Isingeniso

Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngamasu asebenzayo kanye nezinqubo ezingcono kakhulu zomboni zokuvimbela ukuhlukaniswa kwe-PCB okuguquguqukayo, ngaleyo ndlela kuvikelwe izinto zakho zikagesi ekuhlulekeni okungaba khona.

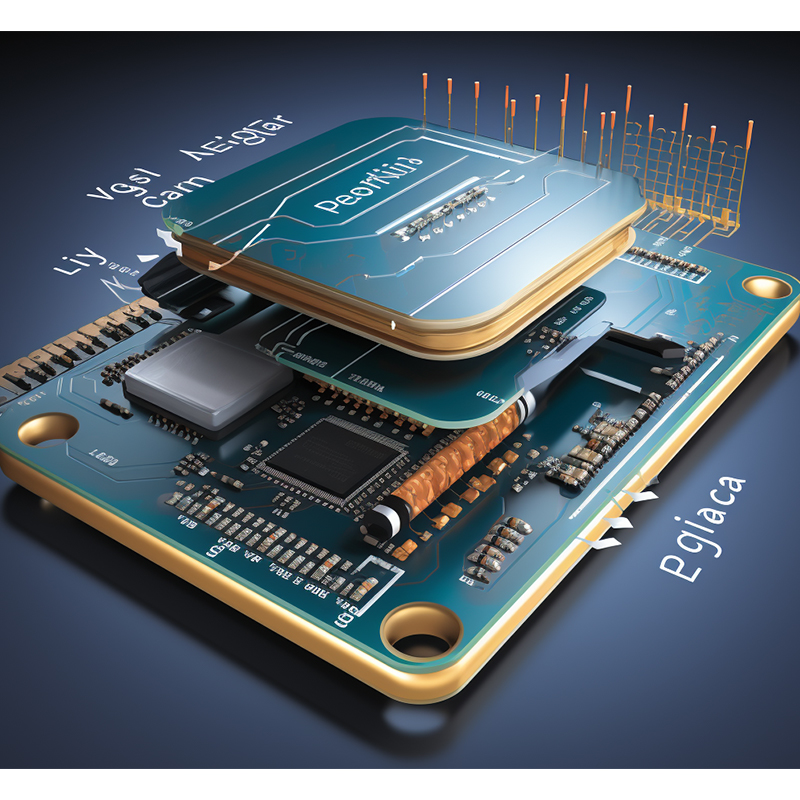

I-Delamination yinkinga ebucayi evame ukuhlupha amabhodi esekethe aphrintiwe aqinile (ama-PCB) phakathi nempilo yawo yesevisi. Lesi simo sisho ukuhlukaniswa kwezingqimba ku-PCB, okuholela ekuxhumekeni okubuthakathaka kanye nokwehluleka kwengxenye okungenzeka. Njengomkhiqizi noma umklami, kubalulekile ukuqonda izimbangela ze-delamination futhi uthathe izinyathelo zokuvimbela ukuze uqinisekise ukuzinza nokuthembeka kwesikhathi eside kwe-PCB yakho.

I. Qonda i-delamination ku-PCB eguquguqukayo eqinile

I-Delamination ibangelwa izici ezihlukahlukene ngesikhathi sokukhiqiza, ukuhlanganisa, kanye nezigaba zokuphatha ama-PCB aqinile-flex. Ukucindezeleka okushisayo, ukumuncwa komswakama kanye nokukhethwa kwezinto ezingafanele kuyimbangela evamile ye-delamination. Ukuhlonza nokuqonda lezi zimbangela kubalulekile ekwakheni amasu okuvimbela aphumelelayo.

1. Ukucindezeleka okushisayo: I-Coefficient of thermal expansion (CTE) ukungafani phakathi kwezinto ezihlukene kungaholela ekucindezelekeni ngokweqile ngesikhathi sokuhamba ngebhayisikili eshisayo, okuholela e-delamination.Uma i-PCB ihlangabezana nokushintsha kwezinga lokushisa, izendlalelo ziyakhula futhi zinciphe ngamanani ahlukene, okudala ukungezwani kumabhondi phakathi kwazo.

2. Ukumuncwa komswakama: I-PCB eguquguqukayo eqinile ivamise ukuchayeka ezindaweni ezinomswakama ophezulu futhi imunca kalula umswakama.Ama-molecule wamanzi angangena ngaphezu kwebhodi ngokusebenzisa ama-microcracks, ama-voids, noma izimbobo ezingavaliwe kahle, okubangela ukwanda kwendawo, ukuvuvukala, futhi ekugcineni kube nokuncipha.

3. Ukukhethwa Kwempahla: Ukucatshangelwa ngokucophelela kwezakhiwo ezibalulekile kubalulekile ekuvimbeleni ukubola.Kubalulekile ukukhetha i-laminate efanele, i-adhesive kanye nokwelashwa kwendawo ukuze kunikeze ukumuncwa okuphansi komswakama kanye nokuzinza okuhle kokushisa.

