Njengoba isidingo sezixazululo ze-elekthronikhi eziguquguqukayo nezihlangene siqhubeka nokwanda, ama-PCB aqinile asephenduke into ethandwayo ekwakhiweni nasekukhiqizeni i-PCB. Lawa mabhodi ahlanganisa izinzuzo zama-PCB aqinile navumelana nezimo ukuze anikeze ukuguquguquka okuthuthukisiwe ngaphandle kokudela ukuqina nokusebenza. Ukuze udizayine ama-PCB aqinile futhi athuthukisiwe aqinile, ukuqonda okuphelele kokucushwa kwesitaki kubalulekile. Isakhiwo sesitaki sinquma ukuhlelwa kanye nesakhiwo sesendlalelo se-PCB, okuthinta ngokuqondile ukusebenza kwayo nokwenziwa kwayo.Lo mhlahlandlela ophelele uzohlola ubunkimbinkimbi bezitaki ze-PCB eziguquguqukayo, unikeze imininingwane ebalulekile ukusiza abaklami benze izinqumo ezinolwazi phakathi nenqubo yokuklama. Izohlanganisa izici ezihlukahlukene ezihlanganisa ukukhethwa kwezinto, ukubekwa kwesendlalelo, ukucatshangelwa kobuqotho besignali, ukulawulwa kwe-impedance, kanye nemingcele yokukhiqiza. Ngokuqonda izinkimbinkimbi zezitaki ze-PCB eziguquguqukayo eziqinile, abaklami bangaqinisekisa ubuqotho nokuthembeka kwemiklamo yabo. Bazothuthukisa ubuqotho besignali, banciphise ukuphazamiseka kwe-electromagnetic (EMI) futhi benze lula izinqubo zokukhiqiza ezisebenzayo. Noma ngabe umusha ekwakhiweni kwe-PCB eguquguqukayo eqinile noma ufuna ukuthuthukisa ulwazi lwakho, lo mhlahlandlela uzoba yinsiza ebalulekile, ekuvumela ukuthi uzulazule ezinkingeni zokupakisha nokuklama izixazululo ze-PCB eziguqukayo zekhwalithi ephezulu, eziqinile zohlu lwemikhiqizo.

1.Iyini ibhodi eliqinile eliguquguqukayo?

