I-PCB (Ibhodi Lesifunda Eliphrintiwe) liyingxenye ebalulekile emikhiqizweni yesimanje ye-elekthronikhi, eyenza uxhumo nemisebenzi yezingxenye ze-elekthronikhi ezihlukahlukene. Inqubo yokukhiqiza ye-PCB ibandakanya izinyathelo ezibalulekile ezimbalwa, esinye sazo esiwukufaka ithusi ku-substrate. Lesi sihloko sizobheka izindlela zokufaka ithusi kuma-PCB substrates ngesikhathi senqubo yokukhiqiza, futhi sihlole amasu ahlukene asetshenziswayo, njenge-electroless copper plating kanye ne-electroplating.

I-1.I-Electroless copper plating: incazelo, inqubo yamakhemikhali, izinzuzo, ukungalungi kanye nezindawo zokufaka isicelo.

Ukuze uqonde ukuthi yini i-electroless copper plating, kubalulekile ukuqonda ukuthi isebenza kanjani. Ngokungafani ne-electrodeposition, ethembele kugesi kagesi ekufakweni kwensimbi, i-electroless copper plating iyinqubo ye-autophoretic. Kubandakanya ukuncishiswa kwamakhemikhali okulawulwayo kwama-ion ethusi ku-substrate, okuholela kungqimba lwethusi olufana kakhulu noluhlelekile.

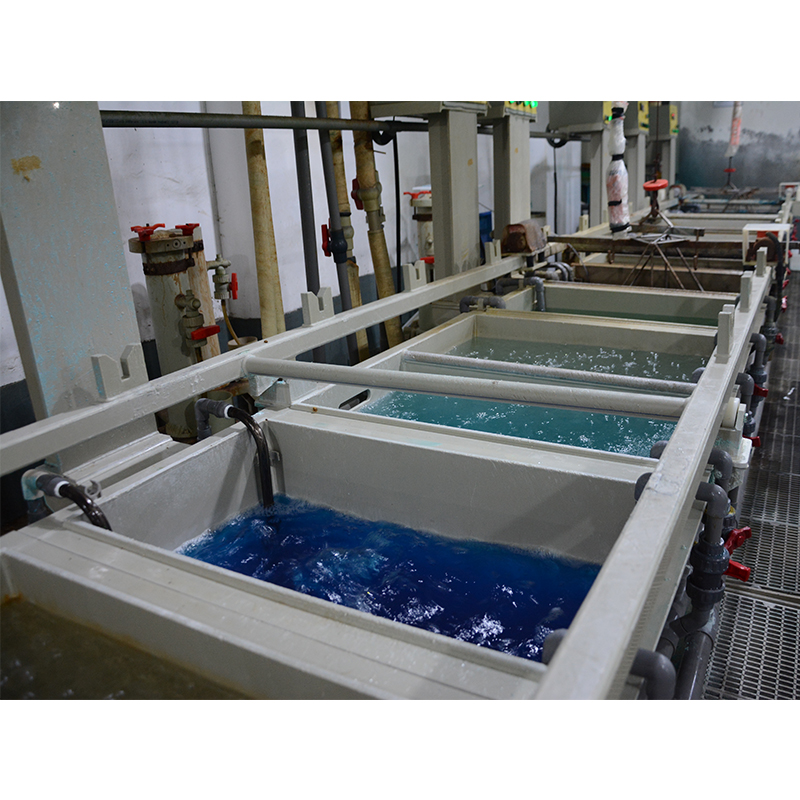

Hlanza i-substrate:Hlanza kahle i-substrate ukuze ususe noma yikuphi ukungcola noma ama-oxide angavimbela ukunamathela. Ukuqalisa: Isixazululo sokwenza kusebenze esiqukethe i-catalyst yensimbi eyigugu njenge-palladium noma iplatinamu isetshenziselwa ukuqalisa inqubo ye-electroplating. Lesi sixazululo sisiza ukufakwa kwethusi ku-substrate.

Gxila kusixazululo se-plating:Gxilisa i-substrate eyenziwe yasebenza kusixazululo se-electroless copper plating. Isixazululo se-plating siqukethe ama-ion ethusi, ama-ejenti anciphisa kanye nezithasiselo ezihlukahlukene ezilawula inqubo yokubeka.

Inqubo ye-Electroplating:I-ejenti yokunciphisa isisombululo se-electroplating inciphisa ama-ion ethusi abe ama-athomu ethusi ensimbi. Lawa ma-athomu abe eseboshelwa endaweni evuliwe, enze ungqimba lwethusi oluqhubekayo nolunye.

Hlanza futhi womise:Uma ugqinsi lwethusi olufunekayo selufinyelelwe, i-substrate iyasuswa ethangini lokucwenga bese ihlanzwa kahle ukuze kukhishwe noma imaphi amakhemikhali ayizinsalela. Yomisa i-substrate epuletiwe ngaphambi kokucubungula okwengeziwe. Inqubo yekhemikhali yokucwenga ithusi Inqubo yamakhemikhali ye-electroless copper plating ihlanganisa ukusabela kwe-redox phakathi kwama-ion ethusi nama-ejenti anciphisayo. Izinyathelo ezibalulekile kule nqubo zihlanganisa: Ukwenza kusebenze: Ukusetshenziswa kwezisusa zensimbi ezihloniphekile njenge-palladium noma iplatinamu ukuze kusebenze indawo engaphansi. I-catalyst inikeza amasayithi adingekayo ukuze kuhlanganiswe amakhemikhali ama-ion ethusi.

I-ejenti yokunciphisa:I-ejenti yokunciphisa isisombululo se-plating (imvamisa i-formaldehyde noma i-sodium hypophosphite) iqala ukusabela kokunciphisa. Lawa ma-reagents anikela ngama-electron kuma-ion ethusi, awaguqule abe ama-athomu ethusi ensimbi.

Ukusabela kwe-Autocatalytic:Ama-athomu ethusi akhiqizwa ukusabela kokunciphisa asabela nge-catalyst ebusweni be-substrate ukuze akhe ungqimba lwethusi olufanayo. Ukusabela kuyaqhubeka ngaphandle kwesidingo somshini wamanje osetshenziswa ngaphandle, okwenza kube "i-electroless plating."

Ukulawulwa kwezinga lokubeka:Ukwakheka nokugxiliswa kwesixazululo se-plating, kanye nemingcele yenqubo efana nezinga lokushisa ne-pH, kulawulwa ngokucophelela ukuze kuqinisekiswe ukuthi izinga lokubeka liyalawulwa futhi lifanayo.

