ayini ngempela amabhodi aqinile-flex, futhi angasetshenziswa ngempela ezinhlelweni zokusebenza zamandla aphezulu? Kulo mhlahlandlela obanzi, sizohlola le mibuzo futhi sikhanyise ngesihloko.

Esimweni sanamuhla sobuchwepheshe obusheshayo, onjiniyela nabaklami bahlala befuna izixazululo ezintsha zokuhlangabezana nesidingo esikhulayo samadivayisi kagesi anamandla futhi ahlangene. Indawo eyodwa lapho lokhu kubaluleke kakhulu kuzinhlelo zokusebenza zamandla aphezulu. Ukuze kuhlangatshezwane nezinselelo ezilethwa yilezi zinhlelo ezinzima, ochwepheshe abaningi baphendukela kumabhodi esekethe aphrintiwe aqinile (ama-PCB).

I. Ukuqonda ama-Rigid Flex PCBs:

A. Incazelo yama-PCB aguquguqukayo aqinile

I-Rigid-flex PCB iyinhlanganisela ye-PCB eqinile yendabuko kanye ne-PCB eguquguqukayo. Aqukethe izendlalelo eziningi zama-substrates aqinile futhi aguquguqukayo axhunywe ngezinto eziguquguqukayo ze-conductive. Lo mklamo uvumela i-PCB ukuthi igobe futhi igobe ngaphandle kokubeka engcupheni ubuqotho boxhumo lwe-elekthronikhi, inikeze inkululeko yokuklama entsha kanye nokuguquguquka.

B. Izinzuzo kanye nokubi kwama-PCB aguquguqukayo aqinile

Izinzuzo ze-rigid-flex board:

Ukulungiswa Kwendawo: Ama-PCB aqinile aguquguqukayo enza abaklami basebenzise kahle indawo enezinhlangothi ezintathu ngoba bangagotshwa, bagoqwe noma basontwe ukuze balingane nendawo etholakalayo. Ukuthembeka okuthuthukisiwe: Azikho izixhumi nezintambo ezixhumanisayo ezidingekayo, okunciphisa amathuba okuhluleka kwemishini nokulahlekelwa kwesignali. I-Rigid-flex PCBs futhi imelana kakhulu nokudlidliza, ukushaqeka, nokuguquguquka kwezinga lokushisa. Thuthukisa ubuqotho besignali: Ngokunciphisa ukuxhumana kanye nokunciphisa izindlela zokudlulisela, ama-PCB aqinile-flex anciphisa ukuhlanekezela kwesignali, aqinisekise ukusebenza okungcono nokuthembeka kwesistimu. Umhlangano Owenziwe Lula: Ama-PCB aqinile-aguquguqukayo aqeda isidingo sezinqubo zokuhlanganisa eziyinkimbinkimbi ngokuqeda isidingo sezixhumi namajoyinti e-solder, ukunciphisa ingozi yephutha lomuntu nokonga isikhathi phakathi nenqubo yokukhiqiza. Ukusebenza Kwezindleko: Nakuba kubiza kakhulu kunama-PCB endabuko, ama-PCB aqinile angakwazi ukonga izindleko ngokunciphisa ukubalwa kwezingxenye futhi aqede isidingo samakhebuli nezixhumi ezengeziwe.

Ukungalungi kwebhodi le-rigid-flex:

Imiklamo eyinkimbinkimbi: Ukuklama ama-PCB aqinile aguquguqukayo kudinga ulwazi olukhethekile nobungcweti ngenxa yokuhlanganiswa kwezinto eziqinile nezivumelana nezimo. Lobu bunzima bungabangela ukwanda kwesikhathi sokuthuthukiswa kanye nezindleko zokuklama eziphezulu. Izindleko zokuqala: Izindleko zokuqala zokuthuthukisa i-PCB eguquguqukayo eqinile ingase ibe phezulu kune-PCB evamile, iyenze ingakufanelekeli ukukhiqizwa kwevolumu ephansi noma amaphrojekthi anesabelomali esilinganiselwe. Ukusebenza kabusha okulinganiselwe: Uma i-PCB eguquguqukayo isihlanganisiwe, kuba nzima ukuyilungisa noma ukuyilungisa ngoba izingxenye eziguquguqukayo zintekenteke kakhulu futhi zizwela izinguquko.

