I-Rigid-flex PCB assembly iwubuchwepheshe obusha nobuguquguqukayo obuhlanganisa izinzuzo zamabhodi esekethe aphrintiwe aqinile naguquguqukayo (ama-PCB). Le ndatshana ihlose ukuhlinzeka ngomhlahlandlela ophelele wokuhlangana kwe-PCB eqinile, egqamisa inqubo yayo yokukhiqiza, ukucatshangelwa kwedizayini, izinhlelo zokusebenza kanye nezinzuzo.

Okuqukethwe:

Iyini i-rigid-flex board assembly?

Inqubo yokukhiqiza ukuhlanganiswa kwebhodi eliqinile

Ukucatshangelwa Okubalulekile Kwedizayini yama-Rigid-Flex PCBs

Izinzuzo zebhodi le-rigid-flex

Izicelo Ezivamile ze-Rigid-Flex PCB Assembly

Amathiphu Okuphumelela I-Rigid-Flex PCB Assembly

I-Rigid-Flex PCB Assembly Challenges kanye nemikhawulo

Ekuphetheni

Iyini i-rigid-flex board assembly?

I-Rigid-flex PCB assembly ihlanganisa ukuhlanganisa ama-PCB aqinile naguquguqukayo abe yiyunithi eyodwa. Ivumela ukudalwa kwamasekhethi ayinkimbinkimbi anezinhlangothi ezintathu (3D) ngendlela ehlangene nephumelelayo. Ingxenye eqinile inikeza ukuzinza nokusekelwa, kuyilapho ingxenye eguquguqukayo ivumela ukugoba nokusonteka.

Inqubo yokukhiqiza ye-Rigid-Flex board assembly:

Inqubo yokukhiqiza yokuhlanganisa i-PCB eguquguqukayo ngokuvamile ihlanganisa izinyathelo eziningi. Lokhu kufaka phakathi ukwakheka kwe-PCB, ukukhethwa kwempahla, ukwakhiwa kwesekethe, ukuhlanganiswa kwezingxenye, ukuhlolwa nokuhlolwa kokugcina. Sebenzisa amathuluzi akhethekile namasu ukuze uqinisekise ukuhlangana okuthembekile phakathi kwezingxenye eziqinile nezivumelana nezimo.

Isinyathelo sokuqala ukuklama isakhiwo se-PCB.Lokhu kuhlanganisa ukunquma ukubekwa kwezingxenye nokulandelelwa kuzo zombili izingxenye zebhodi eziqinile nezivumelana nezimo.

Ukukhetha Okubalulekile:Ukukhetha impahla efanele kubalulekile ekuthembekeni kwebhodi nokuguquguquka. Lokhu kufaka phakathi ukukhethwa kwama-substrates aqinile njenge-FR4 nezinto eziguqukayo ezifana ne-polyimide noma i-polyester.

Ukwakhiwa Kwesekethe:Inqubo yokwenziwa kwe-PCB ibandakanya izinyathelo eziningi ezihlanganisa ukuhlanza, ukusebenzisa izendlalelo zethusi, ukunamathisela ukuze udale imikhondo yesifunda, ukungeza imaski ye-solder kanye ne-silkscreening ukuze kuhlonzwe ingxenye. Inqubo yenziwa ngokwehlukana izingxenye zebhodi eziqinile neziguquguqukayo.

Ukuhlanganiswa Kwengxenye:Izingxenye zibe sezigibezwa ezingxenyeni zebhodi eziqinile nezivumelana nezimo kusetshenziswa i-Surface Mount Technology (SMT) noma nge-Hole Technology (THT). Ukunakekelwa okukhethekile kuthathwa ukuze kuqinisekiswe ukuthi izingxenye zibekwe ngendlela efanele futhi ngokuvikelekile kuzo zombili izingxenye eziqinile nezivumelana nezimo.

I-Bonding:Inqubo yokubopha ibalulekile ukuze kuqinisekiswe ukuxhumana okuthembekile phakathi kwezingxenye eziqinile neziguquguqukayo zebhodi. Sebenzisa izinto ezinamathelayo, ukushisa, nokucindezela ukuze ubophe izingcezu ndawonye. Ngale njongo, kusetshenziswa imishini ekhethekile namasu, njengokusetshenziswa kwama-laminators noma ukushisa okulawulwayo.

