Ukuqonda ukuguquguquka kwe-PCB eguquguqukayo kubalulekile lapho ulungiselela ukusebenza futhi uvula amathuba amasha edizayini. Kule bhulogi, sizocubungula ubunkimbinkimbi balobu buchwepheshe obumangalisayo futhi sihlole izinzuzo obuzilethayo ekusetshenzisweni okuhlukahlukene.

Embonini yanamuhla ye-elekthronikhi ehlala ishintsha, isidingo sobuchwepheshe obuhlangene nobuhlukahlukene sikhula kancane kancane. Onjiniyela nabakhiqizi bayaqhubeka nokufuna izixazululo ezintsha ezinqoba imikhawulo yamabhodi esifunda aphrintiwe aqinile (ama-PCB). Lokhu kulandelwa kuholele ekwenyukeni kwama-PCB aqinile-flex, ahlinzeka ngokulingana okuphelele phakathi kokuqina nokuguquguquka.

Uyini umehluko phakathi kwe-PCB eqinile neguquguqukayo?

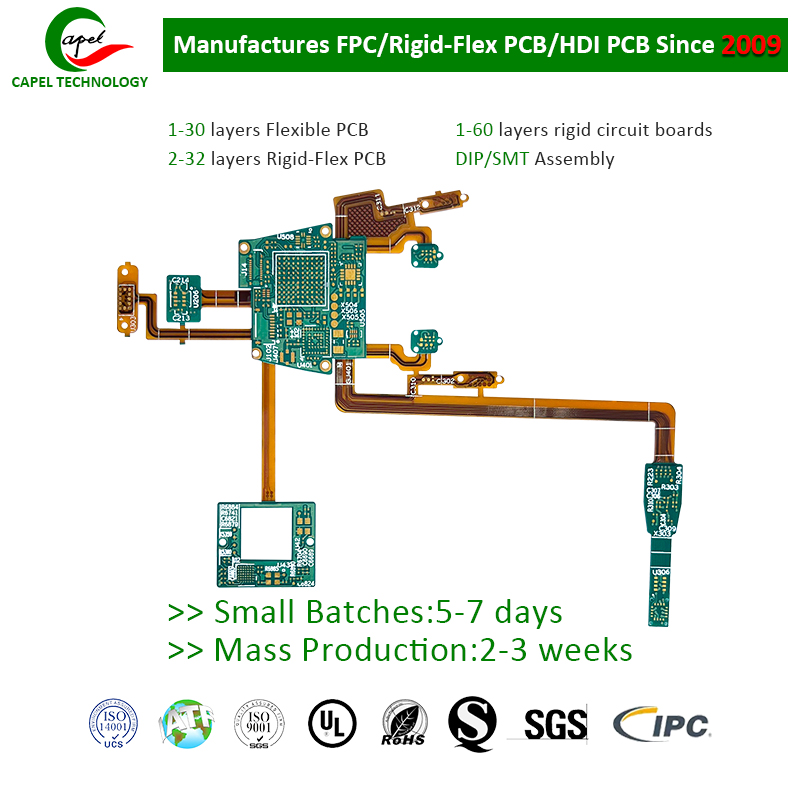

I-Rigid-flex PCB ihlanganisa izinzuzo zama-substrates aqinile futhi aguquguqukayo, ahlanganisa okuhle kakhulu kuyo yomibili imihlaba. Aqukethe izendlalelo eziningi eziguquguqukayo ezixhunywe izigaba eziqinile, okudala ibhodi lesifunda eliqinile neliguquguqukayo. Lesi sakhiwo esiyingqayizivele sivumela onjiniyela ukuthi bakhe ama-PCB akwazi ukugoba, agoqe, futhi avumelane nezimo ezingajwayelekile ngaphandle kokuphazamisa ukusebenza.

Izinzuzo Zokuguquguquka

1. Ukuthuthukisa isikhala: Enye yezinzuzo ezibaluleke kakhulu ze-PCB eguquguqukayo eqinile ikhono layo lokuthuthukisa ukusetshenziswa kwendawo ngaphakathi kwemishini kagesi.Ngokuhlanganisa izigaba eziguquguqukayo, lawa mabhodi angangena ezindaweni ezimise okweqile noma ezingajwayelekile ama-PCB endabuko aqinile angakwazi ukungena kuzo. Lokhu kwenza ama-PCB aqinile aguquguqukayo alungele izinhlelo zokusebenza ezibambezeleke esikhaleni njenge-aerospace, ubuchwepheshe bezokwelapha nobugqokekayo.

2. Ukuthembeka okuthuthukisiwe: Ukuvumelana nezimo akuthuthukisi ukusebenza kahle kwendawo kuphela, kodwa futhi kuthuthukisa ukwethembeka nokuqina kwemishini kagesi.Kuma-PCB aguquguqukayo aqinile, ingxenye eguquguqukayo isebenza njengesidambisi sokucindezeleka, imunca ngempumelelo futhi ihlakaze ukucindezeleka komshini okubangelwa ukudlidliza, umthelela, noma ukwanda okushisayo. Lokhu kunciphisa ubungozi bokulimala kwengxenye, ukwehluleka kokuhlangana kwe-solder kanye nokwehluleka okuphelele kwe-PCB.