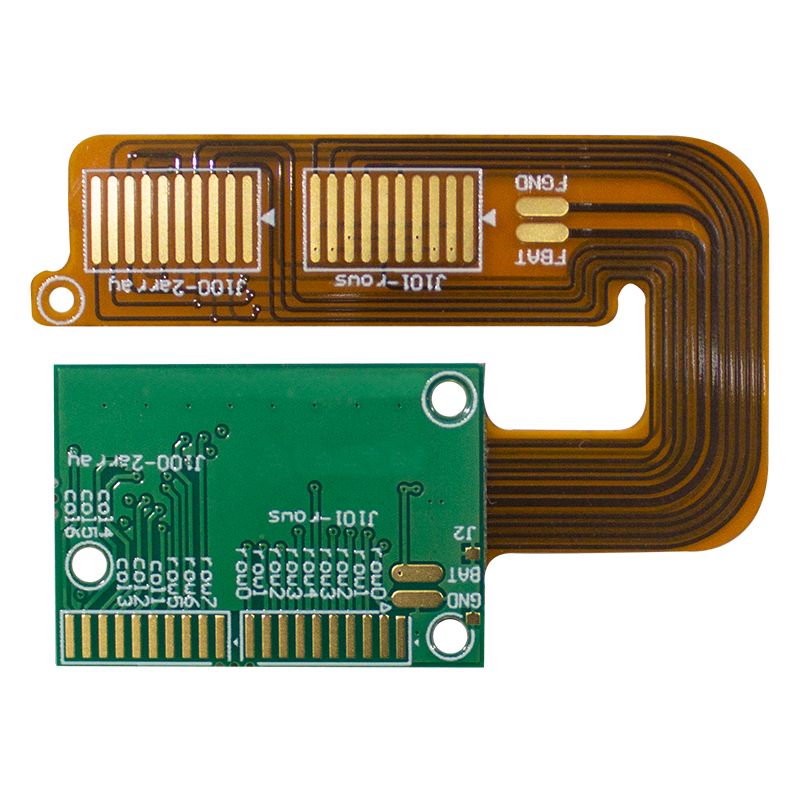

I-Rigid-flex board, eyaziwa nangokuthi ibhodi lesifunda eliphrintiwe eliqinile (PCB), iyi-PCB ehlanganisa ama-substrates aqinile futhi aguquguqukayo ebhodini elilodwa.Ihlanganisa izinzuzo zama-PCB aqinile futhi aguquguqukayo ukuze kuthuthukiswe ukuguquguquka kwedizayini nokuqina. Ebhodini eliguquguqukayo eliqinile, ingxenye eqinile yenziwe ngezinto ezivamile ze-PCB eziqinile (ezifana ne-FR4), kuyilapho ingxenye eguquguqukayo yenziwe ngezinto eziguquguqukayo ze-PCB (njenge-polyimide). Lezi zingxenye zixhunywe ngokugqitshwa ngezimbobo noma izixhumi eziguqukayo ukuze zakhe ibhodi elihlanganisiwe elilodwa. Izigaba eziqinile zinikeza ukusekela nokuzinza ezingxenyeni, izixhumi, nezinye izakhi zemishini, ezifana ne-PCB evamile eqinile. Ingxenye eguquguqukayo, ngakolunye uhlangothi, ivumela ibhodi lesifunda ukuthi ligobe futhi ligobe, livumele ukuba lingene kumishini kagesi enendawo elinganiselwe noma izimo ezingajwayelekile. Amabhodi aguquguqukayo anikeza izinzuzo ezimbalwa ngaphezu kwama-PCB endabuko aqinile noma aguquguqukayo. Zinciphisa isidingo sezixhumi namakhebuli, zonga indawo, zinciphisa isikhathi sokuhlanganisa, futhi zikhulise ukwethembeka ngokuqeda amaphuzu angaba khona okuhluleka. Ngaphezu kwalokho, amabhodi aqinile aguquguqukayo enza inqubo yokuklama ibe lula ngokwenza kube lula ukuxhumana phakathi kwezingxenye eziqinile nezigobekayo, anciphise ubunkimbinkimbi bomzila futhi athuthukise ubuqotho besignali. Amabhodi e-Rigid-flex ngokuvamile asetshenziswa ezinhlelweni lapho isikhala sinqunyelwe noma ibhodi lidinga ukuhambisana nokuma okuthile noma iphrofayela. Zivame ukutholakala ku-aerospace, izinsiza zezokwelapha, i-electronics yezimoto kanye ne-electronics ephathekayo lapho ubukhulu, isisindo nokuthembeka kuyizici ezibalulekile. Ukuklama nokukhiqiza amabhodi aqinile-aguquguqukayo kudinga ulwazi olukhethekile nobungcweti ngenxa yokuhlanganiswa kwezinto eziqinile neziguquguqukayo kanye nokuxhumana. Ngakho-ke, kubalulekile ukusebenzisana nomkhiqizi we-PCB onolwazi okwaziyo ukuphatha izinto eziyinkimbinkimbi zokwenziwa kwebhodi eliguquguqukayo.

2.Kungani ukucushwa kwe-pcb stacking okuqinile kubalulekile?

Ubuqotho Bemishini:

I-Rigid-flex PCBs yakhelwe ukunikeza ukuguquguquka nokuthembeka. Ukucushwa kwama-stacking kunquma ukuhlelwa kwezingqimba eziqinile nezivumelana nezimo, okuqinisekisa ukuthi ibhodi lingakwazi ukumelana nokugoba, ukusonteka nokunye ukucindezeleka komshini ngaphandle kokuphazamisa ubuqotho balo besakhiwo. Ukuqondanisa kahle isendlalelo kubalulekile ekuvimbeleni ukukhathala kwe-PCB, ukugxila kwengcindezi, nokwehluleka ngokuhamba kwesikhathi.

Ukulungiselela isikhala:

Amabhodi e-Rigid-flex asetshenziswa kakhulu kumishini kagesi ehlangene enendawo elinganiselwe. Ukulungiselelwa okustakiwe kuvumela abaklami ukuthi basebenzise kahle indawo etholakalayo ngokuhlela izendlalelo nezingxenye ngendlela ekhulisa ukusetshenziswa kwesikhala se-3D. Lokhu kuvumela ama-PCB ukuthi afakwe ezindaweni ezivalekile eziqinile, amadivayisi amancane kanye nezici zefomu eziyinkimbinkimbi. Ubuqotho Besiginali:

Ubuqotho besignali ye-PCB eguquguqukayo eqinile ibalulekile ekusebenzeni kwayo okufanele. Ukulungiselelwa kokunqwabelanisa kudlala indima ebalulekile ekuthuthukiseni ubuqotho besignali ngokucabangela izici ezifana ne-impedance elawulwayo, umzila wolayini wokudlulisela, nokunciphisa i-crosstalk. Isakhiwo esinezingqimba esinengqondo singaqinisekisa umzila osebenzayo wamasignali anesivinini esikhulu, sinciphise ukuncishiswa kwesignali, futhi siqinisekise ukudluliswa kwedatha okunembile.

Ukuphatha Okushisayo:

Amadivaysi e-elekthronikhi akhiqiza ukushisa, futhi ukuphathwa kahle kokushisa kubalulekile ekuvimbeleni ukushisa ngokweqile kanye nokulimala okungenzeka ezingxenyeni. Ukucushwa okustakiwe kwama-PCB aguquguqukayo aqinile kuvumela ukubekwa kwamasu kwama-vias ashisayo, izendlalelo zethusi, namasinki okushisa ukuze kukhishwe ukushisa okuphumelelayo. Ngokucabangela izinkinga ezishisayo phakathi nenqubo yokuklama isitaki, abaklami bangaqinisekisa ukuphila isikhathi eside kwe-PCB nokwethembeka.

Imicabango Yokukhiqiza:

Ukumiswa kokunqwabelanisa kuthinta inqubo yokukhiqiza ye-PCB eguquguqukayo. Inquma indlela izendlalelo ezihlanganiswe ngayo ndawonye, ukuqondanisa nokubhaliswa kwezendlalelo eziguquguqukayo neziqinile, nokubekwa kwezingxenye. Ngokukhetha ngokucophelela ukulungiselelwa kwesitaki, abaklami bangakwazi ukwenza lula inqubo yokukhiqiza, banciphise izindleko zokukhiqiza, futhi banciphise ubungozi bamaphutha okukhiqiza.

