Amabhodi esekethe aphrintiwe e-Rigid-flex (PCBs) athole ukuduma okukhulu embonini ye-electronics ngenxa yekhono lawo lokuhlanganisa izinzuzo zakho kokubili ama-substrates aqinile futhi aguquguqukayo. Njengoba lawa mabhodi eba yinkimbinkimbi futhi egcwala abantu, ukubala ngokunembile ububanzi bokulandelela obuncane kanye nesikhala kubaluleka ukuze kuqinisekiswe ukusebenza okuthembekile nokugwema izinkinga ezifana nokuphazamiseka kwesignali namasekhethi amafushane.Lo mhlahlandlela ophelele uzoveza izinyathelo ezibalulekile zokubala ububanzi obuncane bokulandelela kanye nesikhala sokwenziwa kwe-PCB eguquguqukayo eqinile, okukuvumela ukuthi uthuthukise imiklamo ye-PCB yekhwalithi ephezulu neqinile.

Ukuqonda i-Rigid-Flex PCBs:

I-Rigid-flex PCB iyibhodi lesifunda eliphrintiwe elihlanganisa ama-substrates aqinile futhi aguquguqukayo ebhodini elilodwa. Lawa ma-substrates axhunywe ngokugqitshwa ngezimbobo (PTHs), ahlinzeka ngoxhumano lukagesi phakathi kwezindawo eziqinile neziguquguqukayo ze-PCB. Izindawo eziqinile ze-PCB zenziwe ngezinto eziqinile, ezingaguquki njenge-FR-4, kuyilapho izindawo eziguquguqukayo zenziwe ngezinto ezifana ne-polyimide noma i-polyester. Ukuvumelana nezimo kwe-substrate kuvumela i-PCB ukuthi igotshwe noma igoqwe ukuze ilingane nezikhala ezingatholakali ngamabhodi aqinile endabuko. I-Rigid-flex Inhlanganisela yezindawo eziqinile nezivumelana nezimo ku-PCB ivumela idizayini ehlangene futhi eguquguqukayo, iyenze ifanele izinhlelo zokusebenza ezinendawo elinganiselwe noma amajiyometri ayinkimbinkimbi. Lawa ma-PCB asetshenziswa ezimbonini nasezinsizeni ezahlukahlukene, okuhlanganisa i-aerospace, izisetshenziswa zezokwelapha, ugesi wezimoto, kanye nogesi wabathengi. I-Rigid-flex PCBs inikeza izinzuzo ezimbalwa ngaphezu kwamabhodi aqinile endabuko. Bangakwazi ukunciphisa usayizi nesisindo semishini kagesi futhi benze inqubo yokuhlanganisa ibe lula ngokususa izixhumi nezintambo ezengeziwe. Futhi zinikeza ukwethembeka okungcono nokuqina ngoba kukhona amaphuzu ambalwa okuhluleka kunamabhodi aqinile endabuko.

Ukubaluleka kokubala ukwakhiwa kwe-PCB eguquguqukayo eqinile Ubuncane Be-Trace Width kanye nesikhala:

Ukubala ubuncane bokulandela ububanzi nesikhala kubalulekile njengoba kuthinta ngokuqondile izici zikagesi zomklamo we-PCB.Ububanzi bokulandelela okunganele bungabangela ukumelana okuphezulu, kukhawule inani lamanje elingageleza ngomkhondo. Lokhu kungabangela ukwehla kwe-voltage nokulahlekelwa amandla okungase kuthinte ukusebenza okuphelele kwesekethe. Isikhala esinganele sokulandelela singaholela kumasekhethi amafushane njengoba amathrekhi aseduze angase athintane. Lokhu kungase kubangele ukuvuza kukagesi, okungalimaza isekethe futhi kubangele ukungasebenzi kahle. Ukwengeza, isikhala esinganele singaholela ku-crosstalk yesignali, lapho isignali evela kumkhondo owodwa iphazamisa ukulandelana okuseduze, ukunciphisa ubuqotho besignali futhi kubangele amaphutha okudlulisa idatha. Ukubalwa okunembile kobubanzi obuncane bokulandelela kanye nesikhala nakho kubalulekile ukuze kuqinisekiswe ukwenziwa kwezinto. Abakhiqizi be-PCB banamakhono athile kanye nezingqinamba mayelana nokwakhiwa komkhondo nezinqubo zokuhlanganisa. Ngokunamathela kububanzi obuncane bokulandelela kanye nezimfuneko zesikhala, ungaqinisekisa ukuthi umklamo wakho ungakhiwa ngempumelelo ngaphandle kwezinkinga ezifana nokuhlanganisa ibhuloho noma ukuvulwa.

