Ekwenziweni kwe-elekthronikhi, ukuhlangana kwe-surface mount technology (SMT) kungenye yezinqubo ezibalulekile zokukhiqiza ngempumelelo izinto zikagesi.Umhlangano we-SMT udlala indima ebalulekile kwikhwalithi iyonke, ukwethembeka nokusebenza kahle kwemikhiqizo kagesi. Ukuze sikusize uqonde kangcono futhi ujwayelane nokuhlanganisa kwe-PCB , i-Capel izoholela ekutheni uhlole izinto eziyisisekelo zokwenziwa kabusha kwe-SMT. futhi nixoxe ngokuthi kungani kubaluleke kangaka ekukhiqizeni izinto zikagesi.

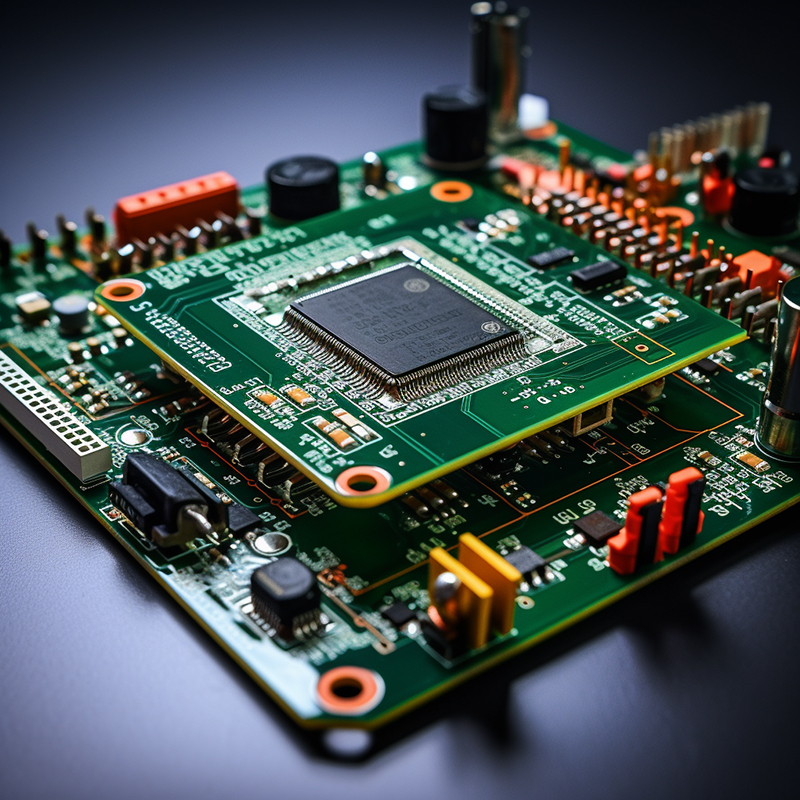

Umhlangano we-SMT, owaziwa nangokuthi umhlangano we-surface mount, uyindlela yokufaka izingxenye ze-elekthronikhi ebusweni bebhodi lesifunda eliphrintiwe (PCB).Ngokungafani nobuchwepheshe bendabuko be- through-hole (THT), obufaka izingxenye ngokusebenzisa izimbobo ku-PCB, ukuhlanganiswa kwe-SMT kuhilela ukubeka izingxenye ngqo phezu kwebhodi. Eminyakeni yamuva nje, lobu buchwepheshe buzuze ukuduma okusabalele ngenxa yezinzuzo zabo eziningi kune-THT, njengokuminyana okuphezulu kwengxenye, usayizi webhodi elincane, ubuqotho besignali obuthuthukisiwe, kanye nokwenyuka kwesivinini sokukhiqiza.

Manje, ake sihlole izinto eziyisisekelo zokuhlanganisa i-SMT.

1. Ukubekwa kwengxenye:Isinyathelo sokuqala sokuhlanganisa i-SMT sibandakanya ukubekwa okunembayo kwezingxenye ze-elekthronikhi ku-PCB. Lokhu kuvame ukwenziwa kusetshenziswa umshini wokukhetha nendawo okhetha ngokuzenzakalelayo izingxenye kumphakeli futhi uzibeke ngokunembile ebhodini. Ukubekwa ngendlela efanele kwezingxenye kubalulekile ekuqinisekiseni ukusebenza okufanele nokuthembeka kwemishini kagesi.

