Embonini ye-elekthronikhi esheshayo, isikhathi sivame ukuba yisisekelo lapho siletha imikhiqizo emisha emakethe. Ukukhiqizwa kwe-Rigid-flex PCB (Ibhodi Lesifunda Eliphrintiwe) kuyindawo ethile lapho ukuguqulwa okusheshayo kubaluleke kakhulu. Ukuhlanganisa izinzuzo zama-PCB aqinile futhi aguquguqukayo, lawa mabhodi esekethe athuthukisiwe adumile ngenxa yekhono lawo lokuhlangabezana nezidingo zedizayini ehlangene kanye nokumelana nezimo zemvelo ezinzima.Kulesi sihloko, sizohlola izici ezihlukahlukene ezithinta izindleko zokukhiqiza ama-PCB aguqukayo aqinile.

Ukuhlola okuyisisekelo kwama-PCB aqinile-flex:

Ngaphambi kokungena ezicini zezindleko, kubalulekile ukuqonda izici eziyisisekelo zama-PCB aqinile-flex.

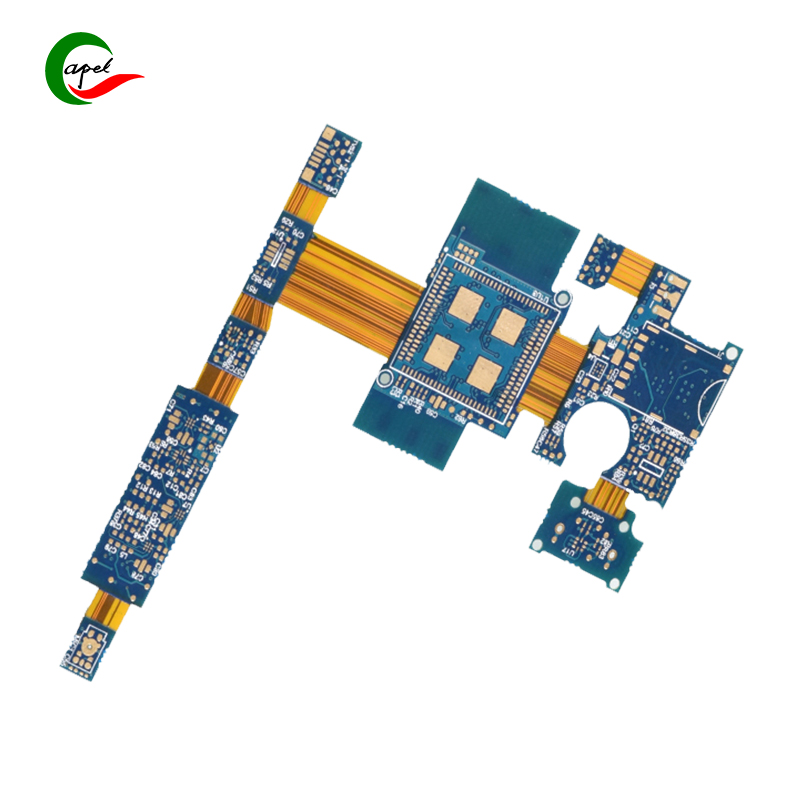

I-PCB eguquguqukayo eqinileiwuhlobo olukhethekile lwebhodi lesifunda elihlanganisa izinto eziqinile neziguquguqukayo ekwakhiweni kwalo. Aklanywe ngezingqimba ezishintshanayo eziqinile nezivumelana nezimo, ezixhunywe imikhondo ne-vias. Le nhlanganisela yenza i-PCB ikwazi ukumelana nokugoba, ukugoqa nokusonteka, ivumela ukubumba okunezinhlangothi ezintathu futhi ingene ezindaweni ezincane noma ezimise ngendlela engavamile.

