Lapho ibhodi lesifunda le-FPC eliguquguqukayo ligobile, izinhlobo zokucindezeleka ezinhlangothini zombili zomugqa oyinhloko zihlukile.

Lokhu kungenxa yamandla ahlukene asebenza ngaphakathi nangaphandle kwendawo egobile.

Ohlangothini lwangaphakathi lwendawo egobile, i-FPC ingaphansi kwengcindezi ecindezelayo. Lokhu kungenxa yokuthi impahla iyacindezelwa futhi iyampintsha njengoba igobela ngaphakathi. Lokhu kucindezela kungabangela izendlalelo ezingaphakathi kwe-FPC ukuthi zicindezelwe, okungase kubangele ukubola noma ukuqhekeka kwengxenye.

Ngaphandle kwendawo egobile, i-FPC ingaphansi kwengcindezi eqinile. Lokhu kungenxa yokuthi impahla iyanwetshwa lapho igobela ngaphandle. Ukulandelela ithusi nezinto zokuqhuba endaweni yangaphandle kungase kube ngaphansi kwengcindezi engase ibeke engozini ubuqotho besekethe. Ukuze unciphise ingcindezi ku-FPC ngesikhathi sokugoba, kubalulekile ukuklama isifunda esiguquguqukayo usebenzisa izinto ezifanele nezindlela zokwenziwa. Lokhu kuhlanganisa ukusebenzisa izinto eziguquguqukayo ezifanele, ukujiya okufanele, kanye nokucabangela irediyasi yokugoba encane ye-FPC. Ukuqinisa okwanele noma izakhiwo zokusekela nazo zingasetshenziswa ukuze kusatshalaliswe ingcindezi ngokulinganayo kuyo yonke isekethe.

Ngokuqonda izinhlobo zokucindezeleka nokuthatha ukucatshangelwa kwedizayini efanele, ukwethembeka nokuqina kwamabhodi esekethe e-FPC aguquguqukayo lapho egobile noma eguquguquka kungathuthukiswa.

Okulandelayo ukucatshangelwa kwedizayini ethile engasiza ukuthuthukisa ukuthembeka nokuqina kwamabhodi esekethe e-FPC aguquguqukayo lapho egobile noma eguquguquka:

Ukukhetha Okubalulekile:Ukukhetha impahla efanele kubalulekile. I-substrate eguquguqukayo evumelana nezimo ezinhle namandla emishini kufanele isetshenziswe. I-Flexible polyimide (PI) iyisinqumo esivamile ngenxa yokuzinza kwayo okushisayo nokuguquguqukayo.

Isakhiwo sesiyingi:Ukuhlelwa kwesekethe okufanelekile kubalulekile ukuze kuqinisekiswe ukuthi ukulandelelwa kwe-conductive kanye nezingxenye zibekwe futhi zihanjiswe ngendlela enciphisa ukugxila kwengcindezi ngesikhathi sokugoba. Kunconywa ukusebenzisa amakhona ayindilinga esikhundleni samakhona abukhali.

Ukuqiniswa Nezakhiwo Zokusekela:Ukwengeza izinhlaka zokuqinisa noma zokusekela ezindaweni ezigobayo ezibucayi kungasiza ukusabalalisa ingcindezi ngokulinganayo futhi kuvimbele ukulimala noma ukuncipha. Izendlalelo zokuqinisa noma izimbambo zingasetshenziswa ezindaweni ezithile ukuze kuthuthukiswe ubuqotho bemishini.

Irediyasi yokugoba:Imitha yokugoba encane kufanele ichazwe futhi icatshangelwe phakathi nesigaba sokuklama. Ukweqa i-radius encane yokugoba kuzoholela ekugxilweni kwengcindezi ngokweqile kanye nokwehluleka.

Ukuvikela kanye ne-Ecapsulation:Ukuvikela okufana nama-conformal coatings noma izinto zokuhlanganisa kunganikeza amandla emishini engeziwe futhi kuvikele amasekhethi ezintweni zemvelo ezinjengomswakama, uthuli, namakhemikhali.

Ukuhlola Nokuqinisekisa:Ukwenza ukuhlola okuphelele nokuqinisekisa, okuhlanganisa ukugoba kwemishini kanye nokuhlola okuguquguqukayo, kungasiza ukuhlola ukwethembeka nokuqina kwamabhodi esekethe e-FPC avumelana nezimo ngaphansi kwezimo zomhlaba wangempela.