Izinto Ezithinta I-Rigid Flex PCB Fabrication Ubuncane Be-Trace Width kanye Nesikhala:

Izinto ezimbalwa zithinta ukubalwa kobubanzi bokulandelela obuncane kanye nesikhala se-PCB eguquguqukayo eqinile. Lokhu kufaka phakathi umthamo wamanje wokuthwala, i-voltage yokusebenza, izakhiwo ze-dielectric material kanye nezidingo zokuzihlukanisa. Ezinye izici ezibalulekile zihlanganisa inqubo yokukhiqiza esetshenziswayo, njengamakhono okukhiqiza kanye namakhono wemishini.

Umthamo wamanje wokuthwala we-trace unquma ukuthi ingakanani imanje engaphatha ngaphandle kokushisisa ngokweqile. Imisinga ephakeme idinga ukulandelelwa okubanzi ukuze kuvinjwe ukumelana nokushisa ngokweqile. I-voltage yokusebenza nayo idlala indima ebalulekile njengoba ithinta isikhala esidingekayo phakathi kwamathrekhi ukuze kuvinjelwe i-arcing noma ukuwohloka kukagesi. Izakhiwo ze-Dielectric material ezifana ne-dielectric constant kanye nogqinsi kuthinta ukusebenza kukagesi kwe-PCB. Lezi zakhiwo zithinta amandla kanye nokuvinjelwa komkhondo, okubuye kuthinte ububanzi bokulandelela kanye nesikhala esidingekayo ukuze kuzuzwe izici zikagesi ezidingekayo. Izidingo zokuhlukaniswa zikhomba isikhala esidingekayo phakathi kwamathrekhi ukuze kuqinisekiswe ukuhlukaniswa okufanele futhi kuncishiswe ingozi yamasekhethi amafushane noma ukuphazamiseka kukagesi. Izinhlelo zokusebenza ezihlukene zingase zibe nezidingo ezihlukile zokuhlukaniswa ngezizathu zokuphepha noma zokwethembeka. Inqubo yokukhiqiza namandla emishini inquma ububanzi bokulandelela obufinyelelekayo kanye nesikhala. Amasu ahlukene, afana ne-etching, i-laser drilling noma i-photolithography, anemikhawulo yawo kanye nokubekezelela. Lezi zingqinamba zidinga ukucatshangelwa lapho kubalwa ububanzi obuncane bokulandelela kanye nesikhala ukuze kuqinisekiswe ukwenziwa kwezinto.

Bala ububanzi obuncane bokulandela umkhondo bokwenziwa kwe-PCB eguquguqukayo:

Ukuze ubale ububanzi obuncane bokulandelela bedizayini ye-PCB, izici ezilandelayo zidinga ukucatshangelwa:

Ikhono Lokuthwala Lamanje Elivumelekile:Inquma umkhawulo wamanje odinga ukulandelwa ngaphandle kokushisisa ngokweqile. Lokhu kunganqunywa ngokusekelwe ezingxenyeni zikagesi ezixhunywe kumkhondo kanye nokucaciswa kwazo.

I-Voltage yokusebenza:Cabangela i-voltage yokusebenza yomklamo we-PCB ukuze uqinisekise ukuthi amathrekhi angakwazi ukuphatha i-voltage edingekayo ngaphandle kokuwohloka noma ukugoqa.