Ukuhlola:Ngemuva kokuhlanganiswa, amabhodi ahlolwe kahle ukuze kuqinisekiswe ukusebenza nokuthembeka. Lokhu kuhlanganisa ukuhlolwa kukagesi, ukuhlola ukusebenza, kanye nokuhlolwa okungenzeka kwemvelo ukuze kuqinisekiswe ukusebenza kwebhodi eliguquguqukayo eliqinile ngaphansi kwezimo ezihlukene.

Ukuhlola Okokugcina:Ukuhlolwa kokugcina kwenziwa ukuze kuhlolwe izinga lomhlangano futhi kuqinisekiswe ukuthi azikho iziphambeko noma izinkinga emkhiqizweni oqediwe. Lesi sinyathelo sibandakanya ukuhlolwa okubonakalayo, izilinganiso zobukhulu, kanye nanoma yikuphi okunye ukuhlola okudingekayo kuhlelo lokusebenza.

Ukucatshangelwa kwedizayini okubalulekile kwama-PCB aqinile-flex:

Ukudizayina i-PCB eguquguqukayo eqinile kudinga ukucatshangelwa ngokucophelela kwezici ezihlukahlukene ezifana nerediyasi egobile, ukunqwabelana kongqimba, ukubekwa kwendawo eguquguqukayo, nokubekwa kwengxenye. Amasu okuklama afanele aqinisekisa ukusebenza okuphelele nokuthembeka komkhiqizo wokugcina.

Irediyasi yokugoba:Amabhodi e-Rigid-flex avunyelwe ukugoba nokugoqa, kodwa anomkhawulo omncane wokugoba okungafanele weqiwe. Irediyasi yokugoba iyiradiyasi encane kunazo zonke ibhodi engakwazi ukugoba ngaphandle kokulimaza umjikelezo noma ukubangela ukucindezeleka komshini. Lapho uklama ukuhlelwa kwezingxenye kanye nemikhondo, kubalulekile ukucabangela i-radius yokugoba yezindawo eziguquguqukayo ukuze kuqinisekiswe ubuqotho bazo ngesikhathi sokugoba.

Isitaki Sesendlalelo:Isitaki sesendlalelo sisho ukuhlelwa kwezingqimba ezihlukene ze-PCB. Ku-PCB eguquguqukayo eqinile, kuvame ukuba nezingqimba eziqinile neziguqukayo. I-stackup kufanele ihlelwe ngokucophelela ukuze kuqinisekiswe ukuhlangana okufanele phakathi kwezingxenye eziqinile neziguquguqukayo kanye nokuhlinzeka ngokusebenza okwanele kukagesi ngenkathi ihlangabezana nezidingo zokugoba nokugoqa.

Isakhiwo se-Flex Area:Indawo eguquguqukayo ye-PCB eguquguqukayo eqinile yindawo lapho ukugoba noma ukugoba kuzokwenzeka khona. Lezi zindawo kufanele zibekwe ngendlela efanele ukuze kugwenywe ukuphazamiseka kwezingxenye, izixhumi, nezakhiwo zemishini. Kubalulekile ukucabangela ukuma kanye nendawo yezindawo eziguquguqukayo ukuze kuncishiswe ukucindezeleka ezingxenyeni ezibalulekile ngesikhathi sokusebenza.

Ukubekwa kwengxenye:Ukubekwa kwezingxenye ku-PCB eguquguqukayo eqinile kufanele kuhlelwe ngokucophelela ukuze kugwenywe ukuphazamisa indawo eguqukayo kanye nokulandisa nganoma yikuphi ukunyakaza ngesikhathi sokugoba. Izingxenye ezibalulekile kufanele zibekwe ezingxenyeni eziqinile, kuyilapho izingxenye ezizwela kancane zingafakwa ezingxenyeni eziguquguqukayo. Ukubekwa kwengxenye kufanele futhi kucabangele ukusebenza okushisayo kwebhodi kanye nekhono elinamandla lokuqeda ukushisa.

