Ukwenziwa kwe-PCBA kuyinqubo ebalulekile neyinkimbinkimbi ehlanganisa ukuhlanganisa izingxenye ezihlukahlukene ebhodini lesekethe eliphrintiwe (PCB). Kodwa-ke, phakathi nale nqubo yokukhiqiza kungase kube nezinkinga ngezingxenye ezithile noma amajoyinti e-solder anamathelayo, okungaholela ezinkingeni ezingase zibe khona njengokungafakwa kahle kwe-solder, izingxenye ezilimele noma izinkinga zokuxhunywa kukagesi. Ukuqonda izizathu zalesi simo nokuthola izixazululo ezisebenzayo kubalulekile ekuqinisekiseni ikhwalithi nokuthembeka komkhiqizo wokugcina.Kulesi sihloko, sizohlola izizathu zokuthi kungani lezi zingxenye noma amalunga e-solder anamathela ngesikhathi sokukhiqiza i-PCBA futhi sinikeze izixazululo ezisebenzayo nezisebenzayo zokuxazulula le nkinga. Ngokusebenzisa izixazululo ezinconyiwe, abakhiqizi bangayinqoba le nkinga futhi bazuze ukuhlanganiswa kwe-PCB okuphumelelayo ngokuthengiswa okuthuthukisiwe, izingxenye ezivikelwe, nokuxhumeka kukagesi okuzinzile.

1: Ukuqonda into eyenzeka ku-PCB Assembly Manufacturing:

Incazelo ye-PCBA Manufacturing:

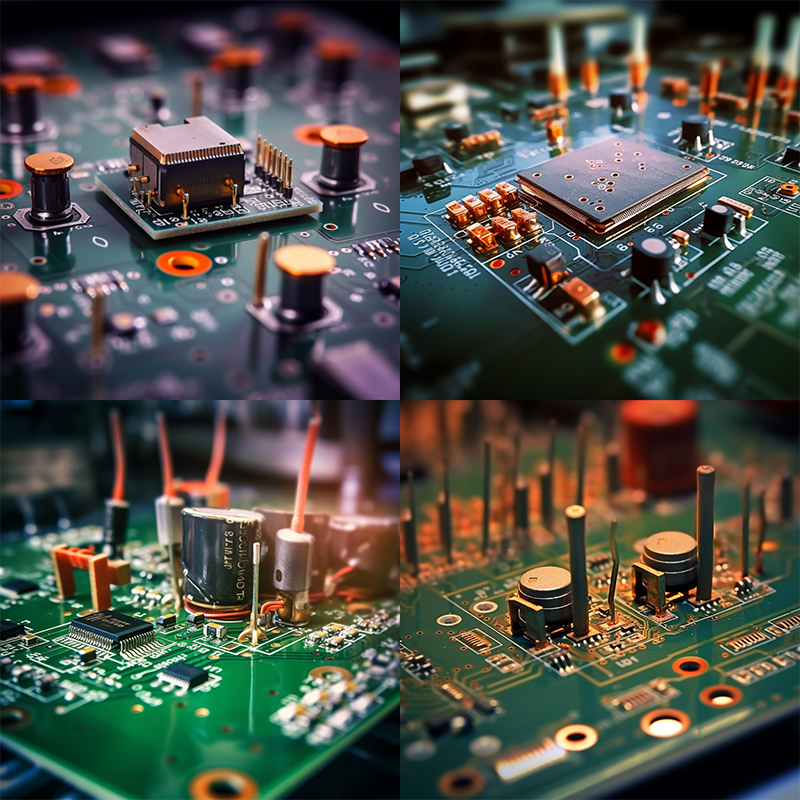

Ukukhiqizwa kwe-PCBA kubhekisela ohlelweni lokuhlanganisa izingxenye ze-elekthronikhi ebhodini lesekethe eliphrintiwe (PCB) ukuze kwakhiwe izinto zikagesi ezisebenzayo. Le nqubo ihilela ukubeka izingxenye ku-PCB futhi uzihlanganise endaweni.

Ukubaluleka Komhlangano Wengxenye Efanele:

Ukuhlanganiswa okufanele kwezingxenye kubalulekile ekusebenzeni okuthembekile kwemishini kagesi. Iqinisekisa ukuthi izingxenye zinamathiselwe ngokuvikelekile ku-PCB futhi zixhunywe ngendlela efanele, okuvumela amasignali avumelekile kagesi futhi kuvimbele noma yikuphi ukuxhuma okuxekethile.