Izinzuzo ze-electroless copper plating Uniformity:I-electroless copper plating inokufana okuhle kakhulu, iqinisekisa ukushuba okufanayo komumo oyinkimbinkimbi kanye nezindawo ezihlehlisiwe. I-Conformal Coating: Le nqubo ihlinzeka ngokunamathela okuvumelanayo okunamathela kahle kuma-substrates angajwayelekile wejometri njengama-PCB. Ukunamathela okuhle: I-electroless copper plating inokunamathela okuqinile ezintweni ezihlukahlukene ze-substrate, okuhlanganisa amapulasitiki, izitsha zobumba nezinsimbi. I-Selective Plating: I-electroless copper plating ingafaka ithusi ngokukhetha ezindaweni ezithile ze-substrate isebenzisa amasu okufihla. Izindleko Eziphansi: Uma kuqhathaniswa nezinye izindlela, i-electroless copper plating iyindlela engabizi kakhulu yokufaka ithusi ku-substrate.

Ububi be-electroless copper plating Izinga lokubeka kancane:Uma kuqhathaniswa nezindlela ze-electroplating, i-electroless copper plating inezinga lokubeka elihamba kancane, elinganweba sonke isikhathi senqubo ye-electroplating. Ugqinsi olulinganiselwe: I-electroless copper plating ngokuvamile ifaneleka ukufaka izendlalelo zethusi ezincane futhi ngenxa yalokho ayifaneleki kangako izinhlelo zokusebenza ezidinga ukujiya okukhulu. Ubunzima: Inqubo idinga ukulawulwa ngokucophelela kwemingcele ehlukahlukene, okuhlanganisa izinga lokushisa, i-pH kanye nokugxila kwamakhemikhali, okwenza kube yinkimbinkimbi kakhulu ukuyisebenzisa kunezinye izindlela ze-electroplating. Ukuphathwa Kwemfucuza: Ukulahlwa kwezixazululo zemfucuza eziqukethe izinsimbi ezinzima ezinobuthi kungadala izinselele zemvelo futhi kudinga ukuphathwa ngokucophelela.

Izindawo ezisetshenziswayo ze-electroless copper plating PCB Manufacturing:I-electroless copper plating isetshenziswa kakhulu ekwenzeni amabhodi esekethe aphrintiwe (PCBs) ukuze kwakheke iminonjana elandelwayo futhi ahlanganiswe ngezimbobo. Imboni ye-semiconductor: Idlala indima ebalulekile ekukhiqizweni kwamadivayisi e-semiconductor afana nabathwali be-chip namafreyimu omthofu. Izimboni zezimoto kanye ne-aerospace: I-electroless copper plating isetshenziselwa ukwenza izixhumi zikagesi, amaswishi kanye nezingxenye ze-elekthronikhi ezisebenza kahle. Izingubo Zokuhlobisa Nezisebenzayo: I-electroless copper plating ingasetshenziswa ukudala ukuqedwa kokuhlobisa kuma-substrates ahlukahlukene, kanye nokuvikela ukugqwala nokuthuthukiswa kokusebenza kukagesi.

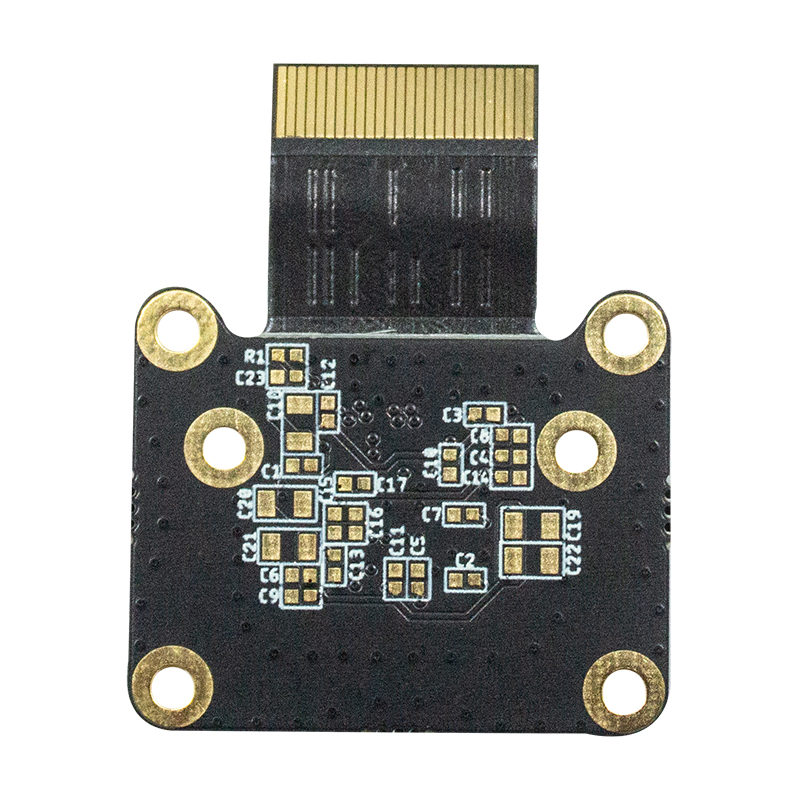

2.I-Copper Plating ku-PCB substrate

Ukufakwa kwe-Copper kuma-substrates e-PCB kuyisinyathelo esibalulekile kunqubo yokukhiqiza yebhodi lesekethe ephrintiwe (PCB). I-Copper ivame ukusetshenziswa njenge-electroplating material ngenxa ye-conductivity yayo kagesi enhle kakhulu kanye nokunamathela okuhle kakhulu ku-substrate. Inqubo ye-copper plating ihlanganisa ukufaka ungqimba oluncane lwethusi ebusweni be-PCB ukuze kwakhiwe izindlela ezisebenzayo zamasignali kagesi.

Inqubo ye-copper plating kuma-PCB substrates ngokuvamile ihlanganisa lezi zinyathelo ezilandelayo: Ukulungiswa Kobuso:

Hlanza kahle i-substrate ye-PCB ukuze ususe noma yikuphi ukungcola, ama-oxides noma ukungcola okungase kuvimbe ukunamathela futhi kuthinte ikhwalithi yokucwenga.

Ukulungiswa kwe-Electrolyte:

Lungiselela isixazululo se-electrolyte esine-copper sulfate njengomthombo wama-ion ethusi. I-electrolyte futhi iqukethe izithasiselo ezilawula inqubo yokucwenga, njengama-leveling agents, izikhanyisi, nezilungisi ze-pH.

I-Electrodeposition:

Gcoba i-substrate ye-PCB elungisiwe esixazululweni se-electrolyte bese usebenzisa isimanje esiqondile. I-PCB isebenza njengoxhumano lwe-cathode, kuyilapho i-anode yethusi nayo ikhona esixazululweni. Okwamanje kudala ukuthi ama-ion ethusi ku-electrolyte ehliswe futhi afakwe endaweni ye-PCB.

Ukulawulwa kwamapharamitha wokucwenga:

Imingcele ehlukahlukene ilawulwa ngokucophelela phakathi nenqubo yokucwenga, okuhlanganisa ukuminyana kwamanje, izinga lokushisa, i-pH, ukunyakazisa kanye nesikhathi sokucwenga. Lezi zinhlaka zisiza ukuqinisekisa ukumiswa okufanayo, ukunamathela, nokuqina okufunayo kongqimba lwethusi.

