Embonini yanamuhla yokuncintisana ye-elekthronikhi, kunesidingo esikhulayo samabhodi esekethe aphrintiwe amasha, asebenzayo (ama-PCB). Njengoba imboni ikhula, siyanda nesidingo sama-PCB angakwazi ukumelana nezimo ezihlukahlukene zemvelo futhi ahlangabezane nezidingo zemishini eyinkimbinkimbi kagesi. Yilapho umqondo we-flex rigid-flex PCB ungena khona.

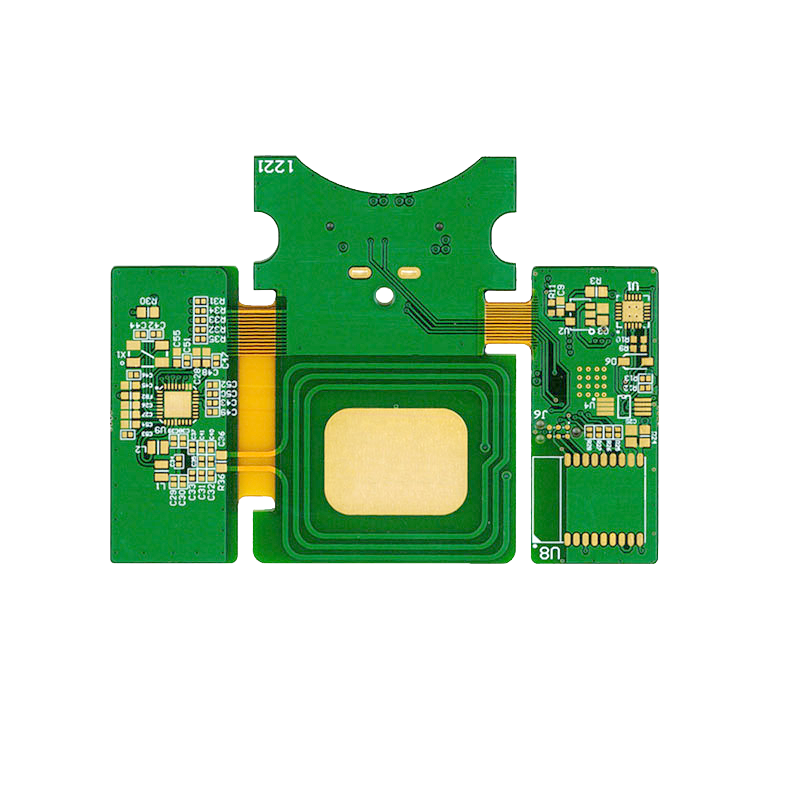

Amabhodi aguquguqukayo aqinile anikeza inhlanganisela eyingqayizivele yezinto eziqinile neziguquguqukayo, azenze zilungele izinhlelo zokusebenza ezidinga ukuqina nokuvumelana nezimo. Lawa mabhodi avame ukutholakala kumishini yezokwelapha, izinhlelo ze-aerospace, nezinye izinhlelo zokusebenza ezithembeke kakhulu.

Ukulawulwa kwe-impedance kuyisici esiyinhloko esithinta kakhulu ukusebenza kwamabhodi aqinile-flex. I-Impedans ukumelana kwesekethe ekunikezayo ekugelezeni kokushintshana kwamanje (AC). Ukulawulwa okufanele kwe-impedance kubalulekile njengoba kuqinisekisa ukudluliswa kwesignali okuthembekile futhi kunciphisa ukulahlekelwa kwamandla.

Kule bhulogi, u-Capel uzohlola izici ezinhlanu ezingase zibe nomthelela omkhulu ekulawuleni i-impedance yamabhodi aguquguqukayo aqinile. Ukuqonda lezi zici kubalulekile kubaklami be-PCB nabakhiqizi ukuletha imikhiqizo yekhwalithi ephezulu ehlangabezana nezidingo zomhlaba wanamuhla oqhutshwa ubuchwepheshe.

1. Ama-substrates ahlukene azothinta inani le-impedance:

Ku-Flex Rigid-Flex PCB, umehluko wezinto eziyisisekelo unomthelela enani lokuvimbela. Emabhodini aguquguqukayo aqinile, i-substrate eguquguqukayo kanye ne-substrate eqinile ivamise ukuba nama-conductivity e-dielectric ahlukene kanye ne-conductivity, okuzodala izinkinga zokungafani kwe-impedance kusixhumi esibonakalayo phakathi kwama-substrates amabili.