Incazelo eqondile yengxenye ne-solder ngokuhlanganyela :

Uma ingxenye noma ijoyinti ye-solder ibizwa ngokuthi "iqondile" ekwenziweni kwe-PCBA, kusho ukuthi ayiphansi noma ayihambelani kahle nendawo ye-PCB. Ngamanye amazwi, ingxenye noma i-solder joint ayihambisani ne-PCB.

Izinkinga ezingaba khona ezibangelwa izingxenye eziqondile namajoyinti e-solder:

Izingxenye eziqondile namajoyinti e-solder angabangela izinkinga eziningi phakathi nokukhiqizwa kwe-PCBA nokusebenza komshini wokugcina we-elekthronikhi. Ezinye izinkinga ezingase zidalwe yilesi simo zihlanganisa:

I-soldering engalungile:

Amajoyinti e-solder aqondile angase angaxhumani kahle namaphedi e-PCB, okuholela ekugelezeni kwe-solder okunganele kanye noxhumo lukagesi olubuthakathaka. Lokhu kunciphisa ukuthembeka okuphelele nokusebenza kwedivayisi.

Ingcindezi yemishini:

Izingxenye eziqondile zingase zibe ngaphansi kokucindezeleka okukhulu komshini ngenxa yokuthi azixhumekile ngokuqinile endaweni ye-PCB. Lokhu kucindezeleka kungabangela izingxenye ukuthi ziphuke noma zihlukane ne-PCB, kubangele idivayisi ukuthi ingasebenzi kahle.

Ukuxhumeka kukagesi okungalungile:

Uma ingxenye noma ijoyinti le-solder lime liqondile, kunengozi yokuthinta kabi ugesi. Lokhu kungase kuhilele ekuxhumekeni kwezikhawu, ukulahlekelwa isignali, noma ukuncipha kwendlela yokusebenza, kuthinte ukusebenza okufanele kwensiza kagesi.

Ukushisa ngokweqile:

Izingxenye eziqondile zingase zingakushisi kahle ukushisa. Lokhu kungase kuthinte ukuphathwa kwe-thermal yedivayisi, kubangele ukushisa ngokweqile kanye nezingxenye ezingase zilimaze noma kufinyeze impilo yazo yesevisi.

Izinkinga zobuqotho besignali:

Izingxenye ezimile noma amajoyinti e-solder angabangela ukufaniswa kwe-impedance okungalungile phakathi kwamasekhethi, ukubonakaliswa kwesignali, noma i-crosstalk. Lezi zinkinga zingehlisa isithunzi sesiginali jikelele kanye nokusebenza kwensiza kagesi.

Phakathi nenqubo yokukhiqiza ye-PCBA, ukuxazululwa okufika ngesikhathi kwezingxenye eziqondile kanye nezindaba ezihlanganyelwe ze-solder kubalulekile ukuze kuqinisekiswe ikhwalithi, ukwethembeka, nokuphila isikhathi eside komkhiqizo wokugcina.

2.Izizathu zokuthi kungani izingxenye noma amajoyinti e-solder ame aqondile ku-PCBA Manufacturing Process:

Ukusabalalisa izinga lokushisa okungalingani: Ukushisisa okungalingani, ukupholisa, noma ukusatshalaliswa kwezinga lokushisa ku-PCB kungabangela izingxenye noma amajoyinti e-solder ukuthi asukume.Ngesikhathi senqubo yokudambisa, uma izindawo ezithile ku-PCB zithola ukushisa okungaphezulu noma okuncane kunezinye, lokhu kungabangela ukucindezeleka okushisayo ezingxenyeni namalunga e-solder. Lokhu kucindezeleka okushisayo kungabangela ukuthi amalunga e-solder aguqe noma agobe, okubangela ukuthi ingxenye ime iqonde.Enye yezimbangela ezivamile zokusatshalaliswa kwezinga lokushisa okungalingani ukudluliswa kokushisa okungekuhle ngesikhathi sokushisela. Uma ukushisa kungasatshalaliswa ngokulinganayo ku-PCB, ezinye izindawo zingase zibe nezinga lokushisa eliphakeme kuyilapho ezinye izindawo zihlala zipholile. Lokhu kungabangelwa ukubekwa okungalungile noma ukusatshalaliswa kwezinto zokushisa, imidiya yokudlulisa ukushisa enganele, noma ubuchwepheshe bokushisa obungasebenzi kahle.

