Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngamathiphu angama-20 okonga izindleko we-PCB angakusiza uhlele inqubo yakho yokukhiqiza futhi ekugcineni wandise inzuzo yakho.

Ezweni lanamuhla lokukhiqiza izinto zikagesi ezincintisana kakhulu, ukuthola izindlela zokunciphisa izindleko nokwandisa ukusebenza kahle kubalulekile kunoma yiliphi ibhizinisi. Amabhodi esekethe aphrintiwe (ama-PCB) adlala indima ebalulekile ekusebenzeni kwemishini kagesi, futhi ukwenza kahle izinqubo zawo zokukhiqiza kungaholela ekongeni kwezindleko ezibalulekile.

1. Hlela nokuklama ukusebenza kahle: Isinyathelo sokuqala sokulondoloza izindleko siqala kusukela esigabeni sokuklama.Khuthaza iqembu lakho ukuthi lidizayine ama-PCB ngokusebenza kahle engqondweni, liqinisekisa ukubekwa kwezingxenye ezifanele, ukulandelela umzila, nokunciphisa usayizi webhodi.

2. Lungiselela ukukhetha kwengxenye: Ukukhetha izingxenye ezibizayo ezihlangabezana nezidingo zephrojekthi kungaba nomthelela omkhulu ezindlekweni ze-PCB.Qhathanisa amanani avela kubahlinzeki abahlukene futhi uqinisekise ukuhambisana nomklamo wakho.

3. Nciphisa inani lezendlalelo: Ukunciphisa inani lezendlalelo ze-PCB kunganciphisa kakhulu izindleko zokukhiqiza.Hlaziya umklamo wakho futhi uhlole ukuthi ingabe izendlalelo ezingadingekile zingasuswa ngaphandle kokuphazamisa ukusebenza.

4. Ukuhlanganisa idizayini yakho ye-PCB: Ukufaka iphaneli idizayini yakho ye-PCB kuhlanganisa ukuhlela amakhophi amaningi omklamo ofanayo kuphaneli eyodwa.Ubuchwepheshe buthuthukisa ukusetshenziswa kwezinto futhi bukhuphule ukusebenza kahle kokukhiqiza, okuholela ekongeni kwezindleko.

5. Hlela ukucaciswa kwe-PCB yakho: Qondisa ukucaciswa kuwo wonke umklamo wakho ukuze uzuze ezomnotho zesikali.Le ndlela ikuvumela ukuthi u-ode amanani amakhulu futhi uxoxisane ngamanani angcono nomkhiqizi.

6. Khetha I-Surface Mount Technology (SMT): Izingxenye ze-SMT ngokuvamile zishibhile futhi ziyashesha ukuhlangana kunezinto eziphuma emgodini.Ukushintshela ku-SMT kusiza ukunciphisa izindleko zokukhiqiza ngenkathi kugcinwa ikhwalithi.

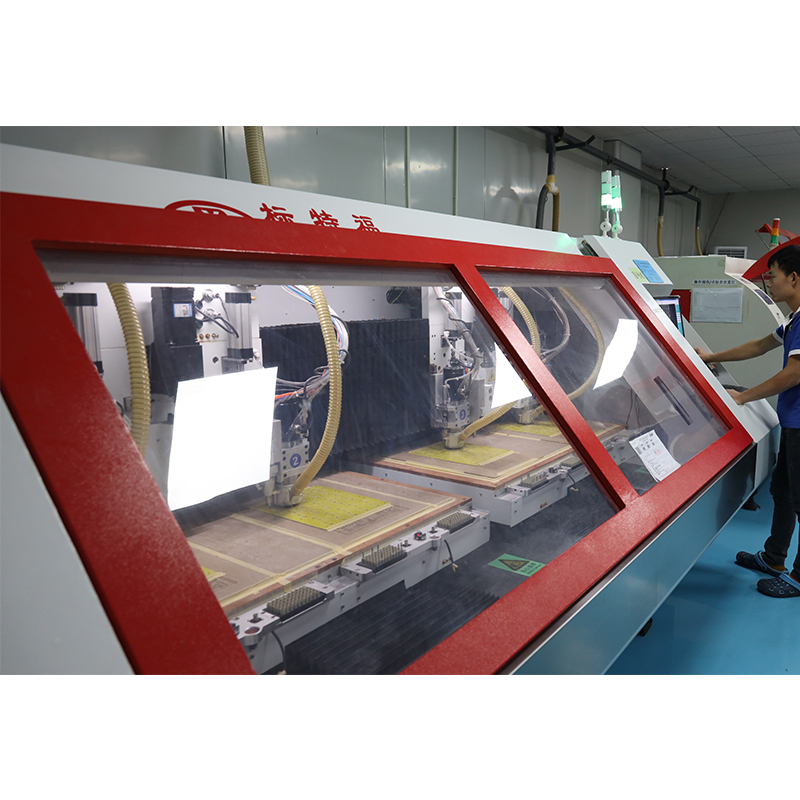

7. Lungiselela ukuhlanganiswa kwe-PCB: Sebenzisana eduze nezimboni zokuhlanganisa ze-PCB ukuze wenze inqubo yokuhlanganisa ibe lula.Ubuchwepheshe obusebenzayo njengemishini yokubeka ezenzakalelayo kanye nama-solder paste stencil angonga isikhathi futhi anciphise amaphutha.

