Kule bhulogi, sizoxoxa ngamasu ajwayelekile okunamathisela asetshenziswa ekuhlanganiseni kwe-PCB eguquguqukayo nokuthi athuthukisa kanjani ukuthembeka okuphelele nokusebenza kwale mishini kagesi.

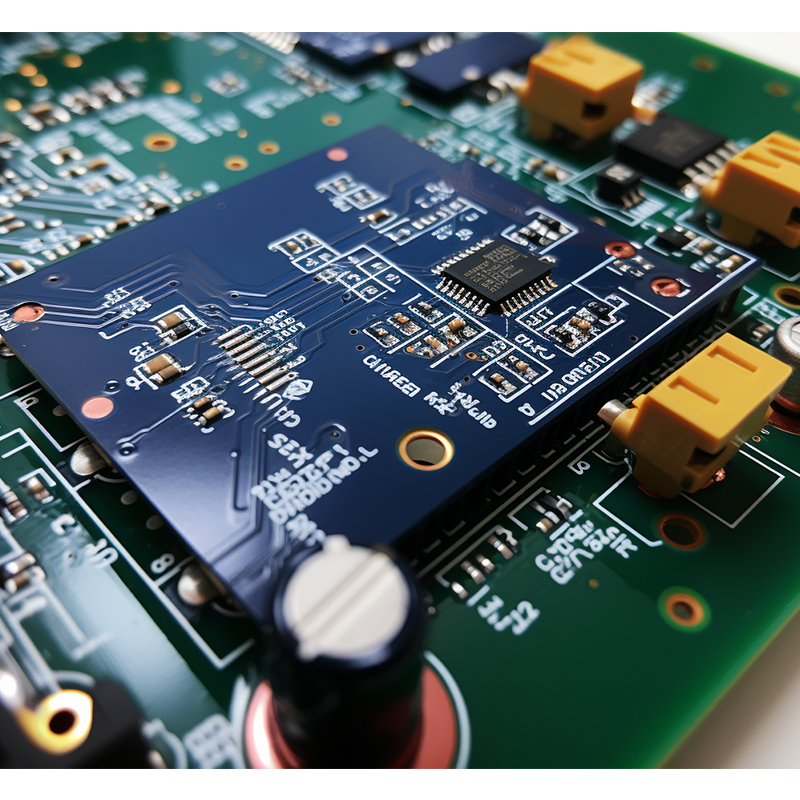

Ubuchwepheshe be-soldering budlala indima ebalulekile enqubweni yokuhlanganisa ye-PCB eguquguqukayo eqinile. Lawa mabhodi ayingqayizivele aklanyelwe ukuhlinzeka ngenhlanganisela yokuqina nokuguquguquka, okwenza abe ekahle ezinhlobonhlobo zezinhlelo zokusebenza lapho isikhala sinomkhawulo noma ukuxhumana okuyinkimbinkimbi kuyadingeka.

1. Ubuchwepheshe be-Surface Mount (SMT) ekukhiqizeni i-PCB eguquguqukayo eqinile:

Ubuchwepheshe be-Surface Mount (SMT) bungobunye bobuchwepheshe bokuthengisa obusetshenziswa kakhulu ekuhlanganisweni kwe-PCB eguquguqukayo eqinile. Le nqubo ihlanganisa ukubeka izinto zokukhweza ngaphezulu ebhodini nokusebenzisa i-solder paste ukuze ibambe endaweni. I-solder paste iqukethe izinhlayiya ezincane ze-solder ezimisiwe ekugubheni ezisiza enqubweni yokuhlanganisa.

I-SMT inika amandla ukuminyana okuphezulu kwengxenye, okuvumela inani elikhulu lezingxenye ukuthi zifakwe nhlangothi zombili ze-PCB. Ubuchwepheshe buphinde bunikeze ukusebenza okuthuthukisiwe kokushisa nogesi ngenxa yezindlela ezimfushane zokuqhuba ezidalwe phakathi kwezingxenye. Kodwa-ke, kudinga ukulawulwa okunembile kwenqubo yokushisela ukuvimbela amabhuloho e-solder noma amalunga anganele e-solder.