2. Isicelo sokunamathisela i-solder:Ngemva kokukhweza izingxenye, sebenzisa unamathisele we-solder (ingxube yezinhlayiya ze-solder kanye ne-flux) kumaphedi e-PCB. I-solder paste isebenza njenge-adhesive yesikhashana, ibamba izingxenye endaweni ngaphambi kokuhlanganisa. Kuyasiza futhi ukudala ukuxhumana kukagesi phakathi kwengxenye ne-PCB.

3. I-Reflow soldering:Isinyathelo esilandelayo ekuhlanganiseni kwe-SMT i-reflow soldering. Lokhu kuhilela ukushisisa i-PCB ngendlela elawulwayo ukuze kuncibilike unamathisele we-solder bese wenza i-solder ehlala njalo. I-reflow soldering ingenziwa kusetshenziswa izindlela ezahlukahlukene ezifana ne-convection, imisebe ye-infrared noma isigaba somhwamuko. Phakathi nale nqubo, i-solder paste ishintsha ibe yisimo esincibilikisiwe, igeleze ku-component lead kanye nama-PCB pads, futhi iqina ukuze yakhe uxhumano oluqinile lwe-solder.

4. Ukuhlola nokulawula ikhwalithi:Ngemva kokuqedwa kwenqubo yokudambisa, i-PCB izodlula ekuhlolweni okuqinile kanye nezinyathelo zokulawula ikhwalithi ukuze kuqinisekiswe ukuthi zonke izingxenye zibekwe ngendlela efanele futhi amalunga e-solder asezingeni eliphezulu. I-Automated Optical Inspection (AOI) kanye namasu okuhlola ama-X-ray avame ukusetshenziswa ukuze kutholwe noma yikuphi ukonakala noma okudidayo ekuhlanganiseni. Noma yikuphi ukungafani okutholakala ngesikhathi sokuhlolwa kuyalungiswa ngaphambi kokuba i-PCB iye esigabeni esilandelayo sokwenziwa.

Ngakho-ke, kungani ukuhlangana kwe-SMT kubaluleke kangaka ekukhiqizeni izinto zikagesi?

1. Ukusebenza kahle kwezindleko:Umhlangano we-SMT unenzuzo yezindleko kune-THT njengoba unciphisa sonke isikhathi sokukhiqiza futhi wenze inqubo yokukhiqiza ibe lula. Ukusetshenziswa kwemishini ezenzakalelayo yokubekwa kwengxenye kanye ne-soldering kuqinisekisa ukukhiqiza okuphezulu kanye nezindleko eziphansi zabasebenzi, okwenza kube inketho esebenza kahle ngokwezomnotho yokukhiqiza ngobuningi.

2. I-Miaturization:Indlela yokuthuthukiswa kwemishini ye-elekthronikhi incane futhi ihlangene kakhulu. Ukuhlanganiswa kwe-SMT kuvumela ukwenziwa okuncane kwezinto zikagesi ngokukhweza izingxenye ezinonyawo oluncane. Lokhu akugcini nje ngokuthuthukisa ukuphatheka, kodwa futhi kuvula amathuba amasha okuklama kubathuthukisi bomkhiqizo.

3. Ukusebenza okuthuthukisiwe:Njengoba izingxenye ze-SMT zifakwe ngokuqondile endaweni ye-PCB, izindlela zikagesi ezimfushane zivumela ubuqotho besignali engcono futhi zithuthukise ukusebenza kwezinto zikagesi. Ukwehliswa kwe-parasitic capacitance kanye ne-inductance kunciphisa ukulahlekelwa kwesignali, i-crosstalk nomsindo, ukuthuthukisa ukusebenza okuphelele.

4. Ukuminyana kwengxenye ephezulu:Uma kuqhathaniswa ne-THT, umhlangano we-SMT ungafinyelela ukuminyana kwengxenye ephezulu ku-PCB. Lokhu kusho ukuthi imisebenzi eminingi ingahlanganiswa endaweni encane, okuvumela ukuthuthukiswa kwemishini kagesi eyinkimbinkimbi futhi enothile. Lokhu kubaluleke kakhulu ezimbonini lapho isikhala ngokuvamile silinganiselwe, njengomakhalekhukhwini, ugesi wabathengi, kanye nemishini yezokwelapha.

