Ingabe ubhekene nokwanda okushisayo kanye nezinkinga zengcindezi yokushisa ngama-PCB anezinhlangothi ezimbili? Ungabe usabheka okunye, kulokhu okuthunyelwe kwebhulogi sizokuqondisa ukuthi ungazixazulula kanjani lezi zinkinga ngempumelelo. Kodwa ngaphambi kokuthi singene ezisombululweni, ake sizethule.

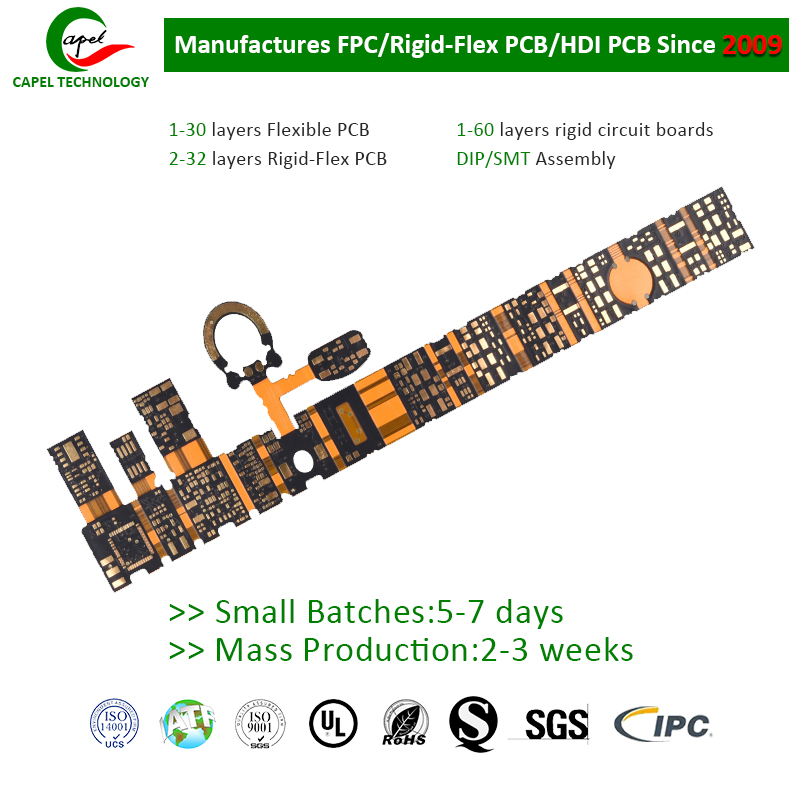

U-Capel ungumkhiqizi onolwazi embonini yebhodi lesifunda futhi usekhonze amakhasimende iminyaka engu-15. Inefektri yayo yebhodi lesifunda eguquguqukayo, ifektri yebhodi lesifunda eqinile-flex, ifektri ye-smt yebhodi lesifunda, futhi isungule idumela elihle ekukhiqizeni amabhodi wesifunda asezingeni eliphezulu aphakathi kuya phezulu. Imishini yethu ethuthukisiwe yokukhiqiza ezenzakalelayo ngokugcwele kanye nethimba elizinikele le-R&D libonisa ukuzibophezela kwethu ekusebenzeni kahle. Manje, ake sibuyele ekuxazululeni inkinga yokwanda okushisayo kanye nengcindezi yokushisa kuma-PCB anezinhlangothi ezimbili.

Ukwanda okushisayo kanye nengcindezi yokushisa kuyizinkathazo ezivamile embonini yokukhiqiza ye-PCB. Lezi zinkinga zivela ngenxa yomehluko ku-coefficient of thermal expansion (CTE) yezinto ezisetshenziswa ku-PCB. Lapho kushisa, izinto zokwakha ziyakhula, futhi uma amazinga okunwetshwa kwezinto ezihlukene ehluka kakhulu, ingcindezi ingakhula futhi ibangele ukwehluleka kwe-PCB. Ukuze uxazulule izinkinga ezinjalo, sicela ulandele le mihlahlandlela:

1. Ukukhetha okubalulekile:

Khetha izinto ezinamavelu e-CTE afanayo. Ngokusebenzisa izinto ezinamazinga afanayo okunweba, amandla okucindezeleka okushisayo nezinkinga ezihlobene nokwanda angancishiswa. Xhumana nochwepheshe bethu noma uthintane namazinga emboni ukuze uthole izinto ezingcono kakhulu zezidingo zakho ezithile.

