Kulokhu okuthunyelwe kwebhulogi, sizohlola izici okufanele zicatshangelwe lapho kukhethwa izinto zefilimu zama-PCB avumelana nezimo futhi sinikeze imininingwane ebalulekile ukukusiza wenze isinqumo unolwazi.

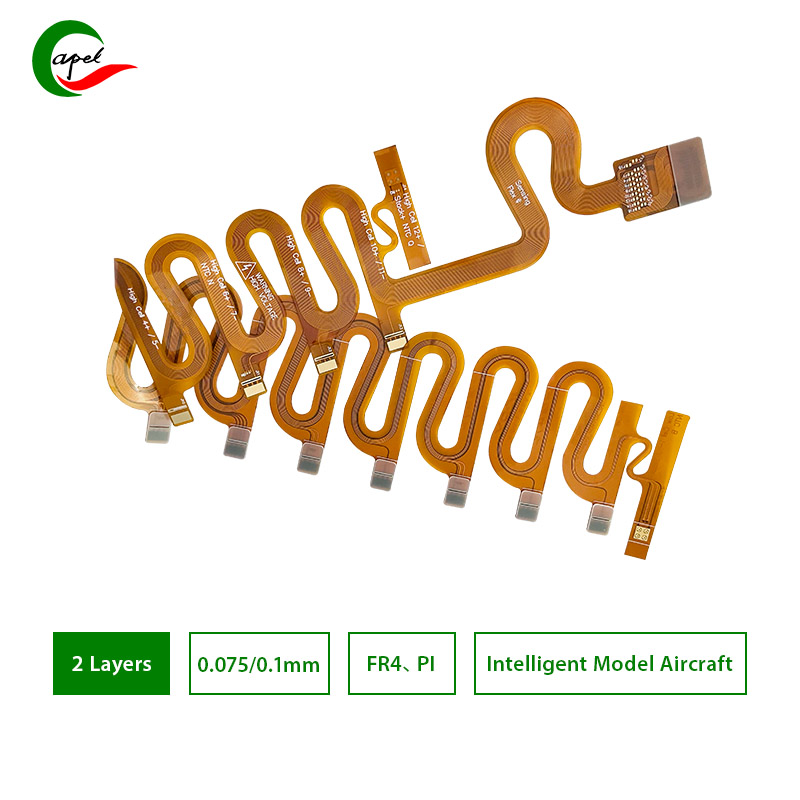

Eminyakeni yakamuva,ama-PCB aguquguqukayo(amabhodi wesifunda aphrintiwe aguquguqukayo) athole ukuthandwa ngenxa yekhono lawo lokuhambisana nokubunjwa okuyinkimbinkimbi, ukuthuthukisa ukusebenza kukagesi, nokunciphisa isisindo kanye nezidingo zesikhala. Lawa mabhodi esekethe aguquguqukayo asetshenziswa kabanzi ezimbonini ezahlukahlukene, kufaka phakathi ezezimoto, ugesi wabathengi, amadivaysi ezokwelapha kanye ne-aerospace. Isici esibalulekile sokuklama ama-PCB aguquguqukayo ukukhetha impahla yefilimu efanele ukuze kuqinisekiswe ukusebenza okudingekile nokwethembeka.

1. Ukuvumelana nezimo nokugoba :

Ama-PCB aguqukayo aziwa ngokuguquguquka kwawo kanye nekhono lokugoba. Ngakho-ke, izinto zefilimu ezincane ezisetshenziselwa ukwakha izifunda ezinjalo kufanele zibe nokuguquguquka okuhle kakhulu nokugoba. Enye yezinto ezisetshenziswa kakhulu ifilimu ye-polyimide (PI). I-Polyimide inezakhiwo ezinhle kakhulu zomshini njengamandla aqine kakhulu, ukuzinza okuhle kokushisa nokumelana namakhemikhali okuhle kakhulu, okuyenza ilungele izinhlelo zokusebenza ze-PCB eziguquguqukayo. Ngaphezu kwalokho, amafilimu e-liquid crystal polymer (LCP) nawo adumile ngokuguquguquka kwawo okuhle kakhulu kanye nokuzinza okuhle kakhulu kohlangothi.