Izidingo Zokushisa:Cabangela izidingo ezishisayo zomklamo we-PCB. Umthamo ophezulu wamanje wokuthwala uphumela ekukhiqizeni ukushisa okwengeziwe, ngakho-ke kungase kudingeke imikhondo ebanzi ukuze kukhishwe ukushisa ngempumelelo. Thola imihlahlandlela noma izincomo ngokunyuka kwezinga lokushisa futhi ulandele ububanzi ngamazinga afana ne-IPC-2221.

Izibali eziku-inthanethi noma amazinga:Sebenzisa isibali esiku-inthanethi noma indinganiso yomkhakha efana ne-IPC-2221 ukuze uthole ububanzi bokulandelela obusikiselwayo obususelwe ekunyukeni okuphezulu kwamanje kanye nezinga lokushisa. Lezi zibali noma izindinganiso zicabangela izici ezifana nokuminyana okukhulu kwamanje, ukukhuphuka kwezinga lokushisa okulindelekile, kanye nezakhiwo ze-PCB.

Inqubo yokuphindaphinda:Ububanzi bokulandelela kungase kudingeke bulungiswe ngokuphindaphindiwe ngokusekelwe kumanani abaliwe nokunye ukucatshangelwa okufana nemingcele yokukhiqiza kanye nezidingo zesignali yobuqotho.

Bala isikhala esincane sokwenziwa kwe-PCB eguquguqukayo:

Ukuze ubale isikhala esincane phakathi kokulandela umkhondo ebhodini eliqinile le-PCB eliguquguqukayo, udinga ukucabangela izici ezimbalwa. Isici sokuqala okufanele sicatshangelwe yi-voltage ye-dielectric breakdown. Lena i-voltage ephezulu kakhulu engamelana ne-insulation phakathi kwama-trace aseduze ngaphambi kokuba ibhidlike. I-voltage ye-dielectric breakdown inqunywa izici ezifana nezakhiwo ezibonakalayo ze-dielectric, izimo zemvelo, kanye nezinga elidingekayo lokuzihlukanisa.

Esinye isici okufanele icatshangelwe yibanga le-creepage. I-Creepage ukuthambekela kwamandla kagesi ukuhamba ngaphezu kwezinto ezivikelayo phakathi kwamathrekhi. Ibanga le-Creepage yibanga elifushane kakhulu elingageleza lamanje endaweni ngaphandle kokudala izinkinga. Amabanga e-creepage anqunywa izici ezifana ne-voltage yokusebenza, ukungcola noma izinga lokungcoliswa, kanye nezimo zemvelo.

Izidingo zokusula nazo zidinga ukucatshangelwa. I-clearance iyibanga elifushane kakhulu phakathi kwezingxenye ezimbili ze-conductive noma imikhondo engabangela i-arc noma isifunda esifushane. Izidingo zokusula zinqunywa izinto ezifana ne-voltage yokusebenza, izinga lokungcola, nezimo zemvelo.

Ukuze kube lula inqubo yokubala, amazinga embonini afana ne-IPC-2221 angabhekiselwa kuwo. Izinga lihlinzeka ngemihlahlandlela nezincomo zokulandelela isikhala ngokususelwe ezicini ezihlukahlukene ezifana namazinga kagesi, izakhiwo ze-insulating material, nezimo zemvelo. Kungenjalo, ungasebenzisa isibali esiku-inthanethi esidizayinelwe ama-PCB aguquguqukayo. Lezi zibali zicabangela amapharamitha ahlukahlukene futhi zinikeza cishe isikhala esincane phakathi kokulandelelwa ngokusekelwe kokokufakayo okunikeziwe.

Idizayini Yokwenziwa Kokwenziwa kokwenziwa kwe-PCB eguquguqukayo eqinile:

I-Design for Manufacturability (DFM) iyingxenye ebalulekile yenqubo yokuklama ye-PCB. Kubandakanya ukucutshungulwa kwezinqubo zokukhiqiza namandla okuqinisekisa ukuthi amadizayini angenziwa ngendlela efanele futhi enokwethenjelwa.Isici esibalulekile se-DFM sinquma ubuncane bobubanzi bokulandelela kanye nesikhala se-PCB.