C. Izicelo zama-PCB aguquguqukayo aqinile

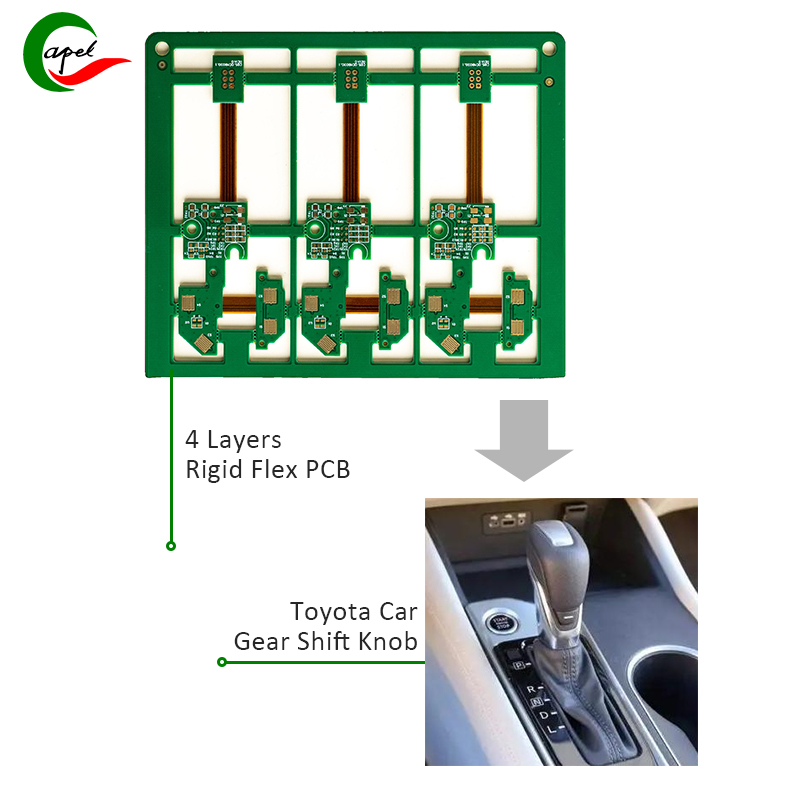

Amabhodi e-Rigid-flex asetshenziswa kakhulu ezimbonini ezihlukahlukene, okuhlanganisa: I-Aerospace kanye ne-Defense: I-PCB eguquguqukayo eqinile ilungele i-aerospace nezicelo zokuzivikela ngenxa yokukwazi ukumelana nezimo ezimbi kakhulu nokuthembeka okuphezulu. Zisetshenziswa ezinhlelweni zezindiza, ama-radar, amasathelayithi kanye nemishini yezempi. Amadivayisi Ezokwelapha: Ama-PCB aqinile-aguquguqukayo aya ngokuya asetshenziswa kumishini yezokwelapha ngenxa yokuguquguquka kwawo kanye nesici sefomu elihlangene. Asetshenziswa kuma-pacemakers, ama-implants, amasistimu wokuthwebula izithombe zezokwelapha kanye namathuluzi okuqapha ezempilo agqokekayo. I-Consumer Electronics: Imakethe ye-elekthronikhi yabathengi izuza kuma-PCB aqinile-flex kumadivayisi afana nama-smartphones, amaphilisi, ama-consoles wegeyimu, nezinto ezigqokekayo. Lawa ma-PCB anika amandla imiklamo emincane kanye nokusebenza okuthuthukisiwe. Imboni yezimoto: I-Rigid-flex PCB ifanele izinto zikagesi zezimoto, okuhlanganisa nezinhlelo ezithuthukisiwe zokusiza abashayeli (ADAS), amasistimu e-infotainment, ama-powertrains namasistimu okukhanyisa. Banikeza ukwethembeka kanye nokwenza kahle kwendawo ezindaweni zezimoto ezinzima.

