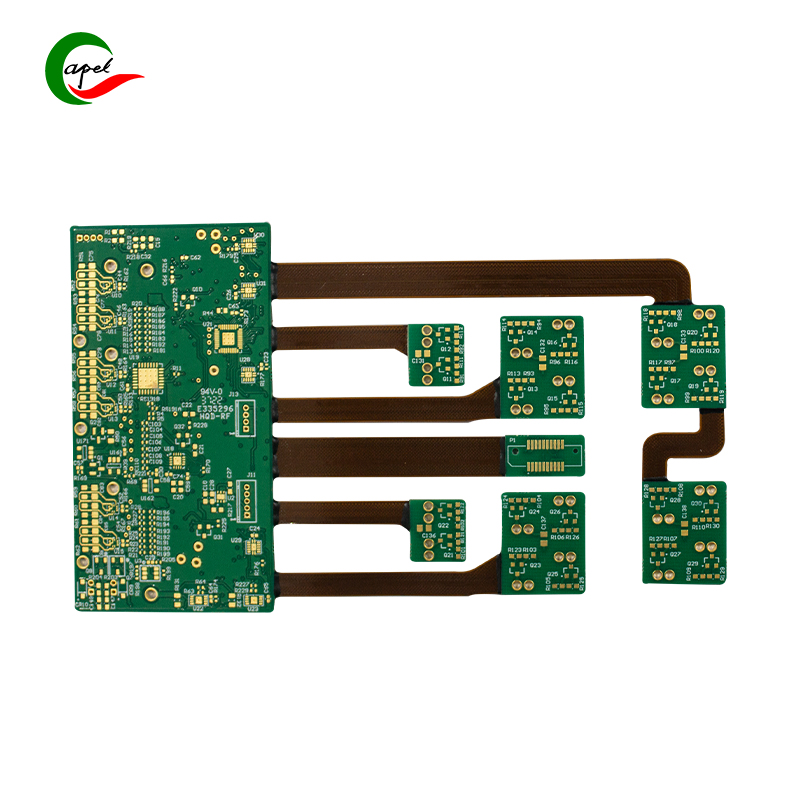

Njengoba ubuchwepheshe buqhubeka buthuthuka ngezinga elingakaze libonwe ngaphambili, isidingo semishini kagesi ehlangene, elula futhi evumelana nezimo kakhulu siye saphakama kakhulu. Ukuze kuhlangatshezwane nalesi sidingo, ukuthuthukiswa kwamabhodi esekethe e-rigid-flex sekuyinto entsha emisha embonini ye-electronics. Lawa mabhodi ahlanganisa ukuguquguquka kwamasekhethi aguquguqukayo nokuqina kwamabhodi aqinile, awenze afanelekele uhla olubanzi lwezinhlelo zokusebenza ezihlanganisa i-aerospace, imishini yezokwelapha, nezinto zikagesi zabathengi.

Isici esibalulekile sokukhiqiza amabhodi wesifunda aqinile-flex inqubo yokubopha. Inqubo idlala indima ebalulekile ekuqinisekiseni ukuzinza nokuthembeka kwalawa mabhodi njengoba ibopha ngokuqinile izingxenye eziguquguqukayo neziqinile ndawonye. Kulokhu okuthunyelwe kwebhulogi, uCapel uzocubungula imininingwane yenqubo yokubopha, edingida imithelela yayo, amasu, kanye nokucatshangelwa.

Qonda incazelo:

Inqubo yokuhlanganisa ibalulekile ekugcineni ubuqotho besakhiwo samabhodi wesifunda aqinile-flex. Kubandakanya ukusetshenziswa kwento enamathelayo phakathi kwesekethe eguquguqukayo kanye ne-substrate eqinile, kwakha isibopho esiqinile esingamelana nezimo zemvelo, ukucindezeleka komshini, nokushintsha kwezinga lokushisa. Ngokuyinhloko, i-adhesive ayibambi kuphela izendlalelo ndawonye, kodwa futhi ivikela isifunda ekulimaleni okungenzeka.

Khetha into enamathelayo efanele:

Ukukhetha izinto ezinamathelayo ezifanele kubalulekile ekuqinisekiseni ukuthembeka kwesikhathi eside kanye nokusebenza kwamabhodi wesifunda aqinile-flex. Kunezici eziningana okufanele zicatshangelwe lapho kukhethwa i-adhesive, njengokuhambisana nezinto ezisetshenzisiwe, ukusebenza okushisayo, ukuguquguquka, kanye nezidingo ezithile zohlelo lokusebenza.

Izinamathiselo ezisekelwe ku-Polyimide zisetshenziswa kakhulu ngenxa yokusimama kwazo okushisayo, ukuguquguquka, nokuhambisana nazo zombili izinto eziqinile nezivumelana nezimo. Ngaphezu kwalokho, izinto zokunamathisela ezisekelwe epoxy zisetshenziswa kakhulu ngenxa yamandla azo aphezulu, ukumelana nomswakama kanye namakhemikhali. Kubalulekile ukubonisana nomkhiqizi we-adhesive kanye nomkhiqizi webhodi lesifunda eliqinile-flex ukuze anqume izinto ezifanele kakhulu zohlelo lokusebenza oluthile.