Umkhiqizi we-PCB okhethiwe udlala indima ebalulekile ekunqumeni ububanzi bokulandelela okufinyelelekayo kanye nesikhala. Abakhiqizi abahlukene bangase babe namakhono ahlukene kanye nemikhawulo. Kufanele kuqinisekiswe ukuthi umkhiqizi angahlangabezana nobubanzi bokulandelela obudingekayo kanye nezimfuneko zesikhala ngaphandle kokufaka engozini ukwethembeka noma ukwenziwa.

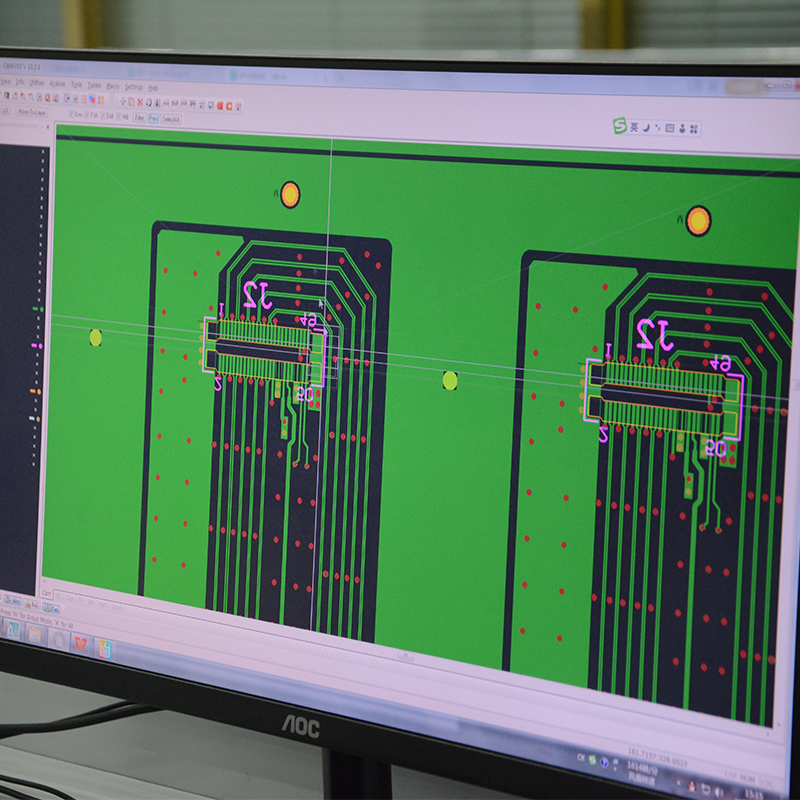

Kunconywa kakhulu ukuxhumana nomkhiqizi okhethiwe ekuqaleni kwenqubo yokuklama. Ngokwabelana ngezicaciso nezidingo zedizayini nabakhiqizi, noma yimiphi imikhawulo engaba khona noma izinselele zingabonakala futhi zixazululwe. Abakhiqizi banganikeza impendulo ebalulekile mayelana nokuba nokwenzeka kwedizayini futhi baphakamise ukuguqulwa noma ezinye izindlela uma kunesidingo. Ukuxhumana kwangaphambi kwesikhathi nabakhiqizi nakho kungasiza ekuthuthukiseni umklamo wokwenziwa. Abakhiqizi banganikeza okokufaka ekwakhiweni kwezinqubo zokukhiqiza ezisebenza kahle, ezifana nokufakwa kwamaphaneli, ukubekwa kwengxenye, nokucatshangelwa komhlangano. Le ndlela yokubambisana iqinisekisa ukuthi umklamo wokugcina awugcini nje ukwenziwa, kodwa futhi uhlangabezana nemininingwane edingekayo kanye nezidingo.

