Yethula:

Njengoba isidingo semishini ye-elekthronikhi ehlakaniphile nehlangene sikhula, abakhiqizi bayaqhubeka nokusungula izinto ezintsha ukuze bahlangabezane nalezi zidingo. Amabhodi esekethe ephrintiwe e-Rigid-flex (ama-PCB) afakazele ukuthi ashintsha igeyimu, avumela imiklamo eguquguqukayo nesebenza kahle kuma-electronics wesimanje. Kodwa-ke, kunombono oyiphutha ovamile wokuthi ukukhiqiza ama-PCB aqinile-flex kudinga imishini yokukhiqiza ekhethekile. Kule bhulogi, sizokhipha le nganekwane futhi sixoxe ngokuthi kungani le mishini ekhethekile ingadingeki.

1. Qonda ibhodi eliguquguqukayo:

I-Rigid-flex PCB ihlanganisa izinzuzo zamabhodi wesifunda aqinile futhi aguquguqukayo ukuze kwandiswe ukuguquguquka komklamo, ukuthuthukisa ukwethembeka nokunciphisa izindleko zokuhlanganisa. Lawa mabhodi ahlanganisa inhlanganisela yama-substrates aqinile futhi aguquguqukayo, axhunywe kusetshenziswa acwecwe ngezimbobo, okunamathelayo okuqhubayo, noma izixhumi ezikhiphekayo. Isakhiwo sayo esiyingqayizivele siyivumela ukugoba, ukugoqa noma ukusonteka ukuze ingene ezindaweni eziqinile futhi yamukele imiklamo eyinkimbinkimbi.

2. Idinga imishini yokukhiqiza ekhethekile:

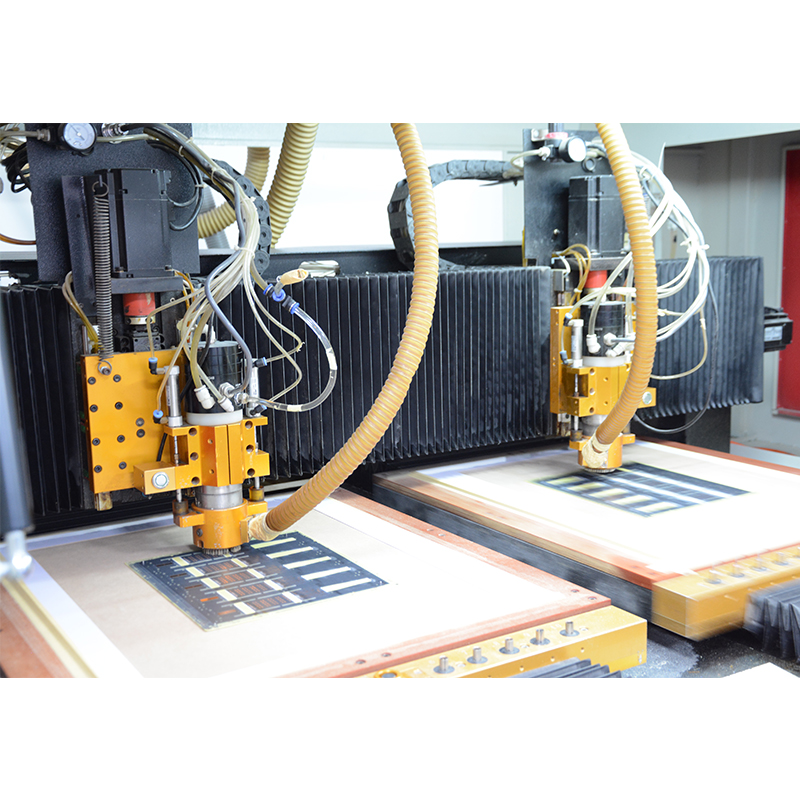

Ngokuphambene nenkolelo evamile, ukutshala imali emishinini yokukhiqiza eqinile eguquguqukayo akudingekile ngaso sonke isikhathi. Nakuba lawa mabhodi edinga ukucatshangelwa okwengeziwe ngenxa yokwakhiwa kwawo, izinqubo eziningi ezikhona zokukhiqiza namathuluzi asengasetshenziswa. Izikhungo zokukhiqiza zesimanje zifakelwe imishini esezingeni eliphezulu ukuze kukhiqizwe amaphaneli aqinile ngaphandle kwesidingo semishini ekhethekile.