Esinye isici esibangela ukusatshalaliswa kwezinga lokushisa okungalingani ukupholisa okungafanele. Uma i-PCB iphola ngokulinganayo ngemva kwenqubo yokuhlanganisa, ezinye izindawo zingaphola ngokushesha kunezinye. Lokhu kupholisa ngokushesha kungabangela ukuncipha kokushisa, kubangele izingxenye noma amalunga e-solder ukuthi ame aqonde.

Imingcele yenqubo yokushisela ayilungile: Izilungiselelo ezingalungile njengezinga lokushisa, isikhathi noma ingcindezi phakathi ne-soldering nazo zingabangela izingxenye noma ama-solder joints ukuthi ame aqonde.I-soldering ihlanganisa ukushisa ukuze kuncibilike i-solder futhi kwakhiwe isibopho esiqinile phakathi kwengxenye ne-PCB. Uma izinga lokushisa lisethelwe phezulu kakhulu ngesikhathi se-solder, kungase kubangele ukuthi i-solder incibilike ngokweqile. Lokhu kungabangela ukugeleza okuhlangene kwe-solder ngokweqile futhi kubangele izingxenye ukuthi zime ziqonde. Ngokufanayo, izinga lokushisa elinganele lingabangela ukuncibilika okwanele kwe-solder, okuholela ekuhlanganyeleni okubuthakathaka noma okungaphelele. Izilungiselelo zesikhathi nengcindezi phakathi nenqubo yokushisela nazo zidlala indima ebalulekile. Isikhathi esinganele noma ukucindezela kungase kubangele amalunga angaphelele noma abuthaka, angabangela ukuba ingxenye ime. Ukwengeza, ukucindezela okukhulu ngesikhathi sokufakwa kwe-solder kungabangela ukugeleza kwe-solder ngokweqile, okubangela ukuthi izingxenye zitsheke noma ziphakamise.

Ukubekwa kwengxenye engafanele: Ukubekwa kwengxenye engafanele kuyimbangela evamile yezingxenye noma amajoyinti e-solder emi aqondile.Ngesikhathi sokuhlanganiswa, uma izingxenye zingaqondani kahle noma zitshekile, lokhu kungabangela ukwakheka okuhlangene kwe-solder okungalingani. Lapho i-solder ihlanganisa izingxenye ezinjalo, i-solder ingase ingagelezi ngokulinganayo, okwenza ukuba ingxenye iphakame. Ukungahleleki kahle kwengxenye kungase kwenzeke ngenxa yephutha lomuntu noma ukungasebenzi kahle komshini wokubeka ozenzakalelayo. Ukubekwa kwengxenye okunembe nokunembe kufanele kuqinisekiswe ukuze kugwenywe izinkinga ezinjalo. Abakhiqizi kufanele balandele ngokucophelela imihlahlandlela yokubeka ingxenye enikezwe idizayini ye-PCB noma imininingwane yomhlangano. Izinto zokuthungatha ezingalungile noma amasu: Izinga lezinto ezisetshenziswayo nezindlela ezisetshenzisiwe zingathinta kakhulu ukwakheka kwamalunga e-solder futhi ngaleyo ndlela ukuzinza kwengxenye. Izinto zokunamathisela ezisezingeni eliphansi zingaqukatha ukungcola, zibe namaphoyinti ancibilikayo angahambisani, noma ziqukathe ukuguquguquka okunganele. Ukusetshenziswa kwezinto ezinjalo kungase kubangele amajoyinti e-solder abuthakathaka noma angalungile angabangela umhlangano ukuthi ume.

Izindlela zokuhlanganisa ezingalungile ezifana nokunamathisela kwe-solder okuningi kakhulu noma okunganele, ukugeleza kabusha okungalingani noma okungahambisani, noma ukusatshalaliswa kwezinga lokushisa okungalungile nakho kungabangela le nkinga. Kubalulekile ukulandela amasu okuthengisa afanele kanye neziqondiso ezinconywe abakhiqizi bezingxenye noma izindinganiso zemboni ukuze kuqinisekiswe ukwakheka okuhlangene kwe-solder okuthembekile.

Ukwengeza, ukuhlanzwa kwe-PCB okwanele ngemva kokudayiswa kungaholela ekwakhiweni kwezinsalela kumajoyinti e-solder. Lezi zinsalela zingabangela izinkinga zokungezwani kwendawo ngesikhathi sokugeleza kabusha, kubangele izingxenye ukuthi zime ziqonde.