Ukwelashwa kwe-post-plating:

Uma ugqinsi lwethusi olufunekayo selufinyelelwe, i-PCB iyasuswa ebhavini lokucwenga bese iyahashazwa ukuze kukhishwe noma yisiphi isisombululo se-electrolyte esisele. Ukwelashwa okwengeziwe kwangemva kokucwenga, okufana nokuhlanza indawo nokudlula, kungenziwa ukuze kuthuthukiswe ikhwalithi nokuzinza kongqimba lwethusi lokucwenga.

Izinto ezithinta ikhwalithi ye-electroplating:

Ukulungiswa kwendawo:

Ukuhlanzwa kahle nokulungiswa kwendawo ye-PCB kubalulekile ukususa noma yikuphi ukungcola noma izendlalelo ze-oxide futhi uqinisekise ukunamathela okuhle kwe-copper plating. Ukwakhiwa kwesixazululo se-Pating:

Ukwakhiwa kwesisombululo se-electrolyte, okuhlanganisa ukugxila kwe-copper sulfate nezithasiselo, kuzothinta ikhwalithi yokucwenga. Ukwakheka kokugeza okucwebezelayo kufanele kulawulwe ngokucophelela ukuze kuzuzwe izici ezifiselekayo zokucwenga.

I-Plating Parameters:

Ukulawula amapharamitha wokucwenga afana nokuminyana kwamanje, izinga lokushisa, i-pH, isikhathi sokunyakazisa kanye ne-plating kuyadingeka ukuze kuqinisekiswe ukubekwa okufanayo, ukunamathela nokuqina kongqimba lwethusi.

I-substrate material:

Uhlobo nekhwalithi ye-PCB substrate material izothinta ukunamathela kanye nekhwalithi ye-copper plating. Izinto ezihlukile ze-substrate zingadinga ukulungiswa kunqubo yokucwenga ukuze uthole imiphumela emihle.

Ubulukhuni bobuso:

Ubukhulu obungaphezulu be-PCB substrate buzothinta ukunamathela kanye nekhwalithi yongqimba lwethusi lokucwenga. Ukulungiswa kahle kwendawo kanye nokulawula amapharamitha wokucwebeza kusiza ukunciphisa izinkinga ezihlobene namahhadla

Izinzuzo ze-PCB substrate copper plating:

I-electrical conductivity enhle kakhulu:

I-Copper yaziwa ngokuguquguquka kwayo okuphezulu kagesi, okuyenza ibe yinketho efanelekile yezinto zokucwenga ze-PCB. Lokhu kuqinisekisa ukuqhutshwa okusebenzayo nokuthembekile kwezimpawu zikagesi. Ukunamathela okuhle kakhulu:

I-Copper ibonisa ukunamathela okuhle kakhulu ezinhlobonhlobo ze-substrates, iqinisekisa isibopho esiqinile nesihlala isikhathi eside phakathi kwe-coating kanye ne-substrate.

Ukumelana Nokugqwala:

I-Copper inokumelana nokugqwala okuhle, ivikela izingxenye ezingaphansi ze-PCB futhi iqinisekisa ukwethembeka kwesikhathi eside. I-Solderability: I-Copper plating inikeza indawo efanelekile yokunamathisela, okwenza kube lula ukuxhuma izingxenye ze-elekthronikhi ngesikhathi somhlangano.

Ukukhipha ukushisa okuthuthukisiwe:

I-Copper iyi-conductor enhle eshisayo, evumela ukuchithwa okusebenzayo kokushisa kwama-PCB. Lokhu kubaluleke kakhulu ezinhlelweni zokusebenza zamandla aphezulu.

Imikhawulo nezinselelo ze-copper electroplating:

Ukulawula Ukuqina:

Ukuzuza ukulawula okunembile phezu kogqinsi lwezendlalelo zethusi kungaba inselele, ikakhulukazi ezindaweni eziyinkimbinkimbi noma izindawo eziqinile ku-PCB. Ukufana: Ukuqinisekisa ukufakwa okufanayo kwethusi phezu kwendawo yonke ye-PCB, okuhlanganisa izindawo ezihlehlisiwe kanye nezici ezinhle, kungaba nzima.

Izindleko:

Ithusi le-Electroplating lingabiza kakhulu uma liqhathaniswa nezinye izindlela ze-electroplating ngenxa yezindleko zamakhemikhali ethangi lokucwenga, okokusebenza, nokugcinwa.

Ukuphathwa Kwemfucuza:

Ukulahlwa kwezixazululo ze-plating ezisetshenzisiwe kanye nokwelashwa kwamanzi angcolile aqukethe ama-ion ethusi namanye amakhemikhali kudinga izindlela ezifanele zokulawula imfucuza ukuze kuncishiswe umthelela wendawo.

Inqubo Eyinkimbinkimbi:

Ikhopha ye-Electroplating ihlanganisa amapharamitha amaningi adinga ukulawula ngokucophelela, edinga ulwazi olukhethekile kanye nokusetha okuyinkimbinkimbi kokucwenga.

3.Ukuqhathanisa phakathi kwe-electroless copper plating kanye ne-electroplating

Umehluko wokusebenza nekhwalithi:

Kunomehluko eminingana ekusebenzeni kanye nekhwalithi phakathi kwe-electroless copper plating kanye ne-electroplating kulezi zici ezilandelayo:

I-electroless copper plating iyinqubo yokubeka amakhemikhali engadingi umthombo wamandla wangaphandle, kuyilapho i-electroplating ihilela ukusebenzisa amandla amanje aqondile ukufaka ungqimba lwethusi. Lo mehluko ezindleleni zokubeka ungaholela ekuhlukeni kwekhwalithi yokumboza.

I-electroless copper plating ngokuvamile ihlinzeka ngokubeka okufanayo endaweni yonke engaphansi, okuhlanganisa izindawo ezihlehlisiwe kanye nezici ezinhle. Lokhu kungenxa yokuthi ukucwenga kwenzeka ngokulinganayo kuzo zonke izindawo ngaphandle kokubheka ukuma kwazo. I-Electroplating, ngakolunye uhlangothi, ingaba nobunzima ekufezeni ukufakwa okufanayo ezindaweni eziyinkimbinkimbi noma okunzima ukufinyelela kuzo.

I-electroless copper plating ingafinyelela i-aspect ratio ephezulu (isilinganiso sobude besici nobubanzi) kune-electroplating. Lokhu kuyenza ifaneleke izinhlelo zokusebenza ezidinga izici ezisezingeni eliphezulu, njengezimbobo eziphuma kuma-PCB.

I-electroless copper plating ngokuvamile ikhiqiza indawo ebushelelezi, eyisicaba kune-electroplating.

