Yethula:

I-prototyping esheshayo ye-PCB, ikakhulukazi ukuhlanganiswa kwezingxenye zephimbo elihle, kudinga ubuchwepheshe nokunemba. Njengoba ubuchwepheshe buqhubeka nokuthuthuka, ukukhiqizwa kwebhodi lesifunda kuba yinkimbinkimbi futhi kufuna kakhulu. Njengoba ineminyaka engaphezu kwengu-15 yokuhlangenwe nakho kulo mkhakha, iCapel iyinkampani ehamba phambili ehlanganisa ubuchwepheshe bezobuchwepheshe kanye nemisha eqhubekayo yokuletha izixazululo ezingenakuqhathaniswa.Kulokhu okuthunyelwe kwebhulogi, sizongena ezindleleni, ezinseleleni, nezindlela ezihamba phambili ze-PCB prototyping esheshayo enezingxenye ezizwakala kahle, kuyilapho sihlola amakhono ka-Capel okukhiqiza angenakuqhathaniswa.

Funda mayelana nezingxenye zephimbo elihle:

Izingxenye ze-Fine-pitch zidlala indima ebalulekile emishinini kagesi yesimanje njengoba zinika amandla ukudluliswa kwesivinini esikhulu, ukwenza kancane, nokusebenza okuthuthukisiwe. Isikhala sephinikhodi salezi zingxenye singaphansi kuka-0.8 mm, okwenza ukubekwa kwazo okunembile ku-PCB kube inselele kakhulu. Ngakho-ke, kubalulekile ukusebenzisa amasu nezindlela ezithile zokuqinisekisa ukuphumelela kwe-prototyping.

Amathuluzi wokuklama we-PCB athuthukisiwe we-prototyping esheshayo:

Ukuze kusetshenziswe ngempumelelo izingxenye ze-pitch-pitch esheshayo ye-PCB prototyping, amathuluzi omklamo we-PCB athuthukisiwe kufanele asetshenziswe. Isofthiwe efana ne-Altium Designer, Ukhozi noma i-KiCad inikeza izici ezifana nokubeka ingxenye enembayo, ukuhlaziya ubuqotho besignali nemisebenzi yomzila ozenzakalelayo, okusiza kakhulu ukwenziwa ngcono kwesakhiwo. Ithimba likaCapel lochwepheshe linekhono ekusebenziseni la mathuluzi ukuze liqinisekise izinga eliphezulu lokunemba phakathi ne-prototyping.

Izinto okufanele uziqaphele lapho ubeka izingxenye zephimbo elihle:

Lapho uklama isakhiwo se-PCB esinezingxenye zephimbo elihle, kubalulekile ukucabangela izici ezithile ukuze kuqinisekiswe ukusebenza okuphelele nokwenziwa. Nazi ezinye izinto ezibalulekile:

1. Idizayini yephedi: Usayizi wephedi nokuma kuwukucatshangelwa okubalulekile kwe-solder efanele kanye nokuxhumana okuhle kagesi nengxenye.Onjiniyela bakwaCapel abanolwazi baklama ngokucophelela amaphedi ngokusekelwe ezidingweni ezithile zezingxenye ze-fine-pitch, ezihlinzeka ngokuthengiswa okuhle kakhulu nokuthembeka.

2. Ukulandela nokudlula: Amasignali anesivinini esiphezulu adlula ezingxenyeni zephimbo elihle adinga umzila ngokucophelela ukuze kuncishiswe umsindo, ukuncishiswa kwesignali, kanye nokungahambisani kahle kokuphazamiseka.Okufanelekile ngokubeka kanye namasu omzila wokulandela umkhondo afana nokufanisa ubude kanye nokuhamba ngakubili okuhlukile kusiza ukugcina ubuqotho besignali.

3. Ukuphathwa kokushisa: Izingxenye ze-Fine-pitch zikhiqiza ukushisa okuningi phakathi nokusebenza.Ukuphatha okushisayo okwanele ngokusetshenziswa kwamasinki okushisa, ama-thermal vents, noma ukubeka ama-thermal pads ngaphansi kwezingxenye kubalulekile ekuvimbeleni ukushisa nokuqinisekisa ukwethembeka kwesikhathi eside.

4. I-Design for Manufacturing (DFM): Sebenzisana nethimba lakwa-Capel elinolwazi ngesikhathi sesigaba sokuklama se-PCB ukuze uqinisekise ukuthi ukukhetha kokuklama kuhambisana namandla abo okukhiqiza.Ukuthuthukisa imiklamo yokwenza kube lula ukusiza ukunciphisa amaphutha e-prototyping futhi kuthuthukise ukusebenza kahle okuphelele kwenqubo.

Izinselelo ze-Prototyping nezisombululo:

Ukwenza i-prototyping esheshayo ye-PCB enezici ezinephimbo elihle kuletha izinselele ezikhethekile. Kodwa-ke, ngolwazi olubanzi lukaCapel kanye nobuchwepheshe obusebenzayo, lezi zinselele zingancishiswa kalula.