Ubuqotho Besiginali:Ama-PCB e-Rigid-flex ngokuvamile adinga ukucatshangelwa ngokucophelela kobuqotho besignali. Ukugoba nokugoba kwe-PCB kungabangela ukungafani kwe-impedance, ukuboniswa kwesignali kanye nezinkinga ze-crosstalk. Kubalulekile ukucabangela umzila wokulandelela kanye nokulawulwa kokuvinjelwa ukuze kugcinwe ubuqotho besignali kulo lonke ibhodi.

Izingqinamba zikaMechanical:Izithiyo zemishini ezifana nokumelana nokushaqeka, ukudlidliza, nokwanda kokushisa zidinga ukucatshangelwa phakathi nesigaba sokuklama. Izingxenye zebhodi eziqinile neziguquguqukayo kufanele zakhelwe ukumelana nalezi zingcindezi zemishini ngaphandle kokuphazamisa ubuqotho besekethe.

Imikhawulo yokukhiqiza:Idizayini yokwenziwa ibalulekile ekwenziweni ngempumelelo kwama-PCB aguquguqukayo aqinile. Izinto ezinjengobubanzi obuncane bokulandelela, ngendawo, ukuminyana kwethusi, kanye nokubekezelela ukukhiqizwa kufanele kucatshangelwe ukuze kuqinisekiswe ukuthi umklamo uyafezeka ngaphakathi kwamakhono okukhiqiza kanye nemikhawulo.

Izinzuzo zamabhodi aqinile-flex:

I-Rigid-flex PCBs inikeza izinzuzo ezimbalwa ngaphezu kwama-PCB avamile aqinile noma aguquguqukayo. Lokhu kufaka phakathi usayizi oncishisiwe nesisindo, ukwethembeka okuthuthukisiwe, ubuqotho besignali obuthuthukisiwe, ukuguquguquka okuthuthukisiwe komklamo, nezinqubo zokuhlanganisa nokuhlola ezenziwe lula.

Usayizi owehlisiwe nesisindo:Ama-PCB aguquguqukayo avumela ukuhlanganiswa kwezingxenye eziqinile neziguquguqukayo ngaphakathi kwebhodi elilodwa, okuqeda isidingo sezixhumi nezintambo ezixhumeneyo. Izingxenye ezimbalwa kanye nezintambo kwenza umkhiqizo uwonke ube mncane futhi ube lula.

Ukuthembeka okuthuthukisiwe:I-Rigid-flex PCBs inokwethenjelwa okuphezulu uma kuqhathaniswa nama-PCB endabuko. Ukuqedwa kwezixhumi nezintambo ezixhumeneyo kunciphisa amathuba okuhluleka ngenxa yokuxega okuxhumekile noma izintambo eziphukile. Ukwengeza, ingxenye yebhodi eguquguqukayo ingakwazi ukumelana nokugoba nokuguquguquka ngaphandle kokuyekethisa ubuqotho besifunda.

Ubuqotho Besiginali Okuthuthukisiwe:Ukuhlanganisa izingxenye eziqinile nezivumelana nezimo ebhodini elilodwa kunciphisa isidingo sokuxhuma okungeziwe futhi kunciphisa ukulahlekelwa kwesignali nokuphazamiseka. Izindlela zesignali ezimfushane kanye nokunqanyulwa kwe-impedance okuncishisiwe kuthuthukisa ikhwalithi yesignali nobuqotho.

Ukwandisa ukuguquguquka kwedizayini:Ama-PCB e-Rigid-flex anikeza abaklami ukuguquguquka okukhulu kusici sefomu nokubekwa kwengxenye. Ikhono lokugoba nokugoqa amabhodi wesekethe linika amandla imiklamo ehlangene futhi enobuciko, okuvumela onjiniyela ukuthi balingane nokusebenza okwengeziwe endaweni encane.