8. Gwema ukubuyekezwa kwedizayini: Ukubuyekezwa kwedizayini okuvamisile kwandisa izindleko ngenxa yesidingo sokusebenza okwengeziwe kokukhiqiza kanye nokumoshakala kwezinto.Qinisekisa ukuqinisekiswa kwedizayini okuphelele ukuze unciphise amathuba okulungiswa.

9. Yenza Ukuhlaziywa Kwedizayini Yezokukhiqiza (DFM): Ukwenza ukuhlaziya kwe-DFM kungabona izinkinga zokukhiqiza ezingaba khona ekuqaleni kwesigaba sokuklama.Ngokubhekana nalezi zinkinga kusenesikhathi, ungavimbela amaphutha abizayo ohlelweni lwakho lokukhiqiza.

10. Sebenzisa isofthiwe Yokuhlola Umthetho Wokuklama (i-DRC): Ukusebenzisa isofthiwe ye-DRC kusiza ukuthola amaphutha omklamo kanye nokwephulwa kwemithetho ngaphambi kokuthumela amafayela okuklama ukuze kwenziwe.Ukulungisa amaphutha kusenesikhathi kungonga isikhathi nemali.

11. Lungiselela amafayela e-Gerber: Lungiselela amafayela akho e-Gerber ukuze uqinisekise ukunemba nokuqeda izici ezingadingekile.Buyekeza kahle amadokhumenti ukuze ugweme amaphutha okukhiqiza abizayo.

12. Hlaziya njalo abahlinzeki-mpahla: Hlala uhlola kabusha abahlinzeki bakho be-PCB ukuze uqinisekise ukuthi uthola ikhwalithi engcono kakhulu ngentengo encintisana kakhulu.Zibandakanye ezingxoxweni zamanani futhi ucabangele abanye abahlinzeki bempahla uma izinketho ezingabizi kakhulu zikhona.

13. Sebenzisa imitapo yolwazi yokuklama: Ukudala imitapo yolwazi yokuklama yezingxenye ezisetshenziswa ngokuvamile kungonga isikhathi futhi kunciphise amaphutha.Ukusebenzisa kabusha izingxenye ezifakazelwe kakade kuqeda isidingo sokuhlolwa kabusha futhi kunciphisa izindleko zokukhiqiza.

14. Cabangela ukushintshwa kwezinto: Cwaninga ezinye izinto ezisetshenziswayo kanye nezindleko zazo ukuze uhlonze izinto ezingashintsha ezingase zehlise zonke izindleko ze-PCB.Qiniseka ukuthi ukushintshwa kuhlangabezana nezidingo zephrojekthi yakho kanye namazinga wekhwalithi.

15. Khetha izinsizakalo ze-PCB ze-turnkey ezithembekile: Abahlinzeki besevisi ye-Turnkey PCB banikeza izixazululo ezibanzi ezihlanganisa ukukhiqizwa kwe-PCB nokuhlanganisa.Ukukhetha umhlinzeki onokwethenjelwa konga isikhathi, kunciphisa izindleko zokuthumela futhi kunciphisa imizamo yokuhlanganisa.

16. Nciphisa izindleko ze-NRE: Izindleko zobunjiniyela obungaphindi (i-NRE) zingaba nomthelela omkhulu ezindlekweni eziphelele zokukhiqizwa kwe-PCB.Hlela inqubo yakho yokukhiqiza futhi ugweme ukuphindaphinda okungadingekile nezinguquko eziletha izindleko ezengeziwe ze-NRE.

17. Khetha isiphetho esilungile se-PCB: Khetha isiphetho esifanele se-PCB ngokusekelwe kuzidingo zakho zephrojekthi kanye nesabelomali.Izinketho ezifana ne-HASL, ENIG, ne-OSP zinikeza izindleko namakhono ahlukahlukene.

18. Khulisa ukusebenza kahle kwamaphaneli: Sebenzisana nabakhiqizi ukuze ukwandise ukusebenza kahle kwamaphaneli ngokuthuthukisa ukwakheka nokuhlelwa kwamaphaneli.Ukusetshenziswa kwamaphaneli okuphumelelayo kunciphisa udoti wezinto ezibonakalayo futhi kwehlisa izindleko.

19. Lungiselela izinqubo zakho zokuhlola: Lungisa izindlela zakho zokuhlola ukuze unciphise izilinganiso zamaphutha nokusebenza kabusha okungadingekile.Ukuhlola okusebenzayo kuqinisekisa ikhwalithi yomkhiqizo ethuthukisiwe kuyilapho kunciphisa izindleko ezihlobene nama-PCB ahlulekile.

20. Yenza lula ukuphathwa kwe-supply chain: Phatha ngempumelelo uchungechunge lwakho lokuhlinzeka ngokuhlanganisa ama-oda, ukukhulisa amazinga e-inventory, kanye nokuhlonza ubambiswano olungase lube khona lokonga nabaphakeli.

Ngokusebenzisa lezi zeluleko zokonga izindleko ze-PCB ezingama-20, ibhizinisi lakho lingehlisa kakhulu izindleko ngaphandle kokubeka engcupheni ikhwalithi.Khumbula ukuthi izidingo zenhlangano ngayinye zingase zehluke, ngakho hlaziya izinqubo zakho, sebenzisana nethimba lakho, bese ukhetha isu elihlangabezana kangcono nemigomo yakho. Ngezinqubo zokukhiqiza ezithuthukisiwe, ungathuthukisa ukuncintisana kwemakethe yakho futhi uzuze ukukhula okuzinzile.

Isikhathi sokuthumela: Oct-12-2023

Emuva