Ngokukhethekile, ama-substrates aguquguqukayo ane-dielectric ephezulu engaguquki futhi ephansi conductivity kagesi, kuyilapho substrates aqinile ane-dielectric engaguquki ephansi kanye conductivity kagesi ephakeme. Lapho isignali isakazeka ebhodini lesifunda eliguquguqukayo, kuyoba khona ukubonakaliswa nokudluliselwa ekuxhumaneni kwe-substrate ye-pcb eqinile-eguquguqukayo. Lezi zenzakalo zokubonisa nokudluliswa zenza ukuthi i-impedance yesiginali ishintshe, okungukuthi, ukungafani kokuphazamiseka.

Ukuze ulawule kangcono i-impedance ye-flex-rigid pcb, izindlela ezilandelayo zingathathwa:

Ukukhetha kwe-substrate:khetha inhlanganisela ye-rigid flex circuit substrates ukuze i-dielectric njalo kanye ne-conductivity ibe eduze ngangokunokwenzeka ukuze kuncishiswe inkinga yokungahambisani kahle kwe-impedance;

Ukwelashwa kwesixhumi esibonakalayo:ukwelashwa okukhethekile kokuxhumana phakathi kwe-pcb rigid flex substrates, njengokusebenzisa isendlalelo esibonakalayo esikhethekile noma ifilimu elaminethiwe, ukuze kuthuthukiswe ukufaniswa kwe-impedance ngezinga elithile;

Ukulawula ukucindezela:Enqubweni yokukhiqiza ye-pcb eguquguqukayo eqinile, imingcele efana nezinga lokushisa, ingcindezi kanye nesikhathi kulawulwa ngokuqinile ukuze kuqinisekiswe ukuhlangana okuhle kwama-substrates ebhodi le-flex eqinile futhi kunciphise izinguquko ze-impedance;

Ukulingisa nokulungisa iphutha:Ngokulingisa nokuhlaziya ukusakazeka kwesignali ku-pcb eqinile eguquguqukayo, thola inkinga yokungafani kwe-impedance, futhi wenze izinguquko ezihambisanayo nokulungiselelwa.

2. Isikhala sobubanzi bomugqa siyisici esibalulekile esithinta ukulawulwa kwe-impedance:

Ebhodini eliguquguqukayo eliqinile, isikhala sobubanzi bomugqa singenye yezinto ezibalulekile ezithinta ukulawulwa kwe-impedance. Ububanzi bomugqa (okungukuthi ububanzi bentambo) kanye nesikhala selayini (okungukuthi ibanga phakathi kwezintambo eziseduze) kunquma ijometri yendlela yamanje, okubuye kube nomthelela kuzimpawu zokudlulisela kanye nenani lokuvimbela isignali.

Okulandelayo umthelela wesikhala sobubanzi bomugqa ku-impedance control yebhodi eliguquguqukayo eliqinile:

I-Impedance Eyisisekelo:Isikhala somugqa sibalulekile ekulawuleni okuthikamezekile okuyisisekelo (okungukuthi, isici esivimbelayo semigqa ye-microstrip, izintambo ezingamakhoaxial, njll.). Ngokusho kwethiyori yomugqa wokudlulisela, izici ezifana nobubanzi bomugqa, isikhala somugqa, nogqinsi lwe-substrate ngokuhlanganyela zinquma isici sokuvimbela umugqa wokudlulisela. Lapho isikhala sobubanzi bomugqa sishintsha, sizoholela ekushintsheni kwesici, ngaleyo ndlela kuthinte umphumela wokudlulisela wesiginali.

Ukufanisa i-impedance:Ukufaniswa kwe-impedance kuvame ukudingeka kumabhodi aqinile-flex ukuze kuqinisekiswe ukudluliswa okuhle kwamasiginali kuyo yonke isekethe. Ukufaniswa kokuphazamiseka ngokuvamile kudinga ukulungisa isikhala sobubanzi bomugqa ukuze kufinyelelwe. Isibonelo, kulayini we-microstrip, i-impedance yesici yolayini wokudlulisela ingafaniswa nokuvimbela okudingwa isistimu ngokulungisa ububanzi bamakholi kanye nesikhala phakathi kwamakhondaktha aseduze.