Amasu okufaka isicelo se-Adhesive:

Ukusetshenziswa ngempumelelo kwezinamatheliso kudinga ukunakwa kwemininingwane nokunamathela kumasu afanele. Lapha sihlola ezinye zezindlela eziyinhloko ezisetshenziswa ku-rigid-flex circuit board bonding inqubo:

1. Ukuphrinta isikrini:

Ukuphrinta isikrini kuyindlela edumile yokusebenzisa izinamathiselo kumabhodi wesekethe. Kuhilela ukusebenzisa i-stencil noma isikrini se-mesh ukudlulisa okunamathelayo ezindaweni ezithile zebhodi. Le ndlela ivumela ukulawula okunembile kokunamathela nokusatshalaliswa kwe-adhesive, ukuqinisekisa isibopho esingaguquki futhi esithembekile. Ngaphezu kwalokho, ukuphrinta kwesikrini kungenziwa ngokuzenzakalela, kuthuthukise ukusebenza kahle kokukhiqiza nokunciphisa iphutha lomuntu.

2. Ukusabalalisa:

Ukukhipha izinto ezinamathelayo kuhilela ukusetshenziswa okunembile kwezinto kusetshenziswa okokusebenza okuzenzakalelayo kokukhipha impahla. Lobu buchwepheshe buvumela ukubekwa okunembayo nokugcwaliswa kwe-adhesive, kuncishiswe ubungozi be-voids nokuqinisekisa amandla aphezulu ebhondi. Ukukhipha kuvame ukusetshenziselwa imiklamo eyinkimbinkimbi noma enezinhlangothi ezintathu zebhodi lesifunda lapho ukuphrinta kwesikrini kungase kungenzeki.

3. Lamination:

I-Lamination inqubo yokuhlanganisa ungqimba lwesekethe oluguquguqukayo phakathi kwezingqimba ezimbili eziqinile nge-adhesive efakwe phakathi. Lobu buchwepheshe buqinisekisa ukuthi i-adhesive isatshalaliswa ngokulinganayo kulo lonke ibhodi, okwandisa ukusebenza kahle kokubopha. I-Lamination ifaneleka ngokukhethekile ukukhiqizwa kwevolumu ephezulu ngoba ivumela amabhodi amaningi ukuthi ahlanganiswe ndawonye ngesikhathi esisodwa.

Amanothi ngenqubo yokuhlanganisa:

Nakuba ukuqonda izinqubo ezihlukahlukene zokunamathisela ezinamathelayo kubalulekile, kukhona ukucatshangelwa okwengeziwe okunomthelela empumelelweni yenqubo yokunamathela iyonke. Lezi zici zidlala indima ebalulekile ekwandiseni ukusebenza nokuthembeka kwamabhodi esekethe e-rigid-flex. Ake sihlole okunye kwalokhu okucatshangelwayo:

1. Inhlanzeko:

Kubalulekile ukuqinisekisa ukuthi zonke izindawo, ikakhulukazi izendlalelo zesekethe eziguquguqukayo, zihlanzekile futhi azinakho ukungcola ngaphambi kokufaka okunamathelayo. Ngisho nezinhlayiya ezincane noma izinsalela zingalimaza ukunamathela, okuholela ekunciphiseni ukuthembeka noma ngisho nokwehluleka. Izinqubo ezifanele zokuhlanza indawo kufanele zisetshenziswe, kuhlanganise nokusetshenziswa kwe-isopropyl alcohol noma izixazululo ezikhethekile zokuhlanza.

2. Izimo zokuphulukisa:

Izimo zemvelo ngesikhathi sokwelapha okunamathelayo zibalulekile ekuzuzeni amandla amakhulu ebhondi. Izinto ezifana nezinga lokushisa, umswakama kanye nesikhathi sokwelapha kufanele zilawulwe ngokucophelela ukuze kuhlangatshezwane neziqondiso zomkhiqizi wokunamathelayo. Ukuchezuka ezimeni zokuphulukisa ezinconyiwe kungase kubangele ukunamathela okungekuhle noma ukusebenza kwebhondi.

3. Ukucatshangelwa kwengcindezi yemishini:

Amabhodi esekethe e-Rigid-flex ngokuvamile aba ngaphansi kwengcindezi ehlukahlukene yemishini njengokugoba, ukusonteka nokudlidliza phakathi nempilo yawo yesevisi. Kubalulekile ukucabangela lezi zici ngesikhathi senqubo yokuhlanganisa. Izinto zokubopha kufanele zikhethwe ngokuguquguquka okuphezulu nokumelana nokukhathala okuhle ukuze kuqinisekiswe ukuthi isibopho singakwazi ukumelana nalezi zingcindezi zemishini ngaphandle kokwehluleka.

Inqubo yokuhlanganisa ekwenziweni kwebhodi lesifunda eliqinile-flex ibalulekile ekuzuzeni ukuzinza, ukuqina nokuthembeka. Ukukhethwa kwezinto ezinamathelayo ezifanele kanye nezindlela ezifanele zokufaka isicelo kanye nezinyathelo zokuphepha kungaqinisekisa ukusebenza kwesikhathi eside kwalawa mabhodi ngisho nasezinhlelweni eziyinselele kakhulu.

Njengoba ubuchwepheshe buqhubeka nokuvela, isidingo semishini kagesi ethuthuke kakhulu futhi evumelana nezimo sizoqhubeka. Inqubo yokuhlanganisa idlala indima ebalulekile ekuhlangabezaneni nalesi sidingo ngokukhiqiza amabhodi esekethe athembekile futhi ahlukahlukene aqinile. Ngokuqonda ukubaluleka kwenqubo yokuhlanganisa nokuyisebenzisa ngendlela efanele, abakhiqizi bangakha amadivaysi e-elekthronikhi asezingeni eliphezulu ahamba phambili ekusungulweni okusha kwezobuchwepheshe.

Isikhathi sokuthumela: Aug-21-2023

Emuva