Ungaqinisekisa kanjani ukuhlanganiswa kanye nekhwalithi yokushisela yamabhodi aneziyingi eziningi futhi ugweme ukuqhekeka kwe-welding kanye nezinkinga zokuchithwa kwe-pad?

Njengoba isidingo semishini ye-elekthronikhi siqhubeka sikhula, isidingo samabhodi wezifunda ezinokwethenjelwa nezisezingeni eliphezulu sesibucayi. Lawa mabhodi esekethe adlala indima ebalulekile ekuqinisekiseni ukusebenza kahle kwemishini kagesi. Kodwa-ke, ngesikhathi somhlangano kanye nenqubo ye-welding yamabhodi wesifunda anezingqimba eziningi, uma kungenziwanga kahle, izinkinga ezifana nokuqhekeka kwe-welding kanye nokuxebuka kwe-pad kungase kwenzeke. Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngezindlela ezisebenzayo zokuqinisekisa ikhwalithi yokuhlangana kwebhodi lezifunda eziningi kanye nokunamathisela futhi kuvimbele ukuthi lezi zinkinga zingenzeki.

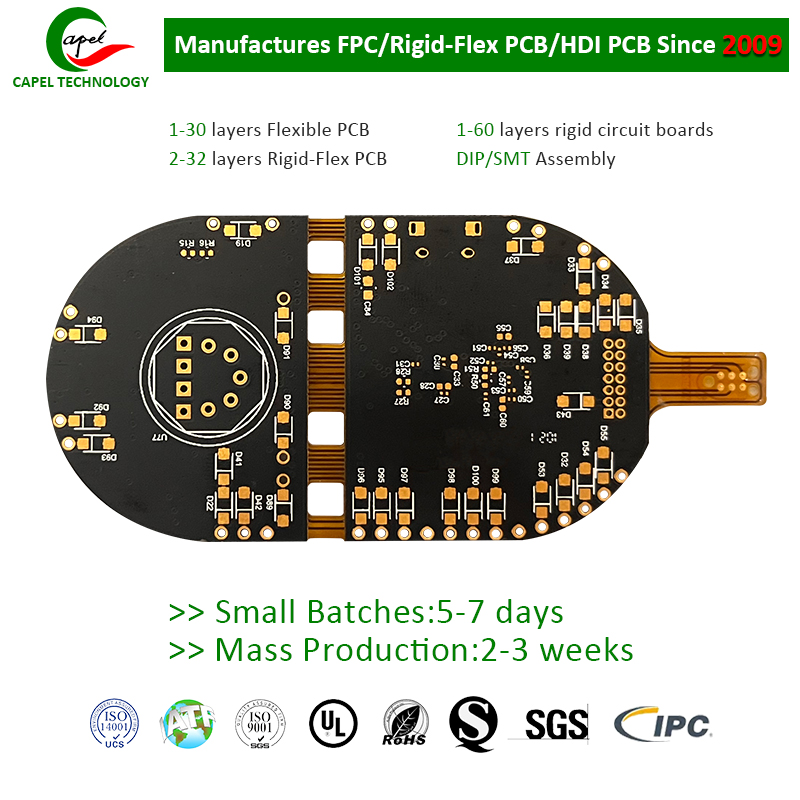

I-Capel yinkampani eneminyaka engu-15 yesipiliyoni sephrojekthi kanye nobuchwepheshe bembonini yobungcweti. Ngeqembu eliqinile kanye nemishini emihle kakhulu ezenzakalelayo, sebengumkhiqizi othembekile embonini. Amasu abo okukhiqiza aqinile nasezingeni eliphezulu ahlanganiswe namandla enqubo athuthukile abenza bakwazi ukukhiqiza amabhodi esekethe asezingeni eliphezulu, anemisebenzi eminingi.

Ukuze uqinisekise ikhwalithi yokuhlanganisa kanye nokushisela kwamabhodi esekethe amaningi, lezi zinyathelo ezibalulekile ezilandelayo kufanele zilandelwe:

1. Khetha impahla efanele:Ukukhethwa kwempahla kubalulekile ekunqumeni ikhwalithi iyonke yebhodi lesifunda. Khetha izinto zokusetshenziswa zekhwalithi ephezulu ezihlangabezana namazinga adingekayo. Lokhu kuzosiza ekuvimbeleni izinkinga ezihambisana nokuqhekeka kwe-solder kanye ne-pad detachment.