2. Ukwandisa amandla e-PCB eguquguqukayo eqinile ezinhlelweni zokusebenza zamandla aphezulu: Ukucatshangelwa okubalulekile:

2.1.Izidingo zamandla kanye nemikhawulo:

A. Qonda izidingo zamandla: Ngaphambi kokuklama i-PCB eguquguqukayo eqinile yezinhlelo zokusebenza zamandla aphezulu, izidingo zamandla kufanele zichazwe ngokucacile. Nquma amazinga kagesi, amanje namandla i-PCB okudingeka iwaphathe, kucatshangelwa ukuphakama nokusebenza okuqhubekayo.

B. Cabangela ukulinganiselwa kwamandla: I-Rigid-flex PCBs inezilinganiso ezithile eziphezulu zamandla okufanele zicatshangelwe phakathi nesigaba sokuklama. Ukulayishwa ngokweqile kwe-PCB kungaholela ekushiseni ngokweqile, ekwehleni kwe-voltage, kanye nokulimala okungenzeka ezingxenyeni. Qinisekisa imikhawulo yamandla enikezwe umkhiqizi futhi uqinisekise ukuthi idizayini ihlangabezana nalokhu kucaciswa.

2.2.Ukucatshangelwa kokukhishwa kokushisa:

A. Khomba izingxenye zokushisisa: Kuzinhlelo zokusebenza zamandla aphezulu, izingxenye ezithile zingakhiqiza inani elikhulu lokushisa. Khomba lezi zingxenye futhi ucabangele indawo yazo ku-PCB eguquguqukayo eqinile. Zihlanganise ukuze ugxile emizamweni yokupholisa futhi uqinisekise isu lokupholisa elifanele.

B. Sebenzisa amasu okuphatha okushisayo asebenzayo: Ukuchithwa kwe-thermal kubalulekile ekugcineni ukusebenza nokuthembeka ezinhlelweni zokusebenza zamandla aphezulu. Faka ama-vias ashisayo, osinki bokushisa, namaphedi ashisayo edizayini ye-PCB ukuthuthukisa ukudluliswa kokushisa. Ukwengeza, uma kunesidingo, cabanga ukusebenzisa izindlela zokupholisa ezithuthukisiwe, njengokupholisa okusebenzayo ngamafeni noma ukupholisa uketshezi. ezintathu.

2.3.Ukukhethwa nokubekwa kwengxenye:

A. Khetha izingxenye ezifanele: Ukukhetha izingxenye ezinamandla okuphatha amandla afanelekile kubalulekile empumelelweni yezinhlelo zokusebenza zamandla aphezulu. Khetha izingxenye ezidizayinelwe futhi zikalelwe ukusetshenziswa kwamandla aphezulu. Cabangela izilinganiso zabo zezinga lokushisa, amandla okuthwala amanje, kanye nemikhawulo kagesi ukuze uqinisekise ukuthi bayakwazi ukuphatha amazinga adingekayo wamandla.

B. Lungiselela ukuhlelwa kwengxenye: Ukuhlelwa kwezingxenye ku-PCB eguquguqukayo eguquguqukayo kungathinta kakhulu ukusebenza kwayo namandla okukhipha ukushisa. Hlanganisa izingxenye zamandla aphezulu ukuze uqinisekise indawo eyanele yokukhipha ukushisa. Ukwengeza, cabangela ukusondela kwengxenye ukuze unciphise ukuphazamiseka kwesignali nokuthuthukisa ukusebenza kukagesi.

2.4.Ukuqina nokuthembeka kwemishini:

A. Khetha Okubalulekile Okumangelengele: Izinhlelo zokusebenza ezinamandla kakhulu ngokuvamile zihlanganisa izindawo ezinokhahlo, ukudlidliza, nezingcindezi zemishini. Khetha izinto eziqinile nezivumelana nezimo ezinezakhiwo ezifanele zomshini ukuze uqinisekise ukuqina nokuthembeka kwe-PCB. Cabangela ukuzinza kwento, ukuguquguquka nokumelana nomswakama, amakhemikhali kanye nokushintshashintsha kwezinga lokushisa.

B. Qinisa indawo eguquguqukayo: Ku-PCB eguquguqukayo eqinile, ingxenye eguquguqukayo isengozini yokucindezeleka kwemishini nokukhathala. Qinisa lezi zindawo ngezendlalelo zethusi ezengeziwe noma izembozo ze-polyimide ukuze ukhulise amandla azo okusebenza futhi welule impilo ye-PCB.