I-Crosstalk kanye nokulahlekelwa:Ukuhlukaniswa kwemigqa nakho kunomthelela obalulekile ekulawulweni kwe-crosstalk nokulahlekelwa. Uma isikhala sobubanzi bomugqa sisincane, umphumela wokuhlanganisa insimu kagesi phakathi kwezintambo eziseduze uyathuthukiswa, okungase kuholele ekwandeni kwe-crosstalk. Ngaphezu kwalokho, ububanzi bezintambo ezincane kanye nezikhala ezinkulu zezintambo kubangela ukusabalalisa kwamanje okugxilile, okwandisa ukumelana nokulahlekelwa kwezintambo.

3. Ubukhulu bezinto ezibonakalayo nakho kuyisici esibalulekile esithinta ukulawulwa kwe-impedance yebhodi eliguquguqukayo eliqinile:

Ukwehluka kogqinsi lwempahla kuthinta ngokuqondile isici somugqa wokudlulisela.

Okulandelayo umphumela wokujiya kwezinto ezibonakalayo ekulawuleni i-impedance yamabhodi a-rigid-flex:

Isici somugqa wokudlulisa i-impedance:Ukuphazamiseka kwesici kolayini wokudlulisela kubhekisela ebudlelwaneni obulinganayo phakathi kwamandla amanje kanye ne-voltage kulayini wokudlulisela ngefrikhwensi ethile. Ebhodini eliguquguqukayo eliqinile, ukushuba kwezinto kuzothinta inani lesici sokuvimbela umugqa wokudlulisela. Ngokuvamile, lapho ubukhulu bezinto ezibonakalayo buba buncane, i-impedance yesici izokhula; futhi lapho ubukhulu bezinto ezibonakalayo buyaqina, i-impedance yesici izokwehla. Ngakho-ke, lapho uklama ibhodi eliguquguqukayo eliqinile, kuyadingeka ukukhetha ukujiya kwezinto ezifanele ukuze kuzuzwe i-impedance yesici edingekayo ngokuya ngezidingo zesistimu nezici zokudlulisa isignali.

Isilinganiso somugqa ukuya emkhathini:Ukwehluka kokujiya kwempahla kuzophinde kuthinte isilinganiso somugqa ukuya-kusikhala. Ngokusho kwethiyori yomugqa wokudlulisela, i-impedance yesici ilingana nenani lobubanzi bomugqa nendawo. Lapho ubukhulu bezinto ezibonakalayo bushintsha, ukuze kugcinwe ukuzinza kwesici se-impedance, kuyadingeka ukulungisa isilinganiso sobubanzi bomugqa kanye nesikhala somugqa ngokufanele. Isibonelo, lapho ubukhulu bezinto ezibonakalayo buncishisiwe, ukuze kugcinwe isici esivimbelayo singaguquki, ububanzi bomugqa budinga ukuncishiswa ngokufanele, futhi isikhala somugqa kufanele sincishiswe ngokuhambisanayo ukuze kugcinwe isilinganiso sobubanzi bomugqa nesikhala singashintshiwe.

4. Ukubekezelelwa kwethusi elenziwe nge-electroplated nakho kuyisici esithinta ukulawulwa kwe-impedance yebhodi eliqinile eliguquguqukayo:

Ithusi elenziwe nge-electroplated ungqimba olusetshenziswayo oluvame ukusetshenziswa kumabhodi aqinile-flex, futhi izinguquko ekugqineni kwawo nokubekezelelana kuzothinta ngokuqondile isici sebhodi.

