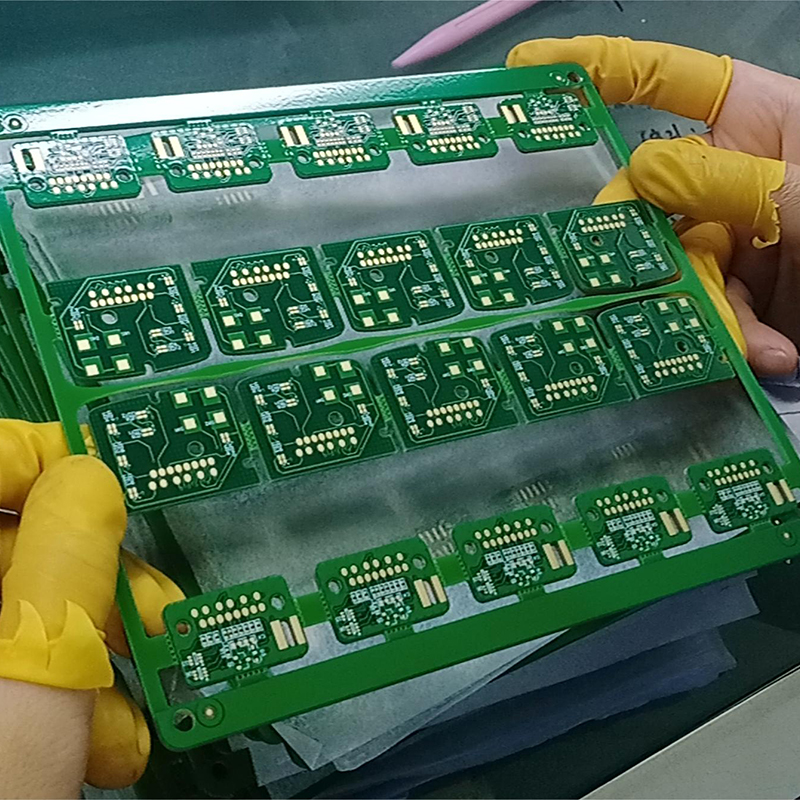

Ukuthuthuka okusheshayo kwemboni yezogesi kuholele ekusetshenzisweni okubanzi kwebhodi eliqinile-flex. Kodwa-ke, ngenxa yomehluko wamandla, ubuchwepheshe, isipiliyoni, inqubo yokukhiqiza, amandla enqubo kanye nokucushwa kwemishini yabakhiqizi abahlukene, izinkinga zekhwalithi zamabhodi aqinile-flex in the process production mass nazo zihlukile.I-Capel elandelayo izochaza ngokuningiliziwe izinkinga ezimbili ezivamile nezisombululo ezizokwenzeka ekukhiqizeni ngobuningi bamabhodi aqinile aguquguqukayo.

Enqubweni yokukhiqiza ngobuningi yamabhodi aqinile-flex, ukuthayela okungalungile kuyinkinga evamile. Ukungafakwa kahle kwamathini kungase kuholele ekungazinzini

amalunga e-solder futhi athinte ukuthembeka komkhiqizo.

Nazi ezinye izimbangela ezingaba nomthelela ongemuhle wamathini:

1. Inkinga yokuhlanza:Uma ingaphezulu lebhodi lesifunda lingahlanzwa kahle ngaphambi kokuthayela, kungase kuholele ekuhlanganiseni okungalungile;

2. Izinga lokushisa lokunamathisela alilungile:uma izinga lokushisa le-solder liphezulu kakhulu noma liphansi kakhulu, kungase kuholele ekuthinini okungalungile;

3. Izinkinga zekhwalithi yokunamathisela odongeni:izinga eliphansi solder unama kungase kuholele tinning abampofu;

4. Izinkinga zekhwalithi yezingxenye ze-SMD:Uma izinga lephedi lezingxenye ze-SMD lingalungile, lizoholela ekuthinini okungalungile;

5. Ukusebenza kwe-welding okungalungile:Ukungasebenzi kahle kwe-welding kungase kuholele ekuthinini okungalungile.

Ukuze ugweme kangcono noma uxazulule lezi zinkinga zokudambisa ezingezinhle, sicela unake amaphuzu alandelayo:

1. Qinisekisa ukuthi ingaphezulu lebhodi lihlanzwa kahle ukuze kukhishwe uwoyela, uthuli nokunye ukungcola ngaphambi kokucwenga;