3.Izingxenye ezibalulekile zesitaki se-PCB esiqinile

Lapho uklama isitaki se-PCB esiqinile, kunezinto ezimbalwa ezibalulekile okufanele zicatshangelwe. Lezi zingxenye zidlala indima ebalulekile ekuhlinzekeni ukwesekwa kwesakhiwo esidingekayo, ukuxhunywa kukagesi, kanye nokuguquguquka kwayo yonke idizayini ye-PCB. Okulandelayo yizici ezibalulekile zesitaki se-PCB esiguquguqukayo:

Isendlalelo esiqinile:

Isendlalelo esiqinile ngokuvamile senziwe ngezinto eziyisisekelo eziqinile ezifana ne-FR-4 noma into efanayo. Lesi sendlalelo sinikeza amandla emishini nokuzinza ku-PCB. Iphinde ibe nezingxenye futhi ivumele ukufakwa kwamadivayisi okufakwa endaweni ephezulu (SMD) kanye nezingxenye ze- through-hole. Isendlalelo esiqinile sinikeza isisekelo esiqinile sesendlalelo esiguquguqukayo futhi siqinisekisa ukuqondanisa okufanele nokuqina kwayo yonke i-PCB.

Isendlalelo esivumelana nezimo:

Isendlalelo esivumelana nezimo siqukethe isisekelo esivumelana nezimo njenge-polyimide noma into efanayo. Lesi sendlalelo sivumela i-PCB ukuthi igobe, igoqe, futhi igobe. I-flex layer yilapho iningi le-circuitry kanye nokuxhunywa kukagesi kutholakala. Inikeza ukuguquguquka okudingekayo kwezinhlelo zokusebenza ezidinga i-PCB ukuthi igobe noma ivumelane nezimo noma izikhala ezihlukene. Ukuvumelana nezimo kwalesi sendlalelo kudinga ukucatshangelwa ngokucophelela ukuze kuqinisekiswe ukuthi sihlangabezana nezidingo zohlelo lokusebenza.

Isendlalelo sokunamathela:

Ungqimba olunamathelayo luwungqimba oluncane lwento enamathelayo esetshenziswa phakathi kongqimba oluqinile nongqimba oluguquguqukayo. Inhloso yayo eyinhloko ukuhlanganisa izingqimba eziqinile neziguquguqukayo ndawonye, okuhlinzeka ngobuqotho besakhiwo ku-laminate. Iqinisekisa ukuthi izendlalelo zihlala zixhumene ngokuqinile komunye nomunye ngisho nangesikhathi sokugoba noma ukugoba. I-adhesive layer iphinde isebenze njenge-dielectric material, ihlinzeka ngokufaka phakathi kwezingqimba. Ukukhethwa kwezinto ezinamathelayo kubalulekile njengoba kudinga ukuba nezakhiwo ezinhle zokubopha, amandla aphezulu e-dielectric, nokuhambisana nezinto eziyisisekelo.

Ukuqinisa kanye nesembozo:

Ukuqiniswa nesembozo kuyizendlalelo ezengeziwe ezivame ukungezwa kusitaki se-PCB ukuze kuthuthukiswe amandla ayo okusebenza, ukuvikela, nokwethembeka. Ukuqiniswa kungafaka izinto ezifana ne-FR-4 noma amashidi angenamathelisi asekelwe ku-polyimide ahlanganiswe ezindaweni ezithile zezingqimba eziqinile noma eziguquguqukayo ukuze anikeze ukuqina nokusekela okwengeziwe. Izindawo ze-PCB zimbozwe ngesembozo esifana namamaski athengisa izinto ezithengiswayo kanye nezingubo zokuzivikela ukuze zivikeleke ezintweni zemvelo ezinjengomswakama, uthuli, kanye nengcindezi yemishini.

Lezi zingxenye ezibalulekile zisebenza ndawonye ukuze zenze isitaki se-PCB esiklanywe ngokucophelela esivumelana nezimfuneko zohlelo lokusebenza. Ubuqotho besakhiwo nokuguquguquka okuhlinzekwa izendlalelo eziqinile neziguquguqukayo, kanye nezendlalelo zokunamathela, kuqinisekisa ukuthi i-PCB ingakwazi ukumelana nokugoba noma ukunyakaza okuguquguqukayo ngaphandle kokuyekethisa ubuqotho besifunda. Ukwengeza, ukusetshenziswa kwezinto eziqinisayo nezimbozayo kuthuthukisa ukwethembeka nokuvikelwa okuphelele kwe-PCB. Ngokukhetha ngokucophelela nokuklama lezi zingxenye, onjiniyela bangakha izitaki ze-PCB eziqinile nezithembekile.