Ukubala ubuncane bokulandela ububanzi nesikhala kuyisinyathelo esibalulekile ekwakhiweni kwe-PCB eguquguqukayo. Ngokucabangela ngokucophelela izici ezifana nomthamo wamanje wokuthwala, amandla kagesi okusebenza, izakhiwo ze-dielectric, nezidingo zokuhlukaniswa, onjiniyela bangakha imiklamo ye-PCB ngokusebenza okuphakeme, ukwethembeka, nokuqina. Ukwengeza, ukuqonda amakhono okukhiqiza kanye nokubandakanya abakhiqizi kusenesikhathi kungasiza ekuxazululeni noma yiziphi izinkinga ezingaba khona futhi kuqinisekiswe ukukhiqizwa okuphumelelayo. Uhlome ngalezi zibalo nokucatshangelwa, ungakha ngokuzethemba ama-PCB ekhwalithi ephezulu eqinile ahlangabezana nezidingo eziqinile zezinhlelo zokusebenza ze-elekthronikhi eziyinkimbinkimbi zanamuhla.

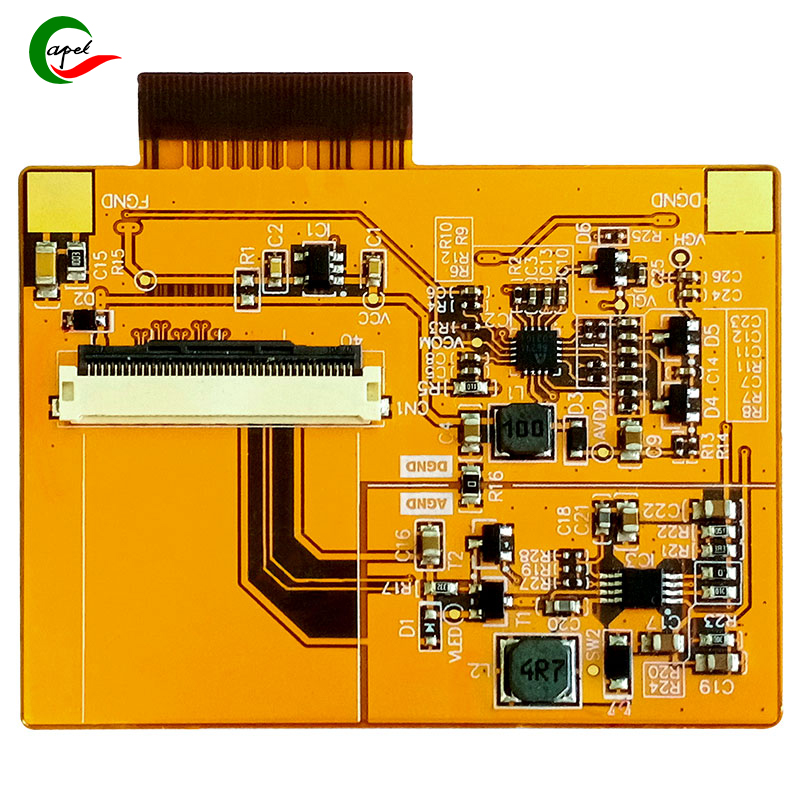

I-Capel isekela i-pcb eguquguqukayo eqinile ene-Min Line Space/ ububanzi obungu-0.035mm/0.035mm.I-Shenzhen Capel Technology Co., Ltd.isungule imboni yayo eqinile ye-pcb ngo-2009 futhi ingumkhiqizi we-Flex Rigid Pcb ochwepheshe. Iminyaka engu-15 yesipiliyoni sephrojekthi esicebile, ukugeleza kwenqubo okuqinile, amakhono obuchwepheshe asezingeni eliphezulu, okokusebenza okuzenzakalelayo okuthuthukisiwe, uhlelo oluphelele lokulawula ikhwalithi, futhi uCapel unethimba lochwepheshe lochwepheshe ukuze anikeze amakhasimende omhlaba ukunemba okuphezulu, ikhwalithi ephezulu ye-1-32 layer rigid flex board, i-hdi Rigid Flex Pcb Fabrication, i-rigid Flex Pcb Fabrication, i-rigid-px-flex pcb prototypes.Izinsizakalo zethu zobuchwepheshe ezisabelayo zangaphambi kokuthengisa kanye nangemuva kokuthengisa kanye nokulethwa okufika ngesikhathi kwenza amakhasimende ethu abambe ngokushesha amathuba emakethe amaphrojekthi awo.

Isikhathi sokuthumela: Aug-29-2023

Emuva