I-Electroplating ngezinye izikhathi ingase ibangele idiphozi engalingani, embi noma engenalutho ngenxa yezinguquko zokuminyana kwamanje nezimo zokugeza. Ikhwalithi yebhondi phakathi kongqimba lwe-copper Plating kanye ne-substrate ingase ihluke phakathi kwe-electroless copper plating kanye ne-electroplating.

I-electroless copper plating ngokuvamile ihlinzeka ngokunamathela okungcono ngenxa yendlela yokubopha amakhemikhali yethusi engena-electro ku-substrate. I-Plating incike ekubopheni komshini kanye ne-electrochemical, okungaholela kumabhondi abuthakathaka kwezinye izimo.

Ukuqhathaniswa Kwezindleko:

I-Chemical Deposition vs. Electroplating: Uma uqhathanisa izindleko ze-electroless copper plating kanye ne-electroplating, izici ezimbalwa kufanele zicatshangelwe:

Izindleko zamakhemikhali:

I-electroless copper plating ngokuvamile idinga amakhemikhali abiza kakhulu uma kuqhathaniswa ne-electroplating. Amakhemikhali asetshenziswa ku-electroless Plating, njengama-ejenti anciphisayo nezinzinzisi, ngokuvamile akhethekile kakhulu futhi ayabiza.

Izindleko zezisetshenziswa:

Amayunithi okucwenga adinga amathuluzi ayinkimbinkimbi futhi abizayo, okuhlanganisa amandla kagesi, izinto zokulungisa izinto kanye nama-anode. Izinhlelo zokucwenga zethusi ezingenagesi zilula futhi zidinga izingxenye ezimbalwa.

Izindleko zokulungisa:

Imishini yokucwenga ingase idinge ukunakekelwa ngezikhathi ezithile, ukulinganisa, nokushintshwa kwama-anode noma ezinye izingxenye. Amasistimu wokucwenga wethusi angenawo ugesi ngokuvamile adinga ukulungiswa kancane futhi anezindleko eziphansi zokunakekela.

Ukusetshenziswa Kwamakhemikhali Okufakwayo:

Ama-plating systems asebenzisa amakhemikhali okucwenga ngezinga eliphezulu ngenxa yokusetshenziswa kwamandla kagesi. Ukusetshenziswa kwamakhemikhali kwezinhlelo zokucwenga zethusi ezingenayo i-electroless kuphansi ngoba ukusabela kwe-electroplating kwenzeka ngokusabela kwamakhemikhali.

Izindleko zokuphatha udoti:

I-Electroplating idala imfucuza eyengeziwe, okuhlanganisa okugeza okuchithwayo kanye namanzi okugeza angcoliswe ama-ion ensimbi, adinga ukwelashwa okufanele nokulahlwa. Lokhu kwandisa izindleko eziphelele zokucwenga. I-electroless copper plating ikhiqiza imfucuza encane ngoba ayincikile ekunikezeni okuqhubekayo kwama-ion ensimbi kubhavu wokucwenga.

Izingqinamba kanye nezinselelo ze-Electroplating kanye ne-Chemical Deposition:

I-Electroplating idinga ukulawulwa ngokucophelela kwemingcele ehlukahlukene njengokuminyana kwamanje, izinga lokushisa, i-pH, isikhathi sokucwenga kanye nokunyakazisa. Ukuzuza ukubekwa okufanayo kanye nezici zokucwenga ezifiselekayo kungaba inselele, ikakhulukazi kumajiyometri ayinkimbinkimbi noma ezindaweni zamanje eziphansi. Ukuthuthukiswa kokwakheka kokugeza okucwebezelayo namapharamitha kungase kudinge ukuhlolwa okubanzi nobungcweti.

I-electroless copper plating nayo idinga ukulawula amapharamitha njengokunciphisa ukugxila kwe-ejenti, izinga lokushisa, i-pH nesikhathi sokucwenga. Kodwa-ke, ukulawulwa kwala mapharamitha ngokuvamile akubalulekanga kangako ekucwecweni okungenawo ugesi kunase-electroplating. Ukuzuza izici ezifiselekayo zokucwenga, njengezinga lokubeka, ukujiya, nokunamathela, kusengadinga ukuthuthukiswa nokuqapha inqubo yokucwenga.

Ekufakweni kwe-electroplating yethusi ne-electroless, ukunamathela ezintweni ezahlukahlukene ze-substrate kungaba inselele evamile. Ukwelashwa kwangaphambili kwe-substrate surface ukususa ukungcola nokukhuthaza ukunamathela kubalulekile kuzo zombili izinqubo.

Ukuxazulula izinkinga nokuxazulula izinkinga ku-electroplating noma i-electroless copper plating kudinga ulwazi olukhethekile nolwazi. Izinkinga ezinjengamahhadla, ukwakheka kokungalingani, i-voids, ukubhamuza, noma ukunamathelisa kahle kungenzeka phakathi nezinqubo zombili, futhi ukuhlonza umsuka kanye nokuthatha isinyathelo sokulungisa kungaba inselele.

Ububanzi bokusetshenziswa kobuchwepheshe obunye:

I-Electroplating ivamise ukusetshenziswa ezimbonini ezihlukene ezihlanganisa eze-elekthronikhi, ezezimoto, i-aerospace nobucwebe obudinga ukulawula ukujiya okunembe, isiphetho sekhwalithi ephezulu kanye nezakhiwo ezibonakalayo ezifiselekayo. Isetshenziswa kabanzi ekuqedweni kokuhlobisa, ukumbozwa kwensimbi, ukuvikela ukugqwala kanye nokukhiqizwa kwezingxenye ze-elekthronikhi.

I-electroless copper plating isetshenziswa kakhulu embonini ye-elekthronikhi, ikakhulukazi ekukhiqizeni amabhodi esekethe aphrintiwe (PCBs). Isetshenziselwa ukwakha izindlela zokuqhuba, izindawo ezithengiswayo kanye nokuqedwa kwangaphezulu kuma-PCB. I-electroless copper plating iphinde isetshenziselwe ukwenza i-metallisa amapulasitiki, ukukhiqiza ukuxhumana kwethusi kumaphakheji we-semiconductor, nezinye izinhlelo zokusebenza ezidinga ukufakwa kwethusi okufanayo nokuvumelanayo.