3. Ukuphatha izinto eziguquguqukayo:

Esinye sezici ezibalulekile zokukhiqiza i-PCB eguquguqukayo eqinile ukuphatha nokucubungula izinto eziguquguqukayo. Lezi zinto zingase zibe ntekenteke futhi zidinga ukunakekelwa okukhethekile ngesikhathi sokukhiqiza. Kodwa-ke, ngokuqeqeshwa okufanele kanye nezinqubo zokukhiqiza ezithuthukisiwe, imishini ekhona ingaphatha lezi zinto ngendlela efanele. Ukulungiswa kwezindlela zokubopha, izilungiselelo zokuthutha kanye namasu okuphatha kungaqinisekisa ukuphathwa okulungile kwama-substrates aguquguqukayo.

4. Ukubhoboza nokuPlalika Ngezimbobo:

Amabhodi e-Rigid-flex ngokuvamile adinga ukubhobozwa emigodini ukuze kuxhunywe izendlalelo nezingxenye. Abanye bangase bakholelwe ukuthi umshini wokumba okhethekile uyadingeka ngenxa yezinguquko ku-substrate material. Nakuba ezinye izimo zingase zidinge izingcezu zokubhola eziqinile noma ama-spindles anesivinini esikhulu, okokusebenza okukhona kungahlangabezana nalezi zidingo. Ngokufanayo, ukufaka izimbobo ngezimbobo ngezinto zokuqhuba kungenziwa kusetshenziswa izinto ezijwayelekile nezindlela ezifakazelwe yimboni.

5. I-copper foil lamination and etching:

I-Copper foil lamination kanye nezinqubo zokunamathisela ezilandelayo ziyizinyathelo ezibalulekile ekwenziweni kwebhodi eliguquguqukayo eliqinile. Phakathi nalezi zinqubo, izingqimba zethusi ziboshelwa ku-substrate futhi zisuswe ngokukhetha ukwenza i-circuitry oyifunayo. Nakuba imishini ekhethekile ingase ibe nenzuzo ekukhiqizweni kwevolumu ephezulu, imishini yokufaka i-lamination evamile kanye ne-etching ingafinyelela imiphumela emihle kakhulu ekukhiqizeni okuncane.

6. Ukuhlanganiswa kwezingxenye kanye nokushisela:

Izinqubo zokuhlanganisa nokuhlanganisa azidingi izisetshenziswa ezikhethekile zama-PCB aguquguqukayo. Ubuchwepheshe bokufaka i-surface mount technology (SMT) nezindlela zokuhlanganisa imbobo yomgodi zingasetshenziswa kulawa mabhodi. Isihluthulelo idizayini efanele ye-manufacturability (DFM), iqinisekisa ukuthi izingxenye zibekwe ngendlela ehlelekile nezindawo eziguquguqukayo kanye namaphuzu okucindezeleka okungenzeka engqondweni.

Ekuphetheni:

Kafushane, kungumbono oyiphutha ukuthi ama-PCB aqinile adinga okokusebenza okukhethekile. Ngokuthuthukisa izinqubo zokukhiqiza, ukuphatha ngokucophelela izinto eziguquguqukayo, kanye nokuthobela imihlahlandlela yokuklama, okokusebenza okukhona kungakhiqiza ngempumelelo lawa mabhodi esekethe anemisebenzi eminingi. Ngakho-ke, abakhiqizi nabaklami kufanele basebenzisane nabalingani bokukhiqiza abanolwazi abanganikeza ulwazi oludingekayo kanye nesiqondiso kuyo yonke inqubo yokukhiqiza. Ukuvula amandla ama-PCB aqinile aguquguqukayo ngaphandle komthwalo wemishini ekhethekile kunikeza izimboni ithuba lokusebenzisa izinzuzo zazo futhi zidale amadivaysi e-elekthronikhi asungula kakhudlwana.

Isikhathi sokuthumela: Sep-19-2023

Emuva