Ingaphakathi lendawo egobile linokucindezela, kanti ingaphandle liyashuba. Ubukhulu bengcindezi buhlobene nogqinsi kanye nerediyasi egobayo yebhodi lesifunda le-FPC eliguquguqukayo. Ukucindezeleka ngokweqile kuzokwenza i-FPC iguquguquke ibhodi lebhodi le-lamination, i-copper foil fracture nokunye. Ngakho-ke, ukwakheka kwe-lamination yebhodi lesifunda le-FPC eliguquguqukayo kufanele kuhlelwe ngokunengqondo ekwakhiweni, ukuze iziphetho ezimbili zomugqa ophakathi nendawo ogobile kufanele zilingane ngangokunokwenzeka. Ngesikhathi esifanayo, i-radius encane yokugoba kufanele ibalwe ngokuya ngezimo ezihlukene zohlelo lokusebenza.

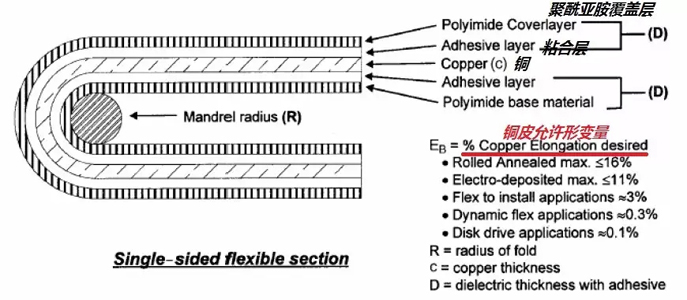

Isimo 1. Ukugoba okuncane kwebhodi lesekethe ye-FPC ehlangothini olulodwa eguquguqukayo kuboniswa esithombeni esilandelayo:

I-radius yayo encane yokugoba ingabalwa ngefomula elandelayo: R= (c/2) [(100-Eb) /Eb]-D

Ubuncane berediyasi yokugoba engu-R=, ukujiya kuka-c= isikhumba sethusi (iyunithi m), ukujiya kwefilimu eyisimbozo engu-D= (m), ukuguqulwa okuvumelekile kwe-EB= isikhumba sethusi (kukalwa ngamaphesenti).

Ukuguqulwa kwesikhumba sethusi kuyahlukahluka ngezinhlobo ezahlukene zethusi.

I-deformation ephezulu ye-A nethusi ecindezelwe ingaphansi kuka-16%.

Ukuguqulwa okuphezulu kwe-B kanye ne-electrolytic yethusi kungaphansi kuka-11%.

Ngaphezu kwalokho, okuqukethwe kwethusi kwento efanayo nakho kuhlukile ezikhathini ezihlukene zokusetshenziswa. Ngesikhathi sokugoba okukodwa, inani elilinganiselwe lesimo esibucayi sokuphuka liyasetshenziswa (inani lingu-16%). Ngomklamo wokufaka ogobayo, sebenzisa inani elincane lokuguquguquka elicaciswe yi-IPC-MF-150 (ethusi eligoqiwe, inani lingu-10%). Ngezinhlelo zokusebenza eziguquguqukayo eziguquguqukayo, ukuguqulwa kwesikhumba sethusi kungu-0.3%. Ukuze kusetshenziswe ikhanda lamagnetic, ukuguqulwa kwesikhumba sethusi kungu-0.1%. Ngokusetha ukuguqulwa okuvumelekile kwesikhumba sethusi, i-radius encane ye-curvature ingabalwa.

Ukuguquguquka okunamandla: indawo yalesi sicelo sesikhumba sethusi ibonakala ngokuguqulwa. Isibonelo, ichashazi le-phosphor ekhadini le-IC liyingxenye yekhadi le-IC elifakwe ku-chip ngemva kokufakwa kwekhadi le-IC. Ngesikhathi sokufakwa, igobolondo likhubazekile ngokuqhubekayo. Lesi sigcawu sohlelo lokusebenza siyaguquguquka futhi sinamandla.