Ingxenye eqinile yebhodi yenziwe ngezinto ze-PCB eziqinile zendabuko ezifana ne-fiberglass (FR-4) noma i-epoxy eyinhlanganisela. Lezi zingxenye zihlinzeka ngosekelo lwesakhiwo, izingxenye zezindlu, kanye nemikhondo yokuxhuma. Izingxenye eziguquguqukayo, ngakolunye uhlangothi, ngokuvamile zenziwe nge-polyimide noma into efanayo eguquguqukayo engakwazi ukumelana nokugoba okuphindaphindiwe nokugoba ngaphandle kokuphuka noma ukulahlekelwa umsebenzi. I-conductive traces kanye ne-vias exhuma izingqimba ku-PCB eguquguqukayo eqinile nayo iyaguquguquka futhi ingenziwa ngethusi noma ezinye izinsimbi zokuqhuba. Zenzelwe ukudala ukuxhumana kukagesi okudingekayo phakathi kwezingxenye nezingqimba ngenkathi kuhlaliswa i-flex kanye ne-flex yebhodi.

Uma kuqhathaniswa nama-PCB endabuko aqinile, ama-PCB aguquguqukayo anezinzuzo ezimbalwa:

Ukuqina: Inhlanganisela yezinto eziqinile nezivumelana nezimo kwenza ama-PCB aguquguqukayo amelane kakhudlwana nengcindezi yemishini nokudlidliza, kunciphise ubungozi bokulimala noma ukwehluleka ezinhlelweni zokusebenza ezinokunyakaza okuvamile noma ukushaqeka.

Ukonga isikhala: Ama-PCB e-Rigid-flex angagoqwa noma agotshwe abe yizimo ezihlangene, enze ukusetshenziswa kahle kwendawo etholakalayo. Lokhu kuzuzisa kakhulu izinhlelo zokusebenza lapho ubukhulu nesisindo kuyizici ezibalulekile.

Ukuthembeka: Ukuqeda izixhumi nezintambo kusukela kumklamo we-PCB oguquguqukayo kunciphisa inani lamaphuzu angaba khona okuhluleka, ngaleyo ndlela kuthuthukisa ukwethembeka okuphelele. Isakhiwo esihlanganisiwe siphinde sinciphise ingozi yokuphazanyiswa kwesignali noma ukulahlekelwa kokudlulisela. Isisindo esincishisiwe: Ngokususa isidingo sezixhumi ezengeziwe, izintambo, noma izingxenyekazi zekhompuyutha ezikhwezwayo, ama-PCB aguquguqukayo asiza ukwehlisa isisindo sazo zonke izinto zikagesi, azenze zilungele i-aerospace, izimoto, nezinhlelo zokusebenza eziphathwayo.

Izinto Ezibalulekile Ezithinta Izindleko Zokukhiqiza Ezisheshayo I-Rigid Flex PCB:

Kunezici ezimbalwa ezithinta izindleko zizonke zokukhiqiza i-PCB eguqukayo eqinile eguquguqukayo esheshayo:

Ubunkimbinkimbi bomklamo:Ubunkimbinkimbi bomklamo wesifunda kuyisici esibalulekile esithinta izindleko zokukhiqiza zamabhodi aqinile-flex. Imiklamo eyinkimbinkimbi enezendlalelo ezengeziwe, izixhumanisi nezingxenye zidinga izinqubo zokukhiqiza ezinemininingwane eminingi nezinembayo. Lokhu kuyinkimbinkimbi kwandisa umsebenzi kanye nesikhathi esidingekayo ukuze kwenziwe i-PCB, okuholela ezindlekweni eziphezulu.