3. Izixazululo zokuxazulula izinkinga:

Lungisa izinga lokushisa lokucubungula: Ukwandisa izinga lokushisa ngesikhathi sokushisela, cabanga ngamasu alandelayo:

Lungisa okokusebenza kokushisisa: Qiniseka ukuthi okokusebenza kokushisisa (njengomoya oshisayo noma i-ovini yokugeleza kabusha kwe-infrared) ilinganiswe kahle futhi inikeza ukushisa okulinganayo ku-PCB.Hlola izindawo ezishisayo noma ezibandayo futhi wenze noma yiziphi izinguquko ezidingekayo noma ukulungisa ukuze uqinisekise ukusatshalaliswa kwezinga lokushisa okungaguquki.

Sebenzisa isinyathelo sokushisa kuqala: Ukushisa kuqala i-PCB ngaphambi kwe-solder kusiza ukunciphisa ukucindezeleka okushisayo futhi kukhuthaze ukusatshalaliswa kwezinga lokushisa okulinganayo.Ukushisa kuqala kungafezwa ngokusebenzisa isiteshi sokushisa esizinikezele noma ngokukhuphula kancane kancane izinga lokushisa esithandweni sokushisa ukuze kuzuzwe ngisho nokudlulisa ukushisa.

Lungiselela amapharamitha wenqubo yokushisela: Ukulungisa kahle imingcele yenqubo yokushisela kubalulekile ukuze kuzuzwe ukuxhumana okuthembekile nokuvimbela izingxenye ukuthi zime ziqonde. Naka izici ezilandelayo:

Izinga lokushisa: Setha izinga lokushisa lokushisela ngokwezidingo ezithile zezingxenye nezinto zokushisela.Landela imihlahlandlela noma amazinga embonini anikezwe umkhiqizi wengxenye. Gwema amazinga okushisa aphezulu kakhulu, angabangela ukugeleza kwe-solder ngokweqile, namazinga okushisa anganele, angabangela amalunga ama-solder brittle.

Isikhathi: Qinisekisa ukuthi inqubo ye-solder inikeza isikhathi esanele sokuthi i-solder incibilike futhi yakhe isibopho esiqinile.Isikhathi esifushane kakhulu singabangela amalunga abuthakathaka noma angaphelele, kuyilapho isikhathi eside sokushisa singabangela ukugeleza kwe-solder ngokweqile.

Ukucindezela: Lungisa ingcindezi esetshenziswayo lapho i-soldering ukugwema ukudayiswa ngokweqile noma ngaphansi.Landela imihlahlandlela yengcindezi enconyiwe ehlinzekwa ngumkhiqizi wengxenye noma umphakeli wempahla yokushisela.

Qinisekisa ukubekwa kwengxenye okulungile: Ukubekwa kwengxenye okunembile nokuqondile kubalulekile ukuze kugwenywe izinkinga ezimile. Cabangela lezi zinyathelo ezilandelayo:

Sebenzisa okokusebenza kokubeka kwekhwalithi: Tshala imali kumpahla yokubeka yengxenye ezenzakalelayo yekhwalithi ephezulu engabeka izingxenye ngokunembile.Linganisa futhi unakekele okokusebenza njalo ukuze uqinisekise ukubekwa okunembile.

Qinisekisa umumo wengxenye: Hlola kabili umumo wengxenye ngaphambi kokubeka.Ukuma okungalungile kwezingxenye kungabangela ukungahambi kahle ngesikhathi sokushisela futhi kubangele izinkinga zokuma.

Ukuqondanisa Nokuqina: Qiniseka ukuthi izingxenye ziyisikwele futhi zibekwe ngokuvikelekile kumaphedi e-PCB ngaphambi kokusoda.Sebenzisa amadivaysi okuqondanisa noma ama-clamps ukuze ubambe izingxenye endaweni ngesikhathi senqubo yokushisela ukuvimbela noma yikuphi ukutsheka noma ukunyakaza.

Khetha izinto ezisezingeni eliphakeme zokushisela: Ukukhethwa kwezinto zokushisela kuthinta kakhulu ikhwalithi yokuhlangana kwe-solder. Sicela ucabangele le mihlahlandlela elandelayo:

Ingxubevange ye-solder: Khetha ingxubevange ye-solder efanele inqubo ethile yokudambisa, izingxenye nezinto ze-PCB ezisetshenziswayo.Sebenzisa ama-alloys anamaphuzu ancibilikayo angaguquki kanye nezakhiwo ezinhle zokumanzisa ukushisela okuthembekile.

