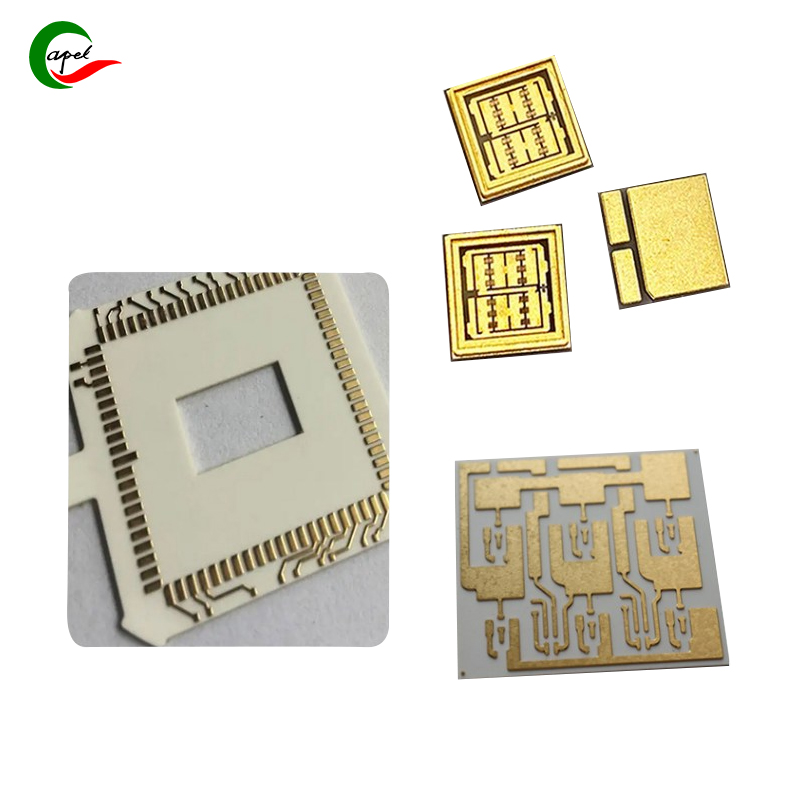

Kulokhu okuthunyelwe kwebhulogi, sizohlola izinhlobo ezahlukene zemiklamo yebhodi lesifunda se-ceramic kanye nezici zabo eziyingqayizivele.

Amabhodi esekethe e-Ceramic aya ngokuya aduma ngenxa yezinzuzo zawo eziningi ngaphezu kwezinto zebhodi lesifunda elivamile njenge-FR4 noma i-polyimide. Amabhodi wesifunda se-Ceramic aba yisinqumo sokuqala sezinhlelo zokusebenza ezihlukahlukene ngenxa ye-conductivity enhle kakhulu yokushisa, ukumelana nokushisa okuphezulu namandla amahle omshini. Njengoba isidingo sikhula, kanjalo nezinhlobonhlobo zemiklamo yebhodi lesifunda se-ceramic etholakala emakethe.

1. Ibhodi lesifunda le-ceramic elisekelwe ku-alumina:

I-Aluminium oxide, eyaziwa nangokuthi i-aluminium oxide, iyinto esetshenziswa kabanzi kumabhodi wesifunda se-ceramic. Inezici ezinhle kakhulu zokuvala ugesi futhi ilungele izinhlelo zokusebenza ezidinga amandla aphezulu e-dielectric. Amabhodi esekethe e-alumina ceramic angamelana namazinga okushisa aphezulu, awenze afanelekele ukusetshenziswa ezinhlelweni zamandla aphezulu njengama-electronics amandla kanye nezinhlelo zezimoto. Ukuqedwa kwayo okubushelelezi kanye ne-coefficient ephansi yokunwetshwa kwe-thermal kuyenza ifaneleke ezinhlelweni ezibandakanya ukuphathwa kokushisa.