2. Lawula izinga lokushisa kanye nesikhathi sokufaka amathini: Ngesikhathi kufakwa amathini, kubaluleke kakhulu ukulawula izinga lokushisa nesikhathi sokufaka amathini. Qinisekisa ukuthi usebenzisa izinga lokushisa elilungile le-soldering futhi wenze izinguquko ezifanele ngokuya ngezinto zokwakha kanye nezidingo. Ukushisa okwedlulele futhi isikhathi eside kakhulu Isikhathi singabangela ukuthi amalunga e-solder ashise kakhulu noma ancibilike, futhi abangele nomonakalo ebhodini eliguquguqukayo eliqinile. Ngokuphambene nalokho, izinga lokushisa eliphansi kakhulu kanye nesikhathi kungabangela ukuthi impahla ye-solder ingakwazi ukumanzisa ngokuphelele futhi isakaze ekuhlanganyeleni kwe-solder, ngaleyo ndlela yakha i-solder ebuthakathaka;

3. Khetha izinto ezifanele zokuhlanganisa: khetha umphakeli othembekile wokunamathisela i-solder, qinisekisa ukuthi uhambisana nezinto zebhodi le-rigid-flex, futhi uqinisekise ukuthi izimo zokugcina nokusebenzisa i-solder paste zinhle.

Khetha izinto zokudambisa ezisezingeni eliphezulu ukuze uqinisekise ukuthi izinto ezisodayo zinokumanzi kahle kanye nephuzu elincibilikayo elifanele, ukuze zikwazi ukusabalalisa ngokulinganayo futhi zenze amajoyinti e-solder azinzile ngesikhathi sokuthayela;

4. Qiniseka ukuthi usebenzisa izingxenye zepheshi zekhwalithi enhle, futhi uhlole ukucaba nokunamathela kwephedi;

5. Ukuqeqesha nokuthuthukisa amakhono okusebenza ngokushisela ukuze kuqinisekiswe indlela efanele yokuhlanganisa nesikhathi;

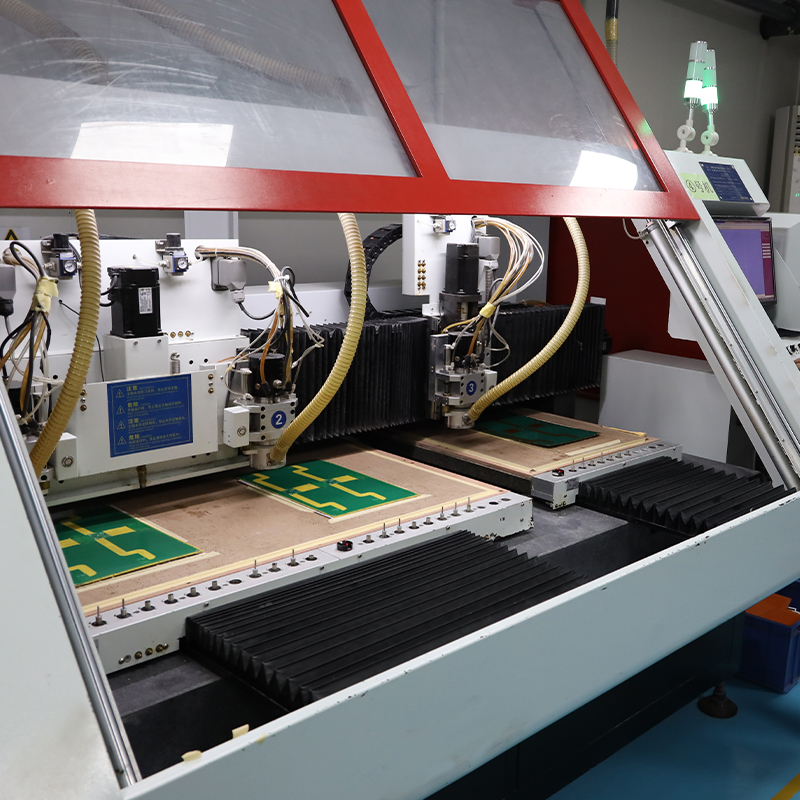

6. Lawula ukujiya nokufana kwe-tin: qinisekisa ukuthi ithini isakazwa ngokulinganayo endaweni ehlanganisiwe ukuze ugweme ukugxila kwendawo kanye nokungalingani. Amathuluzi namasu afanelekile, njengemishini yokufaka amathini noma okokusebenza okuzenzakalelayo, kungasetshenziswa ukuze kuqinisekiswe ukusatshalaliswa nokujiya okufanele kwempahla yokunamathisela;

7. Ukuhlolwa nokuhlolwa okuvamile: Ukuhlolwa nokuhlolwa okuvamile kwenziwa ukuze kuqinisekiswe ikhwalithi yamalungu e-solder ebhodi eliqinile-flex. Izinga nokuthembeka kwamajoyinti e-solder kungahlolwa kusetshenziswa ukuhlola okubukwayo, ukuhlola ukudonsa, njll. Thola futhi uxazulule inkinga ye-tinning embi ngesikhathi ukuze ugweme izinkinga zekhwalithi nokwehluleka ekukhiqizeni okulandelayo.

