Amabhodi esekethe e-FPC, aziwa nangokuthi amabhodi esekethe aphrintiwe avumelana nezimo, adlala indima ebalulekile ekusebenzeni kwemishini kagesi. Kusukela kuma-smartphones namalaptop kuya kumishini yezokwelapha nezinhlelo zezimoto, amabhodi e-FPC asetshenziswa ezinhlelweni eziningi. Izinga lala mabhodi wesifunda lithinta ngqo ukusebenza nokuthembeka kwamadivayisi ahlanganiswe kuwo. Ngakho-ke, kubalulekile ukwazi ukuhlonza ikhwalithi yebhodi le-FPC ngaphambi kokulithenga noma ukulihlanganisa emkhiqizweni wakho.Kulokhu okuthunyelwe kwebhulogi, sizoxoxa ngokuthi singanquma kanjani ikhwalithi yamabhodi esekethe e-FPC ngokusekelwe ekubukekeni nasezimfuneko ezithile.

Ukubukeka kwebhodi le-FPC kunganikeza imininingwane ebalulekile ngekhwalithi yayo iyonke. Ngokuhlaziya nokwahlulela lawa mabhodi wesifunda kusuka ezicini ezintathu ezihlukene, ukuhlolwa kokuqala kwekhwalithi yawo kungenziwa.

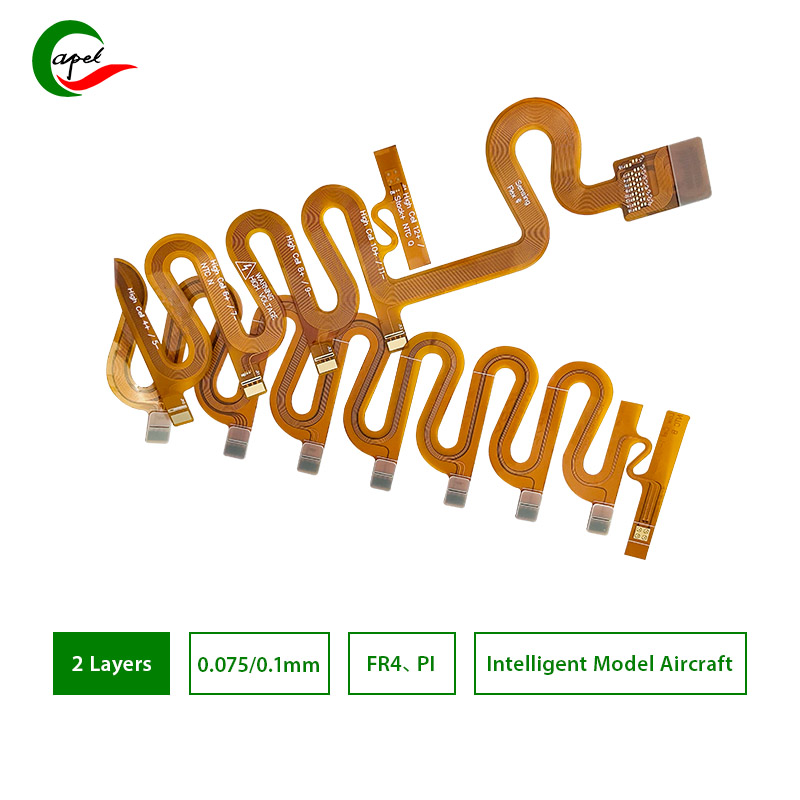

1. Imithetho ejwayelekile yobukhulu nobukhulu

Enye yezinto zokuqala okufanele zicatshangelwe lapho uhlola ukubukeka kwebhodi le-FPC ubukhulu nobukhulu balo. Amabhodi esekethe ajwayelekile anobukhulu obuthile nobukhulu okudingeka kulandelwe. Amakhasimende angakala futhi ahlole ukujiya kanye nokucaciswa kwamabhodi esekethe acabanga ukuwathenga. Noma yikuphi ukuchezuka kubukhulu obujwayelekile nokujiya kungase kubonise izinga eliphansi noma amaphutha okukhiqiza.

2. Ukukhanya nombala

Indawo engaphandle yamabhodi esekethe ye-FPC ivamise ukumbozwa ngoyinki ukuze isebenze njengesivikelo. Ngokubheka umbala nokukhanya kwamabhodi, ungahlola ikhwalithi yokufakelwa. Uma umbala ubonakala ufiphele noma ungekho uyinki owanele ebhodini, okokufaka kungase kungabi kwekhwalithi ephezulu. Ukweqa okunganele kungabangela ukuvuza kukagesi futhi kuphazamise ukusebenza okuphelele kwebhodi lesifunda.

3. Ukubonakala kwe-weld

I-soldering ephumelelayo ibalulekile kumabhodi e-FPC ngoba akhiwe ngezinto eziningi. Uma ingathengiswa kahle, ingxenye ingaphuma kalula ebhodini, engathinta kakhulu izinga layo nokusebenza kwayo. Ngakho-ke, kubalulekile ukuhlola ngokucophelela ukubukeka kwe-soldering yebhodi lesifunda. Ibhodi lesifunda lekhwalithi lizoba namajoyini aqinile, acacile e-solder, ukuqinisekisa ukuxhumana okuthembekile phakathi kwezingxenye.

Nquma ikhwalithi yamabhodi esekethe e-FPC ngokusekelwe ezidingweni ezithile

Ngaphezu kokubukeka, amabhodi esekethe ekhwalithi ephezulu ye-FPC kufanele ahlangabezane nezidingo ezithile ukuze kuqinisekiswe ukusebenza kahle nokuqina. Nazi izimfuneko ezimbalwa ezibalulekile okufanele uzicabangele:

1. Ukuxhunywa kukagesi

Ngemva kokufakwa kwezingxenye, ibhodi lesifunda le-FPC kufanele liqinisekise ukuthi ukuxhunywa kukagesi kuhlangabezana nezindinganiso ezidingekayo. Kufanele kube lula ukuyisebenzisa futhi isebenze ngokuthembekile ngaphandle kwezinkinga zikagesi.