3. Inkululeko yokuklama eyandisiwe: Ukuhlanganisa amandla okugoba e-PCB aqinile futhi aguquguqukayo kuvula indawo entsha yamathuba omklamo.Onjiniyela manje sebengakwazi ukudala amasekhethi agobile noma agoqiwe alandela amakhonsathi wedivayisi, okuholela ekuthuthukisweni kwe-ergonomics nokuhlanganiswa okungcono nezingxenye zemishini. Le nkululeko yokuklama iphinde ivumele ukuthuthukiswa kwemikhiqizo emisha ebithathwa njengento engenzeki.

4. Thuthukisa ubuqotho besignali: Ubuqotho besignali yinkinga ebalulekile kumasistimu kagesi.Ukuvumelana nezimo kwama-PCB aqinile aguquguqukayo kuvumela onjiniyela ukuthi balandele ngokucophelela imikhondo yesignali eduze kwe-flex, bathuthukise ukusebenza kwesignali futhi banciphise ukuphazamiseka kwe-electromagnetic (EMI). Ngokunciphisa ukulahlekelwa kwesignali kanye ne-EMI, ungaqinisekisa ukuxhumana okuthembekile nokudluliswa kwedatha ngesivinini esiphezulu ngaphakathi kwamadivayisi kagesi.

Ukucatshangelwa Kwedizayini yama-PCB Aguqukayo

Lapho uklama i-PCB eguquguqukayo eqinile, izici ezimbalwa okufanele zicatshangelwe ukuze kukhuliswe ukuguquguquka kwayo nokusebenza kukonke:

1. Ukukhetha impahla: Ukukhetha izinto ezifanele zezingxenye eziqinile nezivumelana nezimo kubalulekile.Izingxenye eziqinile ngokuvamile zisebenzisa i-FR4, kuyilapho izindawo eziguquguqukayo zisebenzisa i-polyimide noma amanye ama-substrates avumelana nezimo. Ukusebenza nomkhiqizi we-PCB onesipiliyoni ekwakhiweni kwe-rigid-flex kuzoqinisekisa ukuthi izinto ezihambisanayo nezithembekile ziyakhethwa.

2. I-Bend Radius: Ukunquma ubuncane berediyasi yokugoba eyamukelekayo kubalulekile ekuvimbeleni ukucindezeleka okukhulu ku-PCB.Ubuncane berediyasi i-PCB eguquguqukayo ekwazi ukusiphatha ngokuphephile kufanele ibalwe futhi ichazwe ngokusekelwe kokokusebenza okukhethiwe kanye nohlelo oluhlosiwe.

3. Ukubekwa kwengxenye: Ukubekwa kwengxenye efanele kubalulekile ukugwema ukucindezela noma ukulimaza izingxenye ngesikhathi sokugoba noma ukugoba.Ukusebenzisana eduze nomphakeli wakho wengxenye kanye nomkhiqizi we-PCB kuzoqinisekisa ukubekwa kwengxenye efanele kanye nesibopho esiqinile ukuze umelane nengcindezi yemishini.

4. Ukuhlola nokuqinisekisa: Izinqubo eziqinile zokuhlola nokuqinisekisa ziyadingeka ukuze kuqinisekiswe ukwethembeka nokuqina kwemiklamo ye-PCB eguquguqukayo.Amathuluzi okuhlola imvelo nawokulingisa angasiza ekuhlonzeni izinkinga ezingaba khona futhi aqinisekise ukusebenza komklamo ngaphansi kwezimo zokusebenza ezihlukene.

Ukukhulula amandla aphelele ama-PCB aqinile-flex

Ukuvumelana nezimo kwama-PCB aqinile aguquguqukayo kuveza amathuba amangalisayo kubaklami bemikhiqizo nonjiniyela. Lobu buchwepheshe budala impumelelo kuzo zonke izimboni, kusukela ekufakweni kwezokwelapha kuya kumasistimu we-aerospace kanye nogesi wabathengi. Nokho, ukuze ubone amandla aphelele ezixazululo ze-PCB design eziguquguqukayo, kuyadingeka ukusebenza nomkhiqizi we-PCB onolwazi nothembekile.

Uma ubheke ukuhlanganisa ubuchwepheshe be-PCB obuguquguqukayo kuphrojekthi yakho elandelayo, cabanga ukusebenza nomkhiqizi we-PCB ogxile kuma-PCB aguquguqukayo. Ubuchwepheshe babo namandla angakusiza ukuthi uzulazule ezintweni eziyinkimbinkimbi zokuklama, ukukhiqiza, futhi uhlanganise lobu buchwepheshe obusha emikhiqizweni yakho.

Ngokufigqiwe

Ukuvumelana nezimo kwama-PCB aguquguqukayo aguquguqukayo kuwukushintsha kwegeyimu, okukuvumela ukuthi unqobe izithiyo zesikhala, uthuthukise ukwethembeka, ukhuphule inkululeko yokuklama, futhi uthuthukise ubuqotho besignali.Ngokwamukela lobu buchwepheshe obuguqukayo kanye nokuba ingcweti kokucatshangelwa komklamo wabo, ungavula umhlaba wamathuba futhi ulethe imibono yakho emisha kakhulu ekuphileni. Khetha umkhiqizi olungile we-PCB futhi masiphushe imingcele yomhlaba we-electronics ndawonye.

Isikhathi sokuthumela: Oct-11-2023

Emuva