Indlela yokuphatha ngempumelelo ukungqubuzana phakathi kwezintambo zangaphakathi noxhumo lwangaphandle lwephedi kumabhodi esekethe aphrintelwe izendlalelo eziningi?

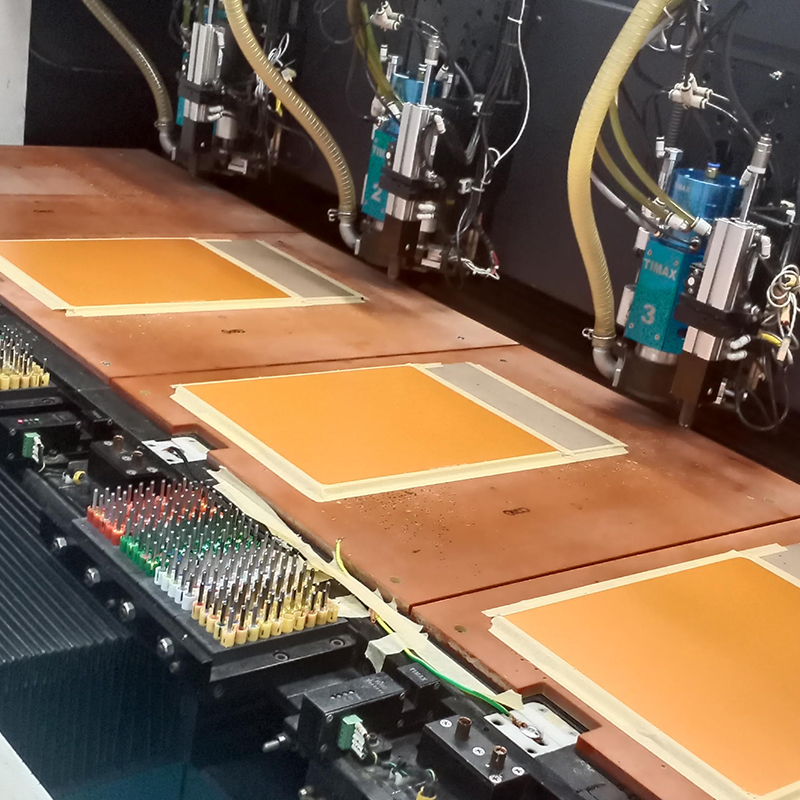

Emhlabeni wezogesi, amabhodi esekethe aphrintiwe (ama-PCB) awulayini wezempilo oxhumanisa izingxenye ezihlukahlukene, okuvumela ukuxhumana nokusebenza okungenazihibe. Ama-PCB anezingqimba eziningi, ikakhulukazi, aya ngokuya aduma ngenxa yokusebenza kwawo okuthuthukisiwe kanye nokuminyana kwengxenye ephezulu. Kodwa-ke, ubunkimbinkimbi babo budala inselele yokulawula ukungqubuzana phakathi kwemigqa yangaphakathi kanye nokuxhumeka kwamaphedi angaphandle.Kule bhulogi, sizohlola amasu asebenzayo okusingatha lokhu kungqubuzana futhi siqinisekise ukusebenza kahle nokwethembeka.

1. Qonda ukungqubuzana:

Ukuze uxazulule ngempumelelo noma iyiphi inkinga, kubalulekile ukuqonda imbangela yayo. Ukungqubuzana phakathi kwemigqa yangaphakathi kanye nokuxhumeka kwephedi yangaphandle kuvela ngenxa yezidingo zabo ezihlukene. Ukulandela umkhondo kwangaphakathi kudinga ububanzi obuncane kanye nesikhala somzila ominyana kakhulu, kuyilapho amaphedi angaphandle adinga osayizi abakhulu bokunamathisela izingxenye kanye noxhumo olubonakalayo. Ukungqubuzana phakathi kwalezi zidingo kungaholela ezinkingeni ezihlukahlukene, njengokulahlekelwa ubuqotho besignali, ukukhiqiza ukushisa okukhulu, ngisho nezikhindi zikagesi. Ukubona nokuqonda lokhu kungqubuzana kuyisinyathelo sokuqala sokuthola isisombululo.

2. Lungiselela idizayini:

Ukhiye wokulawula ukungqubuzana usekuthuthukiseni ukwakheka kwama-PCB anezingqimba eziningi. Lokhu kungafezwa ngamasu alandelayo:

- Ukuhlela isitaki ngokucophelela:Isitaki esicatshangelwe kahle sibalulekile ekulinganiseni izidingo zamathrekhi angaphakathi namaphedi angaphandle. Ukubeka izendlalelo zesignali yangaphakathi eduze nendiza emaphakathi yesitaki se-PCB kuvumela ukuthintana okulawulwayo kanye nobuqotho besignali engcono. Ngakolunye uhlangothi, ukubeka amaphedi angaphandle kungqimba lwangaphandle kunikeza ukufinyeleleka okungcono kwengxenye.