2. Ibhodi lesekhethi ye-Aluminium nitride (AlN) yobumba:

Amabhodi esekethe e-Aluminium nitride Ceramic ane-conductivity ephakeme yokushisa uma kuqhathaniswa nama-alumina substrates. Avame ukusetshenziswa ezinhlelweni ezidinga ukuchithwa kokushisa okusebenzayo, okufana nezibani ze-LED, amamojula wamandla, kanye nemishini ye-RF/microwave. Amabhodi esekethe e-Aluminium nitride ahamba phambili ezinhlelweni zokusebenza zemvamisa ephezulu ngenxa yokulahleka kwawo okuphansi kwe-dielectric kanye nobuqotho besignali obuhle kakhulu. Ukwengeza, amabhodi esekethe e-AlN alula futhi anobungani bemvelo, okuwenza abe yisinqumo esifanele ezimbonini ezahlukahlukene.

3. Ibhodi lesifunda se-Silicon nitride (Si3N4) ceramic:

Amabhodi wesekethe we-Silicon nitride ceramic aziwa ngamandla awo okusebenza kahle kakhulu kanye nokumelana nokushaqeka okushisayo. Lawa maphaneli ngokuvamile asetshenziswa ezindaweni ezinokhahlo lapho kushintsha khona izinga lokushisa elidlulele, ukucindezela okukhulu, nezinto ezonakalisayo. Amabhodi wesifunda we-Si3N4 athola izinhlelo zokusebenza ezimbonini ezifana ne-aerospace, ukuzivikela, kanye nowoyela negesi, lapho ukwethembeka nokuqina kubalulekile. Ngaphezu kwalokho, i-silicon nitride inezindawo ezinhle zokuvikela ugesi, okwenza kube ukukhetha okuhle kakhulu kwezicelo zamandla aphezulu.

4. Ibhodi lesifunda le-LTCC (i-temperature ephansi eqhunyiswa nge-ceramic):

Amabhodi esekethe e-LTCC akhiqizwa kusetshenziswa amateyipu e-ceramic amaningi aphrintwa isikrini ngamaphethini okuqhuba. Izendlalelo ziyapakishwa bese zishiswa emazingeni okushisa aphansi, okwenza ibhodi lesifunda eliminyene kakhulu nelithembekile. Ubuchwepheshe be-LTCC buvumela izingxenye ze-passive ezifana nama-resistors, ama-capacitor nama-inductors ukuthi ahlanganiswe ngaphakathi kwebhodi lesifunda ngokwalo, okuvumela ukuguqulwa okuncane nokusebenza okuthuthukisiwe. Lawa mabhodi afanele ukuxhumana okungenantambo, ugesi wezimoto, kanye nemishini yezokwelapha.

5. Ibhodi lesifunda le-HTCC (i-ceramic co-fired co-fired ceramic board):

Amabhodi esekethe e-HTCC afana namabhodi e-LTCC ngokwenqubo yokukhiqiza. Kodwa-ke, amabhodi e-HTCC ashiswa emazingeni okushisa aphezulu, okuholela ekwandeni kwamandla emishini kanye namazinga okushisa aphezulu okusebenza. Lawa mabhodi ajwayele ukusetshenziswa ezinhlelweni zokushisa eziphezulu njengezinzwa zezimoto, ama-aerospace electronics, namathuluzi okumba ama-downhole. Amabhodi esekethe e-HTCC anokuqina okuhle kakhulu kwe-thermal futhi angakwazi ukumelana nokuhamba ngebhayisikili okwedlulele.

Ngokufigqiwe

Izinhlobo ezahlukene zamabhodi esekethe e-ceramic aklanyelwe ukuhlangabezana nezinhlobonhlobo zezidingo eziqondene nomkhakha. Kungakhathaliseki ukuthi izinhlelo zokusebenza zamandla aphezulu, ukuchithwa kokushisa okuphumelelayo, izimo zemvelo ezimbi kakhulu noma izidingo ze-miniaturization, imiklamo yebhodi lesifunda se-ceramic ingahlangabezana nalezi zidingo. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, amabhodi esekethe e-ceramic kulindeleke ukuthi abambe iqhaza elibalulekile ekuvumelaneni nezinhlelo ze-elekthronikhi ezintsha nezithembekile kuzo zonke izimboni.

Isikhathi sokuthumela: Sep-25-2023

Emuva