2. Ububanzi bomugqa, ukujiya komugqa, isikhala somugqa

Ububanzi bomugqa, ukujiya komugqa kanye nesikhala somugqa wokulandela umkhondo webhodi lesifunda kuyimingcele ebalulekile. Lezi zici zidinga ukuhlangabezana namazinga adingekayo ukuze kuvinjwe izinkinga ezifana nokushisisa izintambo, amasekhethi avulekile namasekhethi amafushane. Idizayini efanele yomugqa wokukhiqiza kanye nokukhiqiza kungavimbela ukwehluleka futhi kwandise impilo yebhodi lesifunda.

3. Ukunamathela kwesikhumba sethusi

Ithusi ebhodini lesekhethi ye-FPC akufanele lixebuke kalula lapho lichayeke emazingeni okushisa aphezulu. Izinkinga zokunamathela zethusi zingaholela ekuziphatheni okubi futhi zithinte ikhwalithi yonke yebhodi. Ngakho-ke, kuyadingeka ukuqinisekisa ukuthi ishidi lethusi lihlala liqinile ngaphansi kwezimo ezihlukene zokushisa.

4. I-oxidation yendawo yethusi

Ibhodi lesekhethi yekhwalithi ephezulu ye-FPC kufanele ibe nendawo yethusi engamelana ne-oxidation. Lapho ithusi livezwa kumswakama noma umoya-mpilo, i-oxidation iyenzeka, ibangele ungqimba lokugqwala. I-Copper oxide izowohloka ngokushesha futhi yonakalise ukusebenza kwebhodi lakho lesifunda. Ngakho-ke, kubalulekile ukuqinisekisa ukuthi indawo yethusi ivikelwe kahle futhi imelana ne-oxidation.

5. Imisebe ye-electromagnetic

Imishini kagesi ikhipha imisebe ye-electromagnetic engaphazamisa indawo ezungezile. Ibhodi lesekhethi yekhwalithi ephezulu ye-FPC kufanele inciphise imisebe kagesi eyengeziwe ekhiqizwa ibhodi lesekhethi ngokwalo. Lokhu kuqinisekisa ukuthi okokusebenza kusebenza kahle ngaphandle kokudala ukuphazamiseka kwezinye izingxenye ezibucayi noma amasistimu.

6. Ukubukeka kanye nezakhiwo zemishini

Ukubukeka kwebhodi lesifunda kubaluleke kakhulu, hhayi nje ngenxa yezizathu zobuhle kodwa futhi nokusebenza. Amashidi kufanele ahambisane nokuma futhi akufanele akhubazeke. Ukufakwa kwamabhodi esekethe ye-FPC kuvamise ukwenziwa ngomshini, futhi noma yikuphi ukuguqulwa kungase kubangele ukungahambi kahle kwembobo yesikulufu noma ezinye izinkinga zokuhlanganisa. Ukuqinisekisa ukuthi ukubukeka kanye nezakhiwo zemishini zihlangabezana nezindinganiso ezidingekayo kubalulekile ekufakweni okuyimpumelelo kanye nokusebenza kahle kwebhodi lesifunda.

7. Ukumelana nezimo ezimbi kakhulu

Amabhodi esekethe e-FPC angase athintwe izinga lokushisa eliphezulu, umswakama ophezulu, noma ezinye izimo ezimbi kakhulu, kuye ngokusebenza kwawo okukhethekile. Amabhodi esekethe ekhwalithi ephezulu kufanele aklanywe futhi enziwe ukuze amelane nalezi zimo ngaphandle kokubangela izinkinga zokusebenza noma ukulimala kwengxenye. Izici ezikhethekile zokuphikisa kufanele zicatshangelwe ngesikhathi sokuhlola nokukhetha.

8. Izakhiwo zemishini yobuso

Izakhiwo zemishini yendawo yebhodi lesekethe ye-FPC nazo zidlala indima ebalulekile ekufakweni kwayo. Indawo engaphezulu kufanele ihlangabezane nezidingo zokufaka ngaphandle kokubangela noma yikuphi ukuwohloka noma ukungahambi kahle. Noma yimaphi amaphutha noma ukungaboni ngaso linye ekubekweni kwembobo yebhodi noma ukujikeleza kungabangela izinkinga ezingathi sína zokuhlanganisa futhi kuthinte ikhwalithi iyonke nokusebenza kwensiza kagesi.

Ngokufigqiwe

Ukuhlonza ikhwalithi yamabhodi esekethe e-FPC kubalulekile ekuqinisekiseni ukusebenza okuthembekile nokuqina kwemishini kagesi. Ngokuhlola ukubukeka nokucabangela izidingo ezithile ezifana nokuxhunywa kukagesi, ukucaciswa kwezintambo, ukunamathela kwethusi, nokumelana nezimo ezimbi kakhulu, umuntu angenza isinqumo esinolwazi lapho ekhetha ibhodi le-FPC ukuze afake isicelo. Ukulandela lezi ziqondiso kuzokusiza ukuthi ukhethe ibhodi lesifunda elilungile elihlangabezana nezindinganiso zekhwalithi ezidingekayo futhi uqinisekise ukusebenza kahle.

Lapho uhlola ikhwalithi yamabhodi esekethe e-FPC, khumbula ukunaka ukubukeka nezidingo ezithile!

Isikhathi sokuthumela: Oct-23-2023

Emuva