Emabhodini aphrintiwe aqinile-flex, ngenxa yokunamathela okungalungile kokugqoka odongeni lwembobo (ifilimu yenjoloba ehlanzekile kanye neshidi lokubopha), kulula ukubangela ukuthi ukugqoka kuhlukane nodonga lwembobo lapho kubhekene nokushaqeka okushisayo. , futhi idinga ikhefu elingaba ngu-20 μm, ukuze indandatho yethusi yangaphakathi kanye nethusi elenziwe nge-electroplated libe endaweni enokwethenjelwa kakhudlwana enamaphuzu amathathu, okuthuthukisa kakhulu ukumelana nokushaqeka okushisayo kwembobo enensimbi. I-Capel elandelayo izokhuluma ngayo ngokuningiliziwe ngawe. Izinyathelo ezintathu zokuhlanza imbobo ngemva kokubhoboza ibhodi eliguquguqukayo.

Ulwazi lokuhlanza ngaphakathi kwembobo ngemuva kokubhoboza ama-flex flex circuits:

Njengoba i-polyimide ingamelani ne-alkali enamandla, i-alkaline eqinile ye-potassium permanganate desmear elula ayiwafanele amabhodi aphrintiwe aguquguqukayo futhi aqinile. Ngokuvamile, ukungcola kokumba ebhodini elithambile neliqinile kufanele kuhlanzwe ngenqubo yokuhlanza i-plasma, ehlukaniswe ngezinyathelo ezintathu:

(1) Ngemva kokuba imbobo yemishini ifinyelele izinga elithile le-vacuum, i-nitrogen ehlanzekile kakhulu kanye nomoya-mpilo ohlanzekile kakhulu kufakwa kuwo ngokulingana, umsebenzi oyinhloko ukuhlanza udonga lwembobo, ukushisa kuqala ibhodi eliphrintiwe, nokwenza i-polymer material. ube nomsebenzi othile, ozuzisa ukucubungula Okulandelayo. Ngokujwayelekile, izinga lokushisa lingu-80 degrees Celsius kanti isikhathi siyimizuzu eyi-10.

(2) I-CF4, i-O2 ne-Nz isabela ne-resin njengegesi yasekuqaleni ukuze kuzuzwe inhloso yokuqeda ukungcola kanye nokubuyela emuva, ngokuvamile ku-85 degrees Celsius kanye nemizuzu engu-35.

(3) I-O2 isetshenziswa njengegesi yasekuqaleni ukuze kukhishwe insalela noma “uthuli” olwakhiwe phakathi nezinyathelo ezimbili zokuqala zokwelapha; hlanza udonga lwembobo.

Kodwa kufanele kuqashelwe ukuthi lapho i-plasma isetshenziselwa ukususa ukungcola kokumba emigodini yamabhodi aphrintiwe aguquguqukayo futhi aqinile-aqinile, ijubane lokugxila lezinto ezihlukahlukene lihlukile, futhi ukuhleleka kusuka ezinkulu kuye ezincane: ifilimu ye-acrylic. , i-epoxy resin, i-polyimide, i-fiberglass nethusi. Amakhanda e-fiber yengilazi aphumile namasongo ethusi kungabonakala ngokucacile odongeni lwembobo kusukela kusibonakhulu.

Ukuze uqiniseke ukuthi isisombululo se-electroless copper plating singathinta ngokugcwele udonga lwembobo, ukuze ungqimba lwethusi lungakhiqizi ama-voids kanye nama-voids, okusele kokusabela kwe-plasma, i-glass fiber ephumayo kanye nefilimu ye-polyimide odongeni lwembobo kufanele kube. isusiwe. Indlela yokwelapha ihlanganisa izindlela zamakhemikhali zemishini nezemishini noma inhlanganisela yalokhu okubili. Indlela yamakhemikhali ukucwilisa ibhodi eliphrintiwe ngesisombululo se-ammonium hydrogen fluoride, bese usebenzisa i-ionic surfactant (isixazululo se-KOH) ukulungisa ukushajwa kodonga lwembobo.

Izindlela zemishini zihlanganisa i-sandblasting emanzi enomfutho ophezulu kanye nokugeza amanzi anengcindezi ephezulu. Inhlanganisela yamakhemikhali kanye nezindlela zemishini inomphumela omuhle kakhulu. Umbiko we-metallographic ubonisa ukuthi isimo sodonga lwembobo enensimbi ngemva kokukhishwa kwe-plasma siyagculisa.

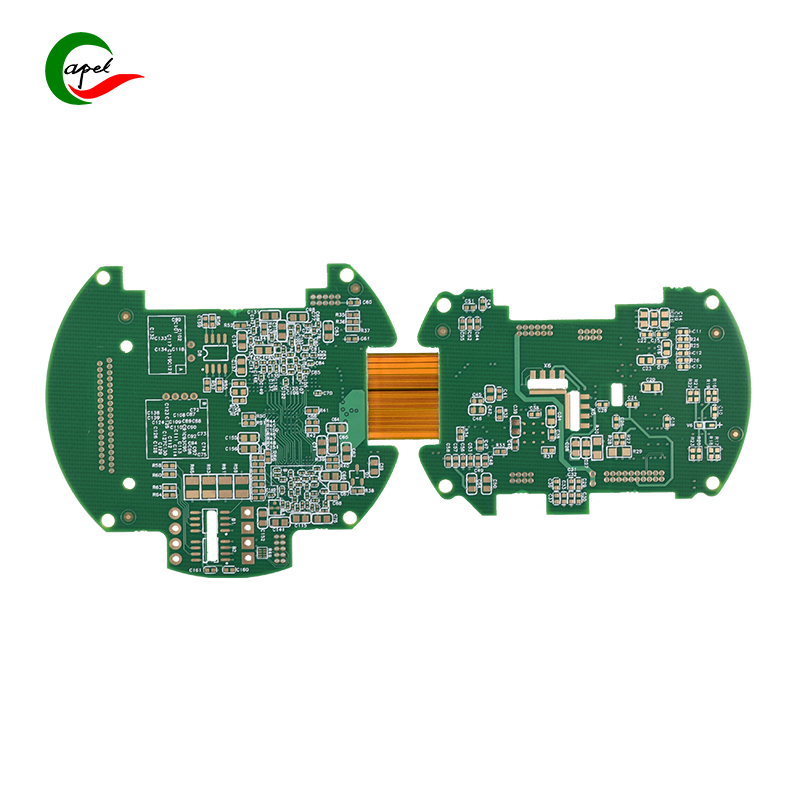

Okungenhla yizinyathelo ezintathu zokuhlanza ingaphakathi lembobo ngemuva kokubhobozwa kwamabhodi aphrintiwe aqinile-flex ahlelwe ngokucophelela nguCapel. U-Capel ugxile ebhodini lesifunda eliphrintiwe eliqinile eliguquguqukayo, ibhodi elithambile, ibhodi eliqinile kanye nomhlangano we-SMT iminyaka engu-15, futhi uye waqoqa ingcebo yolwazi lobuchwepheshe embonini yebhodi lesifunda. Ngethemba ukuthi lokhu kwabelana kuwusizo kuwo wonke umuntu. Uma uneminye imibuzo yebhodi lesifunda, sicela uthintane nethimba lethu lezobuchwepheshe lemboni yezimonyo yaseCapel ngokuqondile ukuze unikeze ukwesekwa kobuchwepheshe obuchwepheshile kuphrojekthi yakho.

Isikhathi sokuthumela: Aug-21-2023

Emuva