2. I-Dielectric constant kanye nesici sokulahlekelwa :

I-dielectric engaguquki kanye ne-dispation factor yefilimu idlala indima ebalulekile ekunqumeni ukusebenza kwama-PCB aguquguqukayo. Lezi zakhiwo zinikeza ukuqonda ngekhono lempahla lokudlulisa amasignali kagesi ngaphandle kokulahlekelwa okukhulu. Amanani aphansi we-dielectric engaguquki kanye ne-dissipation factor alungele izinhlelo zokusebenza ze-high-frequency ngoba anciphisa ukulahleka kwesignali futhi aqinisekise ukusebenza okuthembekile. Ezinye izinto ezivame ukusetshenziswa eziphansi zefilimu ye-dielectric engaguquki yi-polyimide ne-LCP.

3. Ukuzinza kokushisa nokumelana nokushisa :

Ama-PCB aguqukayo avamise ukuchayeka ezimweni zokushisa ezishintshayo, ikakhulukazi ezinhlelweni zokusebenza zezimoto kanye ne-aerospace. Ngakho-ke, ukukhetha izinto zefilimu ezinokuzinza okuhle kakhulu kokushisa nokumelana kubalulekile ukuze kuqinisekiswe ukusebenza kahle nokuthembeka. Amafilimu e-polyimide asezingeni eliphezulu, njenge-Kapton®, asetshenziswa kakhulu ekwenzeni i-PCB eguquguqukayo ngenxa yekhono lawo lokumelana nezinga lokushisa elidlulele kuyilapho egcina ubuqotho besakhiwo. Amafilimu e-LCP, ngakolunye uhlangothi, anokuqina okufanayo okushisayo futhi angabhekwa njengezinye izindlela.

4. Ukuhambisana kwamakhemikhali:

Izinto zefilimu ezacile ezisetshenziswa kuma-PCB aguquguqukayo kufanele zihambisane ngokwekhemikhali nendawo ethile lapho zisetshenziswa khona. Ngesikhathi sokuhlanganiswa nokuphathwa kwe-PCB, ukuchayeka ezintweni ezifana nezincibilikisi, izihlanzi, kanye nokuguquguqukayo kufanele kucatshangelwe. I-Polyimide inokumelana namakhemikhali okuhle kakhulu futhi iyinketho yokuqala yezinhlelo eziningi ze-PCB eziguquguqukayo.

5. Ukuhambisana kwe-Adhesive:

Izinto zefilimu ezacile zivame ukulanywa ngezingqimba zokunamathela ukuze zakhe isakhiwo esiqinile kuma-PCB aguquguqukayo. Ngakho-ke, kubalulekile ukukhetha impahla yefilimu ehambisana nesistimu yokunamathela ekhethiwe. Okubalulekile kufanele kuhlangane kahle ne-adhesive ukuqinisekisa isibopho esiqinile futhi kugcinwe ubuqotho be-PCB eguquguqukayo. Ngaphambi kokuphothula izinto zefilimu, kunconywa ukuthi izinhlelo zokunamathela ezithile zihlolwe ukuhambisana ukuze kuqinisekiswe ukubopha okuthembekile.

6. Ukutholakala Nezindleko:

Okokugcina, ukutholakala kwezinto zefilimu kanye nezindleko kufanele kubhekwe enqubweni yokukhetha. Nakuba i-polyimide itholakala kabanzi futhi ingabizi, ezinye izinto ezifana ne-LCP zingabiza kakhulu. Ukuhlola izidingo zephrojekthi, izingqinamba zesabelomali, nokutholakala kwemakethe kuzosiza ukunquma into engcono kakhulu yefilimu yomklamo wakho we-PCB oguquguqukayo.

Kafushane, ukukhetha ifilimu efanele ye-PCB yakho evumelana nezimo kubalulekile ekuqinisekiseni ukusebenza kahle, ukwethembeka kanye nokuqina kwesikhathi eside.Izinto ezifana nokuguquguquka nokugoba, i-dielectric constant kanye nokulahlekelwa factor, ukuzinza nokumelana nokushisa, ukuhambisana kwamakhemikhali, ukuhambisana kwe-adhesive, nokutholakala kanye nezindleko kufanele zihlolwe ngokucophelela ngesikhathi sokukhetha. Ngokucabangela lezi zici nokwenza ucwaningo olujulile, ungenza isinqumo esinolwazi esizoholela ku-PCB eklanywe kahle, eguquguqukayo yekhwalithi ephezulu yohlelo lwakho lokusebenza oluthile.

Isikhathi sokuthumela: Sep-21-2023

Emuva