2. Ukulawulwa kwekhwalithi kuzo zonke izigaba:Sebenzisa uhlelo oluqinile lokulawula ikhwalithi oluhlanganisa zonke izigaba zenqubo yokukhiqiza. Lokhu kubandakanya ukuhlola izinto ezingenayo, ukuqapha inqubo yokukhiqiza kanye nokuhlola kahle umkhiqizo wokugcina. Ukuhlola okuvamile kungasiza ekutholeni noma yiziphi izinkinga ezingase zibe khona noma izinkinga kusenesikhathi, kunciphise amathuba okuqhekeka kwe-solder kanye nezinkinga zamaphedi e-debonded.

3. Ukugcinwa nokuphatha ngendlela efanele:Ukugcinwa nokuphathwa ngendlela efanele kwamabhodi esekethe kubalulekile ekugcineni ubuqotho bawo. Qinisekisa ukuthi amabhodi esekethe agcinwa endaweni elawulwayo enomswakama owanele kanye nezinga lokushisa. Ziphathe ngokucophelela ukuze ugweme noma yimuphi umonakalo ongase ubangele imifantu ye-solder noma amaphedi awe.

4. Idizayini enembile nesakhiwo:Landela idizayini ejwayelekile kanye nemihlahlandlela yesakhiwo ukuze uqinisekise ukusebenza okufanele nokuthembeka kwebhodi. Isakhiwo esiklanywe kahle singanciphisa ukucindezeleka ezingxenyeni ngesikhathi sokuhlanganiswa nokushisela, ngaleyo ndlela kunciphise ithuba lokuqhekeka noma ukuhlukaniswa.

5. Izindlela ezingcono kakhulu zokuhlanganisa:Sebenzisa amasu okuhlanganisa afanele ahambisana nezidingo ezithile zebhodi. Cabangela izici ezifana nosayizi wengxenye, indlela ye-soldering kanye nephrofayili yokugeleza kabusha ukuze uqinisekise ukuhlangana okuqinile nokuthembekile kwe-solder. Ukulawula izinga lokushisa okufanele ngesikhathi sokushisela kubalulekile ekuvimbeleni ukuqhekeka nokuxebuka.

6. Ukuhlola okuphelele:Ukuhlolwa okuphelele kwebhodi lesifunda elihlanganisiwe ukuze kuqinisekiswe ukusebenza kwalo nekhwalithi. Lokhu kuhlanganisa ukuhlolwa kukagesi, ukuhlola ukusebenza nokuhlola ukwethembeka. Ukuhlola kusiza ukukhomba noma yiziphi izinkinga ezingase zenzeke phakathi nokuhlanganisa nokuhlanganisa ukuze kuthathwe izinyathelo zokulungisa ngaphambi kokuba ibhodi lifinyelele kumsebenzisi wokugcina.

Ngokunamathela kule mihlahlandlela, abakhiqizi bangathuthukisa kakhulu ikhwalithi yokuhlanganisa amabhodi amaningi kanye ne-soldering. Indlela kaCapel eqinile yokuhlangenwe nakho kwebhodi lesifunda iqinisekisa ukuthi izinqubo zabo zokukhiqiza zithuthukiswa ukuze zikhiqize amabhodi esekethe ekhwalithi ephezulu futhi kuncishiswe amathuba okuqhekeka kwe-solder kanye nezindaba zokucwecwa kwephedi.

Ngokufigqiwe,ukuqinisekisa ikhwalithi yokuhlanganisa kanye ne-solder yamabhodi esekethe amaningi kubalulekile ekusebenzeni okuphelele nokuthembeka kwemishini kagesi. Ngokulandela izinyathelo ezingenhla nokukhetha umkhiqizi ohloniphekile onesipiliyoni njengabakhiqizi be-Capel banganciphisa ubungozi bokuqhekeka kwe-solder kanye ne-pad detachment. Ukutshala imali ezintweni ezisezingeni eliphezulu, ukusebenzisa amasistimu okulawula ikhwalithi aqinile, nokusebenzisa amasu okuhlanganisa afanele kubalulekile ekukhiqizeni amabhodi aneziyingi eziningi ezinokwethenjelwa naqinile.

Isikhathi sokuthumela: Oct-01-2023

Emuva