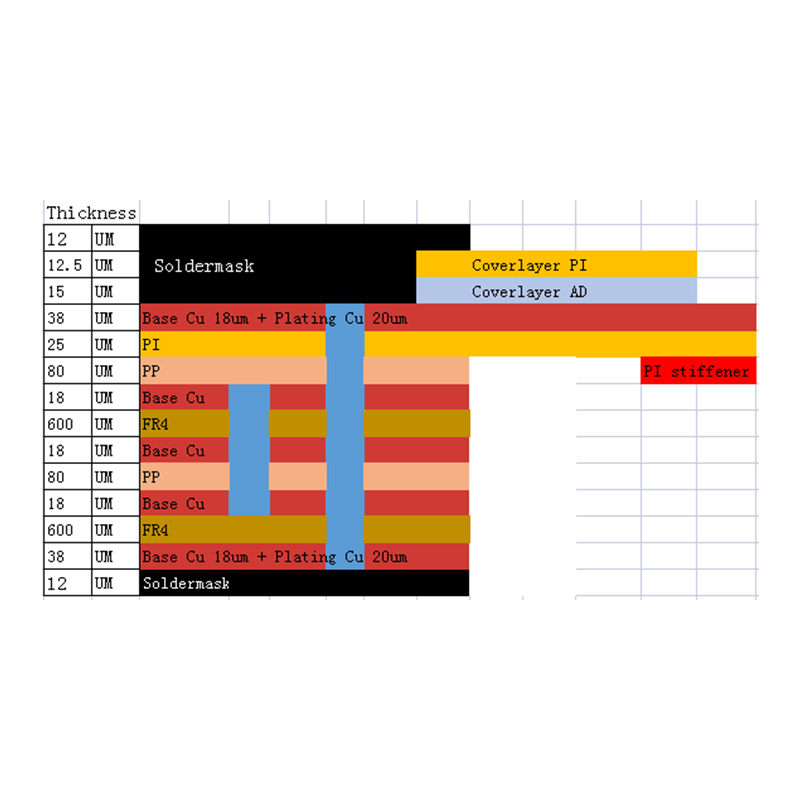

4.I-Rigid-flex-flex PCB yokumisa isitaki

Uma udizayina izitaki ze-PCB eziguquguqukayo, izinhlobo ezahlukene zokucushwa zingasetshenziswa ngokuya ngezidingo ezithile zohlelo lokusebenza. Ukucushwa kwesitaki kunquma inani lezendlalelo ezifakwe ekwakhiweni kanye nokuhlelwa kwezingqimba eziqinile nezivumelana nezimo. Okulandelayo yizinhlobo ezintathu ezijwayelekile zokucushwa kwesitaki se-PCB esiqinile:

1 ungqimba lwe-lamination eqinile nethambile:

Kulokhu kumisa, i-PCB iqukethe ungqimba olulodwa lwempahla eqinile kanye nesendlalelo esisodwa sempahla eguqukayo. Isendlalelo esiqinile sinikeza ukuzinza nokusekelwa okudingekayo, kuyilapho ungqimba oluguquguqukayo luvumela i-PCB ukuthi igobe futhi igobe. Lokhu kulungiselelwa kulungele izinhlelo zokusebenza ezidinga ukuguquguquka okulinganiselwe kanye nomklamo olula.

Izendlalelo ezi-2 ze-superposition eqinile nethambile:

Kulokhu kumisa, i-PCB iqukethe izendlalelo ezimbili - isendlalelo esiqinile kanye nesendlalelo esiguquguqukayo. Isendlalelo esiqinile sihlanganiswe phakathi kwezingqimba ezimbili eziguquguqukayo, okwenza uhlelo "lwencwadi". Lokhu kumisa kunikeza ukuguquguquka okukhulu futhi kuvumela imiklamo eyinkimbinkimbi kusetshenziswa izingxenye zombili izinhlangothi ze-PCB. Inikeza ukuguquguquka okungcono kokugoba nokugoba kunokucushwa kwesendlalelo esisodwa.

I-Multi-layer eqinile nethambile:

Kulokhu kumisa, i-PCB iqukethe izendlalelo eziningi - inhlanganisela yezendlalelo eziqinile neziguquguqukayo. Izendlalelo zipakishwe phezu kwezinye, zishintshana phakathi kwezingqimba eziqinile nezigobekayo. Lokhu kulungiselelwa kunikeza izinga eliphezulu lokuguquguquka futhi kuvumela imiklamo eyinkimbinkimbi kakhulu isebenzisa izingxenye eziningi namasekhethi. Ilungele izinhlelo zokusebenza ezidinga ukuguquguquka okuphezulu kanye nomklamo ohlangene.

Ukukhethwa kokucushwa kwesitaki esiguquguqukayo esiqinile kuncike ezintweni ezifana nezinga lokuguquguquka elidingekayo, inkimbinkimbi yedizayini yesekethe, kanye nemikhawulo yesikhala. Onjiniyela badinga ukuhlola ngokucophelela izidingo nemikhawulo yohlelo lokusebenza ukuze banqume ukucushwa kwesitaki okufanele kakhulu.

Ngaphezu kokwakhiwa kwe-laminate eqinile eguquguqukayo, ezinye izici ezifana nokukhethwa kwezinto ezibonakalayo, ukujiya kwesendlalelo ngasinye, kanye nomklamo wokuxhumana nakho kudlala indima ebalulekile ekunqumeni ukusebenza okuphelele nokuthembeka kwama-PCB aguquguqukayo. Kubalulekile ukusebenzisana eduze nomkhiqizi we-PCB nochwepheshe bokuklama ukuze uqinisekise ukuthi ukulungiselelwa kwesitaki esikhethiwe kuhlangabezana nezimfuneko ezithile kanye namazinga ohlelo lokusebenza.

Ngokukhetha ukucushwa kwesitaki se-rigid-flex esifanele kanye nokuthuthukisa eminye imingcele yedizayini, onjiniyela bangasebenzisa ama-PCB athembekile, asebenza kakhulu aqinile ahlangabezana nezidingo ezihlukile zezinhlelo zabo zokusebenza.