Inqubo yokuhlanganisa nokuhlola eyenziwe lula:I-Rigid-flex PCBs yenza inqubo yokuhlanganisa ibe lula ngokunciphisa inani lezingxenye kanye nokuxhuma okudingekayo. Lokhu kwenza ukuhlanganisa ngokushesha nangempumelelo kakhudlwana. Ukwengeza, ukususa izixhumi kunciphisa ithuba lokungaqondani kahle noma izinkinga zokuxhuma ngesikhathi sokuhlanganisa. Inqubo yokuhlanganisa eyenziwe lula isho izindleko eziphansi kanye nesikhathi esisheshayo sokumaketha.

Izinhlelo zokusebenza ezijwayelekile ze-rigid-flex PCB assembly:

Imihlangano ye-PCB eguquguqukayo isetshenziswa ezimbonini eziningi ezahlukahlukene, kufaka phakathi imishini yezokwelapha, i-aerospace, izimoto, ugesi wabathengi, nokunye. Ilungele izinhlelo zokusebenza ezidinga ugesi ohlangene nothembekile ezindaweni eziyinselele.

Amadivayisi Ezokwelapha:Izilinganiso ze-PCB eziguquguqukayo eziqinile zivame ukusetshenziswa emishinini yezokwelapha efana nama-pacemaker, amaphampu e-insulin, neziqaphi zezempilo ezigqokwayo. Lawa madivayisi adinga usayizi omncane, ukuqina kanye nokuguquguquka ukuze amelane nokunyakaza nokuthintana ngokomzimba. Ubuchwepheshe be-Rigid-flex buvumela amasekethe ahlanganisiwe futhi athembekile kumishini yezokwelapha.

I-Aerospace:Imihlangano ye-PCB eguquguqukayo eqinile ilungele ukusetshenziswa kwe-aerospace lapho ukunciphisa isisindo, izithiyo zesikhala nokwethembeka kuyizici ezibalulekile. Zisetshenziswa ezinhlelweni zezindiza zezindiza, izinto zokuxhumana, izinhlelo zokuzulazula namaphaneli okulawula. Ubuchwepheshe be-Rigid-flex buvumela amasistimu kagesi alula, ahlangene kakhudlwana ezinhlelweni ze-aerospace.

Ezezimoto:Izinhlelo zokusebenza zezimoto zidinga ama-electronics aqinile futhi athembekile angakwazi ukumelana nokudlidliza, ukuguquka kwezinga lokushisa, kanye nokucindezeleka komshini. Imihlangano ye-PCB eguquguqukayo isetshenziswa kumayunithi okulawula izimoto, amasistimu okusiza abashayeli (ADAS), i-infotainment kanye nezinhlelo zokuphatha injini. Ubuchwepheshe be-Rigid-flex buqinisekisa idizayini yokonga isikhala futhi bukhuphula ukuqina.

I-Consumer Electronics:Imihlangano ye-Rigid-flex PCB isetshenziswa kakhulu kumishini kagesi ehlukahlukene yabathengi njengama-smartphone, amaphilisi, izinto ezigqokekayo namakhonsoli egeyimu. Imvelo ehlangene futhi eguquguqukayo yama-PCB aqinile aguquguqukayo inika amandla ukusebenza okuphezulu, ubuhle bedizayini obuthuthukisiwe, nolwazi olungcono lomsebenzisi. Ivumela abakhiqizi ukuthi bakhe amadivaysi azacile, alula, nasebenza kakhulu.

Izisetshenziswa zezimboni:Emishinini yezimboni lapho ukuthembeka nokuqina kubalulekile, imihlangano ye-PCB eguquguqukayo isetshenziswa ezinhlelweni zokulawula, amarobhothi, ukuphathwa kwamandla, kanye nokutholwa kwedatha. Ukuhlanganiswa kwezigaba eziqinile neziguquguqukayo kuvumela ukusetshenziswa kahle kwendawo, kunciphisa izintambo, futhi kwandise ukumelana nezimo zokusebenza ezinzima.

