Uma kuziwa ekuhlanganiseni ingxenye ye-elekthronikhi, izindlela ezimbili ezithandwayo zibusa imboni: umhlangano we-pcb surface Mount technology (SMT) kanye ne-pcb through-hole assembly.Njengoba ubuchwepheshe buthuthuka, abakhiqizi nonjiniyela bahlala befuna isixazululo esingcono kakhulu samaphrojekthi abo. Ukukusiza ukuthi uthole ukuqonda okujulile kwalobu buchwepheshe bokuhlangana okubili, u-Capel uzohola ingxoxo ngomehluko phakathi kwe-SMT nokuhlanganisa imbobo futhi akusize unqume ukuthi iyiphi elungele iphrojekthi yakho.

I-Surface Mount Technology (SMT) Assembly:

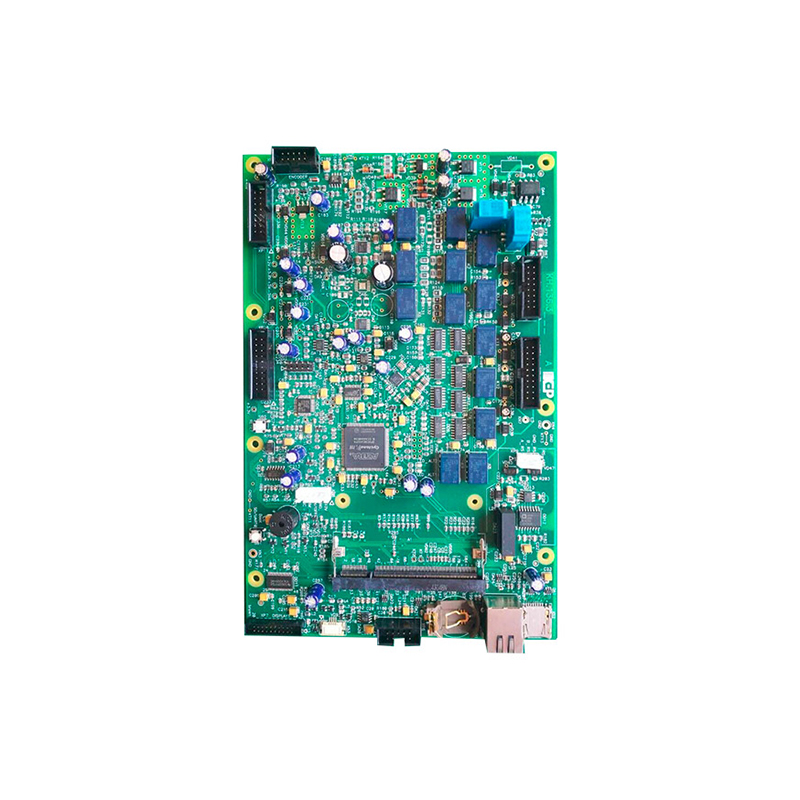

Ukuhlanganiswa kwe-Surface Mount technology (SMT).iyindlela esetshenziswa kakhulu embonini yezogesi. Kubandakanya ukukhweza izingxenye ngqo phezu kwebhodi lesifunda eliphrintiwe (PCB). Izingxenye ezisetshenziswa ekuhlanganiseni kwe-SMT zincane futhi zilula kunalezo ezisetshenziswa ekuhlanganisweni kwemigodi. Izingxenye ze-SMT zinamatheminali ensimbi noma imikhondo ngaphansi edayiswa ebusweni be-PCB.

Enye yezinzuzo ezibalulekile zomhlangano we-SMT ukusebenza kahle kwayo.Asikho isidingo sokubhoboza izimbobo ku-PCB njengoba izingxenye zifakwe ngqo endaweni yebhodi. Lokhu kubangela izikhathi zokukhiqiza ngokushesha kanye nokusebenza kahle okukhulu. Ukuhlanganiswa kwe-SMT nakho kubiza kakhulu njengoba kunciphisa inani lempahla eluhlaza edingekayo ku-PCB.

Ukwengeza, umhlangano we-SMT unika amandla ukuminyana kwengxenye ephezulu ku-PCB.Ngezinto ezincane, onjiniyela bangaklama amadivaysi e-elekthronikhi amancane, ahlangene kakhudlwana. Lokhu kuwusizo ikakhulukazi ezimbonini lapho isikhala sincane, njengomakhalekhukhwini.

Kodwa-ke, umhlangano we-SMT unemikhawulo yawo.Isibonelo, ingase ingafaneleki izingxenye ezidinga amandla aphezulu noma ezingaphansi kokudlidliza okunamandla. Izingxenye ze-SMT zisengozini yokucindezelwa yimishini, futhi usayizi wazo omncane ungakhawulela ukusebenza kwazo kagesi. Ngakho-ke kumaphrojekthi adinga amandla aphezulu, ukuhlanganisa i- through-hole kungase kube ukukhetha okungcono.