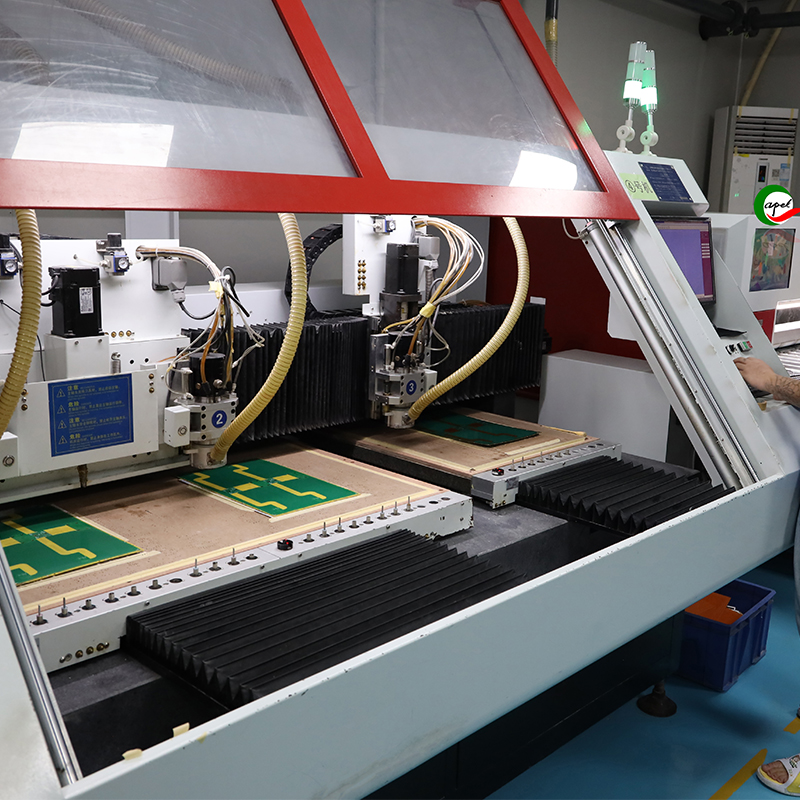

Amamaki amahle nezikhala:Imiklamo yesimanje ye-PCB ivamise ukudinga ukubekezelelana okuqinile, ububanzi obuncane bokulandela umkhondo, kanye nezikhala ezincane zokulandelela ukuze kuhlangatshezwane nokusebenza okwandayo kanye nokwenza kancane. Kodwa-ke, lezi zicaciso zidinga amasu okukhiqiza athuthuke kakhulu, njengemishini enembayo ephezulu kanye namathuluzi akhethekile. Lezi zici zandisa izindleko zokukhiqiza njengoba zidinga ukutshalwa kwezimali okwengeziwe, ubuchwepheshe kanye nesikhathi.

ukukhethwa kwezinto:Ukukhethwa kwe-substrate nezinto zokunamathisela zezingxenye eziqinile neziguquguqukayo ze-PCB nakho kuthinta izindleko zokukhiqiza zizonke. Izinto ezehlukene zinezindleko ezihlukene, ezinye zibiza kakhulu kunezinye. Isibonelo, ukusebenzisa izinto ezisebenza kahle kakhulu njenge-polyimide noma ama-polymer e-crystal ewuketshezi kungathuthukisa ukuqina nokuvumelana nezimo kwama-PCB, kodwa kukhuphule izindleko zokukhiqiza.

Inqubo yokukhiqiza:Isivuno sidlala indima ebalulekile ezindlekweni zokukhiqiza zama-PCB aguquguqukayo. Amanani aphezulu ngokuvamile aholela ezomnotho wesilinganiso, njengoba izindleko ezimisiwe zokusetha inqubo yokukhiqiza zingasatshalaliswa kumayunithi engeziwe, ukunciphisa izindleko zamayunithi. Ngokuphambene, kungase kubize kakhulu ukwenza amaqoqo amancane noma ama-prototypes ngoba izindleko ezigxilile zisakazwa ngenani elincane lamayunithi.

