Kule bhulogi, sizohlola izinketho ezihlukahlukene ezitholakalayo zezendlalelo ze-conductive kumabhodi esekethe aguquguqukayo.

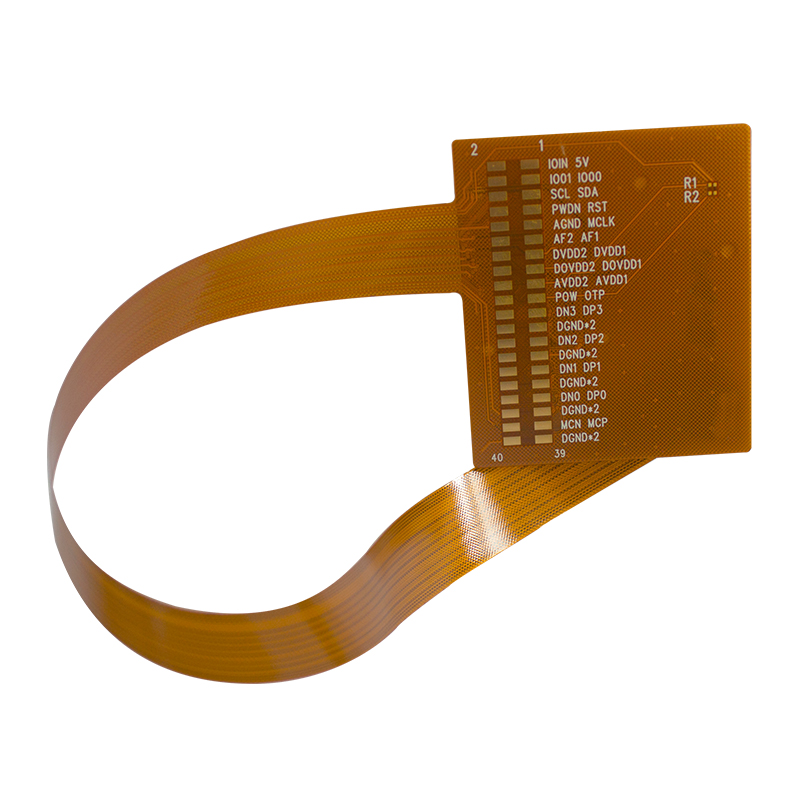

Amabhodi esekethe aguquguqukayo, aziwa nangokuthi amabhodi wesekethe aphrintiwe (ama-PCB) noma izinto zikagesi eziguqukayo, athole ukuduma okukhulu eminyakeni yamuva nje ngenxa yezimpawu zawo ezihlukile kanye nezinzuzo ngaphezu kwama-PCB endabuko aqinile. Ikhono lazo lokugoba, ukusonteka nokugoba lizenza zilungele ukusetshenziswa okubanzi ezimbonini ezifana nezezimoto, i-aerospace, ukunakekelwa kwezempilo kanye nobuchwepheshe obugqokekayo.

Enye yezingxenye ezibalulekile zebhodi lesifunda eliguquguqukayo ungqimba lwalo lokuqhuba. Lezi zingqimba zinesibopho sokudlulisa amasignali kagesi nokwenza lula ukuhamba kukagesi kulo lonke isekethe. Ukukhethwa kwezinto ezisebenzayo zalezi zendlalelo kudlala indima ebalulekile ekusebenzeni okuphelele nokuthembeka kwe-PCB eguquguqukayo.

1. I-copper foil:

I-copper foil iyinto esetshenziswa kakhulu isendlalelo se-conductive kumabhodi wesekethe aguquguqukayo. Ine-conductivity enhle kakhulu, ukuguquguquka nokuqina. Icwecwe lethusi litholakala ngogqinsi oluhlukene, ngokuvamile ama-microns angu-12 kuya kwangu-70, okuvumela abaklami ukuthi bakhethe ukujiya okufanele ngokusekelwe ezindingweni ezithile zohlelo lwabo lokusebenza. I-foil yethusi esetshenziselwa amabhodi wesifunda aguquguqukayo ngokuvamile iphathwa nge-adhesive noma i-ejenti yokubopha ukuze kuqinisekiswe ukunamathela okuqinile ku-substrate eguquguqukayo.