Okulandelayo umthelela wokubekezelela i-electroplating yethusi ekulawuleni i-impedance yamabhodi aqinile aguquguqukayo:

Ukubekezelela ukujiya kwethusi nge-electroplated:Ugqinsi lwethusi elenziwe nge-electroplated kungenye yezinto ezibalulekile ezithinta i-impedance yebhodi eliguquguqukayo eliqinile. Uma ukubekezelelana kokuqina kwethusi elenziwe nge-electroplated kukhulu kakhulu, ukushuba kwesendlalelo se-conductive epuleti kuzoshintsha, ngaleyo ndlela kuthinte isici se-impedance yepuleti. Ngakho-ke, lapho kukhiqizwa amabhodi aqinile aguquguqukayo, kuyadingeka ukulawula ngokuqinile ukubekezelela ukushuba kwethusi elenziwe nge-electroplated ukuze kuqinisekiswe ukuzinza kwesici se-impedance.

Ukufana kwe-electroplating copper:Ngaphezu kokubekezelela ukushuba, ukufana kwe-electroplating copper kuphinde kuthinte ukulawulwa kwe-impedance kwamabhodi aqinile-flex. Uma kukhona ukusatshalaliswa okungalingani kwesendlalelo sethusi se-electroplated ebhodini, okuholela ekugqimeni okuhlukene kwethusi elenziwe nge-electroplated ezindaweni ezihlukene zebhodi, i-impedance yesici nayo izoshintsha. Ngakho-ke, kuyadingeka ukuqinisekisa ukufana kwethusi elenziwe nge-electroplated ukuze kuqinisekiswe ukuhambisana kwesici sokuvimbela lapho kukhiqizwa amabhodi athambile futhi aqinile.

5. Ukubekezelelana kwe-etching nakho kuyisici esibalulekile esithinta ukulawulwa kwe-impedance kwamabhodi aqinile-flex:

Ukubekezelelana kwe-Etching kubhekisela ekuphambukeni kobukhulu bepuleti elingalawulwa lapho ukuqoshwa kwenziwa ohlelweni lokukhiqiza amabhodi aqinile aqinile.

Okulandelayo imiphumela yokubekezelela okunamathiselwe ekulawuleni i-impedance yamabhodi a-rigid-flex:

Ukumatanisa kokuphazamiseka kwebhodi eliguquguqukayo eliqinile: Enqubweni yokukhiqiza ibhodi eliguquguqukayo eliqinile, i-etching ivame ukusetshenziselwa ukulawula inani le-impedance yesici. Nge-etching, ububanzi besendlalelo se-conductive bungalungiswa ukuze kuzuzwe inani le-impedance elidingwa umklamo. Nokho, phakathi nenqubo etching, kusukela isivinini etching of ikhambi etching on plate kungase kube nokubekezelelana okuthile, kungase kube neziphambeko ububanzi ungqimba conductive ngemva etching, okuthinta ukulawula okunembile impedance isici.

Ukungaguquguquki ekubambeni kwesici:Ukubekezelelwa kwe-etching kungaphinda kuholele kumehluko kugqinsi longqimba lwe-conductive ezifundeni ezihlukene, okuholela ekubambeni kwesici okungahambisani. Ukungahambisani kwesici se-impedance kungase kuthinte ukusebenza kokudluliselwa kwesignali, okubaluleke kakhulu ekuxhumaneni kwesivinini esiphezulu noma izinhlelo zokusebenza ze-high-frequency.

Ukulawulwa kwe-impedance kuyisici esibalulekile sokuklama nokwenziwa kwe-Flex Rigid-Flex PCB.Ukuthola amanani anembile futhi angaguquguquki e-impedance kubalulekile ekudluliselweni kwesignali okuthembekile kanye nokusebenza okuphelele kwamadivayisi kagesi.Ngakho-ke ngokunaka kakhulu ukukhetha kwe-substrate, i-trace geometry, ukujiya kwe-dielectric okulawulwayo, ukubekezelelana kwe-copper plating, nokubekezelelana kwe-etch, abaklami be-PCB nabakhiqizi bangaletha ngempumelelo amabhodi aqinile, asezingeni eliphezulu aqinile ahlangabezana nezidingo eziqinile zomkhakha. Iminyaka engu-15 yokwabelana ngolwazi lwemboni, ngithemba ukuthi u-Capel angakulethela usizo oluwusizo. Ngeminye imibuzo yebhodi lesifunda, sicela usithinte ngokuqondile, ithimba lochwepheshe bebhodi lesifunda laseCapel lizokuphendula nge-inthanethi.

Isikhathi sokuthumela: Aug-22-2023

Emuva