Isikhathi sokushintsha esidingekayo kuma-PCB ngesinye isici esibalulekile esithinta izindleko zokukhiqiza.Izicelo zokushintsha ngokushesha ngokuvamile zidinga izinqubo zokukhiqiza ezisheshayo, ukwanda kwabasebenzi kanye namashejuli okukhiqiza athuthukisiwe. Lezi zici zingase ziphumele ezindlekweni ezengeziwe, ezihlanganisa isikhathi esengeziwe sabasebenzi kanye nezindleko ezisheshisiwe zezinto noma amasevisi.

Amazinga Ekhwalithi Nokuhlolwa:Ukuhlangabezana namazinga athile ekhwalithi (njenge-IPC-A-600 Level 3) kungase kudinge izinyathelo ezengeziwe zokuhlola nokuhlola phakathi nenqubo yokukhiqiza. Lezi zinyathelo zokuqinisekisa ikhwalithi zengeza izindleko ngoba zibandakanya imishini eyengeziwe, abasebenzi kanye nesikhathi. Ukwengeza, izidingo zokuhlola ezikhethekile, ezinjengokuhlolwa kokucindezeleka kwemvelo, ukuhlolwa kwe-impedance, noma ukuhlolwa kokushiswa, kungase kwengeze inkimbinkimbi nezindleko enqubweni yokukhiqiza.

Ukucatshangelwa Kwezindleko Ezengeziwe Lapho Ukhiqiza I-Fast Turn Rigid Flex PCB:

Ngaphezu kwezici eziyinhloko ezingenhla, kunezici zezindleko okufanele zicatshangelwe lapho kukhiqizwa i-turnaround fast rigid-flex

Ama-PCB:

Amasevisi Wobunjiniyela Nokuklama:I-PCB prototyping iyisinyathelo esibalulekile ekuguquleni ngokushesha inqubo yokukhiqiza ye-PCB eguquguqukayo. Ubunkimbinkimbi bomklamo wesekethe kanye nolwazi oludingekayo ukuze kuthuthukiswe umklamo kunomthelela ezindlekweni zobunjiniyela nezinsizakalo zokuklama. Imiklamo eyinkimbinkimbi kakhulu ingase idinge ulwazi olukhethekile nolwazi oluthe xaxa, okwandisa izindleko zalezi zinsizakalo.

Ukuphindaphinda kwedizayini:Phakathi nesigaba sokuklama, ukuphindaphinda okuningi noma ukubuyekezwa kungase kudingeke ukuze kuqinisekiswe ukusebenza nokusebenza kwebhodi eliguquguqukayo eliguquguqukayo. Ukuphindwaphindwa ngakunye komklamo kudinga isikhathi esengeziwe nezinsiza, okwandisa izindleko zokukhiqiza zizonke. Ukunciphisa ukubuyekezwa kwedizayini ngokuhlolwa okuphelele nokusebenzisana nethimba lokuklama kungasiza ekunciphiseni lezi zindleko.

Ukuthengwa kwengxenye:Ukuthola izingxenye ezithile ze-elekthronikhi zamabhodi aqinile-flex kuthinta izindleko zokukhiqiza. Izindleko zengxenye zingahluka kuye ngezici ezifana nokuba yinkimbinkimbi kwayo, ukutholakala kanye nenani elidingekayo. Kwezinye izimo, izingxenye ezikhethekile noma ezenziwe ngokwezifiso zingadingeka, ezingabiza kakhulu futhi zinganyusa izindleko zokukhiqiza.

Ukutholakala Kwengxenye:Ukutholakala nezikhathi zokuhola zezingxenye ezithile zithinta ukuthi i-PCB ingakhiwa ngokushesha kangakanani. Uma izingxenye ezithile zidingeka kakhulu noma zinezikhathi zokuhola ezinde ngenxa yokushoda, lokhu kungase kubambezele inqubo yokukhiqiza futhi kungase kunyuse izindleko. Kubalulekile ukucabangela ukutholakala kwengxenye lapho uhlela amashejuli okukhiqiza kanye nesabelomali.