Amathiphu okuhlanganisa ngempumelelo i-rigid-flex PCB:

Ukuqinisekisa ukuhlanganiswa kwe-PCB eqinile okuguquguqukayo okuphumelelayo, izinqubo ezingcono kakhulu kufanele zilandelwe, njengokukhethwa komkhiqizi olungile, ukuphatha impahla efanele nokugcinwa, ukuphatha okushisayo okusebenzayo, kanye nezinqubo zokuhlola nokuhlola okuphelele.

Khetha umkhiqizi onedumela elihle:Ukukhetha umkhiqizi olungile kubalulekile ekuhlanganiseni okuphumelelayo kwe-PCB eqinile eguquguqukayo. Bheka umkhiqizi onolwazi lokukhiqiza ama-PCB aguquguqukayo aqinile kanye nerekhodi lokuletha imikhiqizo yekhwalithi ephezulu. Cabangela ubuchwepheshe babo, amakhono okukhiqiza, izitifiketi, nokubuyekezwa kwamakhasimende.

Qonda izidingo zedizayini:Ujwayelene nezidingo zokuklama zamabhodi aqinile-flex. Lokhu kuhlanganisa ukuqonda izithiyo zemishini nezikagesi ezifana nezidingo zokugoba nokugoqa, ukubekwa kwengxenye nokucatshangelwa kobuqotho besignali. Sebenzisana eduze nomklami wakho we-PCB ukuze uqinisekise ukuthi imiklamo ithuthukiswa ukuze yenziwe futhi ihlanganiswe.

Ukuphatha Okufanelekile Nesitoreji:Amabhodi e-Rigid-flex angonakaliswa kalula ukuphatha kabi kanye nokugcinwa okungafanele. Qiniseka ukuthi umkhiqizi ulandela izinqubo ezifanele zokuphatha impahla, okuhlanganisa nokuvikela izindawo eziguquguqukayo ekugobeni okukhulu noma ekucindezelekeni. Futhi, gcina amabhodi aqinile-flex endaweni elawulwayo ukuze uvimbele ukumuncwa komswakama noma ukuchayeka emazingeni okushisa aphezulu.

Ukuphatha okushisayo okusebenzayo:Ama-Rigid-flex PCB assemblies angase abe nezingxenye ezikhiqiza ukushisa. Ukuphathwa okushisayo okufanelekile kubalulekile ukuze kuqinisekiswe ukusebenza okuthembekile nokuvimbela ukwehluleka okuhlangene kwe-solder. Cabangela amasu afana ne-thermal vias, izisabalali zokushisa, noma amaphedi ashisayo ukuze ulawule ngempumelelo ukuchithwa kokushisa. Sebenza nomkhiqizi ukuze ulungiselele idizayini yokuphatha okushisayo okusebenzayo.

Ukuhlola nokuhlolwa okuphelele:Ukuhlolwa nokuhlolwa okuqinile kuyadingeka ukuze kutholakale noma yiziphi izinkinga ngesikhathi sokuhlanganisa futhi kuqinisekiswe ukwethembeka komkhiqizo wokugcina. Sebenzisa iphrothokholi yokuhlola ephelele okuhlanganisa ukuhlola kukagesi, ukuhlola ukusebenza nokuhlola ukwethembeka. Yenza ukuhlola okubonakalayo okuphelele ukuze uthole noma yimaphi amaphutha noma okudidayo emhlanganweni.

Hlanganyela Nabakhiqizi:Gcina ukuxhumana okuvulekile futhi usebenze eduze nabakhiqizi kuyo yonke inqubo yokuhlanganisa. Xoxa ngokucatshangelwa kwesakhiwo, izidingo zokukhiqiza kanye nanoma yiziphi izindaba ezithile. Buyekeza ngezikhathi ezithile futhi ugunyaze ama-prototypes noma amasampula ukuze uqinisekise ukuthi okulindele kuyahlangatshezwana nayo. Le ndlela yokuhlanganyela izosiza ukuxazulula noma yiziphi izinkinga ezingase zibe khona kusenesikhathi futhi iqinisekise umhlangano ophumelelayo we-PCB oguquguqukayo.