2. Ukucatshangelwa kwedizayini:

Cabangela ukwakheka kwe-PCB nomklamo ukuze unciphise ukucindezelwa okushisayo. Kunconywa ukuthi kugcinwe izingxenye ezisusa ukushisa kakhulu kude nezindawo ezinokushintshashintsha okukhulu kwezinga lokushisa. Izingxenye zokupholisa ngendlela efanele, ukusebenzisa i-thermal vias, kanye nokuhlanganisa amaphethini okushisa nakho kungasiza ekukhipheni ukushisa kahle futhi kunciphise ingcindezi.

3. Ukunqwabelanisa ungqimba:

Isitaki sesendlalelo se-PCB esinezinhlangothi ezimbili sithinta ukuziphatha kwayo okushisayo. Ukuhleleka okulinganiselayo nokulinganisa kusiza ukusabalalisa ukushisa ngokulinganayo, kunciphisa ithuba lokucindezeleka okushisayo. Xhumana nonjiniyela bethu ukuze wenze i-layup ukuze ubhekane nezinkinga zakho zokwanda kokushisa.

4. Ugqinsi lwethusi kanye nezintambo:

Ugqinsi lwethusi nobubanzi bokulandelela kudlala indima ebalulekile ekulawuleni ukucindezeleka okushisayo. Izendlalelo zethusi eziwugqinsi zihlinzeka nge-thermal conductivity engcono futhi zinganciphisa imiphumela yokwanda okushisayo. Ngokufanayo, ukulandelelwa okubanzi kunciphisa ukumelana futhi kusize ekulahlekeni kokushisa okufanele.

5. Ukukhethwa kwezinto ezisetshenziswa ngaphambi kokulungiswa kanye nezinto ezibalulekile:

Khetha izinto ezisetshenziswa ngaphambili ne-core ezine-CTE efana ne-copper cladding ukuze unciphise ubungozi bokuphelelwa amandla ngenxa yengcindezi yokushisa. Izinto ezilashwe ngokufanele neziboshiwe ze-prepreg nezinto ezibalulekile zibalulekile ekugcineni ubuqotho besakhiwo se-PCB.

6. I-impedance elawulwayo:

Ukugcina i-impedance elawulwayo kuyo yonke idizayini ye-PCB kusiza ukuphatha ingcindezi yokushisa. Ngokugcina izindlela zesignali zimfushane futhi ugweme izinguquko ezingazelelwe kububanzi bokulandelela, unganciphisa izinguquko ze-impedance ezibangelwa ukunwetshwa kokushisa.

7. Ubuchwepheshe bokuphatha okushisayo:

Ukusebenzisa amasu okulawula okushisayo njengamasinki okushisa, amaphedi ashisayo, kanye ne-thermal vias kungasiza ukuqeda ukushisa ngempumelelo. Lobu buchwepheshe buthuthukisa ukusebenza okushisayo okuphelele kwe-PCB futhi bunciphise ubungozi bokwehluleka okuhlobene nokucindezeleka okushisayo.

Ngokusebenzisa lawa maqhinga, unganciphisa kakhulu ukwanda kokushisa kanye nezinkinga zengcindezi yokushisa kuma-PCB anezinhlangothi ezimbili. E-Capel, sinobuchwepheshe nezinsiza zokukusiza unqobe lezi zinselele. Ithimba lethu lochwepheshe lingakunikeza isiqondiso esibalulekile nokusekelwa kuzo zonke izigaba zenqubo yakho yokukhiqiza i-PCB.

Ungavumeli ukunwetshwa okushisayo kanye nengcindezi yokushisa kuthinte ukusebenza kwe-PCB yakho enezinhlangothi ezimbili. Xhumana no-Capel namuhla futhi uzwe ikhwalithi nokwethembeka okuza neminyaka engu-15 yokuhlangenwe nakho kwethu embonini yebhodi lesifunda. Masisebenze ndawonye ukuze sakhe i-PCB ehlangabezana nedlula okulindele.

Isikhathi sokuthumela: Oct-02-2023

Emuva