5.Izici Okumelwe Zicatshangwe Lapho Ukhetha Ukucushwa Kwe-Rigid-Flex PCB Stacking

Lapho ukhetha ukucushwa kwesitaki se-PCB eguquguqukayo, kunezici ezimbalwa okufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza okuhle nokuthembeka. Nazi izinto ezinhlanu ezibalulekile okufanele uzikhumbule:

Ubuqotho Besiginali:

Ukukhethwa kokucushwa kwesitaki kungathinta kakhulu ubuqotho besignali ye-PCB. Ukulandelelwa kwesignali kuzindlalelo eziguquguqukayo kungase kube nezici ezihlukile ze-impedance uma kuqhathaniswa nezendlalelo eziqinile. Kubalulekile ukukhetha ukulungiselelwa kwesitaki okunciphisa ukulahleka kwesignali, i-crosstalk, nokungahambisani kahle kwe-impedance. Amasu afanele okulawula i-impedance kufanele asetshenziselwe ukugcina ubuqotho besignali kuyo yonke i-PCB.

Izidingo zokuvumelana nezimo:

Izinga lokuguquguquka elidingekayo ku-PCB liwukucatshangelwa okubalulekile. Izinhlelo zokusebenza ezihlukene zingase zibe nezidingo ezihlukene zokugoba nokugoba. Ukucushwa kwesitaki kufanele kukhethwe ukuze kuhambisane nokuvumelana nezimo okudingekayo kuyilapho kuqinisekiswa ukuthi i-PCB ihlangabezana nazo zonke izidingo zokusebenza komshini nokogesi. Inombolo nokuhlelwa kwezingqimba eziguquguqukayo kufanele kunqunywe ngokucophelela ngokusekelwe ezidingweni ezithile zohlelo lokusebenza.

Imikhawulo yesikhala:

Isikhala esitholakalayo ngaphakathi komkhiqizo noma idivayisi singaba nomthelela omkhulu ekukhethweni kokucushwa kwesitaki. Imiklamo ehlangene enesikhala esilinganiselwe se-PCB ingase idinge ukulungiselelwa okuguquguqukayo kwezendlalelo eziningi ukuze kwandiswe ukusetshenziswa kwendawo. Ngakolunye uhlangothi, imiklamo emikhulu ivumela ukuguquguquka okwengeziwe lapho ukhetha ukucushwa kwesitaki. Ukulungiselela ukunqwabelanisa ukuze kulingane indawo etholakalayo ngaphandle kokuphazamisa ukusebenza noma ukwethembeka kubalulekile.

Ukuphatha Okushisayo:

Ukuphatha okushisayo okusebenzayo kubalulekile ekuvimbeleni ukunqwabelana kokushisa, okungathinta ukusebenza nokuthembeka kwamasekhethi nezingxenye. Ukukhethwa kokucushwa kwesitaki kufanele kucabangele ukunqanyulwa kokushisa. Isibonelo, uma i-PCB ikhiqiza ukushisa okuningi, ingase idinge ukuhleleka okusiza ukuqeda ukushisa, okufana nokuhlanganisa amakhora ensimbi noma ukusebenzisa i-thermal vias. Izingxenye zokushisisa kufanele futhi zibekwe ngendlela ehlelekile esitakini ukuze kukhishwe ukushisa kahle.

Ukucatshangelwa kokwenziwa kanye nokuhlanganisa:

Ukucushwa kwesitaki okukhethiwe kufanele kube lula ukukwakha nokuhlanganisa. Izinto ezinjengokukhiqiza kalula, ukuhambisana nezinqubo zokukhiqiza kanye nobuchwepheshe bokuhlanganisa, kanye nokuba khona kwezinto ezifanele kufanele kucatshangelwe. Isibonelo, okunye ukulungiselelwa kwezitaki kungase kudinge amasu okukhiqiza akhethekile noma kungase kube nemikhawulo ezintweni ezingasetshenziswa. Ukusebenza nomkhiqizi we-PCB ekuqaleni kwenqubo yokuklama kubalulekile ekuqinisekiseni ukuthi ukumisa okukhethiwe kungakhiqizwa futhi kuhlanganiswe kahle.

Ngokuhlola ngokucophelela lezi zici ezinhlanu, onjiniyela bangenza isinqumo esinolwazi mayelana nokukhetha ukucushwa kwesitaki se-PCB esiguquguqukayo. Kunconywa kakhulu ukusebenzisana nochwepheshe bokukhiqiza nokuhlanganisa ukuze kuqinisekiswe ukuthi ukucushwa okukhethiwe kuhlangabezana nazo zonke izidingo zokuklama futhi kuhambisana nenqubo yokukhiqiza. Ukwenza ngokwezifiso isitaki ukuze kubhekwane nobuqotho besignali, ukuguquguquka, izingqinamba zesikhala, ukuphathwa okushisayo nokucatshangelwa kokukhiqiza kuzophumela kusixazululo esiqinile nesithembekile se-PCB eguquguqukayo.

6.Ukucatshangelwa kokuklama kwe-PCB eqinile eguquguqukayo isitaki-up

Lapho udizayina isitaki se-PCB esiguquguqukayo, kunezici ezimbalwa ezibalulekile okufanele zicatshangelwe ukuze kuqinisekiswe ukusebenza okufanele nokuthembeka. Nazi izinto ezinhlanu ezibalulekile zokucatshangelwa kwesakhiwo:

Ukusabalalisa Kwesendlalelo kanye ne-Symmetry:

Ukusatshalaliswa kwesendlalelo ku-stackup kubalulekile ekuzuzeni ibhalansi nokulinganisa ekwakhiweni. Lokhu kusiza ukuvimbela izinkinga zokungqubuzana noma ukubopha phakathi nenqubo yokugoba. Kunconywa ukuthi kube nenani elifanayo lezendlalelo ohlangothini ngalunye lwebhodi le-flex futhi ubeke ungqimba oluguquguqukayo phakathi nendawo yesitaki. Lokhu kuqinisekisa ukusatshalaliswa kokucindezeleka okulinganiselwe futhi kunciphisa ingozi yokwehluleka.