- Izindlela zokufaka izintambo ezifanele:Sebenzisa amasu okufaka izintambo njengama-microvias kanye ne-blind vias ukuxhuma imigqa yangaphakathi kumaphedi angaphandle. I-diameter encane ye-microvia inikeza ukuminyana okuphezulu komzila ngaphandle kokuphazamisa ikhwalithi yesignali. I-Vis eyimpumputhe ixhuma kuphela izendlalelo ezimbalwa ezincikene, inikeze imikhondo yangaphakathi indlela eqondile yamaphedi angaphandle ngaphandle kokudabula sonke isitaki se-PCB.

- Ukucatshangelwa okufanayo kokuphazamiseka:Ukungafani kokuphazamiseka phakathi kwemigqa yangaphakathi namaphedi angaphandle kungase kubangele ukubonakaliswa kwesignali kanye nokwehla kokusebenza. Sebenzisa amasu okufanisa okuvimbayo afana nokungaguquki kwe-dielectric elawulwayo, ububanzi bokulandelela okulungiselelwe, nokunqanyulwa okufanele ukuze uqinisekise amasignali angaguquki kuyo yonke i-PCB.

- Ukuphathwa kwe-Thermal:Ukupholisa okwanele kubalulekile ekusebenzeni okuthembekile kwe-PCB. Dizayina ama-PCB anama-avas ashisayo ukuze adlulise kahle ukushisa okukhiqizwa izingxenye eziseduze namaphedi angaphandle kuzendlalelo zangaphakathi.

3. Ukusebenzisana nokuxhumana:

Ukuphatha izingxabano ekwakhiweni kwe-PCB kuvame ukudinga ukusebenzisana phakathi kwababambe iqhaza abahlukene, njengonjiniyela bokuklama, abakhiqizi be-PCB, nochwepheshe bomhlangano. Ukugcina iziteshi zokuxhumana ezisebenzayo kubalulekile ekuqinisekiseni ukuthi wonke umuntu uyaziqonda izingqinamba nezidingo zedizayini. Imihlangano evamile nezingxoxo zingasiza ukuvumelanisa okulindelwe futhi kuxazululwe izingxabano ngokuxazulula izinkinga ngokuhlanganyela.

4. Ukulingisa nokuhlaziya:

Sebenzisa amathuluzi okulingisa nawokuhlaziya ukuze uqinisekise ukusebenza kukagesi kwedizayini yakho, ubuqotho besignali, nezici ezishisayo. Lawa mathuluzi anikeza ukuqonda okuphelele kokuziphatha kwe-PCB, okusiza ukuhlonza izingxabano ezingaba khona kanye nemiklamo yokushuna kahle ngaphambi kokukhiqiza. Ukulingisa futhi kusiza ukuthuthukisa umzila wesignali nokuqinisekisa ukufaniswa kwe-impedance phakathi kwemigqa yangaphakathi namaphedi angaphandle.

5. I-Prototyping kanyeukuhlola:

I-Prototyping nokuhlola kuyizinyathelo ezibalulekile zokuqinisekisa ukusebenza komklamo nokuxazulula noma yiziphi izingxabano ezisele. Ngokuqapha eduze i-PCB ngesikhathi sokuhlolwa, onjiniyela bangakwazi ukuhlonza izindawo lapho izingxabano ziqhubeka khona futhi bathuthukise umklamo. I-Prototyping iphinde inikeze ithuba lokuqinisekisa amasu okuphatha okushisayo nokuqinisekisa ukwethembeka okuphelele kwe-PCB.

Ngokufigqiwe

Ukulawula ukungqubuzana phakathi kokulandela umkhondo wangaphakathi noxhumo lwangaphandle lwamaphedi kuma-PCB anezingqimba eziningi kudinga indlela ephelele ehlanganisa izinqubo zokuklama ezithuthukisiwe, ukuxhumana okuphumelelayo, amathuluzi okulingisa nawokuhlaziya, nokuhlola okuphelele. Ngokuqonda izimbangela zokungqubuzana nokusebenzisa amasu okukhulunywe ngawo, ungafinyelela umklamo olinganiselayo oqinisekisa ukusebenza okuphelele, ukwethembeka, nokusebenza kwe-PCB yakho yezinhlaka eziningi.

Isikhathi sokuthumela: Sep-26-2023

Emuva