3.Izinzuzo Zokusebenzisa I-Rigid Flex PCBs Yezicelo Ezinamandla Aphezulu

A. Ubuqotho besignali obuthuthukisiwe

Ama-PCB e-Rigid-flex athuthukisa kakhulu ubuqotho besignali, ngaleyo ndlela athuthukise ukusebenza kwezinhlelo zokusebenza zamandla aphezulu. Ngokulawula kangcono i-impedance, ukulahlekelwa kwesignali kungancishiswa, okuholela ekudlulisweni kwesignali okuthembekile, okuphumelelayo. Ukusetshenziswa kwezigaba eziqinile kusiza ukunciphisa ukuvela kokuphazamiseka kwesignali okubangelwa ukudlidliza nokucindezeleka komshini, okuqinisekisa ukusebenza okufanayo kwekhwalithi ephezulu.

B. Ukuphatha okushisayo okuthuthukisiwe

Ukushisa okushisayo kuwukucatshangelwa okubalulekile ezinhlelweni zokusebenza zamandla aphezulu, njengoba ukushisa okudlulele kungabangela ukonakala kokusebenza futhi kubangele nomonakalo ongalungiseki ezingxenyeni. Ama-PCB e-Rigid-flex anekhono elihle kakhulu lokuphatha okushisayo, ahlinzeka ngezindlela ezisebenzayo zokuqeda ukushisa futhi anciphise ukucindezeleka okushisayo. Ngokusebenzisa izinto ezinokuguquguquka okuhle kakhulu kwe-thermal kanye nama-vias ashisayo abekwe ngokucophelela namasinki okushisa, lawa ma-PCB aqinisekisa ukushabalaliswa kokushisa okufanele, aqinisekise ukwethembeka kwesistimu nokwelula ubude bayo bempilo.

C. Amakhono okonga isikhala

Njengoba isidingo sezinhlelo ze-elekthronikhi ezihlangene, ezisebenza kahle ziqhubeka nokukhula, ikhono lokonga isikhala seliyingxenye ebalulekile yomklamo we-PCB. Ama-PCB e-Rigid-flex ahamba phambili kule ndawo, asekela imiklamo enezinhlangothi ezintathu futhi asebenzisa ngokuphumelelayo isikhala esitholakalayo. Ukuqeda izixhumi ezinkulu nezixhumi kunciphisa usayizi nesisindo, okubaluleke kakhulu ezinhlelweni zokusebenza zamandla aphezulu lapho isikhala silinganiselwe.

D. Ukuguquguquka kwemishini okuthuthukisiwe

Ukuvumelana nezimo kwemishini okuthuthukisiwe: Enye inzuzo yama-PCB aqinile-flex ukuguquguquka kwawo okuhle kakhulu kwemishini. Ukuhlanganiswa kwezingxenye eziqinile neziguquguqukayo kuzivumela ukuthi zivumelane nezimo ezingajwayelekile, ukugoba namajika, okuzenza zibe zilungele izinhlelo zokusebenza ezidinga imiklamo eyinkimbinkimbi nehlangene. Lokhu kuguquguquka futhi kwandisa ukumelana kwabo nokucindezeleka kwemishini, ukudlidliza nokushaqeka, okuqinisekisa ukusebenza okuthembekile ezindaweni ezinokhahlo.

E. Amathuba okuklama anda

I-Rigid-flex PCBs ivula umhlaba wamathuba ngokuya ngokuguquguquka kwedizayini. Abakhiqizi banenkululeko yokuhlanganisa izingxenye ezihlukahlukene futhi bathuthukise isakhiwo sabo ukuze bathuthukise ukusebenza kukagesi. Amandla okwenza ngendlela oyifisayo ukwakheka kwe-PCB ngokusekelwe ezidingweni ezithile zohlelo lokusebenza anyusa ukusebenza kahle kohlelo lonke kanye nokusebenza. Lokhu kuvumelana nezimo kuba yigugu ikakhulukazi ezinhlelweni zokusebenza zamandla aphezulu, lapho izithiyo zesikhala nobunkimbinkimbi bedizayini kuvame ukubangela izinselele ezinkulu.