Izinselelo kanye nemikhawulo ye-rigid-flex PCB assembly:

Nakuba umhlangano we-PCB oguquguqukayo unezinzuzo eziningi, futhi uveza izinselele kanye nemikhawulo. Lokhu kufaka phakathi izindleko eziphakeme zokukhiqiza, ukukhuphuka komklamo kanye nobunkimbinkimbi bokukhiqiza, ukutholakala okulinganiselwe kwemishini ekhethekile yokukhiqiza, kanye nengozi enkulu yokukhubazeka kokukhiqiza.

Izindleko zokukhiqiza eziphezulu:Imihlangano ye-PCB eguquguqukayo ivame ukubiza kakhulu kunemihlangano ye-PCB eqinile yendabuko ngenxa yezinto ezengeziwe ezidingekayo, izinqubo zokukhiqiza ezikhethekile, nokuba yinkimbinkimbi okuphezulu. Izindleko zokwenziwa nokuhlanganisa i-PCB eqinile-flex kufanele zicatshangelwe ngokucophelela futhi zibe nesabelomali kuphrojekthi.

Ukwanda kwedizayini nobunkimbinkimbi bokukhiqiza:Ngenxa yokuhlanganiswa kwezinto eziqinile nezivumelana nezimo, ukuklanywa kwama-PCB aqinile-flex kudinga ubuchwepheshe nolwazi. Inqubo yokuklama iyinkimbinkimbi kakhulu njengoba ihlanganisa ukugoba, ukugoqa nokubeka izingxenye. Izinqubo zokukhiqiza ezifana ne-lamination, ukubhoboza kanye nokushisela nazo ziba yinkimbinkimbi ngenxa yokuhlanganiswa kwezinto nezakhiwo.

Ukutholakala Okulinganiselwe Kwezisetshenziswa Zokukhiqiza Ezizinikele:I-Rigid-flex PCB assembly ingase idinge imishini yokukhiqiza ekhethekile okungebona bonke abakhiqizi abanayo. Ukutholakala kwamathuluzi anjalo kungase kube nomkhawulo, okungase kubangele izikhathi zokuhola ezinde noma isidingo sokukhipha ukukhiqizwa ezikhungweni ezikhethekile. Kubalulekile ukuqinisekisa ukuthi umenzi okhethiwe unempahla namandla adingekayo ukuze kuhlanganiswe i-PCB eqinile eguquguqukayo.

Ingozi Ephakeme Yokukhubazeka Kokukhiqiza:Ubunkimbinkimbi bemihlangano ye-PCB eguquguqukayo eguquguqukayo budala ubungozi obukhulu bokwenza amaphutha uma kuqhathaniswa nemihlangano ye-PCB eqinile yendabuko. Izindawo ezithambile nezixhumo ezithambile zisengozini yokulimala ngesikhathi sokukhiqiza nokuhlanganisa. Ukunakekela okwengeziwe kufanele kuthathwe ngesikhathi sokuphatha, ukusoda nokuhlolwa ukuze kuncishiswe ubungozi bokulimala.

Izinselelo zokuhlola nokuhlola:Imihlangano ye-PCB eguquguqukayo eqinile ingaba inselele kakhulu ukuhlola nokuhlola ngenxa yenhlanganisela yezindawo eziqinile nezivumelana nezimo. Izindlela zokuhlola zendabuko ezifana ne-flying probe noma umbhede wokuhlolwa kwezinzipho zingase zingafaneleki imiklamo eyinkimbinkimbi eguquguqukayo. Ukuhlola ngokwezifiso nezindlela zokuhlola zingase zidingeke, kwengeze inkimbinkimbi nezindleko enqubweni yokukhiqiza.

Naphezu kwalezi zinselele kanye nemikhawulo, imihlangano ye-PCB eguquguqukayo eqinile inikeza izinzuzo eziyingqayizivele ngokonga isikhala, ukwethembeka, nokuqina, okuyenza ibe ukukhetha kokuqala kwezinhlelo zokusebenza ezinezidingo ezithile. Lezi zinselele zingaxazululwa ngokuphumelelayo ngokusebenzisana eduze nomkhiqizi onolwazi nokucatshangelwa ngokucophelela kokucatshangelwa komklamo nokukhiqiza, okuholela ekuhlanganiseni okuphumelelayo kwe-PCB eguquguqukayo.