4.Amasu okufakwa kwe-Copper ezinhlobo ezahlukene ze-PCB

I-PCB yohlangothi olulodwa:

Kuma-PCB anohlangothi olulodwa, ukufaka ithusi kuvamise ukwenziwa kusetshenziswa inqubo yokususa. I-substrate ngokuvamile yenziwe ngezinto ezingezona u-conductive ezifana ne-FR-4 noma i-phenolic resin, ehlanganiswe nongqimba oluncane lwethusi ohlangothini olulodwa. Isendlalelo sethusi sisebenza njengendlela yokuhambisa yesifunda. Inqubo iqala ngokuhlanza nokulungiswa kwendawo ye-substrate ukuqinisekisa ukunamathela okuhle. Okulandelayo ukusetshenziswa kongqimba oluncane lwempahla ye-photoresist, evezwa ekukhanyeni kwe-UV nge-photomask ukuze kuchazwe iphethini yesekethe. Izindawo eziveziwe ze-resistance ziyancibilika futhi ngemva kwalokho zikhukhulwe, ziveze ungqimba lwethusi olungaphansi. Izindawo zethusi eziveziwe zibe seziqoshwa kusetshenziswa i-etchant efana ne-ferric chloride noma i-ammonium persulfate. I-etchant isusa ngokukhetha ithusi eliveziwe, ishiya iphethini yesekethe efunekayo. I-resistance esele ibe isihlutshiwe, ishiye imikhondo yethusi. Ngemva kwenqubo yokushumeka, i-PCB ingase ibhekane nezinyathelo ezengeziwe zokulungisa indawo efana ne-solder mask, ukuphrinta kwesikrini, kanye nokusetshenziswa kwezingqimba zokuvikela ukuze kuqinisekiswe ukuqina nokuvikelwa ezintweni ezithinta imvelo.

I-PCB enamacala amabili:

I-PCB enezinhlangothi ezimbili inezendlalelo zethusi ezinhlangothini zombili ze-substrate. Inqubo yokufaka ithusi nhlangothi zombili ibandakanya izinyathelo ezengeziwe uma kuqhathaniswa nama-PCB anohlangothi olulodwa. Inqubo ifana ne-PCB enohlangothi olulodwa, iqala ngokuhlanza nokulungiswa kwendawo engaphansi. Ungqimba lwethusi lube selufakwa ezinhlangothini zombili ze-substrate kusetshenziswa i-electroless copper plating noma i-electroplating. I-Electroplating ivamise ukusetshenziselwa lesi sinyathelo ngoba ivumela ukulawula okungcono phezu kogqinsi nekhwalithi yesendlalelo sethusi. Ngemuva kokuthi ungqimba lwethusi lufakwe, izinhlangothi zombili zimbozwe nge-photoresist futhi iphethini yesifunda ichazwa ngezinyathelo zokuchayeka nezokuthuthuka ezifana nalezo zama-PCB anohlangothi olulodwa. Izindawo zethusi eziveziwe zibe seziqoshwa ukuze zenze imikhondo yesekethe edingekayo. Ngemuva kokuhlanganisa, ukuphikiswa kuyasuswa futhi i-PCB iqhubeka nezinyathelo zokucubungula ezengeziwe ezifana nokufakwa kwemaski ye-solder kanye nokwelashwa kwendawo ukuze kuqedelwe ukwakhiwa kwe-PCB enezinhlangothi ezimbili.

I-Multilayer PCB:

Ama-PCB angama-Multilayer enziwe ngezingqimba eziningi zethusi nezinto zokuvikela ezibekwe phezu kwesinye. Ukufakwa kwe-Copper kuma-PCB anezingqimba eziningi kuhilela izinyathelo eziningi zokudala izindlela zokuqondisa phakathi kwezendlalelo. Inqubo iqala ngokwakha izendlalelo ze-PCB ngazinye, ezifana nama-PCB anohlangothi olulodwa noma anezinhlangothi ezimbili. Isendlalelo ngasinye siyalungiswa futhi i-photoresist isetshenziselwa ukuchaza iphethini yesifunda, ilandelwa ukufakwa kwethusi nge-electroplating noma i-electroless copper plating. Ngemuva kokufakwa, ungqimba ngalunye lumbozwa ngento evikelayo (imvamisa i-epoxy-based prepreg noma inhlaka) bese ihlanganiswa ndawonye. Izendlalelo ziqondaniswe kusetshenziswa ukumba okunembayo nezindlela zokubhalisa ngomshini ukuze kuqinisekiswe ukuxhumana okunembile phakathi kwezingqimba. Uma izendlalelo ziqondaniswe, i-vias idalwa ngokumba izimbobo ngokusebenzisa izendlalelo ezindaweni ezithile lapho kudingeka khona ukuxhumana. Ama-vias abese efakwa ngethusi kusetshenziswa i-electroplating noma i-electroless copper plating ukuze kwakheke ukuxhumana kukagesi phakathi kwezingqimba. Inqubo iqhubeka ngokuphinda izinyathelo zokunqwabelanisa ungqimba, ukubhoboza, kanye ne-copper kuze kube yilapho zonke izingqimba ezidingekayo nezixhumi zidaliwe. Isinyathelo sokugcina sihlanganisa ukwelashwa okungaphezulu, ukufaka imaski ye-solder nezinye izinqubo zokuqeda ukuqedela ukukhiqizwa kwe-PCB enezingqimba eziningi.

I-High Density Interconnect (HDI) PCB:

I-HDI PCB iyi-PCB enezingqimba eziningi eklanyelwe ukuthwala ukuminyana okuphezulu kanye nesici esincane sefomu. Ukufakwa kwe-Copper kuma-HDI PCB kuhlanganisa amasu athuthukile ukuze kunikwe amandla izici ezinhle nemiklamo eqinile yephimbo. Inqubo iqala ngokwakha izendlalelo eziningi ezizacile kakhulu, ezivame ukubizwa nge-core material. Lezi zinhlamvu zine-foil yethusi ezacile ohlangothini ngalunye futhi zenziwe ngezinto ezisebenza kahle ze-resin ezifana ne-BT (Bismaleimide Triazine) noma i-PTFE (Polytetrafluoroethylene). Izinto eziwumgogodla zinqwabelene futhi zihlanganiswe ndawonye ukuze kwakhiwe isakhiwo esinezingqimba eziningi. I-laser drilling bese isetshenziselwa ukwakha ama-microvias, okuyizimbobo ezincane ezixhuma izingqimba. Ama-Microvias ngokuvamile agcwaliswa ngezinto zokuqhuba ezifana nethusi noma i-epoxy conductive. Ngemuva kokuthi ama-microvias akhiwe, izingqimba ezengeziwe zihlanganiswa futhi zifakwe laminated. I-lamination elandelanayo kanye nenqubo yokumba i-laser iyaphindwa ukuze kwakhiwe izendlalelo ezistakiwe eziningi ezine-microvia interconnects. Ekugcineni, ithusi lifakwa ebusweni be-HDI PCB kusetshenziswa amasu afana ne-electroplating noma i-electroless copper plating. Njengoba kunikezwe izici ezinhle nokujikeleza kokuminyana okuphezulu kwama-HDI PCB, ukubekwa kulawulwa ngokucophelela ukuze kuzuzwe ukujiya kanye nekhwalithi yethusi edingekayo. Inqubo iphetha ngokwelashwa okwengeziwe okungaphezulu kanye nezinqubo zokuqeda ukuze kuqedelwe ukukhiqizwa kwe-HDI PCB, okungase kuhlanganise ukufaka isicelo semaski ye-solder, isicelo sokuqeda phezulu nokuhlolwa.

