandla lawa madivayisi. Ama-PCB obuchwepheshe be-High Density Interconnect (HDI) abengushintsho lwegeyimu, anikeza ukuminyana kwesekethe okuphezulu, ukusebenza okuthuthukisiwe nokuthembeka okuthuthukisiwe.Kodwa ingabe wake wazibuza ukuthi lawa ma-PCB obuchwepheshe be-HDI akhiqizwa kanjani? Kulesi sihloko, sizongena ebunzimeni benqubo yokukhiqiza futhi sicacise izinyathelo ezihilelekile.

1. Isethulo esifushane se-HDI technology PCB:

Ama-PCB obuchwepheshe be-HDI adumile ngenxa yekhono lawo lokuhlanganisa inani elikhulu lezingxenye kumklamo ohlangene, okwehlisa usayizi ophelele wamadivayisi kagesi.Lawa mabhodi anezendlalelo eziningi, ama-vias amancane, nemigqa emincane yokuminyana kwemizila. Ukwengeza, banikeza ukusebenza kukagesi okuthuthukisiwe, ukulawulwa kwe-impedance, nobuqotho besignali, okubenza balungele izinhlelo zokusebenza ezinesivinini esikhulu kanye nemvamisa ephezulu.

2. Isakhiwo sedizayini:

Uhambo lokukhiqiza lwe-HDI Technology PCB luqala kusukela esigabeni sokuklama.Onjiniyela abanekhono nabaklami basebenza ndawonye ukuze bathuthukise ukwakheka kwesekethe kuyilapho beqinisekisa ukuthi imithetho yokuklama kanye nemikhawulo kuyahlangatshezwana nayo. Sebenzisa amathuluzi esofthiwe athuthukisiwe ukuze udale imiklamo enembile, uchaze izitaki zezingqimba, ukubekwa kwengxenye kanye nomzila. Isakhiwo siphinde sicabangele izici ezifana nobuqotho besignali, ukuphathwa kwe-thermal, nokuzinza kwemishini.

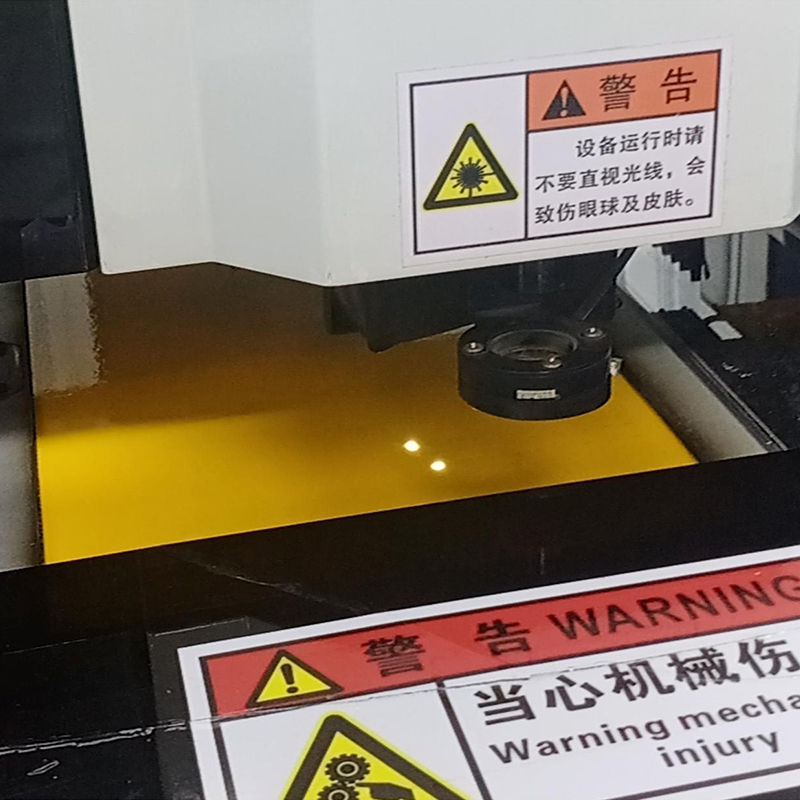

3. Ukubhola nge-laser:

Esinye sezinyathelo ezibalulekile ekukhiqizeni ubuchwepheshe be-HDI PCB ukubhola nge-laser.Ubuchwepheshe be-laser bungakha ama-vias amancane, anembe kakhudlwana, abalulekile ekuzuzeni ukuminyana kwesekethe ephezulu. Imishini yokumba i-laser isebenzisa ukukhanya okunamandla amakhulu ukuze isuse izinto ezibonakalayo ku-substrate futhi idale izimbobo ezincane. Lezi vias ke metallized ukudala uxhumano kagesi phakathi izingqimba ezahlukene.

