I-Delamination ku-PCB ingaholela ezinkingeni zokusebenza ezibalulekile, ikakhulukazi kumiklamo eguquguqukayo eqinile lapho kokubili izinto eziqinile nezivumelana nezimo zihlanganiswa. Ukuqonda indlela yokuvimbela i-delamination kubalulekile ekuqinisekiseni ukuphila isikhathi eside nokuthembeka kwale mihlangano eyinkimbinkimbi. Lesi sihloko sizohlola amathiphu asebenzayo okuvimbela i-PCB delamination, igxile ku-PCB lamination, ukuhambisana kwezinto ezibonakalayo, kanye nemingcele yemishini eyenziwe kahle.

Ukuqonda i-PCB Delamination

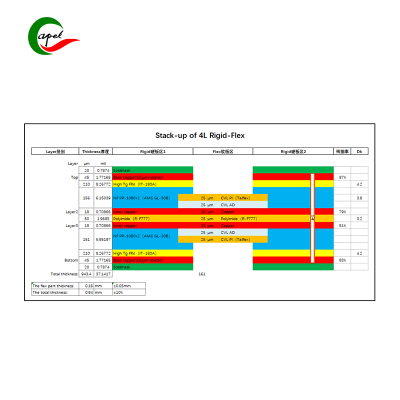

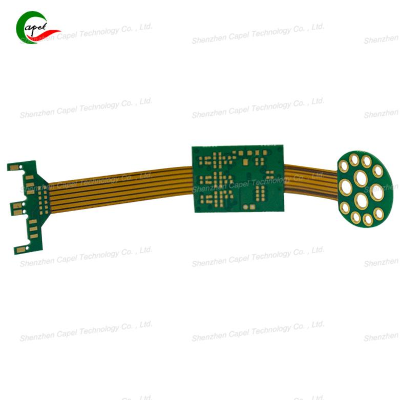

I-Delamination kwenzeka lapho izingqimba ze-PCB zihlukana ngenxa yezici ezihlukahlukene, okuhlanganisa ukucindezelwa kokushisa, ukumuncwa komswakamo, nobunzima bemishini. Kuma-PCB aguquguqukayo aqinile, inselele iyakhula ngenxa yezakhiwo ezihlukene zezinto eziqinile nezivumelana nezimo. Ngakho-ke, ukuqinisekisa ukuhambisana phakathi kwalezi zinto kuyisinyathelo sokuqala sokuvimbela i-delamination.

Qinisekisa Ukuhambisana Kwezinto Ze-PCB

Ukukhetha izinto ezibalulekile kubalulekile ekuvimbeleni i-delamination. Lapho udizayina i-PCB eguquguqukayo eqinile, kubalulekile ukukhetha izinto ezinama-coefficients afanayo wokunweba okushisayo. Lokhu kuhambisana kunciphisa ingcindezi ngesikhathi sokuhamba ngebhayisikili elishisayo, okungaholela ekudaleni. Ukwengeza, cabanga nge-adhesive esetshenziselwa inqubo ye-lamination. Izinamathiselo zekhwalithi ephezulu eziklanyelwe ngokukhethekile izinhlelo zokusebenza eziguquguqukayo zingathuthukisa kakhulu amandla esibopho phakathi kwezendlalelo.

Inqubo ye-PCB Lamination

Inqubo ye-lamination iyisigaba esibalulekile ekukhiqizeni i-PCB. I-lamination efanele iqinisekisa ukuthi izendlalelo zinamathela kahle komunye nomunye, zinciphisa ingozi ye-delamination. Nawa amanye amathiphu asebenzayo we-PCB lamination ephumelelayo:

Ukulawula izinga lokushisa nokucindezela: Qinisekisa ukuthi inqubo yokugcoba iqhutshwa ngezinga lokushisa elifanele nokucindezela. Izinga lokushisa eliphakeme kakhulu lingehlisa izinto, kanti ukucindezela okunganele kungaholela ekunamatheleni okubi.

I-Vacuum Lamination: Ukusebenzisa i-vacuum ngesikhathi senqubo yokugcoba kungasiza ekuqedeni amabhamuza omoya angabangela izindawo ezibuthakathaka kusibopho. Le nqubo iqinisekisa ingcindezi efanayo kakhulu kuzo zonke izendlalelo ze-PCB.

Isikhathi sokuphumula: Vumela isikhathi esanele sokuphulukisa ukuze okunamathelayo kuhlanganiswe kahle. Ukusheshisa le nqubo kungaholela ekunamatheleni okungaphelele, okwandisa ingozi ye-delamination.

Kwenzelwe i-Rigid-Flex PCB Machining Parameters

Amapharamitha womshini adlala indima ebalulekile ekuthembekeni kwama-PCB aguquguqukayo. Nawa amanye amathiphu wokwenza imishini alungiselelwe ukuvimbela i-delamination:

Drilling Techniques: Sebenzisa izingcezu zokubhola ezifanele kanye nesivinini ukuze unciphise ukukhiqiza ukushisa ngesikhathi sokumba. Ukushisa okwedlulele kungenza buthaka isibopho sokunamathela futhi kuholele ekudaleni.

Umzila Nokusika: Uma uthungatha noma usika i-PCB, qinisekisa ukuthi amathuluzi abukhali futhi anakekelwa kahle. Amathuluzi abuthuntu angabangela ukucindezela okukhulu nokushisa, onakalise ubuqotho bezendlalelo.

Ukwelashwa Kwe-Edge: Phatha kahle imiphetho ye-PCB ngemuva komshini. Lokhu kungabandakanya ukwenza bushelelezi noma ukuvala imiphetho ukuvimbela ukungena komswakama, okungaba nomthelela ekuncipheni ngokuhamba kwesikhathi.

Amathiphu Awusizo Okuvimbela Ukuhlukaniswa kwe-PCB

Ngaphezu kwamasu angenhla, cabangela amathiphu asebenzayo alandelayo:

Ukulawulwa Kwemvelo: Gcina ama-PCB endaweni elawulwayo ukuze uvimbele ukumuncwa komswakama. Umswakama ungenza buthaka isibopho sokunamathela futhi kuholele ku-delamination.

Ukuhlola Okuvamile: Qalisa ukuhlolwa okuvamile kwama-PCB ukuze uthole izimpawu zokungabi nalutho ngesikhathi senqubo yokukhiqiza. Ukutholwa kusenesikhathi kungasiza ekwehliseni izinkinga ngaphambi kokuthi zikhule.

Ukuqeqeshwa Nokuqwashisa: Qinisekisa ukuthi bonke abasebenzi abathintekayo ohlelweni lokukhiqiza lwe-PCB baqeqeshelwa izindlela ezingcono kakhulu zokugaya kanye nokwenza imishini. Ukuqwashisa ngezinto ezinomthelela ku-delamination kungaholela ekuthathweni kwezinqumo okungcono.

Isikhathi sokuthumela: Oct-31-2024

Emuva