Ibhodi lesifunda eliguquguqukayo:

Ama-PCB aguquguqukayo, aziwa nangokuthi ama-flex circuits, aklanyelwe ukuguquguquka futhi akwazi ukuzivumelanisa nokuma okuhlukile noma ukugoba ngesikhathi sokusebenza. Ukufakwa kwethusi kuma-PCB avumelana nezimo kuhilela amasu athile ahlangabezana nezimfuneko zokuguquguquka nokuqina. Ama-PCB aguqukayo angaba nohlangothi olulodwa, amahlangothi akabili, noma anezendlalelo eziningi, futhi amasu okubeka ithusi ayahluka ngokuya ngezidingo zokuklama. Ngokuvamile, ama-PCB aguquguqukayo asebenzisa i-foil yethusi ezacile ngokuqhathaniswa nama-PCB aqinile ukuze afinyelele ukuguquguquka. Kuma-PCB anohlangothi olulodwa oluvumelana nezimo, inqubo ifana nama-PCB aqinile ohlangothini olulodwa, okungukuthi, ungqimba oluncane lwethusi lufakwa ku-substrate eguquguqukayo kusetshenziswa i-electroless copper plating, i-electroplating, noma inhlanganisela yakho kokubili. Kuma-PCB anezinhlangothi ezimbili noma ezendlalelo eziningi eziguquguqukayo, inqubo ihilela ukufaka ithusi ezinhlangothini zombili ze-substrate eguquguqukayo kusetshenziswa i-electroless copper plating noma i-electroplating. Ngokucabangela izici eziyingqayizivele zemishini yezinto eziguquguqukayo, ukufakwa kulawulwa ngokucophelela ukuze kuqinisekiswe ukunamathela okuhle nokuguquguquka. Ngemva kokufakwa kwethusi, i-PCB eguquguqukayo idlula ezinqubweni ezengeziwe ezifana nokubhola, iphethini yesekethe, nezinyathelo zokwelashwa kwendawo ukuze yakhe isifunda esidingekayo futhi iqedele ukukhiqizwa kwe-PCB eguquguqukayo.

5.Intuthuko kanye Nokusungulwa Kwethusi Kuma-PCB

Ukuthuthukiswa Kobuchwepheshe Bamuva: Phakathi neminyaka edlule, ubuchwepheshe bokufakwa kwe-copper kuma-PCB buqhubekile nokuvela futhi buthuthuke, okuholela ekwenyukeni kokusebenza nokuthembeka. Ezinye zentuthuko yakamuva yezobuchwepheshe ekufakweni kwethusi kwe-PCB zifaka:

Ubuchwepheshe be-plating obuthuthukisiwe:

Ubuchwepheshe obusha bokucwenga, obufana ne-pulse plating kanye ne-reverse pulse plating, buthuthukisiwe ukuze kuzuzwe ukufakwa kwethusi okucolekile nokufana okufanayo. Lobu buchwepheshe busiza ekunqobeni izinselele ezinjengokuqina kwendawo, usayizi wokusanhlamvu nokusabalalisa ukushuba ukuze kuthuthukiswe ukusebenza kukagesi.

I-Metallization eqondile:

Ukwenziwa kwe-PCB yendabuko kuhilela izinyathelo eziningi zokudala izindlela ezisebenzayo, okuhlanganisa nokufaka ungqimba lwembewu ngaphambi kokucwecwa ngethusi. Ukuthuthukiswa kwezinqubo ze-metalization eziqondile kuqeda isidingo sesendlalelo sembewu ehlukile, ngaleyo ndlela kube lula inqubo yokukhiqiza, ukunciphisa izindleko nokuthuthukisa ukwethembeka.

Ubuchwepheshe be-Microvia:

Ama-Microvias ayizimbobo ezincane ezixhuma izingqimba ezihlukene ku-PCB enezingqimba eziningi. Intuthuko kubuchwepheshe be-microvia njengokugaya i-laser kanye ne-plasma etching inika amandla ukudalwa kwama-microvias amancane, anembe kakhudlwana, okuvumela amasekhethi aphezulu okuminyana kanye nobuqotho besignali obuthuthukisiwe. I-Surface Finish Innovation: Ukuqedwa kwendawo kubalulekile ekuvikeleni imikhondo yethusi ekufakweni kwe-oxidation kanye nokuhlinzeka ngokuthengiswa. Ukuthuthukiswa kobuchwepheshe bokwelapha okungaphezulu, obufana ne-Immersion Silver (ImAg), Organic Solderability Preservative (OSP), kanye ne-Electroless Nickel Immersion Gold (ENIG), buhlinzeka ngokuvikeleka okungcono kokugqwala, ukuthuthukisa ukubola, nokwandisa ukuthembeka kukonke .

I-Nanotechnology kanye ne-Copper Deposition: I-Nanotechnology idlala indima ebalulekile ekuthuthukisweni kokufakwa kwethusi kwe-PCB. Ezinye izinhlelo zokusebenza ze-nanotechnology ekufakweni kwethusi zifaka:

I-Nanoparticle-based Plating:

Ama-nanoparticles e-Copper angafakwa kusixazululo se-plating ukuze kuthuthukiswe inqubo yokubeka. Lawa ma-nanoparticles asiza ukuthuthukisa ukunamathela kwethusi, usayizi wokusanhlamvu nokusabalalisa, ngaleyo ndlela kuncishiswe ukumelana nokuthuthukisa ukusebenza kukagesi.

Izinto Zokuqhuba Ezingahleliwe:

Izinto ezisetshenziswayo nanostructured, njengama-carbon nanotubes ne-graphene, zingahlanganiswa kuma-substrates e-PCB noma zisebenze njengezigcwalisi ze-conductive ngesikhathi sokubekwa. Lezi zinto zine-conductivity ephakeme kagesi, amandla emishini kanye nezakhiwo ezishisayo, ngaleyo ndlela zithuthukise ukusebenza okuphelele kwe-PCB.

I-Nanocoating:

I-Nanocoating ingasetshenziswa endaweni ye-PCB ukuze kuthuthukiswe ukushelela kwendawo, ukuqina nokuvikela ukugqwala. Lezi zembatho zivame ukwenziwa ngama-nanocomposites ahlinzeka ngokuvikeleka okungcono ezicini zemvelo futhi andise impilo ye-PCB.

I-Nanoscale interconnects:Ukuxhumana kwe-Nanoscale, okufana nama-nanowires nama-nanorod, kuyahlolwa ukuze kunikwe amandla amasekhethi aphezulu kuma-PCB. Lezi zakhiwo zenza kube lula ukuhlanganiswa kwamasekhethi amaningi endaweni encane, okuvumela ukuthuthukiswa kwamadivaysi kagesi amancane, ahlangene kakhulu.