Ngokuhlanganisa imbobo

Ukuhlanganiswa kwemigodikuyindlela endala yokuhlanganisa izingxenye ze-elekthronikhi ezibandakanya ukufaka ingxenye enemithombo emigodini ebhobozwe ku-PCB. Imikhondo ibe isidayiswa kolunye uhlangothi lwebhodi, inikeze isibopho esiqinile semishini. Ama-ssemblies emigodini avame ukusetshenziselwa izingxenye ezidinga amandla aphezulu noma ezingaphansi kokudlidliza okunamandla.

Enye yezinzuzo zokuhlanganisa i- through-hole ukuqina kwayo.Izixhumi ezidayisiwe zivikeleke kakhulu ngokwemishini futhi azingenwa kalula yingcindezi yemishini nokudlidliza. Lokhu kwenza izingxenye zembobo zilungele amaphrojekthi adinga ukuqina namandla aphakeme emishini.

Umhlangano we- through-hole uphinde uvumele ukulungiswa kalula nokushintshwa kwezingxenye.Uma ingxenye yehluleka noma idinga ukuthuthukiswa, ingachithwa kalula futhi ishintshwe ngaphandle kokuthinta yonke isifunda. Lokhu kwenza ukuhlanganisa imbobo kube lula ukwenza i-prototyping kanye nokukhiqizwa kwezinga elincane.

Kodwa-ke, ukuhlanganisa i- through-hole nakho kunezinye izinkinga.Lena inqubo edla isikhathi edinga izimbobo zokumba ku-PCB, enezela esikhathini sokukhiqiza nezindleko. Ukuhlanganisa imbobo ngembobo nakho kukhawulela ukuminyana kwengxenye ku-PCB ngoba kuthatha isikhala esiningi kunomhlangano we-SMT. Lokhu kungaba umkhawulo wamaphrojekthi adinga ukwenziwa kancane noma anezingqinamba zesikhala.

Yikuphi okungcono kakhulu kuphrojekthi yakho?

Ukunquma indlela engcono kakhulu yokuhlanganisa yephrojekthi yakho kuncike ezintweni ezifana nezidingo zensiza kagesi, ukusetshenziswa kwayo okuhlosiwe, umthamo wokukhiqiza, kanye nesabelomali.

Uma udinga ukuminyana okuphezulu kwengxenye, ukwenziwa kancane kanye nokusebenza kahle kwezindleko, ukuhlanganiswa kwe-SMT kungase kube ukukhetha okungcono. Ifanele amaphrojekthi afana nogesi wabathengi lapho usayizi nokuthuthukisa izindleko kubaluleke kakhulu. Umhlangano we-SMT nawo uwufanelekele kahle amaphrojekthi okukhiqiza aphakathi nendawo kuya amakhulu njengoba unikeza izikhathi zokukhiqiza ngokushesha.

Ngakolunye uhlangothi, uma iphrojekthi yakho idinga izidingo zamandla aphezulu, ukuqina, kanye nokulungisa kalula, ukuhlanganisa imbobo kungase kube ukukhetha okungcono kakhulu. Ifanele amaphrojekthi afana nemishini yezimboni noma ugesi wezimoto, lapho ukuqina nokuphila isikhathi eside kuyizici ezibalulekile. Ukuhlanganisa imbobo ngembobo nakho kuyakhethwa kuma-run amancane okukhiqiza kanye ne-prototyping.

Ngokusekelwe ekuhlaziyeni okungenhla, kungaphethwa ngokuthi kokubilipcb SMT umhlangano kanye pcb ngokusebenzisa-hole umhlangano babe izinzuzo zabo siqu kanye nokulinganiselwa.Ukukhetha indlela efanele yephrojekthi yakho kuncike ekuqondeni izidingo ezithile kanye nezidingo zephrojekthi. Ukubonisana nochwepheshe onolwazi noma umhlinzeki wesevisi yokukhiqiza izinto zikagesi kungakusiza wenze isinqumo unolwazi. Ngakho-ke kala okuhle nokubi bese ukhetha indlela yokuhlanganisa esebenza kangcono kuphrojekthi yakho.

I-Shenzhen Capel Technology Co., Ltd. inefekthri yokuhlanganisa i-PCB futhi inikeze le nsizakalo kusukela ngo-2009. Ineminyaka engu-15 yokuhlangenwe nakho okucebile kwephrojekthi, ukugeleza kwenqubo eqinile, amakhono amahle kakhulu obuchwepheshe, imishini ethuthukisiwe ezenzakalelayo, uhlelo oluphelele lokulawula ikhwalithi, futhi iCapel ine ithimba lochwepheshe lochwepheshe ukuze linikeze amakhasimende omhlaba ukunemba okuphezulu, ukujika okusheshayo kwekhwalithi ephezulu kwe-PCB Assemble prototyping. Le mikhiqizo ihlanganisa umhlangano we-PCB oguquguqukayo, umhlangano we-PCB oqinile, umhlangano we-PCB oguquguqukayo, umhlangano we-HDI PCB, umhlangano we-PCB we-high-frequency kanye nomhlangano we-PCB wenqubo ekhethekile. Izinsizakalo zethu zobuchwepheshe ezisabelayo ngaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kuvumela amaklayenti ethu ukuthi abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-24-2023

Emuva