2. Amasu okuvimbela i-delamination

Manje njengoba sesiyaqonda ukuthi kungani, ake sihlole amasu abalulekile okuvimbela ukuhlukaniswa kwe-PCB okuqinile:

1. Ukucatshangelwa kwedizayini efanele:

a) Nciphisa ukujiya kwethusi:Ukuqina kwethusi okweqile kudala ingcindezi enkulu ngesikhathi sokuhamba ngebhayisikili okushisayo. Ngakho-ke, ukusebenzisa ubuncane bethusi obudingekayo kukhulisa ukuguquguquka kwe-PCB futhi kunciphisa ubungozi bokuthi i-delamination.

b) Isakhiwo sesendlalelo esilinganiselwe:Lwela ukusatshalaliswa okufanayo kwezingqimba zethusi ngaphakathi kwezingxenye eziqinile neziguquguqukayo ze-PCB. Ibhalansi efanele isiza ukugcina ukunwetshwa kokushisa okulinganayo kanye nokufinyela, kunciphisa amandla e-delamination.

c) Ukubekezelelana okulawulwayo:Sebenzisa ukubekezelela okulawulwayo kusayizi wembobo, ngobubanzi nobubanzi bokulandelela ukuze uqinisekise ukuthi izingcindezi phakathi nezinguquko ezishisayo zisatshalaliswa ngokulinganayo kuyo yonke i-PCB.

d) Izibopho kanye nezibopho:Amafayili anciphisa amaphuzu okugxilisa ingcindezi, asize ukufeza izinguquko ezishelelayo zokugoba futhi anciphise amandla e-delamination.

2. Ukukhetha okubalulekile:

a) High Tg Laminates:Khetha ama-laminates anamazinga okushisa engilazi aphezulu (Tg) njengoba enikeza ukumelana okungcono kwezinga lokushisa, ehlisa ukungafani kwe-CTE phakathi kwezinto, futhi anciphise izinqubo zokuhamba ngamabhayisikili ashisayo izingozi ezihlukanisiwe.

b) Izinto eziphansi ze-CTE:Khetha izinto ezisetshenziswayo ezinamavelu e-CTE aphansi ukuze unciphise ukungezwani kokwanda okushisayo phakathi kwezendlalelo ezihlukene, ngaleyo ndlela wehlise ingcindezi futhi uthuthukise ukwethembeka okuphelele kwama-PCB aguquguqukayo.

c) Izinto ezivikela umswakama:Khetha izinto ezinokumunca umswakama ophansi ukuze unciphise ubungozi bokubola ngenxa yokumuncwa komswakama. Cabangela ukusebenzisa ama-coatings akhethekile noma ama-sealant ukuze uvikele izindawo ezisengozini ze-PCB ekungeneni komswakama.

3. Imikhuba Eqinile Yokukhiqiza:

a) Ukuphazamiseka okulawulwayo:Sebenzisa inqubo elawulwayo yokukhiqiza i-impedance ukuze unciphise izinguquko zengcindezi ku-PCB ngesikhathi sokusebenza, ngaleyo ndlela wehlise ingcuphe yokuncipha.

b) Ukugcinwa Okufanelekile Nokuphatha:Gcina futhi uphathe ama-PCB endaweni elawulwayo enomswakama olawulwayo ukuze uvimbele ukumuncwa komswakamo kanye nezinkinga ezihlobene nokububula.

c) Ukuhlola Nokuhlola:Izinqubo zokuhlola nokuhlola eziqinile ziyenziwa ukuze kutholwe noma yiziphi izici ezingase zibe khona zokukhiqiza ezingase zidale i-delamination. Ukusebenzisa amasu okuhlola angonakali njengokuhamba ngebhayisikili elishisayo, i-microsectioning, kanye nokuskena i-acoustic microscopy kungasiza ekutholeni ama-delaminations afihliwe kusenesikhathi.

Isiphetho

Ukuvimbela i-delamination yama-PCB aqinile-flex kubalulekile ekuqinisekiseni ukuphila kwawo isikhathi eside nokusebenza okuthembekile. Unganciphisa ingcuphe ye-delamination ngokuqonda izimbangela kanye nokuthatha izinyathelo zokuphepha ezifanele ngesikhathi sokuklama, ukukhetha izinto ezibonakalayo, nokukhiqiza.Ukusebenzisa ukuphathwa kokushisa okufanele, ukusebenzisa izinto ezinezakhiwo ezifanele, ukusebenzisa izinqubo zokukhiqiza eziqinile, kanye nokwenza ukuhlola okuphelele kungathuthukisa kakhulu ikhwalithi nokuthembeka kwama-PCB aqinile. Ngokulandela lawa maqhinga nokuhlala unolwazi lwakamuva ngenqubekelaphambili yakamuva yezinto zokwakha kanye nobuchwepheshe bokukhiqiza, ungaqinisekisa ukuthuthukiswa okuyimpumelelo kwama-PCB ahlala isikhathi eside futhi athembekile anikela ekuzinzeni nasekuthembekeni kwezinto zakho zikagesi.

Isikhathi sokuthumela: Sep-20-2023

Emuva