Izinselelo nezikhombisi-ndlela zesikhathi esizayo: Naphezu kwenqubekelaphambili ebalulekile, izinselele ezimbalwa namathuba asele okuqhubeka nokuthuthukisa ukufakwa kwethusi kuma-PCB. Ezinye izinselelo ezibalulekile nezikhombisi-ndlela zesikhathi esizayo zifaka:

I-Copper Fill in High Aspect Ratio Structures:

Izakhiwo ze-aspect ratio ephezulu ezifana ne-vias noma i-microvias ziletha izinselele ekuzuzeni ukugcwaliswa kwethusi okufanayo nokuthembekile. Ucwaningo olwengeziwe luyadingeka ukuze kuthuthukiswe amasu okucwenga athuthukile noma ezinye izindlela zokugcwalisa ukuze kunqotshwe lezi zinselele futhi kuqinisekiswe ukubekwa kwethusi okulungile ezakhiweni ze-aspect ratio ephezulu.

Ukunciphisa Ububanzi Be-Copper Trace:

Njengoba izinto ze-elekthronikhi ziba zincane futhi ziminyene, isidingo semikhondo yethusi emincane siyaqhubeka sikhula. Inselele iwukuthola ukufakwa kwethusi okufanayo nokuthembekile phakathi kwalezi zindlela eziwumngcingo, ukuqinisekisa ukusebenza kukagesi okungaguquki nokwethembeka.

Enye impahla ye-conductor:

Nakuba ithusi liyinto esetshenziswa kakhulu yokuqhuba, ezinye izinto ezifana nesiliva, i-aluminium, nama-carbon nanotubes ziyahlolwa ngezakhiwo zazo ezihlukile kanye nezinzuzo zokusebenza. Ucwaningo lwangomuso lungagxila ekuthuthukiseni amasu okufakwa kwalezi zinto ezihlukile zomqhubi ukuze kunqotshwe izinselele ezinjengokunamathela, ukumelana nokumelana, nokuhambisana nezinqubo zokukhiqiza ze-PCB. NgokwemveloIzinqubo ezinobungane:

Imboni ye-PCB ihlezi isebenzela ezinqubweni ezihambisana nemvelo. Intuthuko yesikhathi esizayo ingase igxile ekwehliseni noma ekuqedeni ukusetshenziswa kwamakhemikhali ayingozi ngesikhathi sokufakwa kwethusi, ukwandisa ukusetshenziswa kwamandla, kanye nokunciphisa ukukhiqizwa kwemfucuza ukuze kuncishiswe umthelela wemvelo wokukhiqizwa kwe-PCB.

Ukulingisa Okuthuthukisiwe Nokumodela:

Amasu okulingisa nawokumodela asiza ukuthuthukisa izinqubo zokubeka ithusi, abikezele ukuziphatha kwemingcele yokubeka, futhi athuthukise ukunemba nokusebenza kahle kokukhiqizwa kwe-PCB. Intuthuko yesikhathi esizayo ingase ihlanganise ukuhlanganisa amathuluzi okulingisa okuthuthukile kanye nenqubo yokumodela enqubweni yokuklama neyokukhiqiza ukuze kunikwe amandla ukulawula okungcono nokwenza kahle.

6.Isiqiniseko Sekhwalithi kanye Nokulawulwa Kokufakwa Kwethusi Kuma-PCB Substrates

Ukubaluleka kokuqinisekisa ikhwalithi: Ukuqinisekisa ikhwalithi kubalulekile enqubweni yokubeka ithusi ngenxa yalezi zizathu ezilandelayo:

Ukuthembeka Komkhiqizo:

Ukufakwa kwethusi ku-PCB kwakha isisekelo sokuxhunywa kukagesi. Ukuqinisekisa ikhwalithi yokubeka ithusi kubalulekile ekusebenzeni okuthembekile nokuhlala isikhathi eside kwamadivayisi kagesi. Ukufakwa kwethusi okungekuhle kungaholela kumaphutha okuxhumana, ukunciphisa isignali, kanye nokwethenjwa kwe-PCB okuncishisiwe kukonke.

Ukusebenza kukagesi:

Izinga le-copper plating lithinta ngqo ukusebenza kukagesi kwe-PCB. Ubukhulu nokusatshalaliswa kwethusi okufanayo, ukuqedwa kwendawo eshelelayo, nokunamathela okufanele kubalulekile ukuze kuzuzwe ukumelana okuphansi, ukudluliswa kwesignali okuphumelelayo, nokulahlekelwa kwesignali okuncane.

Yehlisa izindleko:

Ukuqinisekisa ikhwalithi kusiza ukukhomba nokuvimbela izinkinga kusenesikhathi, kunciphisa isidingo sokusebenza kabusha noma ukulahla ama-PCB angasebenzi. Lokhu kungonga izindleko futhi kuthuthukise ukusebenza kahle kokukhiqiza sekukonke.

Ukwaneliseka Kwekhasimende:

Ukuhlinzeka ngemikhiqizo yezinga eliphezulu kubalulekile ekwanelisekeni kwamakhasimende kanye nokwakha igama elihle embonini. Amakhasimende alindele imikhiqizo ethembekile nehlala isikhathi eside, futhi ukuqinisekiswa kwekhwalithi kuqinisekisa ukuthi ukufakwa kwethusi kuhlangabezana noma kudlula lokho okulindelekile.

Izindlela zokuhlola nokuhlola zokubekwa kwethusi: Kusetshenziswa izindlela ezahlukahlukene zokuhlola nezindlela zokuhlola ukuze kuqinisekiswe ikhwalithi yokubeka ithusi kuma-PCB. Ezinye izindlela ezijwayelekile zihlanganisa:

Ukuhlola Okubonakalayo:

Ukuhlola okubukwayo kuyindlela eyisisekelo nebalulekile yokuthola ukukhubazeka okusobala okufana nokuklwebheka, ama-dents noma ama-rough. Lokhu kuhlola kungenziwa ngesandla noma ngosizo lwesistimu ye-automated optical inspection (AOI).

I-microscope:

I-Microscopy isebenzisa amasu afana nokuskena i-electron microscopy (SEM) ingahlinzeka ngokuhlaziywa okuningiliziwe kokufakwa kwethusi. Ingakwazi ukuhlola ngokucophelela ukuphela kwendawo, ukunamathela kanye nokufana kongqimba lwethusi.

Ukuhlaziywa kwe-X-ray:

Amasu okuhlaziya ama-X-ray, afana ne-X-ray fluorescence (XRF) kanye ne-X-ray diffraction (XRD), asetshenziselwa ukukala ukubunjwa, ukujiya kanye nokusatshalaliswa kwediphozithi yethusi. Lawa masu angakwazi ukuhlonza ukungcola, ukwakheka kwezinto, futhi athole noma yikuphi ukungahambisani ekufakweni kwethusi.