1. Ukuthola ingxenye: Izingxenye zephimbo elihle ngokuvamile zinezikhathi zokuhola ezinde noma ukutholakala okulinganiselwe, okwenza ukuthola kwazo kube inselele kakhulu.Inethiwekhi enkulu yabahlinzeki be-Capel kanye nobudlelwano obuqinile buqinisekisa ukufinyelela okufika ngesikhathi ezingxenyeni zekhwalithi ephezulu, okuqinisekisa ukukhiqizwa okungaphazanyiswa.

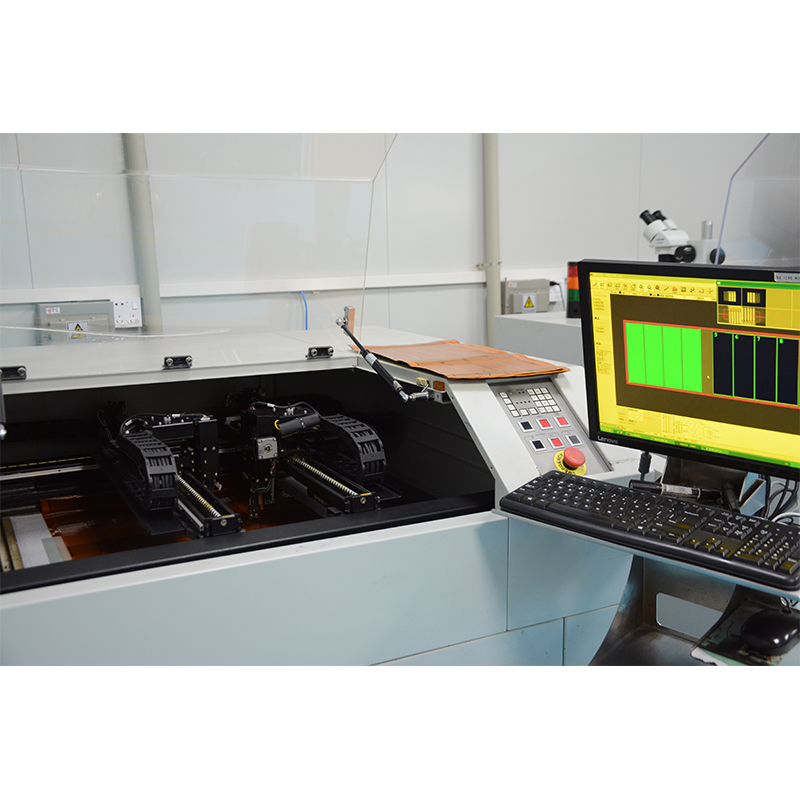

2. Ukushisela: Ukushisela izingxenye ze-pitch emihle kudinga ukunemba okuphezulu.I-Capel isebenzisa ubuchwepheshe bokuhlanganisa obuthuthukisiwe obufana nama-ovens agelezayo anamaphrofayili okushisa alawulwayo, imishini yokubeka ezenzakalelayo kanye nokuhlolwa kwe-solder paste ukuze kuqinisekiswe amajoyini e-solder aphelele.

3. Ukuhlola Nokuhlola: Phakathi nesigaba se-prototyping, ukuhlolwa okuphelele nokuhlolwa kubalulekile ukuze kutholakale amaphutha angenzeka njengamabhuloho athengiswayo, ama-opens, noma amatshe amathuna.U-Capel wenza ukuhlola okuqinile kwekhwalithi esebenzisa i-automated Optical inspection (AOI), ukuhlolwa kwe-X-ray kanye nokuhlola ukuskena komngcele ukuze kuqinisekiswe ukuthi ama-prototypes awanasici.

Amandla okukhiqiza e-Capel angenakuqhathaniswa:

Ukuzibophezela kukaCapel kukhwalithi ephezulu kanye nentuthuko eqhubekayo yezobuchwepheshe kuyenze yaba uzakwethu othembekile embonini yokukhiqiza ye-PCB.Ubuchwepheshe obukhulu benkampani, obuhambisana nezindawo zokukhiqiza ezisezingeni eliphezulu kanye nokubambelela ezindinganisweni zekhwalithi zamazwe ngamazwe, buyenza ikwazi ukunikeza amakhono okukhiqiza angenakuqhathaniswa.

Ekuphetheni:

Ukwenziwa kwe-prototyping okusheshayo kwama-PCB kusetshenziswa izingxenye zephimbo elihle kudinga ulwazi olukhethekile namakhono. Njengoba ineminyaka engu-15 yesipiliyoni, ubuchwepheshe kanye nokuzibophezela emisha eqhubekayo, i-Capel isesimweni esikhethekile sokuhlangabezana nalezi zinselele futhi idlule lokho obekulindelwe.Ukusebenza noCapel kuqinisekisa ama-prototypes angenasici, izinqubo zokukhiqiza eziphumelelayo kanye nokusekelwa okungenakuqhathaniswa kuzo zonke izigaba zephrojekthi. Thembela ochwepheshe bakwa-Capel ukuthi baphile isibonelo sakho se-PCB ngenkathi uhlangabezana nezidingo ezidinga kakhulu embonini yesimanje ye-electronics.

Isikhathi sokuthumela: Oct-18-2023

Emuva