4.Umhlahlandlela Wokwenza Idizayini Ye-PCB Yamandla Anamandla Aphezulu: Indlela Eya Empumelelweni yethula:

A. Ububanzi bokulandelela obanele nesikhala:

Ukucatshangelwa okubalulekile ekuklameni ama-PCB anamandla amakhulu aqinile ukuqinisekisa ububanzi obanele bokulandela kanye nesikhala. Ukulandelela okubanzi kwenza ukugeleza kwamanje okusebenzayo futhi kunciphise ukumelana, kunciphisa ingozi yokushisa ngokweqile nokuqinisekisa ukusebenza kahle. Ukuhlukaniswa okufanele phakathi kokulandelelwa kusiza ukuvimbela ukungqubuzana okungaba khona kanye nokuphazamiseka futhi kugcine ubuqotho besignali. Ukulandela izindinganiso zemboni zobubanzi bokulandelela nesikhala kubalulekile ukuze kuqinisekiswe ukuphepha, ukwethembeka, nokuzinza kwezicelo zamandla aphezulu.

B. Ukupakishwa kwesendlalelo esifanele nokukhetha okubalulekile:

Ukunqwabelana kwesendlalelo nokukhethwa kwezinto kuthinta kakhulu ukusebenza nokuqina kwama-PCB anamandla amakhulu aguquguqukayo. Ukupakishwa kwesendlalelo okwanele kunika amandla ukusatshalaliswa kwamandla okusebenzayo nokudluliswa kwesignali kuyilapho kunciphisa ukuphazamiseka komsindo. Ukukhetha ngokucophelela izinto ezifanele, njengama-laminates ekhwalithi ephezulu kanye ne-foil yethusi ene-conductivity enhle yokushisa, kungasiza ukuthuthukisa ukuchithwa kokushisa nokuthembeka okuphelele.

C. Ukubekwa kwengxenye nokucatshangelwa komzila:

Ukubekwa kwengxenye okusebenzayo kanye nomzila kubalulekile ekusebenzeni kahle kwama-PCB anamandla amakhulu aqinile. Ukubekwa kwengxenye yecebo kunciphisa ubude bendlela yesiginali, kunciphisa ukwehla kwamandla kagesi futhi kuthuthukisa ikhwalithi yesignali. Lapho uklama ama-PCB ezinhlelo zokusebenza zamandla aphezulu, kubalulekile ukuqonda izici ezishisayo zezingxenye. Amasu afanele omzila, njengokugwema ukugoba okubukhali nokusebenzisa amapheya ahlukile uma kudingeka, angasiza ukulawula umsindo nokuqinisekisa ubuqotho besignali.

D. Izindlela zokuphatha ezishisayo:

Ukuphatha okushisayo kubalulekile ekuvimbeleni ukushisa nokugcina ukuzinza kwama-PCB anamandla aqinile aguquguqukayo. Ukufaka ubuchwepheshe obufana ne-thermal vias, osinki bokushisa nokusebenzisa izindawo zethusi zamasu kusiza ukuqeda ukushisa futhi kuvimbele izingxenye ukuthi zifinyelele amazinga okushisa abalulekile. Kubalulekile ukucabangela izici ezishisayo zezinto zokwakha kanye nezingxenye phakathi nesigaba sokuklama ukuze kuqinisekiswe ukungena kahle komoya kanye nokukhishwa okusebenzayo kokushisa, ngaleyo ndlela kunwetshwe impilo ye-PCB.

E. Ukuhambisana namazinga okuphepha:

Ezinhlelweni zokusebenza zamandla aphezulu, ukuphepha kubaluleke kakhulu futhi nokuqinisekisa ukuthi ukuthobelana nezindinganiso zokuphepha kubalulekile. Ukuthobelana namazinga afana ne-UL, IEC, kanye ne-IPC kuqinisekisa ukuthi amadizayini e-PCB ahlangabezana nezidingo zemboni zokuvala ugesi, ukuvutha, nokuvikelwa ezingozini ezingaba khona. Ukuthobelana nezindinganiso zokuphepha kuqinisekisa ukwethembeka nobuqotho bama-PCB anamandla aqinile aguquguqukayo, okuqinisekisa ukusebenza okuphephile kwabasebenzisi bokugcina.