Ukuhlolwa kukagesi:

Yenza izindlela zokuhlola zikagesi, okuhlanganisa izilinganiso zokumelana nokuhlola ukuqhubeka, ukuhlola ukusebenza kukagesi kwediphozithi yethusi. Lezi zivivinyo zisiza ukuqinisekisa ukuthi isendlalelo sethusi sinokusebenza okudingekayo nokuthi awekho ama-opens noma izikhindi ngaphakathi kwe-PCB.

Ukuhlolwa kwamandla e-Peel:

Ukuhlolwa kwamandla ekhasi kukala amandla okubopha phakathi kongqimba lwethusi ne-PCB substrate. Inquma ukuthi ingabe idiphozi yethusi inawo yini amandla ebhondi anele ukumelana nokuphathwa okuvamile kanye nezinqubo zokukhiqiza ze-PCB.

Amazinga neziqondiso zemboni: Imboni ye-PCB ilandela amazinga nemithethonqubo ehlukahlukene ukuze kuqinisekiswe ikhwalithi yokubekwa kwethusi. Ezinye izindinganiso ezibalulekile nemithethonqubo ihlanganisa:

IPC-4552:

Leli zinga licacisa izimfuneko zokwelapha i-electroless nickel/immersion gold (ENIG) ezivame ukusetshenziswa kuma-PCB. Ichaza ubuncane begolide ukujiya, ukujiya kwe-nickel kanye nekhwalithi yangaphezulu yezokwelapha ezithembekile neziqinile ze-ENIG.

IPC-A-600:

Izinga le-IPC-A-600 lihlinzeka ngemihlahlandlela yokwamukela i-PCB, okuhlanganisa amazinga okuhlukaniswa kwe-copper plating, ukonakala kwendawo namanye amazinga ekhwalithi. Isebenza njengereferensi yokuhlolwa okubonakalayo kanye nezindlela zokwamukela ukufakwa kwethusi kuma-PCB. I-RoHS Directive:

Isiyalezo Sokukhawulelwa Kwezinto Eziyingozi (RoHS) sikhawulela ukusetshenziswa kwezinto ezithile eziyingozi emikhiqizweni ye-elekthronikhi, okuhlanganisa umthofu, i-mercury ne-cadmium. Ukuthobela isiyalezo se-RoHS kuqinisekisa ukuthi amadiphozi ethusi kuma-PCB awanazo izinto eziyingozi, okuwenza aphephe futhi anobungani nemvelo.

I-ISO 9001:

I-ISO 9001 iyindinganiso yamazwe ngamazwe yezinhlelo zokuphatha ikhwalithi. Ukusungula nokusebenzisa isistimu yokuphatha ikhwalithi esekelwe ku-ISO 9001 kuqinisekisa ukuthi izinqubo ezifanele nezilawuli zikhona ukuze kulethwe ngokungaguquki imikhiqizo ehlangabezana nezidingo zamakhasimende, okuhlanganisa ikhwalithi yokufakwa kwethusi kuma-PCB.

Ukunciphisa izinkinga ezivamile kanye nokukhubazeka: Ezinye izinkinga ezivamile kanye nokukhubazeka okungenzeka ngesikhathi sokufakwa kwethusi kufaka phakathi:

Ukunamathela okunganele:

Ukunamathela okungalungile kwesendlalelo sethusi ku-substrate kungaholela ku-delamination noma ukuxebuka. Ukuhlanzwa kahle kwendawo, ukushwabana kwemishini, kanye nokwelapha okugqugquzela ukunamathela kungasiza ekudambiseni le nkinga.

Ukuqina Kwethusi Okungalingani:

Ubukhulu bethusi obungalingani bungabangela ukuguquguquka okungaguquki futhi kuvimbele ukudluliswa kwesignali. Ukuthuthukisa amapharamitha wokucwebeza, ukusebenzisa i-pulse noma i-reverse pulse plating kanye nokuqinisekisa ukuyaluza okufanele kungasiza ekufinyeleleni ukujiya kwethusi okufanayo.

Ama-Voids nama-Pinholes:

Izikhala namaphinifa ongqimba lwethusi kungalimaza ukuxhumana kukagesi futhi kwandise ingozi yokugqwala. Ukulawulwa okufanele kwamapharamitha wokucwenga kanye nokusetshenziswa kwezithasiselo ezifanele kunganciphisa ukuvela kwama-voids namaphinikhodi.

Ubulukhuni bobuso:

Ukumatsheka okwedlulele kungase kube nomthelela omubi ekusebenzeni kwe-PCB, kuthinte ukuthengiswa nobuqotho bukagesi. Ukulawula kahle imingcele yokubeka ithusi, ukwelashwa kwangaphambili kwendawo kanye nezinqubo zangemuva kokwelashwa kusiza ukufeza ukuqeda okubushelelezi.

Ukuze kuncishiswe lezi zinkinga kanye nokushiyeka, ukulawulwa kwezinqubo ezifanele kufanele kusetshenziswe, ukuhlolwa okujwayelekile nokuhlolwa kufanele kwenziwe, futhi amazinga nemithetho yemboni kufanele ilandelwe. Lokhu kuqinisekisa ukubekwa kwethusi okungaguquki, okuthembekile kanye nekhwalithi ephezulu ku-PCB. Ngaphezu kwalokho, ukuthuthukiswa kwezinqubo eziqhubekayo, ukuqeqeshwa kwabasebenzi, kanye nezindlela zokuphendula kusiza ukukhomba izindawo okufanele zithuthukiswe futhi kuxazululwe izinkinga ezingase zibe khona ngaphambi kokuba zibe zimbi kakhulu.

Ukufakwa kwethusi ku-PCB substrate kuyisinyathelo esibalulekile enqubweni yokukhiqiza ye-PCB. I-electroless copper deposition kanye ne-electroplating yizindlela eziyinhloko ezisetshenziswayo, ngayinye inezinzuzo zayo kanye nokulinganiselwa kwayo. Intuthuko yezobuchwepheshe iyaqhubeka nokuqhuba izinto ezintsha ekufakweni kwethusi, ngaleyo ndlela ithuthukise ukusebenza kwe-PCB nokwethembeka.Ukuqinisekisa ikhwalithi nokulawula kudlala indima ebalulekile ekuqinisekiseni ukukhiqizwa kwama-PCB ekhwalithi ephezulu. Njengoba isidingo semishini kagesi emincane, esheshayo, futhi enokwethenjelwa kakhudlwana siqhubeka nokwanda, kanjalo nesidingo sokunemba nokusebenza kahle kubuchwepheshe bokufakwa kwethusi kuma-substrates e-PCB. Qaphela: Isibalo samagama esihlokweni singamagama angu-3,500, kodwa sicela uqaphele ukuthi inani langempela lamagama lingahluka kancane phakathi nenqubo yokuhlela nokufunda.

Isikhathi sokuthumela: Sep-13-2023

Emuva