I-Flux: Sebenzisa i-flux yekhwalithi ephezulu efanele inqubo yokuhlanganisa nezinto ezisetshenziswayo ze-PCB.I-flux kufanele ikhuthaze ukumanzisa okuhle futhi inikeze ukuhlanzwa okwanele kwendawo ye-solder.

I-Solder Namathisela: Qinisekisa ukuthi unamathisele we-solder osetshenzisiwe unokubunjwa okulungile nokusabalalisa usayizi wezinhlayiyana ukuze kuzuzwe izici ezifanele zokuncibilika nokugeleza.Ukwakheka okuhlukile kokunamathisela kwe-solder kuyatholakala kumasu ahlukahlukene wokunamathisela, njengokugeleza kabusha noma ukufaka i-wave soldering.

Gcina i-PCB yakho ihlanzekile: Indawo ehlanzekile ye-PCB ibalulekile ekuhlanganisweni kwekhwalithi ephezulu. Sicela ulandele lezi zinyathelo ukuze ugcine i-PCB yakho ihlanzekile:

Ukususwa Kwezinsalela ze-Flux: Susa ngokuphelele izinsalela ze-flux ku-PCB ngemva kokudayiswa.Sebenzisa isihlanzi esifanele, esifana ne-isopropyl alcohol (IPA) noma isikhiphi se-flux esikhethekile, ukuze ususe noma iyiphi insalela egelezayo engase iphazamise ukwakheka kwamalunga e-solder noma kubangele izinkinga zokungezwani kwendawo.

Ukususa Ukungcola: Susa konke ukungcola okunjengokungcola, uthuli noma uwoyela endaweni ye-PCB ngaphambi kokusoda.Sebenzisa iragi elingena-lint noma ibhulashi ukuze uhlanze ngobumnene indawo ye-PCB ukuze ugweme ukulimaza izingxenye ezibucayi.

Isitoreji Nokuphatha: Gcina futhi uphathe ama-PCB endaweni ehlanzekile, engenazo izintuli.Sebenzisa izembozo zokuzivikela noma izikhwama ukuvimbela ukungcola ngesikhathi sokugcina kanye nokuhamba. Hlola njalo futhi uqaphe ukuhlanzeka kwe-PCB bese usungula izilawuli zenqubo ezifanele ukuze ugcine amazinga okuhlanzeka angaguquki.

4.Ukubaluleka kosizo lochwepheshe ku-PCBA Manufacturing:

Lapho ubhekene nezinkinga eziyinkimbinkimbi ezihlobene nezingxenye zokuma noma izihlanganisi ze-solder phakathi nokuhlanganiswa kwe-PCB, kubalulekile ukufuna usizo lochwepheshe kumkhiqizi onolwazi. Umkhiqizi womhlangano we-PCB onguchwepheshe u-Capel unikeza izinzuzo ezihlukahlukene ezingasiza ekuxazululeni izinkinga nokuxazulula lezi zinkinga ngempumelelo.

isipiliyoni: Umkhiqizi womhlangano we-PCB ochwepheshe uCapel uneminyaka engu-15 yokuhlangenwe nakho ekuxazululeni izinselele ezihlukahlukene zomhlangano we-PCB.Bahlangabezane futhi baxazulula ngempumelelo izinkinga ezihlukahlukene, okuhlanganisa ukuhlanganisa okuqondile kanye nezindaba ezihlangene ze-solder. Ulwazi lwabo lubavumela ukuba babone ngokushesha izimbangela zalezi zinkinga futhi basebenzise izixazululo ezifanele. Ngolwazi oluzuzwe kumaphrojekthi amaningi, banganikeza imininingwane ebalulekile nezeluleko zokuqinisekisa impumelelo yomhlangano we-PCB.

Ubuchwepheshe: AbakwaCapel baqasha ochwepheshe be-PCB abanamakhono aphezulu nabaqeqeshwe kahle.Laba chwepheshe banolwazi olujulile lwamasu okunamathisela, ukubekwa kwezingxenye kanye nezinyathelo zokulawula ikhwalithi. Bayabuqonda ubunkimbinkimbi benqubo yokuhlanganisa futhi banolwazi oluningi ngamazinga emboni kanye nezindlela ezihamba phambili. Ubuchwepheshe bethu busivumela ukuthi sihlole ngokucophelela, sihlonze izingozi ezingaba khona, futhi senze izinguquko ezidingekayo ukuze sinqobe izinto eziqondile noma izinkinga ezihlanganyelwe. Ngokusebenzisa ubuchwepheshe bethu, umkhiqizi womhlangano we-PCB onguchwepheshe angaqinisekisa ikhwalithi ephezulu kakhulu yomhlangano futhi anciphise amathuba okuba nezinkinga zesikhathi esizayo.