Ubuncane berediyasi yokugoba ye-PCB eguquguqukayo yohlangothi olulodwa incike ezintweni ezimbalwa, okuhlanganisa okokusebenza okusetshenzisiwe, ukushuba kwebhodi, kanye nezidingo ezithile zohlelo lokusebenza. Ngokuvamile, irediyasi egobekayo yebhodi lesifunda le-flex icishe iphindwe ka-10 ubukhulu bebhodi. Isibonelo, uma ubukhulu bebhodi bungu-0.1mm, i-radius encane yokugoba icishe ibe ngu-1mm. Kubalulekile ukuqaphela ukuthi ukugoba ibhodi ngaphansi kobubanzi obuncane bokugoba kungase kubangele ukugxilisa ingqondo, ukucindezeleka emithonjeni ye-conductive, futhi mhlawumbe ukuqhekeka noma ukuhlukaniswa kwebhodi. Ukugcina ubuqotho bogesi kanye nemishini yesifunda, kubalulekile ukunamathela ku-radii ye-bend enconywayo. Kunconywa ukuthi uthintane nomkhiqizi noma umphakeli webhodi eliguquguqukayo ukuze uthole imihlahlandlela ethile yerediyasi egobayo futhi uqinisekise ukuthi umklamo nezidingo zohlelo lokusebenza ziyahlangatshezwa. Ukwengeza, ukwenza ukuhlolwa komshini kanye nokuqinisekisa kungasiza ekunqumeni ingcindezi enkulu ibhodi engakwazi ukumelana nayo ngaphandle kokuphazamisa ukusebenza nokuthembeka kwayo.

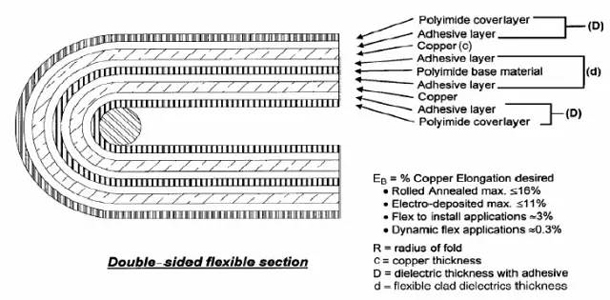

Isimo 2, ibhodi le-FPC elinezinhlangothi ezimbili zebhodi lesifunda eliguquguqukayo ngokulandelayo:

Phakathi kwazo: R= ubuncane berediyasi yokugoba, iyunithi m, c= ukujiya kwesikhumba sethusi, iyunithi m, D= ukujiya kwefilimu yokumboza, iyunithi mm, EB= ukuguqulwa kwesikhumba sethusi, kukalwa ngamaphesenti.

Inani le-EB liyafana nalelo elingenhla.

D= ukujiya kwe-interlayer medium, iyunithi M

Irediyasi encane yokugoba yebhodi lesifunda eguquguqukayo ye-FPC (Flexible Printed Circuit) ezinhlangothi zombili ngokuvamile inkulu kunephaneli yohlangothi olulodwa. Lokhu kungenxa yokuthi amaphaneli anezinhlangothi ezimbili anemikhondo yokuqondisa nhlangothi zombili, esengozini enkulu ekucindezelekeni nasekucindezelekeni ngesikhathi sokugoba. Ibanga eliphansi lokugoba le-FPC enezinhlangothi ezimbili eziguquguqukayo ze-pcb baord ngokuvamile licishe libe izikhathi ezingu-20 ukujiya kwebhodi. Usebenzisa isibonelo esifanayo nesangaphambili, uma ipuleti liwugqinsi elingu-0.1mm, i-radius encane yokugoba icishe ibe ngu-2mm. Kubaluleke kakhulu ukulandela imihlahlandlela yomkhiqizi kanye nokucaciswa kokugoba amabhodi we-pcb we-FPC anezinhlangothi ezimbili. Ukweqa irediyasi yokugoba enconyiwe kungase konakalise ukulandelelwa kwe-conductive, kubangele ukwehla kongqimba, noma kubangele ezinye izinkinga ezithinta ukusebenza kwesekethe nokwethembeka. Kunconywa ukuthi uthintane nomkhiqizi noma umphakeli ukuze uthole imihlahlandlela ethile yerediyasi egobile, futhi wenze ukuhlola komshini nokuqinisekisa ukuze uqinisekise ukuthi ibhodi lingakwazi ukumelana nokugoba okudingekile ngaphandle kokuphazamisa ukusebenza kwalo.

Isikhathi sokuthumela: Jun-12-2023

Emuva