Yethula:

I-PCB soldering ephumelelayo ibalulekile ekuhlanganiseni okuphumelelayo nokusebenza kwamasekhethi kagesi. I-soldering efanele iqinisekisa ukuxhumana okuthembekile kagesi, okuthinta ngokuqondile ukusebenza kwesifunda sonke.Lo mhlahlandlela ophelele uzohlola amasu ahlukahlukene, izinhlobo, kanye namasu ahilelekile ekuhlanganisweni kwe-PCB. Ngokuqonda lezi zici, ungenza izinqumo ezinolwazi lapho ukhetha izinqubo ezifanele zokushisela kanye nemishini.

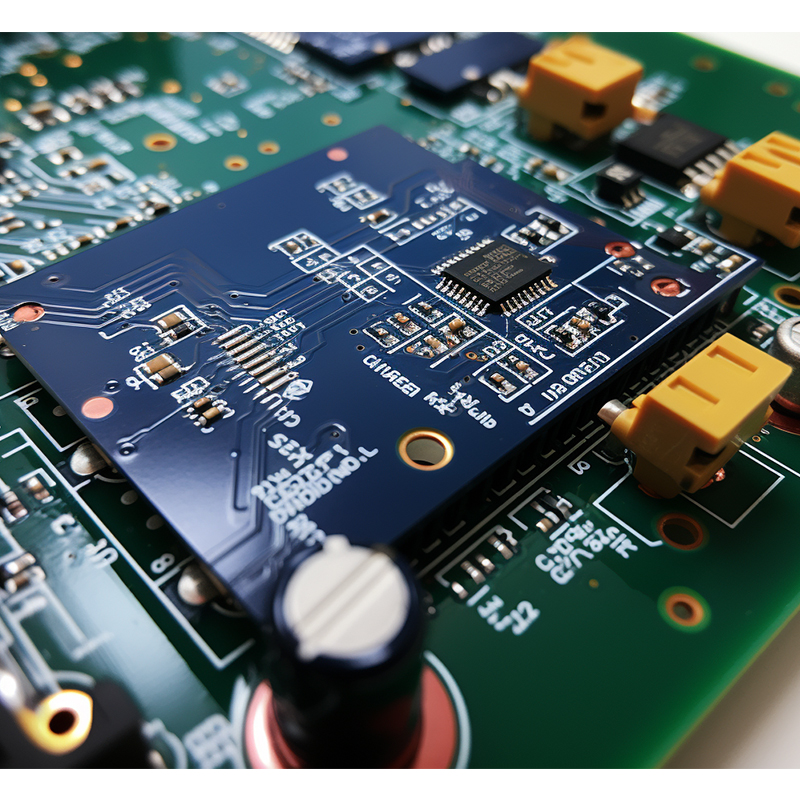

Ukubuka konke kwe-PCB soldering:

I-PCB welding, eyaziwa nangokuthi i-soldering, ihlanganisa ukwenza ukuxhumana okuthembekile kukagesi phakathi kwezingxenye ze-elekthronikhi namabhodi wesekethe. Idlala indima ebalulekile ekuqinisekiseni ukusebenza okuvamile kwawo wonke umjikelezo. Kusetshenziswa izindlela ezihlukene zokuhlanganisa i-PCB, ngayinye inezinzuzo zayo nokucatshangelwa.

Funda mayelanaPCB soldering ubuchwepheshe:

A. PCB inqubo yokushisela:

Ukuze kuzuzwe i-weld ephumelelayo, kubalulekile ukulandela inqubo enemininingwane. Lesi sigaba sizochaza inqubo yesinyathelo ngesinyathelo ye-PCB soldering. Izophinde ihlanganise ukulungiswa kwezingxenye ze-PCB zokuhlanganisa futhi ichaze amathuluzi adingekayo kanye nemishini.

B. Izindlela zokuhlanganisa ze-PCB ezijwayelekile:

Ukusebenzisa imbobo:

I- Through-hole soldering iyindlela esetshenziswa kabanzi ehlanganisa izingxenye zokunamathisela ngokusebenzisa izimbobo ezimbozwe ngaphambilini ebhodini lesifunda. Lesi sigaba sizohlinzeka ngencazelo yendlela ye- through-hole soldering, sixoxe ngezinzuzo nezinkinga zayo, futhi sigqamise izinqubo ezingcono kakhulu nezindlela zokusebenza.