Ubunkimbinkimbi bomhlangano:Ubunkimbinkimbi bokuhlanganisa nokuhlanganisa izingxenye ze-solder kuma-PCB aqinile-flex futhi kuthinta izindleko zokukhiqiza. Izingxenye ze-fine-pitch kanye namasu okuhlanganisa athuthukile adinga isikhathi esengeziwe nomsebenzi onekhono. Lokhu kungengeza ezindlekweni zokukhiqiza uma ngabe ukuhlanganisa kudinga amathuluzi akhethekile noma ubuchwepheshe. Ukunciphisa ubunkimbinkimbi bomklamo nokwenza lula inqubo yokuhlanganisa kungasiza ekunciphiseni lezi zindleko.

Ukuqedwa kobuso:Ukukhethwa kwe-PCB surface finish nakho kuthinta izindleko zokukhiqiza. Ukwelashwa okuhlukile okungaphezulu, okufana ne-ENIG (Electroless Nickel Immersion Gold) noma i-HASL (Hot Air Solder Leveling), kunezindleko ezihambisanayo ezihlukile. Izinto ezifana nezindleko zempahla, izidingo zemishini, kanye nabasebenzi kungathinta izindleko eziphelele zendawo ekhethiwe. Lezi zindleko kufanele zicatshangelwe lapho kukhethwa indawo efanelekile yokuqedela i-PCB eguquguqukayo eqinile.

ukubala ngalezi zici zezindleko ezengeziwe ekukhiqizweni kwama-PCB aguqukayo aqinile aguquguqukayo kubalulekile ekuqinisekiseni uhlahlomali olusebenzayo kanye nokwenziwa kwezinqumo. Ngokuqonda lezi zici, abakhiqizi bangakwazi ukuthuthukisa ukukhetha kwabo kwedizayini, ukuthola ingxenye, izinqubo zokuhlanganisa, nokukhetha kokuqedwa kwendawo ukuze kukhiqizwe ngendlela eyongayo ngaphandle kokubeka engcupheni ikhwalithi.

Ukukhiqiza ama-PCB aguqukayo aguqukayo aqinile kuhlanganisa izici ezimbalwa ezithinta izindleko zenqubo yokukhiqiza iyonke.Ubunkimbinkimbi bedizayini, ukukhethwa kwempahla, izinqubo zokukhiqiza, izindinganiso zekhwalithi, izinsizakalo zobunjiniyela, ukutholakala kwengxenye nokuba yinkimbinkimbi kokuhlanganisa konke kudlala indima ebalulekile ekunqumeni izindleko zokugcina. Ukuze ulinganisele ngokunembile izindleko zokukhiqiza i-PCB eguqukayo esheshayo eguquguqukayo, kubalulekile ukucabangela zonke lezi zici futhi uxhumane nomqambi onolwazi we-PCB onganikeza isixazululo esilungiselelwe ngenkathi kulinganisa isikhathi, ikhwalithi kanye nezidingo zebhajethi . Ngokuqonda lezi zindleko, izinkampani zingenza izinqumo ezinolwazi zokuthuthukisa izinqubo zazo zokukhiqiza futhi zilethe ngempumelelo imikhiqizo esezingeni eliphezulu emakethe.

I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yokuhlangenwe nakho kwephrojekthi ecebile, ukugeleza kwenqubo okuqinile, amakhono obuchwepheshe asezingeni eliphezulu, okokusebenza okuzenzakalelayo okuthuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe lochwepheshe ukuze anikeze amakhasimende omhlaba ukunemba okuphezulu, izinga eliphezulu le-1-32 layer rigid flex. ibhodi, hdi Rigid Flex Pcb, Rigid Flex Pcb Fabrication, rigid-flex pcb assembly, fast turn rigid flex pcb, ukujika okusheshayo pcb prototypes.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kwenza amakhasimende ethu abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-29-2023

Emuva