Isakhiwo Sekhebula Nokulandelela:

Ukuhlelwa kwezintambo nokulandela umkhondo ku-PCB kufanele kucatshangelwe ngokucophelela. Umzila wamakhebuli kanye nemikhondo kufanele kuhlelwe ukuze kuncishiswe ukugxila kwengcindezi futhi kuvinjwe umonakalo ngesikhathi sokugoba. Kunconywa ukuthi uhambise izintambo eziguquguquka kakhulu futhi ulandele kude nezindawo ezinengcindezi ephezulu yokugoba, njengendawo eseduze yokugoba noma amaphoyinti. Ngaphezu kwalokho, ukusebenzisa amakhona ayindilinga esikhundleni samakhona acijile kunganciphisa ukugxila kwengcindezi futhi kuthuthukise ukuguquguquka kwe-PCB.

Izindiza Eziphansi Nezamandla:

Ukusatshalaliswa kwendiza ephansi kanye namandla kubaluleke kakhulu ukuze kugcinwe ubuqotho besignali efanele kanye nokusabalalisa amandla. Kuyatuswa ukwaba izindiza ezizinikezele zomhlabathi namandla ukuze kuhlinzekwe ukusatshalaliswa kwamandla okulinganayo nokuzinzile kuyo yonke i-PCB. Lezi zendlalelo ziphinde zisebenze njengezihlangu zokuphazanyiswa kwe-electromagnetic (EMI). Ukuma ngendlela efanele kwe-ground vias kanye ne-vias ethungiwe kubalulekile ekwehliseni ukuthikamezeka komhlaba kanye nokwenza ngcono ukusebenza kwe-EMI.

Ukuhlaziywa kobuqotho besignali:

Ubuqotho besignali bubalulekile ekusebenzeni okuvamile kwe-PCB. Ukulandelela amasignali kufanele kuklanywe ngokucophelela ukuze kuncishiswe ukungaqhubeki kwe-impedance, i-crosstalk, nokuboniswa kwesignali. Abaklami be-PCB kufanele basebenzise amathuluzi esofthiwe ukwenza ukuhlaziya kobuqotho besignali ukuze kuthuthukiswe ububanzi bokulandelela nesikhala, kugcinwe i-impedance elawulwayo, nokuqinisekisa ubuqotho besignali kuyo yonke i-PCB eguquguqukayo eqinile.

Izindawo eziguqukayo nezigobekile:

Izingxenye eziguquguqukayo neziqinile ze-PCB zinezidingo ezihlukile ngokuya ngokuguquguquka nokugoba. Kuyadingeka ukuchaza nokuqoka izindawo ezithile zezigaba eziguquguqukayo neziqinile. Indawo eguquguqukayo kufanele ikwazi ukugoba ngokwanele ukuze ikwazi ukwamukela irediyasi yokugoba edingekayo ngaphandle kokugcizelela iminonjana noma izingxenye. Izindlela zokuqinisa ezifana nezimbambo noma i-polymer coatings zingasetshenziswa ukwandisa amandla omshini nokuthembeka kwezindawo eziguquguqukayo.

Ngokucabangela lezi zici zokuklama, onjiniyela bangathuthukisa ngokugcwele izitaki ze-PCB eziguquguqukayo ezilungiselelwe ngokugcwele. Kubalulekile ukusebenzisana nabakhiqizi be-PCB ukuze baqonde amakhono abo, izinketho zezinto ezibonakalayo, kanye nemikhawulo yokukhiqiza. Ukwengeza, ukubandakanya ithimba elikhiqizayo kusenesikhathi enqubweni yokuklama kungasiza ekuxazululeni noma yiziphi izinkinga zokwenziwa futhi kuqinisekiswe ukushintshwa okushelelayo kusuka kumklamo kuye ekukhiqizeni. Ngokunaka ukusatshalaliswa kwezingqimba, umzila kanye nokulandela ukubekwa, izindiza eziphansi kanye namandla, ubuqotho besignali kanye nezindawo eziguquguqukayo eziguquguqukayo, abaklami bangakha ama-PCB aqinile futhi asebenza ngokugcwele aqinile.

7.Layer design ubuchwepheshe for pcb eqinile nezimo

Lapho uklama amabhodi aguquguqukayo aqinile, amasu okuklama isendlalelo adlala indima ebalulekile ekuqinisekiseni ukusebenza okulungile nokwethembeka. Nazi izindlela ezine eziyinhloko zokuklama izendlalelo:

I-lamination elandelanayo:

I-lamination elandelanayo ubuchwepheshe obusetshenziswa kakhulu ekukhiqizeni ibhodi eliqinile-flex. Ngale ndlela, izingqimba ezihlukene eziqinile nezivumelana nezimo zenziwa ngokuhlukana bese zihlanganiswa ndawonye. Izendlalelo eziqinile ngokuvamile zenziwa kusetshenziswa i-FR4 noma izinto ezifanayo, kuyilapho izendlalelo eziguqukayo zenziwa kusetshenziswa i-polyimide noma ama-substrates afanayo aguquguqukayo. I-lamination elandelanayo ihlinzeka ngokuguquguquka okukhulu ekukhetheni isendlalelo nokuqina, okuvumela ukulawula okukhulu kwezakhiwo zikagesi nezomshini ze-PCB. Ukucwecwa kokufinyelela okukabili:

Ku-lamination yokufinyelela okukabili, i-vias ibhobhozwa izendlalelo eziqinile neziguquguqukayo ukuvumela ukufinyelela kuzo zombili izinhlangothi ze-PCB. Lobu buchwepheshe buhlinzeka ngokuguquguquka okukhulu ekubekweni kwengxenye kanye nomzila womkhondo. Iphinde isekele ukusetshenziswa kwe-vias eyimpumputhe nengcwatshwe, okusiza ukunciphisa ukubalwa kongqimba nokuthuthukisa ubuqotho besignali. I-Dual-channel lamination iwusizo ikakhulukazi lapho uklama ama-PCB aqinile aguquguqukayo anezendlalelo eziningi kanye nemingcele yesikhala esiqinile.

I-Z-axis conductive adhesive:

I-Z-axis conductive adhesive isetshenziselwa ukusungula ukuxhumana kukagesi phakathi kongqimba oluqinile kanye nongqimba oluguqukayo ebhodini eliguquguqukayo eliqinile. Isetshenziswa phakathi kwamaphedi okuqhuba ungqimba oluguquguqukayo kanye namaphedi ahambisanayo kungqimba oluqinile. I-adhesive iqukethe izinhlayiya ze-conductive ezakha izindlela zokuqhuba lapho zicindezelwa phakathi kwezingqimba ngesikhathi sokucwenga. I-Z-axis conductive adhesive inikeza uxhumano lukagesi oluthembekile ngenkathi igcina ukuguquguquka kwe-PCB nobuqotho bemishini.

Ukucushwa kwe-Hybrid stacking:

Ekucushweni kwe-hybrid stacking, inhlanganisela yezendlalelo eziqinile neziguquguqukayo zisetshenziselwa ukudala isitaki sesendlalelo esenziwe ngokwezifiso. Lokhu kuvumela abaklami ukuthi bathuthukise ukwakheka kwe-PCB ngokusekelwe ezidingweni ezithile zomklamo. Isibonelo, izendlalelo eziqinile zingasetshenziswa ukukhweza izingxenye futhi zinikeze ukuqina komshini, kuyilapho izendlalelo eziguquguqukayo zingasetshenziswa ukuze amasiginali womzila ezindaweni lapho kudingeka khona ukuguquguquka. Ukucushwa kwe-Hybrid stacking kunikeza abaklami izinga eliphezulu lokuguquguquka nokwenza ngokwezifiso imiklamo eyinkimbinkimbi ye-PCB eguquguqukayo.

Ngokusebenzisa lezi zindlela zokuklama izendlalelo, abaklami bangakha ama-PCB aqinile aguquguqukayo aqinile futhi asebenzayo. Nokho, kubalulekile ukusebenzisana eduze nomkhiqizi we-PCB ukuqinisekisa ukuthi ubuchwepheshe obukhethiwe buhambisana nekhono labo lokukhiqiza. Ukuxhumana phakathi kwamathimba aklamayo kanye nabakhiqizi kubalulekile ekuxazululeni noma yiziphi izinkinga ezingase zibe khona kanye nokuqinisekisa ukuguquguquka okushelelayo kusuka ekuklanyweni kuya ekukhiqizeni. Ngamasu afanele wokuklama isendlalelo, abaklami bangafinyelela ukusebenza kukagesi okudingekayo, ukuguquguquka kwemishini kanye nokwethembeka kuma-PCB aguquguqukayo aqinile.

8.Inqubekelaphambili yobuchwepheshe be-PCB yokufaka i-lamination eqinile

Intuthuko kubuchwepheshe be-lamination PCB obuqinile-flex yenze inqubekelaphambili ebalulekile emikhakheni ehlukahlukene. Nazi izindawo ezine zenqubekelaphambili ebonakalayo:

I-Material Innovation:

Ukuthuthuka kwesayensi yezinto kwenze kwaba lula ukwakhiwa kwezinto ezintsha ze-substrate eziklanyelwe ngokukhethekile amabhodi aguquguqukayo aqinile. Lezi zinto zinikeza ukuguquguquka okukhulu, ukuqina, nokumelana nezinga lokushisa kanye nomswakama. Okwezendlalelo eziguquguqukayo, izinto ezifana ne-polyimide ne-liquid crystal polymer (LCP) zinikeza ukuguquguquka okuhle kakhulu ngenkathi kugcinwa izakhiwo zikagesi. Ngezendlalelo eziqinile, izinto ezifana ne-FR4 kanye nama-laminates asezingeni eliphezulu zinganikeza ukuqina nokuthembeka okudingekayo. Amasekhethi aphrintiwe we-3D:

Ubuchwepheshe bokuphrinta be-3D buye benza izinguquko ezimbonini eziningi, kuhlanganise nokukhiqiza i-PCB. Ikhono lokuphrinta i-3D lokuphrinta i-conductive traces ngqo kuma-substrates aguquguqukayo livumela imiklamo eyinkimbinkimbi neyinkimbinkimbi ye-PCB. Ubuchwepheshe busiza ukwenza i-prototyping ngokushesha nokwenza ngokwezifiso, okuvumela abaklami ukuthi bakhe izici zefomu ezihlukile futhi bahlanganise izingxenye ngokuqondile izendlalelo eziguquguqukayo. Ukusetshenziswa kwamasekhethi e-3D aphrintiwe kuma-PCB aqinile aguquguqukayo kukhulisa ukuguquguquka komklamo futhi kufinyeze imijikelezo yokuthuthuka.