5.Ama-PCB aqinile aziguqula kanjani izinhlelo zokusebenza zamandla aphezulu:

A. Isibonelo 1: Imboni yezimoto:

Imboni yezimoto ihamba phambili ngokusungula izinto ezintsha, ilokhu icindezela njalo imingcele ukuze ithuthukise ukusebenza kwezimoto, ukuphepha nokusebenza kahle. I-Rigid-flex PCBs ibambe iqhaza elibalulekile ekuguquleni lo mkhakha, ikhuthaza ukuthuthukiswa kwezinhlelo ze-elekthronikhi ezithuthukile. Ezinhlelweni zezimoto ezinamandla amakhulu njengezimoto zikagesi (EVs), ama-PCB aqinile avula indlela yokuphathwa kwamandla okuthuthukisiwe, imiklamo ehlangene kanye nokwethembeka okungenakuqhathaniswa. Ukuguquguquka kwazo kuvumela ukuhlanganisa okungenamthungo ezindaweni ezilinganiselwe, kuqede isidingo samahhanisi ezintambo ezinkulu kanye nokunciphisa isisindo. Ama-PCB aguquguqukayo aguqula amasistimu okuphatha amabhethri, amayunithi okulawula izimoto nezinye izingxenye ezibalulekile, aqinisekise ukusatshalaliswa kwamandla okuphumelelayo, anikeze amandla amabanga okushayela amade futhi athuthukise ukusebenza kwemoto iyonke - ukubeka izindinganiso ezintsha embonini yezimoto.

B. Isibonelo sesi-2: I-Aerospace kanye nemboni yezokuvikela:

Embonini ye-aerospace nokuvikela, ukunemba, ukuqina nokuthembeka kubalulekile. I-Rigid-flex PCBs ifakazele ukuthi ishintsha umdlalo ekuhlangabezaneni nezidingo eziqinile zezinhlelo zokusebenza zamandla aphezulu kulo mkhakha. Amasistimu omkhathi, njengamasistimu okulawula indiza, amasistimu ezindiza kanye nezokuxhumana, adinga izingxenye ze-elekthronikhi ezimazombezombe neziqinile ukuze zimelane nezimo ezimbi kakhulu. Ama-PCB e-Rigid-flex ahlinzeka ngokuzinza komshini okungenakuqhathaniswa ngenxa yokuhlanganiswa kwezingqimba eziqinile neziguquguqukayo, ezivumela ukuthi zimelane nokudlidliza, ukushaqeka, noshintsho lwezinga lokushisa ngaphandle kokuphazamisa ukusebenza. Ukwengeza, i-compact form factor kanye nesisindo esincishisiwe kunomthelela ekuthuthukisweni kokusebenza kahle kukaphethiloli kanye nomthamo womthwalo okhulayo. Ngokwamukela ama-PCB aguquguqukayo aqinile, imboni ye-aerospace neyokuvikela yenze intuthuko enkulu ezinhlelweni ezibucayi zemishini, yathuthukisa ukusebenza nokuqinisekisa ukwethembeka okungantengantengi.

C. Isibonelo sesi-3: Umkhakha wamandla avuselelekayo:

Imboni yamandla avuselelekayo ibhekene nenselelo yokusebenzisa nokusabalalisa ugesi ngempumelelo ovela emithonjeni evuselelekayo efana nelanga nomoya. I-Rigid-flex PCBs isiyingxenye ebalulekile yemboni, ishayela ukuqamba okusha futhi ivumela ukuhlanganiswa okungenamthungo kwamadivayisi ayinkimbinkimbi kagesi. Ama-Solar inverters, amasistimu egridi ahlakaniphile nezilawuli ze-turbine yomoya konke kuncike emandleni wamandla aphezulu kanye nokuqina kwama-PCB aguquguqukayo aqinile. Ikhono labo lokumelana nezimo zemvelo ezinzima, kuhambisana nezakhiwo ezinhle kakhulu zokulawula ukushisa, kuqinisekisa ukusebenza okuthembekile nokuphila isikhathi eside kwenkonzo. Ama-PCB aqinile avumelana nezimo asiza ukuthuthukisa ukusebenza kahle konke kwezinhlelo zamandla avuselelekayo, anikeze amandla ukuguqulwa kwamandla okunembayo, ukuqapha okuhlakaniphile nokusebenzisa kahle amandla asimeme.