Imishini ethuthukisiwe: Umkhiqizi womhlangano we-PCB ochwepheshe u-Capel utshala imali kumishini yesimanje nobuchwepheshe ukuze kuthuthukiswe izinqubo zokuhlanganisa nokuhlanganisa.Basebenzisa amahhavini agelezayo athuthukile, imishini yokubeka izingxenye ezizenzakalelayo namathuluzi okuhlola ukuze bathole imiphumela enembile nethembekile. Le mishini ilinganiswa ngokucophelela futhi inakekelwe ukuze kuqinisekiswe ukulawulwa okunembile kwezinga lokushisa, ukubekwa kwengxenye enembile, nokuhlolwa okuphelele kwamalunga e-solder. Ngokusebenzisa imishini ethuthukisiwe, i-Capel ingakwazi ukuqeda izimbangela eziningi ezivamile zokuhlangana kwe-stand-up noma izinkinga ezihlangene ze-solder, njengokushintsha kwezinga lokushisa, ukungahambi kahle, noma ukugeleza kwe-solder okungalungile.

I-QC: Umkhiqizi womhlangano we-PCB ochwepheshe u-Capel unezinyathelo eziphelele zokulawula ikhwalithi zokuqinisekisa izinga eliphezulu lekhwalithi yomkhiqizo nokuthembeka.Balandela izinqubo eziqinile zokulawula ikhwalithi kuyo yonke inqubo yokuhlanganisa, kusukela ekuthengeni ingxenye kuya ekuhlolweni kokugcina. Lokhu kuhlanganisa ukuhlolwa okuphelele kwezingxenye, amalunga e-solder kanye nokuhlanzeka kwe-PCB. Sinezinqubo eziqinile zokuhlola ezifana nokuhlola i-X-ray kanye nokuhlola okuzenzakalelayo kokubona ukuze sithole noma yikuphi ukukhubazeka okungaba khona noma okudidayo. Ngokunamathela ezinyathelweni eziqinile zokulawula ikhwalithi, abakhiqizi abangochwepheshe banganciphisa ukuvela kwengxenye eqondile noma izinkinga ezihlangene ze-solder futhi banikeze imihlangano ye-PCB ethembekile.

Ukusebenza kahle kwezindleko nesikhathi: Ukusebenza nomkhiqizi womhlangano we-PCB onguchwepheshe u-Capel ungonga isikhathi nezindleko.Ubuchwepheshe babo kanye nemishini ethuthukisiwe ingakwazi ukukhomba ngokushesha futhi ixazulule ingxenye yokuma noma izinkinga ezihlanganyelwe ze-solder, kunciphise ukubambezeleka okungaba khona kumashejuli okukhiqiza. Ukwengeza, ingozi yokwakhiwa kabusha okumba eqolo noma ukuchithwa kwezingxenye ezingasebenzi kahle ingancishiswa kakhulu lapho usebenza nochwepheshe abanolwazi oludingekayo nolwazi. Lokhu kungonga izindleko ngokuhamba kwesikhathi.

Ngokufigqiwe,ukuba khona kwezingxenye eziphakeme noma amalunga e-solder ngesikhathi sokukhiqiza kwe-PCBA kungabangela izinkinga ezinkulu. Ngokuqonda izizathu zalesi simo nokusebenzisa izixazululo ezifanele, abakhiqizi bangathuthukisa ikhwalithi ye-weld, bavimbele ukulimala kwengxenye, futhi baqinisekise ukuxhumana okuthembekile kukagesi. Ukusebenza nomkhiqizi womhlangano we-PCB ochwepheshe uCapel anganikeza nokusekelwa okudingekayo kanye nobuchwepheshe bokuxazulula le nkinga. Ngokulandela le mihlahlandlela, abakhiqizi bangathuthukisa izinqubo zabo zokukhiqiza ze-PCBA futhi banikeze amakhasimende ngemikhiqizo yekhwalithi ephezulu.

Isikhathi sokuthumela: Sep-11-2023

Emuva