4. I-electroless copper plating:

Ukuqinisekisa ukuxhumana kahle kukagesi phakathi kwezingqimba, kusetshenziswa i-electroless copper deposition.Kule nqubo, izindonga zembobo ebhoboziwe zimbozwe ungqimba oluncane kakhulu lwethusi eliqhutshwayo ngokucwiliswa kwamakhemikhali. Lesi singqimba sethusi sisebenza njengembewu yenqubo ye-electroplating elandelayo, ithuthukisa ukunamathela okuphelele nokuhamba kwethusi.

5. Lamination nokucindezela:

Ukukhiqizwa kwe-HDI Technology PCB kuhilela imijikelezo eminingi yokucwasa kanye nokucindezela lapho izingqimba ezihlukene zebhodi lesifunda zipakishwa futhi zihlanganiswe ndawonye.Ukucindezela okuphezulu kanye nezinga lokushisa kuyasetshenziswa ukuze kuqinisekiswe ukubopha okufanele futhi kuqedwe noma yimaphi amaphakethe omoya noma ama-voids. Le nqubo ihilela ukusetshenziswa kwemishini ekhethekile yokuhlobisa ukuze kuzuzwe ukujiya kwebhodi elidingekayo kanye nokuzinza kwemishini.

6. I-Copper Plating:

I-Copper plating idlala indima ebalulekile kuma-PCB wobuchwepheshe be-HDI njengoba isungula ukuqhutshwa kukagesi okudingekayo.Le nqubo ihilela ukucwilisa ibhodi lonke esitshalweni se-copper plating bese udlulisela umsinga kagesi kulo. Ngenqubo ye-electroplating, ithusi lifakwa phezu kwebhodi lesifunda, lakha ama-circuits, iminonjana nezici ezingaphezulu.

7. Ukwelashwa kwendawo:

Ukwelashwa okungaphezulu kuyisinyathelo esibalulekile enqubweni yokukhiqiza ukuze kuvikelwe amasekhethi nokuqinisekisa ukwethembeka kwesikhathi eside.Ubuchwepheshe obujwayelekile bokwelashwa okungaphezulu kwama-PCB wobuchwepheshe be-HDI buhlanganisa isiliva lokucwiliswa, igolide lokucwiliswa, izilondolozi ze-organic solderability (OSP), kanye ne-electroless nickel/immersion gold (ENIG). Lobu buchwepheshe buhlinzeka ngesendlalelo esivikelayo esivimbela i-oxidation, sithuthukise ukuthengiselana, futhi senze ukuhlangana kube lula.

8. Ukuhlola Nokulawula Ikhwalithi:

Ukuhlola okuqinile nezinyathelo zokulawula ikhwalithi kuyadingeka ngaphambi kokuba ama-PCB obuchwepheshe be-HDI ahlanganiswe emishinini kagesi.Ukuhlola okuzenzakalelayo kwe-Optical Inspection (AOI) kanye nokuhlolwa kukagesi (E-test) kuvame ukwenziwa ukuze kutholwe futhi kulungiswe noma yiziphi izinkinga noma izinkinga zikagesi kusekethe. Lokhu kuhlola kuqinisekisa ukuthi umkhiqizo wokugcina uhlangabezana nokucaciswa okudingekayo futhi usebenza ngokwethembeka.

Ekuphetheni:

Ama-PCB Obuchwepheshe be-HDI aguqule imboni yezogesi, asiza ukuthuthukiswa kwemishini kagesi emincane, elula, nanamandla kakhulu.Ukuqonda inqubo yokukhiqiza eyinkimbinkimbi ngemuva kwalawa mabhodi kugqamisa izinga lokunemba nobungcweti obudingekayo ukuze kukhiqizwe ama-PCB obuchwepheshe be-HDI bekhwalithi ephezulu. Kusukela ekwakhiweni kokuqala ngokumba, ukucwenga kanye nokulungiswa kwendawo, zonke izinyathelo zibalulekile ukuze kuqinisekiswe ukusebenza kahle nokwethembeka. Ngokusebenzisa amasu okukhiqiza athuthukile kanye nokuthobela izindinganiso eziqinile zokulawula ikhwalithi, abakhiqizi bangahlangabezana nezidingo ezishintshayo njalo zemakethe yezogesi futhi bavule indlela yokusungula izinto ezintsha.

Isikhathi sokuthumela: Sep-02-2023

Emuva