6.Ukunqoba izinselele kanye nokunciphisa ubungozi kuzinhlelo zokusebenza zamandla aphezulu ngama-PCB aguquguqukayo:

A. Ukucatshangelwa kwezindleko:

Izindleko ziyisici esibalulekile abenzi bezinqumo okudingeka basikale lapho becabangela ama-PCB aguquguqukayo ezinhlelo zokusebenza zamandla aphezulu. Uma kuqhathaniswa nama-PCB endabuko aqinile, ama-PCB aqinile-flex avame ukubiza kakhulu ngenxa yedizayini eyengeziwe, izinto zokwakha, nobunkimbinkimbi bokukhiqiza obuhilelekile. Ukuhlanganisa izingxenye eziqinile nezivumelana nezimo kudinga ubunjiniyela obunembile nezakhiwo eziyinkimbinkimbi, okuholela ezindlekweni zokukhiqiza eziphakeme. Nokho, kufanele kubhekwe njengokutshalwa kwezimali esikhundleni somkhawulo. Izindleko zokusebenzisa ama-PCB aguquguqukayo angavunywa ngezinzuzo eziningi ezilethwayo, njengokwethenjwa okuthuthukisiwe, isisindo esincishisiwe, ukonga isikhala, nokuqina okuthuthukisiwe. Ngokuqonda izinzuzo zesikhathi eside kanye nokwenza ukuhlaziya okuphelele kwezindleko zenzuzo, izinkampani zingenza izinqumo ezinolwazi futhi zandise imbuyiselo ekutshalweni kwezimali lapho zihlanganisa ama-PCB aguquguqukayo aqinile kuzicelo zamandla aphezulu.