2. Uyinki oqhubayo:

Uyinki we-conductive ungenye inketho yokudala izendlalelo ze-conductive kumabhodi wesekethe aguquguqukayo. Lo uyinki uqukethe izinhlayiya ze-conductive ezimiswe endaweni ewuketshezi, njengamanzi noma i-organic solvent. Ingasetshenziswa kuma-substrates aguquguqukayo kusetshenziswa amasu ahlukahlukene, njengokuphrinta isikrini, ukuphrinta kwe-inkjet noma ukugcotshwa kwesifutho. Ama-inki e-conductive nawo anenzuzo eyengeziwe yokudala amaphethini esekethe ayinkimbinkimbi angenziwa ngokwezifiso ukuze ahlangabezane nezidingo ezithile zokuklama. Kodwa-ke, zingase zingaqhubeki njenge-foil yethusi futhi zingadinga ukumbozwa okwengeziwe kokuzivikela ukuze zithuthukise ukuqina kwazo.

3. Ingcina ye-conductive:

Ama-adhesive e-conductive ayindlela ehlukile yezindlela zendabuko zokuhlanganisa zokudala izendlalelo ze-conductive kumabhodi wesifunda aguquguqukayo. Lezi zinamathiselo ziqukethe izinhlayiya ze-conductive, njengesiliva noma i-carbon, ezihlakazekile ku-polymer resin. Zingasetshenziselwa ukuhlanganisa izingxenye ngokuqondile kuma-substrates aguquguqukayo, ukuqeda isidingo sokuhlanganisa. Ama-adhesive e-conductive aqhuba kahle ugesi futhi angakwazi ukumelana nokugoba nokugoba ngaphandle kokuphazamisa ukusebenza kwesekethe. Kodwa-ke, bangase babe namazinga aphezulu okumelana uma kuqhathaniswa ne-foil yethusi, okungase kuthinte ukusebenza kahle kwesekethe.

4. Ifilimu eyenziwe ngensimbi:

Amafilimu enziwe ngensimbi, afana namafilimu e-aluminium noma esiliva, angasetshenziswa njengezendlalelo ze-conductive kumabhodi esekethe aguquguqukayo. Lawa mafilimu ajwayele ukufakwa ku-vacuum kuma-substrates aguquguqukayo ukuze akhe ungqimba olufana noluqhubekayo lwamakhondatha. Amafilimu ensimbi ane-conductivity enhle kakhulu kagesi futhi angenziwa iphethini kusetshenziswa amasu e-etching noma ama-laser ablation. Kodwa-ke, zingaba nemikhawulo ekuguquguqukeni ngoba izingqimba zensimbi ezifakiwe zingaqhekeka noma zinciphise lapho zigotshwa ngokuphindaphindiwe noma zisontekile.

5. I-Graphene:

I-Graphene, ungqimba olulodwa lwama-athomu ekhabhoni ahlelwe ku-lattice ene-hexagonal, ithathwa njengento ethembisayo yezendlalelo eziqhutshwayo kumabhodi esekethe aguquguqukayo. Ine-conductivity enhle kakhulu kagesi kanye ne-thermal, kanye namandla amahle kakhulu wemishini nokuguquguquka. I-graphene ingasetshenziswa kuma-substrates aguquguqukayo kusetshenziswa izindlela ezihlukahlukene, ezifana nokubeka umhwamuko wamakhemikhali noma ukuphrinta kwe-inkjet. Kodwa-ke, izindleko eziphezulu nobunkimbinkimbi bokukhiqizwa nokucubungula kwe-graphene okwamanje kunciphisa ukusetshenziswa kwayo okusabalele ezinhlelweni zentengiso.

Kafushane, kunezinketho eziningi zezendlalelo eziqhutshwayo kumabhodi wesifunda aguquguqukayo, ngalinye linezinzuzo zalo kanye nokulinganiselwa kwalo. I-copper foil, o-ink abaqhubayo, izinto zokunamathisela ezibambayo, amafilimu enziwe ngensimbi ne-graphene konke kunezakhiwo ezihlukile futhi kungenziwa ngokwezifiso ngokwezidingo ezithile zezinhlelo zokusebenza ezahlukahlukene.Abaqambi nabakhiqizi kufanele bahlole ngokucophelela lezi zinketho futhi bakhethe okokusebenza okufanele kakhulu ngokusekelwe ezintweni ezifana nokusebenza kukagesi, ukuqina, ukuguquguquka, kanye nezindleko.

Isikhathi sokuthumela: Sep-21-2023

Emuva