Ubukhulu bembobo obunganele kanye ne-copper plating yembobo engalingani nakho kuyizinkinga ezingase zenzeke ekukhiqizeni okuningi.

amabhodi aqinile-flex. Ukuvela kwalezi zinkinga kungase kuthinte ikhwalithi yomkhiqizo. Okulandelayo kuhlaziya izizathu futhi

izixazululo ezingase zidale le nkinga:

Isizathu:

1. Inkinga yokwelashwa kwangaphambili:Ngaphambi kwe-electroplating, ukulungiswa kodonga lwembobo kubaluleke kakhulu. Uma kunezinkinga ezifana nokugqwala, ukungcola noma ukungalingani odongeni lwembobo, kuzothinta ukufana nokunamathela kwenqubo yokucwenga. Qinisekisa ukuthi izindonga zembobo zihlanzwa kahle ukuze kukhishwe noma yikuphi ukungcola kanye nezendlalelo ze-oxide.

2. Inkinga yokwakhiwa kwesisombululo seplating:Ukubunjwa kwesixazululo se-plating okungalungile nakho kungaholela ekucwebeni okungalingani. Ukwakheka nokugxila kwesisombululo sokucwenga kufanele kulawulwe ngokuqinile futhi kulungiswe ukuze kuqinisekiswe ukufana nokuzinza ngesikhathi senqubo yokucwenga.

3. Inkinga yamapharamitha e-electroplating:amapharamitha e-electroplating ahlanganisa ukuminyana kwamanje, isikhathi se-electroplating nezinga lokushisa, njll. Izilungiselelo zepharamitha yokucwenga okungalungile zingaholela ezinkingeni zokungalingani nokushuba okunganele. Qinisekisa ukuthi amapharamitha alungile abekwe ngokwezidingo zomkhiqizo futhi enze izinguquko ezidingekayo kanye nokuqapha.

4. Izinkinga zenqubo:Izinyathelo zenqubo kanye nokusebenza kunqubo ye-electroplating kuzophinde kuthinte ukufana kanye nekhwalithi ye-electroplating. Qiniseka ukuthi opharetha balandela ngokuqinile ukugeleza kwenqubo futhi basebenzise amathuluzi namathuluzi afanelekile.

Isixazululo:

1. Lungiselela inqubo yokwelapha ngaphambi kwesikhathi ukuze uqinisekise ukuhlanzeka nokucaba kodonga lwembobo.

2. Hlola njalo futhi ulungise ukwakheka kwesisombululo se-electroplating ukuze uqinisekise ukuzinza nokufana kwayo.

3. Setha amapharamitha alungile wokunamathisela ngokwezidingo zomkhiqizo, futhi uqaphe futhi ulungise eduze.

4. Ukuqhuba ukuqeqeshwa kwabasebenzi ukuthuthukisa amakhono okusebenza kwenqubo nokuqwashisa.

5. Yethula uhlelo lokuphatha ikhwalithi ukuze kuqinisekiswe ukuthi yonke isixhumanisi silawulwa ngokuqinile futhi sihlolwe ikhwalithi.

6. Qinisa ukuphathwa kwedatha nokuqoshwa: sungula ukuphathwa kwedatha ephelele kanye nesistimu yokuqopha ukuze urekhode imiphumela yokuhlolwa yogqinsi lwezimbobo zethusi nokufana kwe-plating. Ngezibalo nokuhlaziywa kwedatha, isimo esingavamile sogqinsi lwethusi lwembobo nokufana kwe-electroplating kungatholwa ngesikhathi, futhi izinyathelo ezihambisanayo kufanele zithathwe ukulungisa nokuthuthukisa.

Okungenhla yizinkinga ezimbili ezinkulu zokuthina okungalungile, ukujiya kwethusi kwembobo enganele, kanye ne-copper plating yembobo engalingani evame ukwenzeka ebhodini eliguquguqukayo eliqinile.Ngithemba ukuthi ukuhlaziya kanye nezindlela ezinikezwe nguCapel kuzoba usizo kuwo wonke umuntu. Ukuze uthole eminye imibuzo ephrintiwe yebhodi lesifunda, sicela uthintane nethimba lochwepheshe base-Capel, iminyaka engu-15 yobungcweti bebhodi lesifunda kanye nolwazi lobuchwepheshe kuzophelezela iphrojekthi yakho.

Isikhathi sokuthumela: Aug-21-2023

Emuva