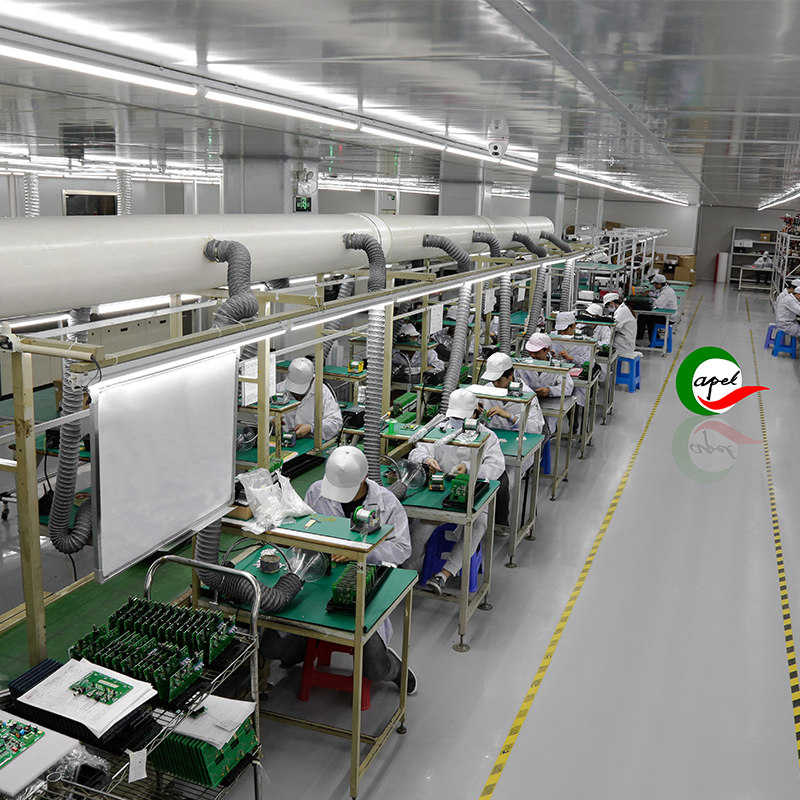

I-Rigid-flex PCB assembly iwubuchwepheshe obunamandla obungasetshenziswa ukudala amadivaysi e-elekthronikhi ahlakaniphile futhi ahlangene.Izici zayo ezihlukile kanye nezinzuzo ziyenza ifaneleke ezinhlobonhlobo zezinhlelo zokusebenza kuzo zonke izimboni. Kodwa-ke, ukucatshangelwa ngokucophelela kokuklama, ukukhiqiza kanye nenqubo yokuhlanganisa kubalulekile ukuze kuqinisekiswe ukuqaliswa okuyimpumelelo. Sengiphetha, ukuqonda inqubo yokukhiqiza, ukucatshangelwa kwedizayini, izinhlelo zokusebenza, izinzuzo kanye nemikhawulo ye-rigid-flex PCB assembly kubalulekile konjiniyela, abaklami nabakhiqizi. Ngokusebenzisa amandla alobu buchwepheshe obuthuthukile, izinto zikagesi ezisezingeni eliphezulu nezithembekile zingathuthukiswa ukuze zihlangabezane nezidingo zezimboni zanamuhla ezithuthukayo ngokushesha.I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yokuhlangenwe nakho kwephrojekthi ecebile, ukugeleza kwenqubo okuqinile, amakhono obuchwepheshe asezingeni eliphezulu, okokusebenza okuzenzakalelayo okuthuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe lochwepheshe ukuze anikeze amakhasimende omhlaba ukunemba okuphezulu, izinga eliphezulu le-1-32 layer rigid flex. ibhodi, hdi Rigid Flex Pcb, Rigid Flex Pcb Fabrication, rigid-flex pcb assembly, fast turn rigid rigid flex pcb assembly,shesha vula i-pcb assembly prototypes.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kwenza amaklayenti ethu abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-29-2023

Emuva