2. Ubuchwepheshe be- Through-hole (THT) ekwenziweni kwe-PCB eguquguqukayo eqinile:

Ngenkathi izingxenye zokukhweza ngaphezulu zivame ukusetshenziswa kuma-PCB aqinile-flex, izingxenye zembobo nazo ziyadingeka kwezinye izimo. Ubuchwepheshe be-Threhth-hole (THT) bubandakanya ukufaka izingxenye eziholela emgodini ku-PCB nokuyidambisa ngakolunye uhlangothi.

I-THT inikeza amandla emishini ku-PCB futhi inyusa ukumelana nokucindezeleka komshini nokudlidliza. Ivumela ukufakwa okuphephile kwezingxenye ezinkulu, ezisindayo okungenzeka zingafaneli i-SMT. Nokho, i-THT iphumela ezindleleni ezinde futhi ingase ikhawulele ukuguquguquka kwe-PCB. Ngakho-ke, kubalulekile ukwenza ibhalansi phakathi kwezingxenye ze-SMT ne-THT kumiklamo ye-PCB eguquguqukayo eqinile.

3. Ukulinganisa komoya oshisayo (HAL) ekwenzeni i-PCB eguquguqukayo eqinile:

I-Hot air leveling (HAL) iyindlela yokunamathisela esetshenziselwa ukufaka ungqimba olulinganayo lwe-solder emithonjeni yethusi eveziwe kuma-PCB aqinile aguquguqukayo. Inqubo ihlanganisa ukudlulisa i-PCB endaweni yokugeza ye-solder encibilikisiwe bese uyichaya emoyeni oshisayo, osiza ukususa i-solder eyeqile futhi kwakha indawo eyisicaba.

I-HAL ivame ukusetshenziselwa ukuqinisekisa ukudayiswa okufanele kweminonjana yethusi edaluliwe kanye nokuhlinzeka nge-coating evikelayo ngokumelene ne-oxidation. Inikeza ukumbozwa okuhle kwe-solder jikelele futhi ithuthukise ukwethembeka okuhlangene kwe-solder. Nokho, i-HAL ingase ingafaneli yonke imiklamo ye-PCB eguquguqukayo, ikakhulukazi leyo enokunemba noma ukujikeleza okuyinkimbinkimbi.

4. Ukushisela okukhethiwe ku-PCB eguquguqukayo eqinile ekhiqizayo:

I-selective soldering iyindlela esetshenziselwa ukuthengisa ngokukhetha izingxenye ezithile kuma-PCB aguquguqukayo. Le nqubo ihilela ukusebenzisa i-wave soldering noma i-soldering iron ukuze usebenzise ngokunembile i-solder ezindaweni ezithile noma izingxenye ze-PCB.

I-solder ekhethiwe iwusizo ikakhulukazi uma kunezingxenye ezizwela ukushisa, izixhumi, noma izindawo eziminyene kakhulu ezingakwazi ukumelana nezinga lokushisa eliphezulu lokuphinda kufakwe i-solder. Ivumela ukulawula okungcono kwenqubo yokushisela futhi inciphisa ingozi yokulimaza izingxenye ezibucayi. Kodwa-ke, i-soldering ekhethiwe idinga ukusetha okwengeziwe kanye nezinhlelo uma kuqhathaniswa namanye amasu.

Ukufingqa, ubuchwepheshe bokushisela obusetshenziswa ngokujwayelekile bokuhlanganisa ibhodi eliqinile buhlanganisa ubuchwepheshe be-surface mount (SMT), ubuchwepheshe be- through-hole (THT), ukulinganisa komoya oshisayo (HAL) kanye nokushisela okukhethiwe.Ubuchwepheshe ngabunye bunezinzuzo zabo nokucatshangelwa, futhi ukukhetha kuncike ezidingweni ezithile zomklamo we-PCB. Ngokuqonda lobu buchwepheshe kanye nemithelela yabo, abakhiqizi bangaqinisekisa ukwethembeka nokusebenza kwama-PCB aguquguqukayo aqinile ezinhlelweni ezihlukene.

Isikhathi sokuthumela: Sep-20-2023

Emuva