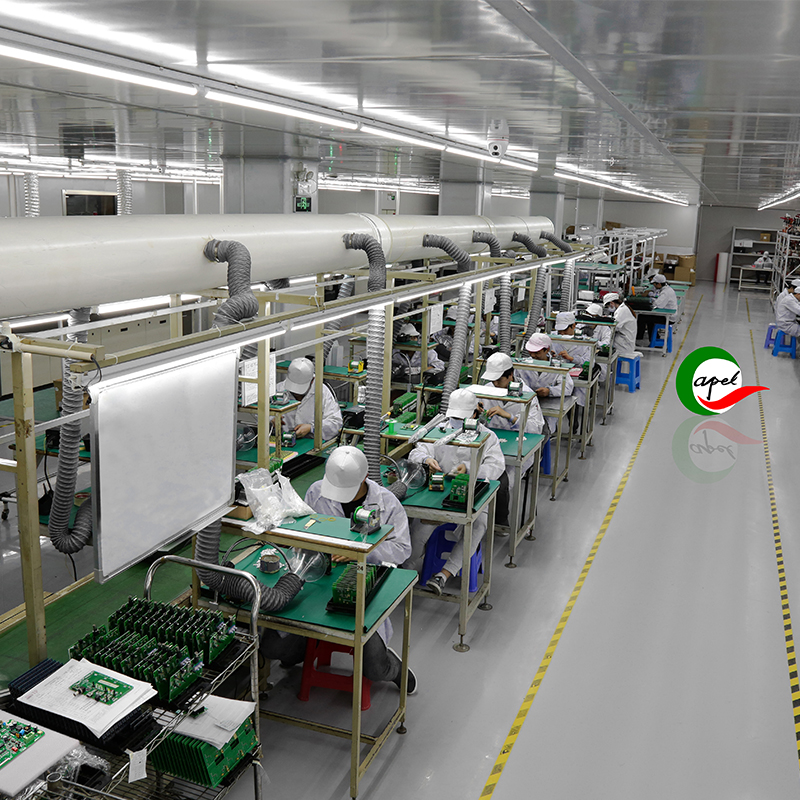

Ngokusekelwe ekuhlaziyeni okungenhla,ukuqonda okuyisisekelo komhlangano we-SMT kubalulekile kunoma ubani ohileleke ekukhiqizeni izinto zikagesi. Umhlangano we-SMT unikeza izinzuzo eziningi kunobuchwepheshe obungokwesiko bokusebenzisa imbobo, okuhlanganisa ukusebenza kahle kwezindleko, amandla okwenza izinto ezincane, ukusebenza okuthuthukisiwe, kanye nokuminyana kwezingxenye eziphezulu. Njengoba isidingo semishini kagesi emincane, esheshayo, futhi enokwethenjelwa kakhudlwana siqhubeka sikhula, umhlangano we-SMT uzodlala indima ebaluleke kakhulu ekuhlangabezaneni nalezi zidingo.I-Shenzhen Capel Technology Co., Ltd. inefekthri yayo yokuhlanganisa i-PCB futhi inikeze le nsizakalo kusukela ngo-2009. Ineminyaka engu-15 yokuhlangenwe nakho okucebile kwephrojekthi, ukugeleza kwenqubo eqinile, amakhono amahle kakhulu obuchwepheshe, imishini ethuthukisiwe ezishintshayo, uhlelo oluphelele lokulawula ikhwalithi, kanye noCapel ithimba lochwepheshe elichwepheshile ukuze linikeze amakhasimende omhlaba ukunemba okuphezulu, ukujika okusheshayo kwekhwalithi ephezulu kwe-PCB Assemble prototyping. Le mikhiqizo ihlanganisa umhlangano we-PCB oguquguqukayo, umhlangano we-PCB oqinile, umhlangano we-PCB oguquguqukayo, umhlangano we-HDI PCB, umhlangano we-PCB we-high-frequency kanye nomhlangano we-PCB wenqubo ekhethekile. Izinsizakalo zethu zobuchwepheshe ezisabelayo ngaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kuvumela amaklayenti ethu ukuthi abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-24-2023

Emuva