Izingxenye Ezishumekiwe Ezivumelanayo:

Enye intuthuko enkulu kubuchwepheshe be-lamination ukuhlanganiswa okuqondile kwezingxenye kungqimba eguquguqukayo ye-PCB eguquguqukayo eqinile. Ngokushumeka izingxenye ezinjengama-resistors, ama-capacitor ngisho nama-microcontrollers kuma-substrates avumelana nezimo, abaklami bangaqhubeka nokunciphisa usayizi we-PCB wonkana futhi bathuthukise ubuqotho besignali. Lobu buchwepheshe buvumela imiklamo eminyene futhi engasindi, ibenze ilungele izinhlelo zokusebenza ezinezingqinamba zesikhala.

Izintambo zesignali ezinesivinini esikhulu:

Njengoba isidingo sokuxhumana ngesivinini esikhulu siqhubeka sikhula, intuthuko kubuchwepheshe be-lamination inika amandla izintambo zesignali ezinesivinini esikhulu kuma-PCB aqinile aguquguqukayo. Sebenzisa amasu athuthukisiwe afana nomzila olawulwayo we-impedance, umzila wokubhanqa ohlukile, kanye nemiklamo ye-microstrip noma ye-stripline ukuze ugcine ubuqotho besignali futhi unciphise ukulahlekelwa kwesignali. Ukucatshangelwa kwedizayini kuphinde kucubungule imithelela yokuhlanganisa, i-crosstalk, nokuboniswa kwesignali. Ukusetshenziswa kwezinto ezikhethekile kanye nezinqubo zokukhiqiza kusiza ukufeza ukusebenza kwesivinini esikhulu sama-PCB aqinile aguquguqukayo.

Intuthuko eqhubekayo kubuchwepheshe be-rigid-flex lamination ivumela ukuthuthukiswa kwemishini kagesi ehlangene, eguquguqukayo, futhi enezici ezigcwele. Intuthuko ekusungulweni kwezinto ezintsha, amasekhethi e-3D aphrintiwe, izingxenye ezishumekiwe eziguquguqukayo kanye nomzila wesignali wesivinini esikhulu kunikeza abaklami ukuguquguquka okukhulu namathuba okudala imiklamo ye-PCB eguquguqukayo nethembekile. Njengoba ubuchwepheshe buqhubeka nokuvela, abaklami nabakhiqizi kufanele bahlale bevuselelwe futhi basebenzisane eduze ukuze basebenzise intuthuko yakamuva futhi bazuze ukusebenza kwe-PCB eqinile eqinile.

Ngokufigqiwe,ukudizayina nokukhetha ukumiswa kwesitaki se-PCB eqinile eguquguqukayo okulungile kubalulekile ukuze kuzuzwe ukusebenza kahle, ukwethembeka, nokuguquguquka. Ngokucabangela izici ezifana nobuqotho besignali, izimfuneko zokuvumelana nezimo nezingqinamba zokukhiqiza, abaklami bangakwazi ukuhlela isitaki ukuze sihlangabezane nezidingo zabo zohlelo lokusebenza. Ukuthuthuka okuqhubekayo kubuchwepheshe bezinto ezibonakalayo kunikeza amathemba abanzi edizayini ye-elekthronikhi ethuthukisiwe. Izinto ezintsha ze-substrate ezenzelwe ama-PCB aqinile-flex zithuthukisa ukuguquguquka, ukuqina, kanye nezinga lokushisa nokumelana nomswakama. Ngaphezu kwalokho, ukuhlanganisa izingxenye ngokuqondile kungqimba oluguquguqukayo kunciphisa usayizi nesisindo se-PCB, kuyenze ifanelekele izinhlelo zokusebenza ezinezithiyo zesikhala eziqinile. Ukwengeza, intuthuko kubuchwepheshe be-lamination inikeza amathuba ajabulisayo. Ukusetshenziswa kobuchwepheshe bokuphrinta be-3D kunganika amandla imiklamo eyinkimbinkimbi futhi kusize ukwenza i-prototyping ngokushesha nokwenza ngokwezifiso.

Ukwengeza, inqubekelaphambili kubuchwepheshe bomzila wesignali wesivinini esikhulu yenza ama-PCB aqinile-aguquguqukayo afinyelele ukuxhumana okusebenzayo nokuthembekile.

Njengoba ubuchwepheshe buqhubeka nokuvela, abaklami kufanele bahlale benolwazi ngentuthuko yakamuva futhi basebenzisane eduze nabakhiqizi. Ngokusebenzisa intuthuko ezintweni zokwakha kanye nobuchwepheshe bokukhiqiza, abaklami bangakha imiklamo ye-PCB eguquguqukayo nethembekile ukuze kuhlangatshezwane nezidingo zemboni yezogesi ehlala ishintsha. Ngesithembiso sedizayini ye-elekthronikhi ethuthukisiwe, ikusasa lezitaki ze-PCB eziguquguqukayo libukeka lithembisa.

Isikhathi sokuthumela: Sep-12-2023

Emuva