I-Surface Mount soldering:

I-Surface mount soldering, eyaziwa nangokuthi i-surface mount technology (SMT) soldering, ijwayele ukusetshenziselwa ukwenza izinto ezincane ze-elekthronikhi. Lesi sigaba sizohlinzeka ngemininingwane yobuchwepheshe bokuthengisa be-SMT, izinzuzo zabo, imikhawulo, kanye nokucatshangelwa okubalulekile kokuqaliswa ngempumelelo.

I-pitch welding enhle:

Izingxenye ze-soldering fine-pitch zingaletha izinselele eziyingqayizivele ngenxa ye-pitch eseduze yezikhonkwane. Lesi sigaba sihlola ubunzima obuhlobene ne-soldering izingxenye ze-fine-pitch futhi sinikeza amathiphu kanye nezinyathelo zokuphepha ukuze kuzuzwe amajoyinti e-solder anembile. Ukwengeza, kuzoxoxwa ngemishini ethuthukisiwe namathuluzi asiza ekufinyeleleni ukushisela okunembe kahle kwephimbo.

Ukushisela ibhodi eliqinile-flex:

I-Rigid-flex welding ibhekisela kwinqubo yokuhlanganisa izingxenye ebhodini lesifunda eliguquguqukayo elihlanganiswe nengxenye eqinile. Lesi sigaba sizokwethula ubuchwepheshe obusemuva kwe-rigid-flex soldering, sixoxe ngezinselele ezihilelekile, futhi sinikeze izixazululo zokuqinisekisa amajoyinti e-solder ekhwalithi ephezulu kumihlangano ye-PCB eguquguqukayo eqinile.

I-HDI PCB soldering:

I-High-density interconnect (HDI) PCBs ifaka imiklamo eyinkimbinkimbi kanye nokuminyana okuphezulu kwezingxenye. I-Soldering HDI PCB idinga ulwazi olukhethekile. Lesi sigaba sihlola ubunkimbinkimbi bokuthengisa ama-PCB we-HDI, sigqamisa ubuchwepheshe obudingekayo, futhi sidingida izinzuzo nokucatshangwa kwe-HDI PCB soldering.

Amathiphu okuphumelela kwe-PCB soldering:

A. Ukulungiselela Nokuhlela:

Ukuthengiswa kwe-PCB okuphumelelayo kuqala ngokulungiselela nokuhlela okufanele. Lesi sigaba sidingida ukubaluleka kwesakhiwo se-PCB nokubekwa kwengxenye ukuze kube lula inqubo yokuhlanganisa. Izophinde igcizelele isidingo sokukhetha indlela efanele yokuhlanganisa esekelwe kumklamo we-PCB kanye nokubaluleka kokusetshenziswa okufanele kwe-solder paste.

B. Inqubo yokushisela nokukhethwa kwemishini:

Ukukhetha amathuluzi okushisela afanele kanye nemishini kubalulekile ekuzuzeni imiphumela ephumelelayo yokushisela. Lesi sigaba sizokuqondisa ekunqumeni amathuluzi nezinto zokusebenza ezifanele zomsebenzi othile. Izophinde idingide izici okufanele zicatshangelwe lapho kukhethwa izinto zokushisela futhi igcizelele ukubaluleka kokusebenzisa amaphrofayili okushisa okushisela afanelekile.

C. Ukulawula Ikhwalithi Nokuhlola:

Ukusebenzisa izinyathelo zokulawula izinga kanye nokuhlolwa kokuhlolwa ngesikhathi senqubo yokushisela kubalulekile ekuqinisekiseni amalunga athembekile e-solder. Lesi sigaba sidingida amasu okuhlola okubonwayo ahlangene, kanye nezindlela zokuhlola ezithuthukile namathuluzi angasetshenziswa ukuhlola ikhwalithi ye-weld.

Isiphetho:

Kafushane, lo mhlahlandlela obanzi uhlanganisa ukubaluleka kokusebenza kwe-PCB soldering kanye nomthelela i-solder efanele enawo ekusebenzeni kwesekhethi. Ngokukhetha inqubo efanele ye-solder kanye namasu, ungafinyelela amalunga aphezulu e-solder. Ukulungiselela kahle, ukukhethwa kwemishini ngokucophelela, kanye nokulawulwa kwekhwalithi okuphelele yizihluthulelo ze-PCB soldering ephumelelayo. Ukutshala imali emishinini yokusoda yekhwalithi ephezulu kanye nokulandela izinqubo ezihamba phambili kuzoveza imiphumela ephakeme ekuhlanganiseni kwe-PCB.

Isikhathi sokuthumela: Nov-07-2023

Emuva