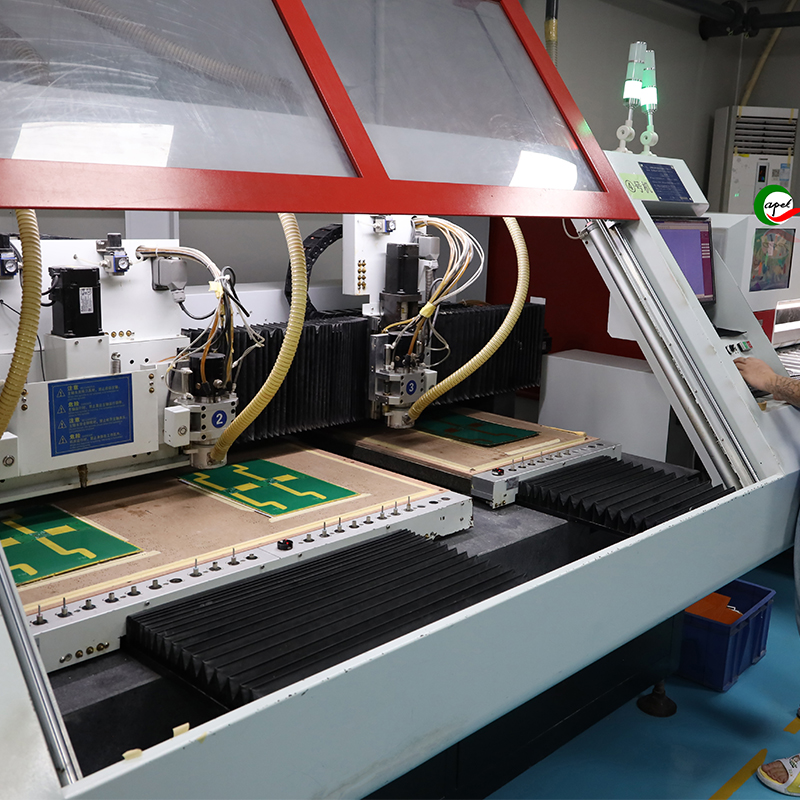

B. Izinto eziyinkimbinkimbi zokukhiqiza:

Ukukhiqiza ama-PCB aqinile aguquguqukayokwezinhlelo zokusebenza zamandla aphezulu ziletha izinselele eziyingqayizivele ngenxa yemiklamo yazo eyinkimbinkimbi kanye nokucaciswa okudingayo. Ukuhlanganiswa kwezingxenye eziqinile neziguquguqukayo kudinga izinqubo zokukhiqiza eziyinkimbinkimbi kanye nemishini ekhethekile. Ukuqondanisa okunembe kwezendlalelo, ukuqinisekisa ukuxhunywa kukagesi okuthembekile, nokugcina amandla emishini kuyo yonke impilo yebhodi lesifunda konke kudinga ukunakwa ngokucophelela emininingwaneni. Abakhiqizi badinga ukutshala imali emishinini ethuthukisiwe, baqashe ochwepheshe abanamakhono futhi basebenzise izinyathelo eziqinile zokulawula ikhwalithi ukuze kuncishiswe ubungozi enqubweni yokukhiqiza. Ukusebenza nomkhiqizi we-PCB onolwazi futhi onedumela elihle eliqinile eliguquguqukayo kubalulekile ekuqinisekiseni ukwenziwa ngempumelelo kwezinhlelo zokusebenza zamandla aphezulu. Ngokusebenzisa ubuchwepheshe balaba bakhiqizi, izinkampani zinganciphisa ubunzima bokukhiqiza futhi ziqinisekise ukulethwa kwemikhiqizo ethembekile nesezingeni eliphezulu.

C. Ukutholakala okulinganiselwe kwabahlinzeki abakhethekile:

Enye inselele lapho usebenzisa ama-PCB aqinile-flex kuzinhlelo zokusebenza zamandla aphezulu inombolo elinganiselwe yabahlinzeki abakhethekile. Izakhiwo eziyinkimbinkimbi nezinqubo zokukhiqiza eziyinkimbinkimbi zivimbele abakhiqizi abaningi be-PCB ukuthi bangene kule makethe ye-niche. Ngakho-ke, ukuthola abahlinzeki abathembekile nabanolwazi kungaba inselele. Ukusebenza nomphakeli ochwepheshile kubuchwepheshe be-PCB obuqinile obuguquguqukayo kubalulekile ukuze uthole izinto ezisezingeni eliphezulu, ubungcweti obuqondene nemboni kanye nokwesekwa kobuchwepheshe. Ukusebenzisana eduze nalaba bahlinzeki abakhethekile kusiza ekunciphiseni izingozi ezingaba khona, kuqinisekiswe ukuthi izingxenye ezifanele nezinto zokwakha zitholakala, futhi kuqondisa yonke inqubo yokukhiqiza. Ukwakha ubudlelwano besikhathi eside nabahlinzeki abathembekile kuyisu elihle kakhulu elingagcini nje ngokudambisa izinselele zokutholakala okulinganiselwe, kodwa futhi elikhuthaza ukubambisana nokuqamba izinto ezintsha ngaphakathi kwemboni yamandla aphezulu.

Ngokufigqiwe:

I-Rigid-flex PCBs iyisinqumo esihle kakhulu sezinhlelo zokusebenza zamandla aphezulu. Ikhono labo lokusingatha ukucindezeleka okushisayo, usayizi ohlangene kanye nobuqotho besignali obuthuthukisiwe bubenza babe yisixazululo esithembekile, esisebenza kahle.Kodwa-ke, ukucatshangelwa kwedizayini okulungile nokukhetha okubalulekile kubalulekile ukuze kuzuzwe imiphumela emihle. Ukubonisana nochwepheshe be-PCB abanolwazi kuyingxenye ebalulekile yenqubo.

Uma ufuna isixazululo sezidingo zakho zohlelo lokusebenza lwamandla aphezulu, cabanga ukuhlola izinzuzo zobuchwepheshe be-PCB eguquguqukayo. Ngomklamo wawo oyingqayizivele nokusebenza, lawa mabhodi angakusiza uhlangabezane nezidingo zomhlaba wezinto zikagesi ezihlala zivela.-UCapel uneminyaka engu-15 yesipiliyoni sobuchwepheshe embonini ye-Rigid Flexible PCB.

Isikhathi sokuthumela: Sep-16-2023

Emuva